UNIT 1

WATER TECHNOLOGY

The impurities of water are filtered from the drinking water to make the water pure for drink. The types of impurities in water can include dust, dirt, harmful chemicals, biological contaminants, radiological contaminants, and total suspended solids (TSS). Total suspended solids are visible particles that can make water appear cloudy or hazy.

| Concentration found in Ground Water | Concentration found in surface water |

Total Hardness | 300 – 400 ppm | 75 – 200 ppm |

Alkalinity | 250 – 350 ppm | 45 – 250 ppm |

Dissolved Oxygen | Near 0 | 2 – 14 ppm |

CO2 | 1 – 10 ppm | Low |

Calcium Hardness | High | Usually low |

Magnesium Hardness | Tends to be high | Usually low |

For Drinking Water:

(i) Drinking water must be supplied under continuous positive pressure.

(ii) Drinking water is unmodified except for the limited treatment of the water from a natural source.

(iii) It is common for drinking-water to be derived from a public water supply that may be a combination of more than one of the natural sources.

(iv) It is also common for public water supply organizations to conduct tests and guarantee that the drinking-water delivered is of drinking quality.

(v) Drinking-water quality is covered by the WHO drinking-water guidelines, standards from the International Organization for Standardization (ISO) and other regional and national agencies. Drinking-water should comply with the relevant regulations laid down by the competent authority.

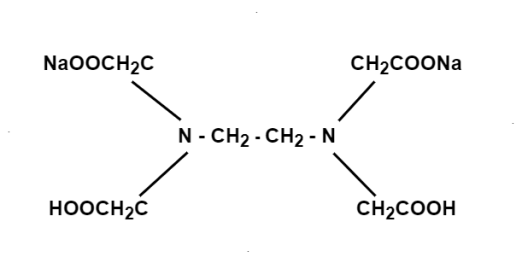

Principle: This is a complex metric method. It is in the form of its sodium salt which yields the anion and this forms complex with Ca+2 and Mg+2 ions.

(Molecular Wt. - 372.24, Equivalent Wt. - 186.14 i.e., M=2N)

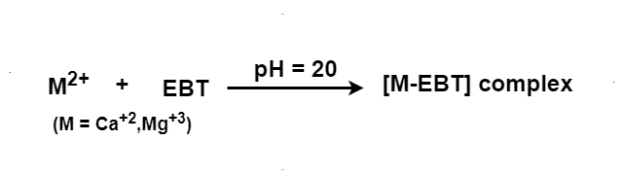

In order to determine the equivalence point (i.e., just completion of metal-EDTA complex formation) indicator Eriochrome Black-T (EBT) an alcoholic solution of blue dye is employed which forms an unstable wine red complex with Ca+2 and Mg+2 ions. The indicator is effective at about pH 10. When EBT is added to hard water, buffered to a pH of about 10 (employing NH4OH-NH4Cl buffer), a wine red unstable complex is formed. Thus,

During the course of titration against EDTA solution, EDTA combines with M+2 (or Ca+2 or Mg+2) ions from stable complex M-EDTA and releasing free EBT, which instantaneously combines with M+2 ions still present in the solution, thereby wine red color is retained. Thus, titration

When nearly all M+2 (Ca+2 or Mg+2) ions have formed [M-EDTA] complex, then next drop of EDTA added drop wise displace the EBT indicator from [M-EBT] complex and wine red color changes to blue color (due to EBT). Thus at equivalence point

Steps involved:

1. Preparation of Standard Hard Water: Dissolve 1gm of pure dry CaCO3 in minimum quantity of dil. HCl and then evaporate the solution to dryness on water bath. Dissolve the residue n distilled water to make 1L solution. Each 1ml of this solution contains 1mg of CaCO3 hardness. 6

2. Standardization of EDTA solution: Rinse and fill the burette with EDTA solution. Pipette out 50ml of standard hard water in a conical flask. Add 10-15ml of buffer solution and 4 drops of indicator. Titrate with EDTA solution till wine red color changes to clear blue. Let the volume used be V1ml.

3. Titration of Unknown Hard Water: Titrate 50ml of water sample just in step5. Let the volume used be V2ml.

4. Titration of Permanent Hardness: Take 250ml of water sample in a large beaker. Boil till the volume is reduced to about 50ml (all the bicarbonates are decomposed into insoluble CaCO3+Mg(OH)2). Filter, wash the precipitate with distilled water collecting filtrate and washings in a 250 ml measuring flask. Finally make up the volume to 250ml with distilled water.

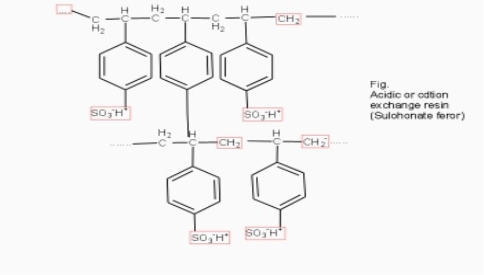

Ion exchange or de ionization or de mineralization ion exchange resins are insoluble cross linked long chain organic polymers with a microporous structure and the functional group attached to the chains are responsible for the ion exchange properties resins contaning acidic function groups are capable of exchaning their anions with other anions which comes in their contact the ion exchange resins may be classified as :-

Cation exchange resins ( RH+) :-

They are mainly styrene divinly benzene co-polymers which on sulphonation or carbonoxylation become capable to exchange their hydrogen ions with the cations in the water.

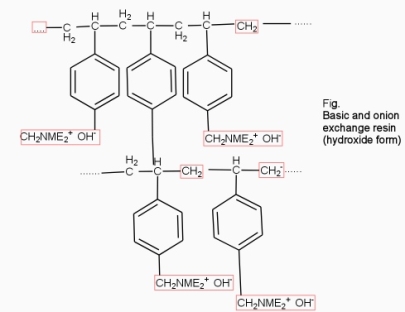

- Anion exchange resins :-

They are styrene – divinly benzene or amine fermaldehyde which contain amino or quaternary ammonium or4 quaternary phosphonium or tertiary sulphonium group as an integral part of the resin matrix.these after treatment with dilute NaOH solution become capable to exchange their OH- anions with anions in water .

Processes :-

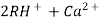

The hard water is passed first through cation exchange column which removes all the cations like Ca²+ , Mg² + e.t.c . From it and equivalent amount of H+ ions are released from this column Water

2RH+ + Ca².+ ---------------------- R2Ca2+ + 2H

2RH+ Mg2+ --------------------------- R2Mg2+ 2H+

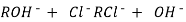

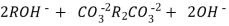

After cation exchange column the hard water passed through anion like cl- . Present in the water and equivalent amount of OH- ions are released from this column to water,

H+ And OH – ions ( released from cation exchange and anion exchange columns respectively ) get combined to produce water molecule.

H+ + OH -  H2O

H2O

Thus,

The water coming out form the exchanger is free from cations as well as an ions . Ion free water is known as de mineralizes water.

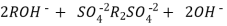

Regeneration :-

When capacities of cation and anion exchangers to exchange H+ and OH- ions respectively . Are lost they are then said to be exhausted.

The exhausted cation exchange column is regenerated by passing a solution of dil.HclH2SO4. The regeneration can be represented as

( washing )

( washing )

The column is washed with deionized water and washing ( which contains Ca2+ and Cl2- ions ) is passed to sink or drain.

The exhausted anion exchange column is regenerated by passing a solution of dil. NaOH.

The column is washed with de-ionized water and washing (which contains NA+ and  ions ) is pass to sink or drain.

ions ) is pass to sink or drain.

The regenerated ion exchange ion exchange resins are then used again.

Advantages :-

- The processes can be used to soften highly acidic or alkaline waters.

- It produces water of very low hardness ( say 2 ppm ) so it is very good for treating water for use in high pressure boilers.

Disadvantages :-

- The equipment is costly and more expensive chemicals are needed.

If water contains turbidity, then the out- put of the processes is reduced .the turbidity must be below 10 ppm if it is more it has to be removed first by filtration.

Coagulation

After all the large objects are removed from the original water source, various chemicals are added to a reaction tank to remove the bulk suspended solids and other various contaminants. This process starts off with an assortment of mixing reactors, typically one or two reactors that add specific chemicals to take out all the finer particles in the water by combining them into heavier particles that settle out. The most widely used coagulates are aluminum-based such as polyaluminum chloride.

Filtration

The next step is generally running through some type of filtration to remove any suspended particles such as sediment, turbidity, and certain types of organic matter. It is often useful to do this early on in the process, as the removal of suspended solids upstream can help protect membranes and ion exchange resins from fouling later on in the pretreatment process. Depending on the type of filtration used, suspended particles can be removed down to under one micron.

Chlorination is the process of adding chlorine to drinking water to disinfect it and kill germs. Different processes can be used to achieve safe levels of chlorine in drinking water. Chlorine is available as compressed elemental gas, sodium hypochlorite solution (NaOCl) or solid calcium hypochlorite (Ca(OCl)2. While the chemicals could be harmful in high doses, when they are added to water, they all mix in and spread out, resulting in low levels that kills germs but are still safe to drink. Chlorine combines with dissolved chemicals of water, micro-organisms. It is important to add sufficient amount of chlorine to the water to meet the chlorine demand and provide residual disinfection. The chlorine that does not combine with other components in the water is free chlorine, and the breakpoint is the point at which free chlorine is available for continuous disinfection. An ideal system supplies free chlorine at a concentration of 0.3-0.5 mg/l. Simple test kits, most commonly the DPD colorimetric test kit (so called because diethyl phenylene diamine produces the color reaction), are available for testing breakpoint and chlorine residual in private systems. The kit must test free chlorine, not total chlorine.

It involves addition of sufficient amount of chlorine to oxidize organic matter reducing substance and free ammonia in raw water by leaving behind free chlorine which possesses disinfecting action against disease- producing bacteria. The addition of chlorine at the dip or break is called “break point” chlorination. This indicates the point at which free residual chlorine begins to appear.

Advantages:

(1) It oxides completely organic compounds, ammonia and other reducing compounds.

(2) It removes color, odor and taste of water.

(3) It removes completely all the disease causing bacteria/micro-organism

(4) It prevents the growth of any weeds in water.

Deaeration or degasification

At this point in the boiler feed water treatment process, any condensate being returned to the system will mix with the treated makeup water and enter the deaeration or degasification process. Any amount of gasses such as oxygen and carbon dioxide can be extremely corrosive to boiler equipment and piping when they attach to them, forming oxides and causing rust. Therefore, removing these gases to acceptable levels (nearly 100%) can be imperative to the service life and safety of the boiler system. There are several types of deaeration devices that come in a range of configurations depending on the manufacturer, but generally, you might use a tray- or spray-type deaerator for degasification or oxygen scavengers.

Distribution

After the boiler feed water has been sufficiently purified according to the boiler manufacturer’s recommendation and other industry-wide regulations, the water is fed to the boiler where it is heated and used to generate steam. Pure steam is used in the facility, steam and condensate are lost, and condensate return is pumped back into the process to meet up with the pretreated makeup water to cycle through pretreatment again.

The water that is fed into the boiler for the production of steam is called boiler feed water. The fed water into the boiler must be free from turbidity, free from oil, alkalis and most important things the hardness causing substances. The used water are contaminated in maximum time. If the hard water is used then it leads to 4 major problems that are-

- Scale & Sludge Formation

- Primming and Foaming

- Caustic Embrittlement

- Boiler Corrosion

Scale & Sludge Formation:The water evaporates continuously and the dissolved salts concentration increases progressively. When their concentrations reach at saturation point, they are thrown out of water in precipitate form which get stick in inner walls of boiler. If the precipitation takes place in the form of loose or slimy precipitate it is called sludge. While if the precipitated matter forms a hard adhering coating on inner walls of boiler, then it is called as scale. Eg- MgCO3, MgCl2, MgSO4 etc.

Priming & Foaming: The duration at which boiler is producing steam rapidly, some particles of the condensed liquid are carried along with the steam. The process of wet steam formation is called priming. Priming is mainly caused by the presence of large amounts of dissolved solids, high steam velocities, sudden boiling etc. Whereas the continuous production of foam or bubbles in boilers which do not break easily are called as the foaming. This is caused due to the presence of substance like oils in water that reduce the surface tension in water.

Caustic Embrittelment: The use of high alkaline water in the boiler cause rust in the boiler which is called as Caustic Embrittelment. The presence of sodium carbonate plays a major role during the softening process.

Na2CO3 + H2O →NaOH + CO2

the caustic embrittelment is caused by using sodium phosphate as a softening agent instead of sodium carbonate.

Boiler Corrosion: The decay of the boiler material by attack of chemicals or electro-chemicals at its environment is called as boiler corrosion.

Reasons of boiler corrosion:

(i) Dissolved Oxygen

(ii) Dissolved Carbon di oxide

(iii) Acid from dissolved salts

Sludge, scale, priming and foaming, caustic embrittlement, boiler corrosion are collectively known as boiler troubles.

Boiler feed water treatment

Makeup water intake

The water replacing evaporated or leaked water from the boiler, is first drawn from its source, whether raw water, city water, city-treated effluent, in-plant wastewater recycle, well water, or any other surface water source.

Coagulation and chemical precipitation

After all the large objects are removed from the original water source, various chemicals are added to a reaction tank to remove the bulk suspended solids and other various contaminants. This process starts off with an assortment of mixing reactors, typically one or two reactors that add specific chemicals to take out all the finer particles in the water by combining them into heavier particles that settle out. The most widely used coagulates are aluminum-based such as polyaluminum chloride.

Filtration and ultrafiltration

The next step is generally running through some type of filtration to remove any suspended particles such as sediment, turbidity, and certain types of organic matter. It is often useful to do this early on in the process, as the removal of suspended solids upstream can help protect membranes and ion exchange resins from fouling later on in the pretreatment process. Depending on the type of filtration used, suspended particles can be removed down to under one micron.

Ion exchange softening

When pre-treating boiler feed water, if there’s high hardness complex with bicarbonates, sulphate, chlorides, or nitrates, a softening resin can be used. This procedure uses a strong acid cation exchange process, whereby resin is charged with a sodium ion, and as the hardness comes through, it has a higher affinity for calcium, magnesium, and iron so it will grab that molecule and release the sodium molecule into the water.

Dealkalization

After the softening process, some boiler feed water treatment systems will utilize dealkalization to reduce pH, an impurity in boiler feed water that can cause foaming, corrosion, and embrittlement. Sodium chloride dealkalization uses a strong anion exchange resin to replace bicarbonate, sulfate, and nitrate for chloride anions. Although it doesn’t remove alkalinity 100%, it does remove the majority of it with what can be an easy-to-implement and economical process. Weak acid dealkalization only removes cations bound to bicarbonate, converting it to carbon dioxide (and therefore requiring degasification). It is a partial softening process that is also economical for adjusting the boiler feed water pH.

Reverse osmosis (RO) and nanofiltration (NF)

Reverse osmosis (RO) and nanofiltration (NF) are often used down the line in the boiler feed water treatment system process so most of the harmful impurities that can foul and clog the RO/NF membranes have been removed. Similar processes of separation, they both force pressurized water through semipermeable membranes, trapping contaminants such as bacteria, salts, organics, silica, and hardness, while allowing concentrated, purified water through. Not always required in boiler feed water treatment, these filtration units are used mostly with high-pressure boilers where concentration of suspended and dissolved solids needs to be extremely low.

Deaeration or degasification

At this point in the boiler feed water treatment process, any condensate being returned to the system will mix with the treated makeup water and enter the deaeration or degasification process. Any amount of gasses such as oxygen and carbon dioxide can be extremely corrosive to boiler equipment and piping when they attach to them, forming oxides and causing rust. Therefore, removing these gases to acceptable levels (nearly 100%) can be imperative to the service life and safety of the boiler system. There are several types of deaeration devices that come in a range of configurations depending on the manufacturer, but generally, you might use a tray- or spray-type deaerator for degasification or oxygen scavengers.

Distribution

After the boiler feed water has been sufficiently purified according to the boiler manufacturer’s recommendation and other industry-wide regulations, the water is fed to the boiler where it is heated and used to generate steam. Pure steam is used in the facility, steam and condensate are lost, and condensate return is pumped back into the process to meet up with the pretreated makeup water to cycle through pretreatment again.

Corrosion: The destruction of metal by chemical or electrochemical attack of environment this process starting at the surface of metal known as corrosion. Corrosion is the two step process that requires three things i.e., a metallic surface, an electrolyte and oxygen. In the process of corrosion a metal atom at surface dissolve into an aqueous solution leaving the metal with excess negatively charged ions.These resultant ions are removed by a suitable electron acceptor. Corrosion can be thought of as the spontaneous return of metals to their ores through the process of oxidation.

Corrosion occurs due to the electrochemical process of oxidation and reduction process. In the corroding solution electrons are released by the metal and that is gained by the elements in the corroding solution. The release of electron from metal is called as the oxidation while vice-versa that is gain of electron by elements is reduction. The regular electron flow in the corrosion reaction can be measured and controlled electronically. This is why controlled electrochemical experimental methods are used to characterize the corrosion properties of metal.

For example,

(i) a thin film of moisture on a metal surface forms the electrolyte for atmospheric corrosion.

(ii) when wet concrete is the electrolyte for reinforcing rod corrosion in bridges.

Primming and Foaming:

The duration at which boiler is producing steam rapidly, some particles of the condensed liquid are carried along with the steam. The process of wet steam formation is called priming. Priming is mainly caused by the presence of large amounts of dissolved solids, high steam velocities, sudden boiling etc. Whereas the continuous production of foam or bubbles in boilers which do not break easily are called as the foaming. This is caused due to the presence of substance like oils in water that reduce the surface tension in water.

Causes of Corrosion:

Corrosion is the electrochemical process that occurs in various forms such as chemical forms and atmospheric forms. On the contact of acid substance with iron it pretend to form rust. Rust is the result of corroding steel after the iron (Fe) particles have been exposed to oxygen and moisture. When steel is exposed to water, the iron particles are lost to the water’s acidic electrolytes. The iron particles then become oxidized, which results in the formation of Fe⁺⁺. When Fe⁺⁺ is formed, two electrons are released and flow through the steel to another area of the steel known as the cathodic area.

Oxygen causes these electrons to rise up and form hydroxyl ions (OH). The hydroxyl ions react with the Fe2+ to form hydrous iron oxide, better known as rust. Where the affected iron particles were, has now become a corrosion pit, and where they are now, is called the corrosion product (rust).

Phosphate conditioning is used for high pressure boiler. There is no risk for CO2 liberation in it.

3CaSO4 + 2Na3PO4 Ca3(PO4)2 + 3Na2SO4

There are three types of phosphate salts are used:

Salt | Name | Used for treating |

Na3PO4 | Tri Sodium Phosphate | Highly acidic water |

Na2HPO4 | Di Sodium hydrogen phosphate | Slightly acidic water |

NaH2PO4 | Sodium di hydrogen phosphate | Highly alkaline water |

Calgon Conditioning: Calgon is the common name of sodium hexa meta phosphate- Na2 [Na4 (PO3)6]. With calcium ions it forms a soluble complex and prevents scale and sludge formation. It is used for high and low pressure boilers.

2CaSO4 + Na2[Na4(PO3)6] Na2[Ca2(PO3)6] + 2Na2SO4

Carbonate Conditioning: This is used for low pressure boilers. Here the salts like CaSO4 are converted to easily removable CaCO3. But some times it produces NaOH, CO2 and hence Carbonic acid. So it is less preferred.

CaSO4 + Na2CO3 CaCO3 + Na2SO4

Surface water hardly exceed hardness level above 200 mg/1 and softening is not at all required in most of the cases, unless the water is being polluted by some effluent sources. In case of groundwater, hardness level of more than 1000 mg/1 are quite common. Since, soft water is corrosive, therefore public water supply are usually not softened below 30 to 50 mg/1. The most accepted and commonly used water softening methods are cat ion exchange and precipitation method. In order to obtain maximum profit, the factors to be considered are a good choice of a softening process, quality of the raw water, the cost of softening chemicals and the cost of disposing of waste streams.

Precipitation methods

The principle that follows the precipitation method is to bind calcium cations Ca and magnesium cations Mg , with ions of CO3 and OH . The precipitate CaC03 and Mg (OH)2 formed are removed from the water. Slake lime Ca(OH)2, Quick lime CaO , soda ash NaC03 and sodium hydroxide (caustic soda) NaOH, are reagents that are commonly used in water softening. Depending upon the quality of initial water, the following main precipitation methods are determined. a) Lime softening b) Lime - Soda softening c) Sodium Hydroxide softening Lime affects the carbonate hardness (alkalinity) and therefore can be used in order to decrease the carbonate hardness present in the initial water. This method however does not result in deep softening. Magnesium is removed from water if there is excess of OH” present. Water dissolved carbon dioxide is removed, total solids in the treated water diminishes and the total hardness in the lime treated water also reduces. But the pH increases to 10 or beyond. When lime is added to the hard water following reactions occurs, In the above reactions,

Lime Addition:-

Hardness Lime Precipitate

CO2 + Ca(OH)2 -- > CaCO3 + H2O Ca(HCO3)2 + Ca(OH)2 -- > 2CaCO3 + 2H2O Mg(HCO3)2 + Ca(OH)2 -- > CaCO3 + MgCO3 + 2H2O MgCO3 + Ca(OH)2 -- > CaCO3 + Mg(OH)2 CO2 the insoluble products do not contribute to the hardness, but It reacts with the lime, and thereby uses up some lime before the lime can start removing the hardness in water. Lime - Soda softening method is commonly practiced in most of the Public water supply. (Belan1984) The method is universal as water of almost any composition is treated with lime and soda. In this treatment, two reagents are used namely lime and soda ash. Lime as earlier discussed , decreases the carbonate hardness, (Mg2+) and removes C02 from the water.

Soda therefore reduces the non - carbonate hardness, mainly due to Ca2+, that shows after reaction with lime and the reaction occurs after the addition of soda ash is as follows.

Lime and Soda ash Addition:- Lime Precipitate MgSO4 + Ca(OH)2 -- > Mg(OH)2 + CaSO4 Soda ash Precipitate CaSO4 + Na2CO3 -- > CaCO3 + Na2SO4

Ion Exchange Process

Ion exchange process to soften water ,using cations or anions .This is done by exchanging cations or anions with the calcium and magnesium ions in hard water. This process involves a reversible chemical reaction. However, we can use this technique only in dilute solutions. The equipment that we use for this purpose is ion exchangers.

Types

There are two types;

- Cation exchangers – use zeolite, greensand, sulfonated coal, etc. as the exchanging material.

- Anion exchangers – uses metallic oxides, synthetic resins, etc.

The materials used in cation exchangers include either weak acids or strong acids. Strong acid cation exchangers mainly contain sulfate functional groups. Weak acid cation exchangers mainly contain carboxyl groups. The materials that are used in anion exchangers include either weak bases or strong bases. Moreover, there are several categories of ion exchange process used for water softening, Dealkalization and demineralization. The ions that are part of the exchange process (the ions that exchange with the calcium and magnesium cations in hard water) include sodium ions, hydrogen cations, chloride anions and hydroxyl anions.

Desalination: The process of converting up of saline water into fresh water by removing of salts and minerals from the target source is called as the Desalination. Saltwater is desalinated to produce water suitable for human consumption or irrigation. The by-product of the desalination process is brine. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on cost-effective provision of fresh water for human use. Along with recycled wastewater, it is one of the few rainfall-independent water sources.

Desalination using electro dialysis:

The passing up of direct current through the water in order to drive the ions through membranes to electrodes of opposite charge. The common techniques which applied the electro dialysis principle is electro dialysis reversal (EDR). This system uses ion transfer anion and cation membranes to separate the ions in source water. This membrane allows the unidirectional transfer of ions of given charge through them. E.g.- the cation transfer membranes allow only positive charge ions to pass.

Desalination using reverse osmosis:

Reverse osmosis is a process where the water is separated from the salts in the source water by pressure-driven transport through a membrane. This process uses semi-permeable membrane and applied pressure to preferentially induce water permeation through the membrane while rejecting salts. The RO plant uses less energy than thermal desalination process. This process uses thin-film composite membrane that too comprises of ultra thin aromatic polyamide thin film. The used polyamide film gives the transparent properties while the remaining part provides the mechanical supports. The polyamide films are very dense void free polymer with high surface area allowing for its high permeability. RO desalination plant include source water intake system, pretreatment facilities and high pressure feed pumps, RO membrane trains, energy recovery and desalinated water conditioning system. The intake system may be the open surface water intake or series of seawater beach wells. The pretreatment system may be the screening, chemical conditioning, sedimentation or filtration that totally depends on the used quality water further the filtered water is conveyed by transfer pump from filtrate water storage tank through cartridge filter and into the suction pipe of high pressure RO feed pumps. The cartridge filters are designed in such a manner that can retain 1 to 20 microns particles which remained in the source water after pretreatment. The high pressure feed pumps are designed to deliver the source water to the RO membranes at pressure required for membrane separation of the fresh water from the salts. The actual required feed pressure is site-specific and is mainly determined by the source water salinity and the configuration of the RO system.