Unit 3

Safety, Social Responsibility and Rights

Safety and Risk

The terms of safety and risk are inter-related. It is amazing to understand that what can be safe enough for one person might not be for somebody else. It is attributable to either different perceptions about what's safe or different predispositions to harm.

For better understanding, below are some examples explore safety and risk further.

Safety

According to William W Lowrance, safety may be defined as “A thing is safe if its risks are judged to be acceptable.”

Safety is often expressed in terms of degree and comparisons. The words like fairly-safe and relatively-safe are used where an individual is judged on the basis of settled values and it is further decided that the risks of anything are more or less acceptable as compared with the risks of the other thing. For example, the consideration that road travel is safer than air-travel.

The concept of safety can be easily comprehended by understanding the following examples:

Case 1: Let the first case be where we seriously underestimate the risks of something. Buying a non-brand electric dryer from a domestic market without any guarantee, may eventually send us to a hospital with a severe electric shock or burn. While buying this dryer, consistent with Lowrance's definition, this can be quite safe, because the risks are judged to be acceptable.

Case 2: Let the second case be where we grossly overestimate the risks of something. If we suddenly know that the consumption of carbonated beverages like cola are the cause of cancer for 5% of the world’s cancer patients, then we start worrying considering Cola as a poisonous drink. So, in this case, in line with Lowrance's definition, the Cola becomes unsafe the instant we judged the risks of using it to be unacceptable for us.

Case 3: Let the third case be a situation wherein, a group makes no judgment at all about whether the risks of a thing are acceptable or not. As defined by Lowrance's, this can be the position where the thing is neither safe nor unsafe with reference to that group. Just like using the products of certain brands are considered safe, while others are not where nothing seems to differ.

Risk

Risk can be understood as any task which might lead to harm us and is not considered safe. According to a popular definition, “A risk is the potential that something unwanted and harmful may occur.” William D Rowe defines risk as the "potential for the realization of unwanted consequences from impending events."

Risk can be considered as a broad concept covering many different kinds of unwanted occurrences. When it involves technology, it can equally well include dangers of bodily harm, of economic loss or of environmental degradation. These successively may be caused by delayed job completion, faulty products or systems or economically or environmentally injurious solutions to technological problems.

With the advancement in technology, people are now aware of all that goes into a process. Further, risks are understood as those that are often identified. Overall, the general public perception has also undergone a change.

Probability of safety = 1 – Probability of risk

Risk = Probability of occurrence × Consequence in magnitude

Acceptability of Risk

Safety as acceptable risk has been observed and identified by Lowrance in his definition of risk. On the acceptability of risk, William D. Rowe says, “a risk is acceptable when those affected are generally no longer apprehensive about it”.

Influential factors that result in such apprehension are −

- Whether the risk is accepted voluntarily.

- The effects of information on how the possibilities of harm (or benefit) are known or perceived.

- Pressures exist that cause people to be conscious of or to overlook risks or if the risks are job-related.

- Whether the consequences of a risky activity or situation are immediately noticeable or are close at hand.

- Whether the potential victims are identifiable beforehand.

The acceptability of risk depends upon the types of risks such as voluntary and involuntary risks, short term and long-term consequences, expected probability, reversible effects, threshold levels for risk, delayed and immediate risk, etc.

Risk Analysis

The study of risk analysis covers other areas like risk identification, risk analysis, risk assessment, risk rating, suggestions on risk control and risk mitigation. In fact, risk analysis may be deeply discussed with a view on risk management study. The study of risk management also incorporates residual risk transfer, risk financing, etc.

A step-wise risk analysis includes:

- Hazards identification

- Failure modes and frequencies evaluation from established sources and best practices.

- Selection of credible scenarios and risks.

- Fault and event trees for various scenarios.

- Consequences-effect calculations with work out from models.

- Individual and societal risks.

- ISO risk contours superimposed on layouts for various scenarios.

- Probability and frequency analysis.

- Established risk criteria of countries, bodies, standards.

- Comparison of risk against defined risk criteria.

- Identification of risk beyond the placement boundary, if any.

- Risk mitigation measures.

All of these again rely on how the risk is compared with the benefit in doing the work with some risk. How far is it beneficial to risk also counts the actions of an individual while setting out of the safety bounds.

Moral Responsibility of Engineers for Safety

One of the main duties of an engineer is to ensure the safety of the people that may be affected by the products that he designs. The code of ethics of the professional engineering societies has made it clear that safety of the general public is of paramount importance to an engineer. The engineering codes of ethics show that engineers have a responsibility toward society that involves the production of safe and risk-free goods. It is true that no manufactured products can be 100% safe, but engineers are required to make products as safe as reasonably possible. Thus, safety should be an integral part of any engineering design and therefore, engineers are morally obligated to take note of safety while designing products.

Safety occupies a prominent place in all the engineering professional codes of ethics. Engineers are expected to uphold the safety, health and welfare of the general public. The statements within the codes concerning safety are associated with the concept of risk. The American codes use the term "safety" but the term "risk" is rarely used even though they are closely associated. The London Institute of Mechanical Engineers (IMechE) Joint Code of professional Practice and Risk Issues, however, could be a ten-points code that discusses professional responsibility, the law, and professional conduct regarding risk.

The National Society of Professional Engineers (NSPE) Code of Ethics for states in the first canon for engineers to: "Hold paramount the safety, health and welfare of the general public in the performance of their professional duties." It requires engineers to design safely in terms of "Accepted Engineering Standards." It encourages engineers to not "Complete, sign or seal plans and/or specifications that are not of a design safe to the public health and welfare and in conformity with accepted engineering standards." Concerning informed consent, it instructs engineers that if their professional judgment is overruled in "Circumstances where the safety, health, property or welfare of the general public are endangered," they're obligated to "Notify their employer or client and such other authority as may be appropriate."

One of the basic principles of the Institute of Electrical and Electronic code of ethics include the statement "to uphold paramount the safety, health, and welfare of the general public, to strive to accommodate ethical design and sustainable development practices, to safeguard the privacy of others, and to disclose promptly factors which may endanger the people or the environment;" which implies the moral responsibility of engineers towards public health and safety. The ASME code of ethics also provides statements for safety in its canonic principles such as "Engineers shall consider environmental impact while conducting professional duties." and "Engineers shall hold the safety, health and welfare of the general public as paramount in the performance of their professional duties."

Bhopal Gas Tragedy

Bhopal’s Gas tragedy is considered as one of the world’s worst industrial disaster that occurred in 1984, because of the gas leakage from a pesticide production plant, The Union Carbide India Limited (UCIL) located in Bhopal, Madhya Pradesh.

It was believed that the disaster was triggered by slack management and deferred maintenance which together created a situation where routine pipe maintenance caused a backflow of water into the MIC tank.

What Led to The Disaster?

In the early hours of December 3rd, 1984, a rolling wind carried a toxic gray cloud from the Union Carbide Plant in Bhopal, Madhya Pradesh of India. Forty tons of Methyl Iso Cyanate (MIC) which is a very poisonous gas, was released in the process. This particular gas is extremely toxic that leaked and spread throughout the town.

The residents of the vicinity, awakened to the clouds of suffocating gas and struggled to breath. They started running desperately through the dark streets. The victims arrived at hospitals, breathless and blind.

The lungs, brain, eyes, muscles were severely affected of the surviving people. Their gastro intestinal system, neurological, reproductive and immune systems were also adversely affected. By the morning, when the sun rose clearly, the roads were all crammed with dead bodies of humans and animals, the trees turned black and the air was filled with a foul smell.

Cause of the Accident

The Union Carbide Corporation (UCC) team and the CBI (Central Bureau of Investigation) reached a similar conclusion after conducting separate investigations regarding the reasons behind the accident. It was established that a large volume of water had been released into the MIC tank which led to a chemical reaction that forced the pressure release valve to open and allowed the gas to leak.

The investigation conducted by the UCC proved with virtual certainty that the disaster was caused by the direct entry of water into Tank 610 through a hose connected to the tank.

The documented evidence gathered after the incident reveals that the valve near the plant’s water-washing section was fully closed and leak-proof. Based on several investigations, the protection system in place couldn't have prevented a chemical change of this magnitude from causing a leak.

The safety systems are designed in such a way that water cannot enter unless it's deliberately switched and the water flow is allowed forcefully. The reasons and the individuals responsible for this deliberate operation are yet unknown.

Effects of the Disaster

A total of 3,787 deaths occurred immediately, as per government records. Around 8,000 of the survivors died within a period of two weeks and other 8,000 or more died from acute diseases caused because of the gas later.

A 2006 government affidavit stated that the gas leak incident caused 5,58,125 health risks, including 38,478 temporary partial injuries and approximately 3,900 severely and permanently disabling injuries. None can say if future generations won't be affected.

Initial effects of exposure were −

- Coughing

- Severe eye irritation

- Feeling of suffocation

- Burning sensation in the respiratory tract

- Blepharospasm

- Breathlessness

- Stomach pains

- Vomiting

The staff at the nearby hospitals lacked the information and procedural knowledge required to treat the casualties in such situations. Also, there is no antidote known for MIC. Hence, even after running to the hospitals, the survivors were not able to be cured and most of them had to face death eventually.

Primary causes of deaths were −

- Choking

- Reflexogenic Circulatory Collapse

- Pulmonary Oedema

- Cerebral Oedema

- Tubular Necrosis

- Fatty Degeneration of the Liver

- Necrotizing Enteritis

As an after effect of this disaster, the rate of stillbirths increased by 300% and also the neonatal mortality rate by around 200%. This came to be referred to as one of the world’s worst disaster within the industrial sector.

Chernobyl Disaster

The Chernobyl disaster refers to the accident that took place at Chernobyl Nuclear Power Plant on April 26, 1986. The accident was caused by a nuclear meltdown in one of the reactors which led to a fire that sent a plume of radioactive fallout that eventually spread all over Europe.

Built at the banks of Pripyat river of Ukraine, the Chernobyl nuclear reactor plant had four reactors, each capable of producing 1,000 MWs of electric power.

A group of engineers, planned an electrical engineering experiment on the evening of April 25th 1986, on the Number 4 Reactor. With their little knowledge on Nuclear physics, the concept of their experimenting involved determining how long turbines would spin and supply power to the main circulating pumps following a loss of main electrical power supply.

What Led to the Disaster?

The reactor unit 4 was to be shut down for routine maintenance on 25 April 1986. But, it was decided to take advantage of this shutdown to determine whether the slowing turbine could provide enough electrical power to operate the main core cooling water circulating pumps, until the diesel emergency power supply became operative in the event of a loss of station power. The primary objective of this experiment was to determine whether cooling of the core could continue in the event of a loss of power.

The experiment was carried out without a proper exchange of information between the testing department and the safety department due to the misconception that this experiment belongs to the non-nuclear part of the power plant. Thus, the test started with inadequate safety precautions and the operating engineers were not made aware of the nuclear safety implications of the electrical test and its potential danger.

The Experiment

According to the test planned, the Emergency Core Cooling System (ECCS) of the reactor, which provides water for cooling the reactor core, was shut down deliberately.

For the test to be conducted, the reactor needed to be be stabilized at about 700-1000 MW before shut down, but it fell all the way down to 5000 MW because of some operational phenomenon. Later, the operator working in the night shift committed an error, by inserting the reactor control rods so far. This caused the reactor to go into a near-shutdown state, dropping the resource output to around 30 MW.

Since this low power wasn't sufficient to create the test and will make the reactor unstable, it had been decided to restore the power by extracting the control rods, which made the power stabilize at 200 MW. This was actually a violation to safety law, because of the positive void co-efficiency of the reactor. Positive void coefficient refers to the increasing number of reactivity in a reactor that changes into steam. The test was decided to be administered at this power level.

Actually, the reactors were highly unstable at the low power level, primarily as a result of the control rod design and also the positive void coefficient factors that accelerated nuclear chain reaction and the power output if the reactors lost cooling water.

At 1:23, on April 26th 1986, the engineers continued with their experiment and shut down the turbine engine to examine if its inertial spinning would power the reactor’s water pumps. In fact, it didn't adequately power the water pumps and without the cooling water the power level within the reactor got surged.

The water pumps started pumping water at a slower rate and they in conjunction with the entry to the core of slightly warmer feed water, may have caused boiling (void formation) at the bottom of the core. This, together with xenon break down, might have increased the power level at the core. The power level was then increased to 530 MW and continued to rise. The fuel elements were ruptured and resulted in steam generation, which increased the positive void coefficient leading to high power output.

The high-power output alarmed the engineers who tried to insert all the 200 control rods, which was a conventional procedure administered in order to regulate the core temperature. But these rods got blocked half the way, owing to their graphite tip design. So, before the control rods with their five-meter absorbent, could penetrate the core, 200 graphite tips simultaneously entered the core which facilitated the reaction to extend, causing an explosion that blew off the 1,000-ton heavy steel and concrete lid of the reactor, consequently jamming the control rods, which were halfway down the reactor. As the channel pipes begin to rupture, mass steam generation occurred as a result of depressurization of the reactor cooling circuit.

Two explosions were reported as a result. The first one was the initial steam explosion. Eventually, after two to 3 seconds, a second explosion occurred, which may be possibly from the build-up of hydrogen because of zirconium-steam reactions.

All the materials like Fuel, Moderator and Structural materials were ejected, starting a number of fires and the destroyed core was exposed to the atmosphere. In the explosion and ensuing fire, over 50 tons of radioactive material were released into the atmosphere, where it had been carried by air currents. This was 400 times more than the quantity of radioactive materials released at the time of Hiroshima bombing.

Fatal Effects of the Disaster

The Chernobyl Nuclear Power Plant disaster in Ukraine, is considered the only accident in the history of commercial nuclear power to cause fatalities from radiation.

The release of radiation caused many fatal after effects. A few of these effects are listed below −

- Two workers had died. One immediately got burnt to ashes after the accident, while the other individual was declared dead at the hospital within few hours of admission.

- 28 emergency workers and staff died within 4 months of the accident because of the thermal burns and also the radiation effect on their bodies.

- This accident created 7,000 cases of thyroid cancer.

- 237 people who were on-site and involved in cleaning up were diagnosed with Acute Radiation Syndrome (ARS).

- The land, air and ground water were all contaminated to a great extent.

- The direct and indirect exposure to radiation led to Downs Syndrome, Chromosomal Aberrations, Mutations, Leukaemia, Thyroid Cancer and Congenital Malfunctions and many other severe health problems.

- Ecological effects of the disaster include destruction of plant and animal life.

Fukushima Nuclear Disaster

On 11 March 2011, the eastern coast of Japan near Fukushima experienced a considerably high magnitude 9 earthquake and enormous tsunami waves that caused widespread devastation with about 20 000 lives lost (confirmed dead and presumed dead).

The earthquake and tsunami led to a nuclear accident at the Fukushima Daiichi reactor complex. The Fukushima nuclear accident has been categorized at the highest rating on the INES scale, almost identical to the Chernobyl rating. The accident severely damaged the reactor complex.

Causes of the Disaster

On March 11, 2011, the Fukushima Daiichi plant on the north-eastern Japanese coastline suffered a major multiunit accident. At 2:46 p.m., an extremely high magnitude 9.0 earthquake struck 180 km off the eastern coast, leading to an automatic shutdown of units 1, 2, and 3, which were operating at the time. The earthquake led to damage to the electrical power system which in turn resulted in the loss of offsite power, but onsite diesel generators were started to supply equipment like decay heat removal systems for these three BWRs.

A tsunami 14 to 15 m in height inundated the plant site approximately an hour after the earthquake. The flooding caused due to the tsunami rendered the emergency diesel generators and other required electrical switchgear inoperable. The plant experienced a station blackout with the loss of both onsite and offsite power. Only the Unit 3 dc batteries were supplying its instrumentation and control systems at this point, but sufficient power for giant equipment like pumps wasn't available. Although the fission process had ceased when the plant scrammed, the fission product decay heat requires large heat removal systems.

Unit 1 incorporates a passive isolation condenser (IC) system, but had been turned off before the arrival of the tsunami. Units 2 and 3 feature a reactor core isolation cooling (RCIC) system. The RCIC pump is driven by steam from the reactor to supply makeup water when the conventional cooling water supply is unavailable. Liquid water from the toroidal wet-well is pumped into the reactor, while the vapor exiting the reactor through the RCIC turbine is condensed within the wet-well to suppress pressure. However, the requisite batteries for this method to function will eventually be depleted. This closed system has no capability of dissipating its heat beyond ambient heat loss mechanisms.

Without temperature reduction (e.g., when the reactor isolation pump stops), the coolant pressure within the reactor increased as decay heat continued to produce steam. Without the introduction of more water into the reactor, the liquid level within the vessel descended and therefore the top of the core was no longer submerged in liquid. This led to cladding and fuel began to overheat, releasing gaseous fission products and hydrogen into the reactor vessel, which eventually passed into the wet-well and later the drywell atmosphere. Over the subsequent few days, core damage occurred to reactors 1, 3, and 2 (in order).

The steam and released gases drove up pressure within the first containment. The operators partially depressurized the system instead of allowing the containment to rupture, which resulted in the venting of radioactive fission products and H2 into the upper floor of the reactor building. This led to the explosion of the flammable H2 thereby destroying the steel frame structure of the Unit 1, 3, and 4 reactor service levels; the Unit 3 H2 gas underwent backflow, thereby migrating to Unit 4, which was defueled previously. The Unit 2 suppression chamber was damaged, leading to mass discharge of radioactive material.

The basic rights of engineers include the right to live freely and pursue their legitimate interests as any individual, in conjunction with the right to be against racial or sexual discrimination, receiving one’s salary consistent with the work, choosing of political activities, etc., as other employees.

Professional Rights

Professional Rights are those rights that engineers enjoy as professionals. These professional rights include:

Right of Professional Conscience

This is a basic right which explains that the choices taken while carrying on with the duty, where they're taken in moral and ethical manner, shall not be opposed. The right of professional conscience refers to the ethical right to exercise professional judgement in pursuing professional responsibilities. It requires autonomous moral judgement in trying to uncover the foremost morally reasonable courses of action, since correct courses of action aren't always obvious.

There are two general ways to justify the fundamental right of professional conscience.

- The exercise of ethical reflection and conscience that justifies professional duties is critical, with regard to that duty.

- The general duties to respect individuals and rule-utilitarianism would accent the general public good of allowing engineers to pursue their professional duties.

Right of Conscientious Refusal

The right of conscientious refusal includes the right to refuse to engage in unethical behaviour. This can be done solely because it feels unethical to the doer. The right of conscientious refusal might lead to conflicts within the authority-based relationships.

The two main situations to be considered with conscientious refusal are:

- When it's already stated that certain act is unethical in a widely shared agreement among all the workers.

- When there occurs disagreement among considerable number of individuals whether the act is unethical.

Hence it is established that engineers and other professionals have an ethical right to refuse the unethical acts like bribery, forging documents, altering test results, lying, padding payrolls or coercing employees into acting by threatening, etc.

Right to Recognition

An engineer has a fundamental right to the recognition of their work and accomplishments. An engineer also has right to talk about the work one does by maintaining confidentiality and may receive external recognition. The right for internal recognition which incorporates patents, promotions, raises etc. along with a good remuneration, also are a part of it.

The fulfilment of right to recognition motivates the worker to be a trustful member of the organization, which also benefits the employer. This makes the employee morally bound which reinforces the moral nature to be abide by the professional ethics.

Gender Discrimination

The demeaning of a person based on personal factors such as one’s gender, sexual orientation, race, skin colour, age or political or religious outlook is referred to as discrimination. Discrimination of any kind must never be allowed at any workplace; this is where everyone has to be treated equally. It is often observed that discrimination internally affect the person’s self-identity and self-respect which is pernicious within the work environment, where the work itself should represent a person’s self-image.

The Civil Rights Act of 1964 states that, “It shall be unlawful employment practice for an employer to fail or refuse to hire or to discharge any individual, or otherwise to discriminate against any individual with respect to his compensation, terms, conditions, or privileges of employment, because of such individual’s race, colour, religion, sex or national origin”.

Workplace gender discrimination comes in various forms, but generally it implies that an employee or a job applicant is treated differently or less favourably as a result of their sex or gender, or because the person is affiliated with a corporation or group that's related to a specific sex or gender. Even though the words “sex” and “gender” have different meanings, laws against discrimination at work often use them interchangeably.

Sometimes workers experience discrimination due to their gender and something else, like their race or ethnicity. For example, a female of colour may experience discrimination within the workplace differently from a white female co-worker. She may be harassed, paid less, evaluated more harshly, or disregarded for promotion due to the combination of her sex and her race.

Components of gender discrimination in the workplace

Men and women alike may face issues regarding gender inequality within the workplace, although women typically contend with it more often than men. Gender discrimination in the workplace can be identified by these components:

- Pay

The gender pay gap continues to be a large part of gender discrimination in the workplace. The pay gap is characterized by one gender being paid less to do an identical job as the other gender. Usually, women are paid less than men even though they hold identical positions, have similar work experience and academic backgrounds. Based on 2019 Census data, women in the United States are paid 82 cents for every dollar paid to men.

2. Leadership

In addition to the pay gap, there’s also a gender leadership gap. Many women are often passed up for promotion opportunities in the workplace due in part to gender discrimination. Data shows that there are enough qualified women to fill existing leadership positions, but gender bias is keeping women from reaching toward these positions.

3. Hiring

Male employers often prefer hiring male employees, and hiring managers are more likely to click on a male application profile rather than a female’s. In one gender experiment, when a male employer was making a hiring decision,women had only a 40% chance of getting hired. This means that women are at a disadvantage from the start of the hiring process —even if they have the same skills, experience and qualifications.

4. Inclusion

Gender inclusion within the workplace varies depending on the business. However, excluding a person from team projects, company outings, meetings and necessary decision-making due to gender falls within the realm of gender discrimination. When a person is not being included in tasks or events, it can prevent them from becoming successful and productive workers.

The process of getting rid of gender discrimination involves the following steps:

- Increase diversity in hiring

- Begin a pay audit

- Consider updating your training

- Revise pay secrecy policies

- Promote work-life balance

- Create an open-minded atmosphere

- Provide mentorship for everyone

- Keep accurate documentation

- Sexual Harassment at Workplace

Sexual Harassment at Work Place

Sexual harassment can be defined as, “The unwanted imposition of sexual requirements in the context of a relationship of unequal power”. Sexual harassment could be a display of power and aggression through sexual means. Sexual harassment is generally divided into two types:

- Quid Pro Quo which literally translates to 'A favour for a favour' includes cases where supervisors require sexual favours as a condition for some employment benefit (a job, promotion or raise). It can take the shape of a sexual threat (of harm) or sexual offer (of a benefit reciprocally for a benefit).

- Hostile work environment in contrast, is any sexually oriented aspect of the workplace that threatens employee's rights to equal opportunity. A hostile work environment may encompass unwanted sexual proposals, lewd remarks, sexual leering, posting nude photos and inappropriate physical contact.

Very often situations that commence innocently result in inappropriate and unprofessional behaviours. It is important to recollect that workplace sexual harassment is sexual, unwelcome and the experience is subjective. It is the impact of the action and not the intent of the thought that matters and it almost always occurs in a matrix of power. It is possible that a woman may experience one instance of harassment or a series of incidents over a period of time. It is important also to remember that each case is unique and must be examined in its own context and in line with the encompassing circumstances as a whole. To enable prevention of sexual harassment at the workplace, it's critical to acknowledge and differentiate between welcome and unwelcome sexual behaviour.

Examples of sexually harassing behaviour include:

- Unwelcome touching;

- Staring or leering;

- Suggestive comments or jokes;

- Sexually explicit pictures or posters;

- Unwanted invitations to go out on dates;

- Requests for sex;

- Intrusive questions regarding an individual's private life or body;

- Deliberately brushing up against a person or other forms of showing unnecessary familiarity;

- Insults or taunts based on sex;

- Sexually explicit physical contact; and

- Sexually explicit emails or SMS text messages.

Impact of Sexual Harassment

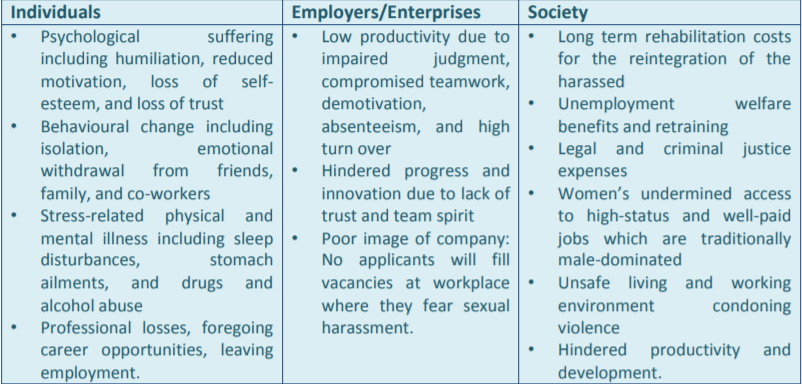

When sexual harassment takes place, there is a long lasting negative and traumatic impact on individuals including psychological suffering, physical suffering and professional losses.

Workers suffering from sexual harassment are most unlikely to be highly productive. The negative impacts do not stop at an injury to the one individual. It has a ripple and multiplier effect on the rest of the workers in the organization, impacting the workplace and bringing negative consequences such as compromised team work, economic loss, impaired productivity, and hindered development.

For the society at large, sexual harassment impedes the achievement of equality between men and women as it condones sex discrimination and sexual violence, and has detrimental effects on the development of the country as a whole and the well-being of people. Therefore, preventing and addressing sexual harassment is very important on individual, organizational as well as social level.

The effect of sexual harassment on individuals, employers/companies and society in general can be studied from the table below:

A law is a body of rules of action prescribed by controlling legal authority and having binding legal force. Typically, laws refer to all the rules established by authority or custom for regulating the behaviour of members of a community or country. A balanced outlook of laws emphasizes the necessity of laws and regulations and their limitations in governing engineering practice

Law and ethics are inextricably related as ethics define what should be done or not done in any given situation whereas law defines the standard lawful behaviour of an individual in a given situation.

The necessity of laws and regulations and also the limitations that are present in engineering practice may be understood with an outline of the laws within the Engineering profession. To live in harmony within the society, one should learn to keep up a balance between individual needs and collective needs of the society.

The ethical conduct which might maintain such balance, will be applied with the assistance of laws. Laws are important because people aren't completely responsible and because of the competitive nature of the market economy system which doesn't encourage moral initiative.

Let us inspect some examples from the past that represent the importance of law.

Case 1: Babylon’s Building Code (1758 BC)

The Babylonian Building Code was formulated by Hammurabi, king of Babylon. It aimed toward the builders of his time wherein, they were forced to follow the code by law. He ordered them,

“If a builder has made a house for an individual and has not made his work sound, and the house which he has built has collapsed thereby causing the death of the householder, that builder shall be put to death. If it leads to the death of the house holder’s son, they shall put that builder’s son to death. If the collapse results in the death of the house holder’s slave, he shall give slave to the householder. If it destroys property and since he has not made the house sound which he has built and it's fallen down, he shall rebuild the house which has fallen down from his own property. If a builder has built a house for a person and doesn't make his work perfect and the wall bulges, that builder shall put that wall into sound condition at his own cost”.

The above portion of Babylon’s code was respected duly. But the aspects find only little approval today. This code gives a powerful incentive for self-regulation.

Case 2: The United States Steamboat Code (1852 AD)

The steam engines used for travel during those days were really heavy and hulking. James Watt who invented external combustion steam engine worked with two more scientists Oliver Evans and Richard Trevithick who had modified the old steam engines by removing condensers and made them compact.

These redesigned engines though made lighter, couldn’t solve the issue of boiler explosions. The increase in the speed of the steam boats led to the explosion of the boilers on steam boats causing disasters. Then Alfred Guthrie, an engineer of Illinois had inspected around 200 steam boats with his own funding and discovered the causes for the boiler explosions and later prepared a report relating to the care that could be taken later.

The recommendations made by him were published by Senator Shields of Illinois and incorporated in senate documents which later was made a law, which made the mechanical engineers of America (ASME), to formulate the standards in the manufacturing of steam boats.