Unit - 4

Flexural Stresses

When the beam is subjected to a constant bending moment no shear stresses are induced in that portion of beam is called as simple bending or pure bending.

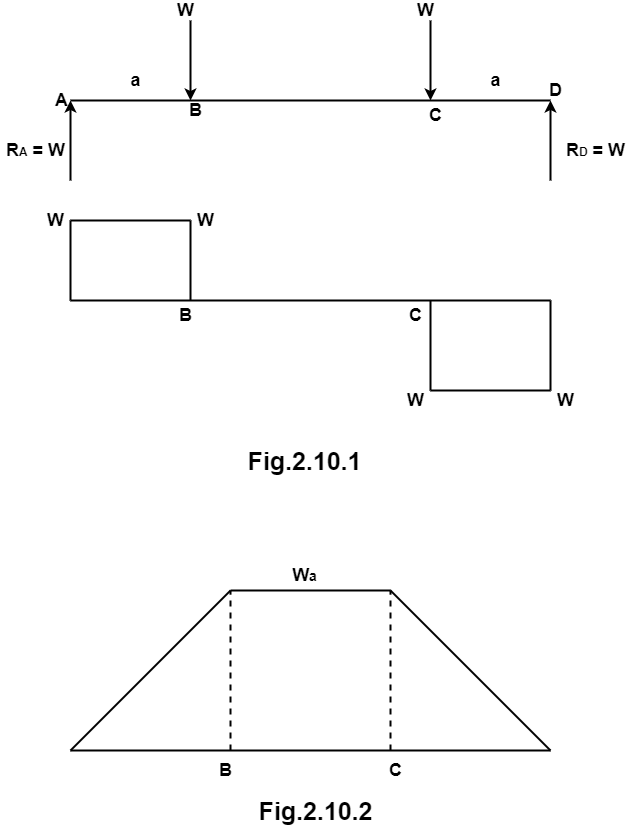

A simply supported beam ABCD subjected to two equal point load w at equal distance ‘a’ from each support.

In this chapter we are considering the beam is subjected to pure bending only. i.e., shear force neglected.

In shear force diagram the shear force between portion BC is zero.

In bending moment diagram the bending moment between portions BC is constant. The portion BC is said to be under pure bending.

1. The material of beam is homogeneous and isotropic. (Isotropic means having the properties same in all direction.)

2. The beam is straight before loading.

3. The beam is uniform cross section throughout its length.

4. Transverse section which is plane before loading remains plan even after loading.

5. The material is elastic and hooks law is applicable.

6. The effect of shear is neglected therefore the analysis is meant for pure bending.

7. The modulus of elasticity E has same value in tension and compression.

8. Each layer is free to expand or compact having no influence in the neighboring layers for their extraction and contraction.

9. The beam is initially straight and all longitudinal filaments bend into circular area with a common center of curvature.

Derivation of flexural formula:

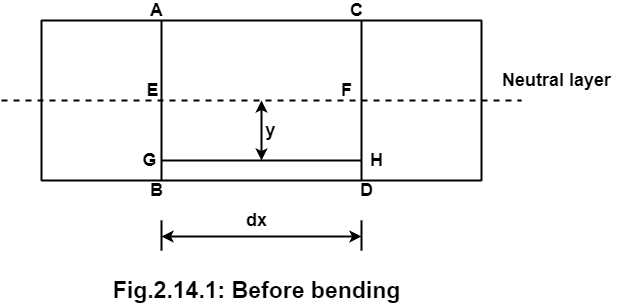

Fig. Before Bending

Consider any two normal sections AB and CD of a beam for a small length ‘dx’ apart as shown in fig. After the application of the transverse loading on the beam will be bends A B

Let AB and CD intersect each other at ‘O’

Fig. After Bending

Let,

R = Radius of curvature of the neutral layer EF

θ = subtended angle at ‘O’

Consider a layer GH at a distance y from neutral axis

Stain in layer GH due to bending

e = change in length/ original length

= GH-GH

GH

But GH = EF

From Fig.

Length of arc = subtended angle x radius

Original length EF = EF = R θ

Length of layer GH = (R + y) θ

Change in length = GH - GH = (R + y) Θ - R θ

……. (i)

……. (i)

By definition, modulus of elasticity, ……. (ii)

……. (ii)

…….. (iii)

…….. (iii)

From equation (i) and (ii)

Since E and R are constant, the stress is directly proportional to the distance from neutral axis (N, A)

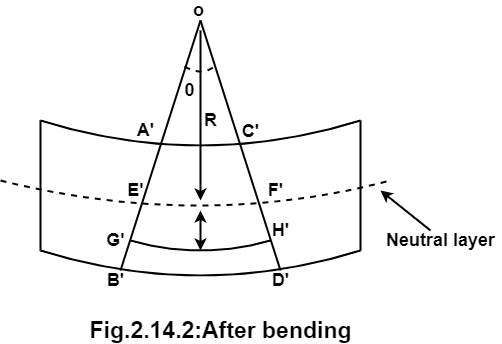

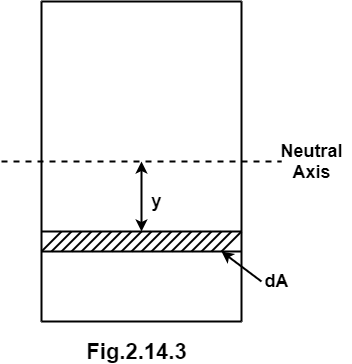

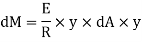

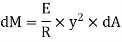

Now consider cross section of the beam consider an elementary strip at ‘y’ from N.A. and area of the strip ‘dA’

Force on the strip = stress on the strip x area on the strip

Moment of this force about N.A

Total moment of whole section about N.A

But  = Moment of inertia about neutral axis

= Moment of inertia about neutral axis

From equation (iii) and (iv) we get,

This is known as bending formula or flexural formula

Key takeaway:

1. The beam is straight before loading.

2. The beam is uniform cross section throughout its length.

3. Transverse section which is plane before loading remains plan even after loading.

4. The material is elastic and hooks law is applicable.

5. The effect of shear is neglected therefore the analysis is meant for pure bending.

In the beam a layer which does not change its original length even after bending is called as neutral layer or neutral axis

The bending stress is always zero at the neutral axis

Neutral axis is the line of intersection of the neutral layer with any normal section of the beam

It will be proved that the neutral axis of the beam passes through the centroid of the section

1. Determination of bending stresses – section modulus of rectangular:

Example1]

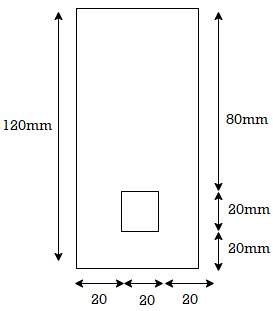

Maximum bending moment of simply supported beam of 10 KNM. The cross section of the beam is as shown in fig. Find the maximum bending stress in tension and compression.

Diagram:

Solution

Given:

M = 10 KNM = 10 x 104 N.mm

Beam = simply supported

To find:

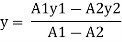

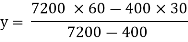

Strep 1) Position of neutral axis

A1 = 60 x 120 = 7200 mm2

A2 = 20x 20 = 400 mm2

y1 = 120/2 = 60 mm

y2 = 20/2 + 20 = 30 mm

Since, the beam is simply supported,

yt = y = 61.76mm

yc = 120 –y -= 120 – 61.76 = 58.24 mm

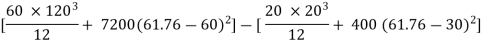

Step 2) moment of inertia

Ixx = Ixx1 – Ixx2

[IG1 + A1h12] – [IG2 + A2h22]

= 8.662 x 106 – o.4168 x 106

= 8.245 x 106 mm4

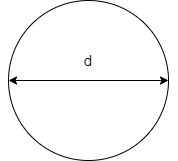

2. Determination of bending stresses – section modulus of circular:

Example:

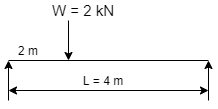

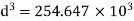

A beam is circular section of diameter d and length L is a simply supported at ends carries central point load W- 2KN L= 4m what should be the value of diameter d so that maximum stresses in beam does not exceed 80 Mpa

Solution:

Given:

L= 4 m

W= 2 KN

To find:

Bending moment

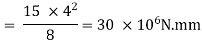

M= WL/4

= 2x 4 /4

= 2 KN.m

Using bending moment formula

3. Determination of bending stresses – section modulus of I angle:

Example1]

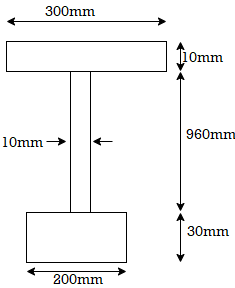

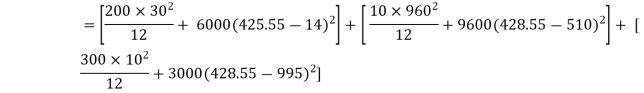

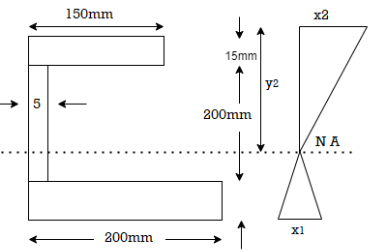

A beam of span 4 m carries a udl 15 KN/M the cross section of the beam as shown in fig. find maximum stress induced bending stress diagram.

Diagram:

Solution:

Given:

L = 4m

W = 15 KN/M

To find:

Maximum bending moments

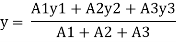

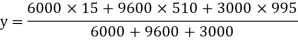

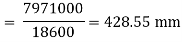

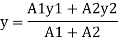

Position neutral axis:

A1 = 200 x 30 = 6000 mm2

A2 = 10 x 960 = 9600 mm2

A3 = 300 x 10 = 3000mm2

y1 = 30/2 = 15 mm

y2 = 960/2 +30 = 510 mm

y3 = 10/2 + 960+30 = 995 mm

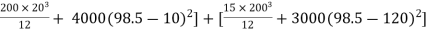

Moment of inertia

I = Ixx1+ Ixx2+Ixx3

= [Ix1+A1h12] + [Ix2+A2h22] + [Ix3+A3h32]

= 2.7896 x 103 mm4

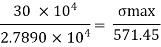

Depth of neutral axis from top

yc = 1000-y1 = 1000-428.55

ymax. 571.45mm

Maximum bending stress

The maximum stress induce in the bean section is 6.15 mpa

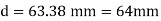

4. Determination of bending stresses – section modulus of T angle

Example 1]

A simply supported beam of 5 m span carries uniformly distributed load of 2 KN/M over span cross section of the beam is shown in fig. Find maximum bending stress induced in beam

Diagram

Solution:

Given:

L =5m

Udl w = 2 KN/M

To find:

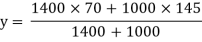

Position of neutral axis

A1 = 140 x 10 = 1400 mm2

A2 = 100x10 = 1000mm2

y1 = 140/2 = 70mm

y2 = 140+10/2 = 145mm

y= 101.25mm

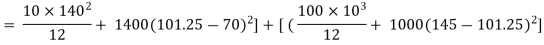

Moment of Inertia

I = Ixx1 + Ixx2

= 5.576x104 mm4

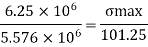

Find moment

wL2/2 = 2x52/2 = 6.25KN-m

since, the beam is simply supported tension induced below N.A

y= yt= 101.25mm

yc= 150-101.25= 48.75 mm

Maximum bending stress using flexure formula

The maximum bending stress induced in the beam is 113.5 N/mm2

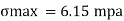

5. Determination of bending stresses – section modulus of channel section:

Example:

A CI beam of c section with top flange 150 mm x 15mm bottom flange 200mmx20mm and web 15mmx 200 mm is supported over a span of them it the permissible stresses are 120 mpa compression what udl can be safety applied on beam. what will be tensile stress in the beam

Solution

Given:

To find:

Safe udl w and tensile stress

Position of neutral axis

A1 = 200 x 20 = 4000 mm2

A2 = 200 x 15 = 3000 mm2

A3 = 15 x 150 = 2250 mm2

y1 = 10 mm

y2= 120 mm

y3 = 227.5 mm

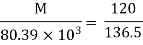

Moment of inertia

Ixx= Ixx1+Ixx2

=

Ixx = 80.33 x 106 mm4

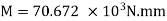

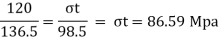

Position of extreme fiber from NA

y= yt = 98.5 mm

yc = 235-98.5 = 136.5 mm

bending formula

Maximum bending moment = wl2/8 = 15.7 kN/m

Tensile stress:

Simply supported beam or Cantilever beam

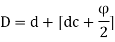

Step1) Preliminary dimension of beam

c/c dist. of support

Clear span + effective depth (d)

b. Effective Depth of beam

The effective depth of beam between

deff. = leff. /15 to leff/10

Assuming suitable cover and bar dia. calculating the overall depth

Calculating the overall depth

D = deff. + d’ (effective cover)

General bar dia. use for beam is from 12mm to 20 mm

Step2) Load calculation and Design moments

For trapezoidal loading =

For triangular loading = Wu. Leff. /3

c. Load from wall = 20x thickness of wall x ht. of wall

d. Live load

B. Design moment:

For simply supported beam mu= Wu. leff.2/8

For cantilever beam mu = Wu l/2

C. Design of shear force:

Simply supported beam = wl/2

Cantilever beam = wl

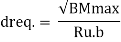

Step 3) Check for depth

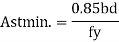

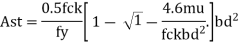

Step4) Check for Steel

Singly reinforced beam:

For doubly r/f beam section find our Ast1 and Ast2 for Mu1 and Mu2

Ast1 = Mu1/(0.87fy(d-0.42xu))

Ast2 = Mu2/ (0.87 fy (d-dc’)

Hence calculate the Astprov. Is equal to

Ast provide= ast x no. of bars

Step 5) Check for width:

If N is no. of bars

breq. = 2c1+N + (N-1) c2

+ (N-1) c2

where,

c1 = clear cover + dia. of stirrups

c2 =  or maximum size of agg. + 5mm

or maximum size of agg. + 5mm

Step 6) Check for deflection

Step 7) Check for shear

Step 8) Check for development length

Key takeaway:

References: