Module -2

Reinforced Cement Concrete & Structure

Plain Cement Concrete is a hardened mass obtained from a mixture of cement, sand, gravel and water in definite proportions. These ingredients are mixed together to form a plastic mass which is poured into desired shape moulds called as forms. This plastic mass hardens on setting and we get plain cement concrete. The hardening of this mixture is caused by a chemical reaction between cement and water.

Plain cement concrete has good compressive strength but very little tensile strength, thus limiting its use in construction. Plain concrete is used where good compressive strength and weight are the main requirements and tensile stresses are very low.

Plain cement concrete has very low tensile strength. To improve the tensile strength of concrete, some sort of reinforcement is needed which can take up the tensile stresses developed in the structure. The most common type of reinforcement is in the form of steel bars which are quite strong in tension.

The reinforcing steel is placed in the forms and fresh concrete is poured around it. This solidified composite mass is called as Reinforced cement concrete and is abbreviated as R.C.C.

R.C.C. Consists of concrete and reinforcing material. The strength of an R.C.C. Section depends upon the kind of concrete and reinforcement used.

Concrete

The properties of concrete depend upon the proportions and type of its ingredients. A properly designed concrete mix is very durable. A good concrete mix should satisfy the following requirements:

(i) The concrete should be mixed thoroughly to from a homogeneous mix.

(ii) Concrete should be compacted properly to prevent it from being porous.

(iii) Sufficient curing of concrete required for developing full strength.

(iv) The water cement ratio should be appropriate, considering the strength and workability criteria.

(v) The concrete mix should be designed properly and should have all the ingredients in right proportions.

The properties of concrete depend upon the properties and proportions of its ingredients. The following are the important properties of concrete which are used in the design:

Compressive Strength:

The compressive strength of concrete is determined by the cube test. The characteristic compressive strength of concrete is defined as the compressive strength of 15 cm cubes at 28 days in N/mm. Below which net more than 5% of the test results are expected to fall. It is represented as f Cube samples are taken at the batching plant and are cured for 28 days.

The compressive and tensile strength in bending and modulus of elasticity of concrete can be correlated with the characteristic compressive strength. So the compressive strength of concrete is an important indication of its overall strength. The strength of concrete is greatly affected by the water cement ratio.

Workability:

The workability of concrete is defined as the ease by which it can be mixed, placed, compacted and finished. A workable concrete should not bleed or segregate. Workability depends upon the following factors:

- Shape of aggregate

- Ratio of fine to coarse aggregate

- Water cement ratio

- Size aggregate

The workability can be measured by the following tests;

- Slump test

- Vee Bee Compression test

- Compaction factor test

Durability:

The concrete should be durable to the environment it is exposed to, during its life, the various types of exposure conditions are listed in Table 5 of IS 456:2000 which specifies the maximum water cement ratio and minimum cement content under different conditions of exposures.

Tensile Strength:

As written earlier, the tensile strength of concrete can be correlated with the characteristic compressive strength of concrete. IS 456 gives the correlation which can be used in the design.

Modulus of Elasticity:

The short term static modulus of elasticity can also be expressed in terms of the characteristic compressive strength and may be written as follows:

E = 5000 √fck

Concrete Mix Proportioning

The determination of the proportions of cement, aggregates and water to attain the desired strength and properties such as workability, durability etc., is called as concrete mix proportioning.

The design of concrete mix is classified into following two types by IS 456:2000 (Clause 9)

(1) Nominal mix concrete

(2) Design mix concrete.

Nominal Mix Concrete:

A concrete mix in which the proportions of cement, aggregate and water are adopted is called as nominal mix. It is not necessary that such a mix will give the desired strength and properties. For example, nominal mix proportions of M15 is 1:2:4. Nominal mix is not used for grades higher than M20. It is used for ordinary concrete works only.

Design Mix Concrete

The concrete obtained by properly determining the proportions of the ingredients of concrete to get the concrete of desired strength and properties is called as Design Mix Concrete. It is seen that 'mix design' not only produce concrete of desired strength but also an economical one. A design mix concrete is preferred over a nominal mix concrete.

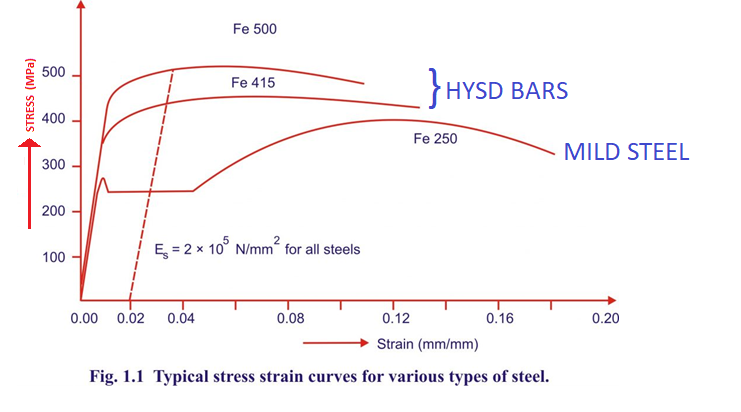

Steel is basically 3 types

- Mild Steel

- HYSD

- TMT

- CRS (Corrosion Resistant Steel) Bars

The latest development in steel bars is the production of CRS or corrosion resistant steel bars. The carbon content in the CRS bars is 0.18% as compared to 0.2% of HYSD bars. The percentage of corrosion resisting elements Such as chromium is as high as 1.5%. Thus making the steel bars more corrosion resistant while keeping its other properties unchanged. In India, SAIL and TISCO (Tata Iron and Steel Company) are producing CRS bars.

- Steel Wire Fabric

Wire fabric is a fabric made by welding or weaving steel wire in the form of a mesh which is also called as steel wire mesh. This mesh is used as reinforcement in slabs, shells, Pavements and roads etc.

- Structural Steel

Sometimes for very heavily loaded elements such as foundations and columns rolled sections like rolled steel joists, channels or angles are embedded in concrete and used as reinforcement.

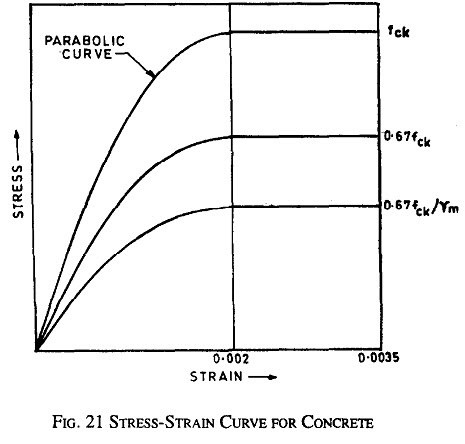

The stress-strain curve for concrete is given in IS456:2000 and is parabolic from zero strain up to strain 0.002. From then onwards up to strain 0.0035 stress remains constant at the value 0.446 f_ck (actually 0.67 f_ck/1.5=0.446 f_ck).

Mild steel bars are also known as Fe 250 because the yield strength of this steel is 250 N / mm2 . The stress strain curve for mild steel. It shows a clear, definite yield point . Although mild steel bars are very ductile, they are not preferred over high yield strength deformed of their less strength and weak bond.

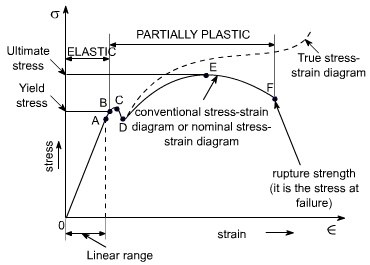

STRESS STRAIN RELATION FOR BRITTLE & DUCTILE MATERIAL

Reference Books:

- RCC Design and drawing By Neelam Sharma

- Limit state design of reinforced concrete by P.C. Verghese, PHI

- Reinforced concrete: Limit state by A.K. Jain

- Reinforced concrete by B.C. Punamia, A.K. Jain and A.K. Jain

- IS Code 456:2000