Unit – 1

Introduction

Introduction

Steel shape is a steel shape that is made of structural metal* additives join with every different to hold hundreds and offer complete rigidity. Because of the high electricity grade of metal, this shape is dependable and calls for much less raw substances than different styles of shape like concrete shape and timber shape.

In current creation, metal systems are used for nearly each kind of shape together with heavy business constructing, high-upward push constructing, system help system, infrastructure, bridge, tower, airport terminal, heavy business plant, pipe rack, etc.

Main structural types

Properties of metal

1. Cost savings

Steel shape is the price chief for maximum tasks in substances and design. It is less expensive to manufacture and erection, calls for much less preservation than different traditional constructing methods.

2. Creativity

Steel has an herbal splendor that maximum architects can’t wait to take gain of. Steel permits for lengthy column-unfastened spans and you may have a number of herbal mild in case you need it in any form of systems.

3. Control and Management

Steel systems is fabricated at manufacturing facility and swiftly erected at creation web website online with the aid of using skilled employees that makes secure creation process. Industry surveys consistently show that metal systems are the top-quality answer in management.

4. Durability

It can face up to extreme forces or harsh climate conditions, inclusive of sturdy winds, earthquakes, hurricanes and heavy snow. They also are unreceptive to rust and, not like wooden frames, they aren't stricken by termites, bugs, mildew, mildew and fungi.

The houses that want to be taken into consideration with the aid of using designers when specifying metal creation merchandise are:

For design, the mechanical houses are derived from minimal values special withinside the relevant product standard. Weldability is decided with the aid of using the chemical content material of the alloy, that is ruled with the aid of using limits in the product standard. Durability depends at the specific alloy type - normal carbon metal, weathering metal or stainless metal.

Toughness

It is withinside the nature of all substances to include some imperfections. In metal those imperfections take the shape of very small cracks. If the metal is insufficiently tough, the crack can propagate swiftly, without plastic deformation and bring about a brittle fracture. The danger of brittle fracture will increase with thickness, tensile strain, strain raisers and at less warm temperatures. The longevity of metal and its cap potential to resist brittle fracture are depending on various of things that have to be taken into consideration on the specification stage. A handy degree of longevity is the Charpy V-notch effect take a look at - see photograph at the right. This takes a look at measures the effect strength required to interrupt a small notched specimen, at a special temperature, with the aid of using an unmarried effect blow from a pendulum.

The various product standards specify minimal values of effect strength for distinctive sub-grades of every electricity grade. For non-alloy structural steels, the main designations of the subgrades are JR, J0, J2 and K2. For great grain steels and quenched and tempered steels (which might be normally tougher, with higher effect strength) distinctive designations are used. A precis of the longevity designations is given withinside the desk below.

Standard | Subgrade | Impact strength | Test temperature |

BS EN 10025-2[1] | JR | 27J | 20oC |

J0 | 27J | 0oC | |

J2 | 27J | -20oC | |

K2 | 40J | -20oC | |

BS EN 10025-3[8] | N | 40J | -20oc |

NL | 27J | -50oc | |

BS EN 10025-4[9] | M | 40J | -20oc |

ML | 27J | -50oc | |

BS EN 10025-5[10] | J0 | 27J | 0oC |

J2 | 27J | -20oC | |

K2 | 40J | -20oC | |

J4 | 27J | -40oC | |

J5 | 27J | -50oC | |

BS EN 10025-6[11] | Q | 30J | -20oc |

QL | 30J | -40oc | |

QL1 | 30J | -60oc | |

Specified minimum impact energy for carbon steel sub-grades | |||

For skinny gauge steels for bloodless forming, no effect electricity necessities are exact for cloth much less than 6 mm thick.

The choice of the correct sub-grade, to offer good enough durability in layout conditions is given in BS EN 1993‑1‑10[12] and its related UK NA [13]. The regulations relate the publicity temperature, pressure degree etc., to a limiting thickness for every sub-grade of metallic. PD 6695-1-10[14] contains beneficial look-up tables and steering on choice of the correct sub-grade is given in ED007.

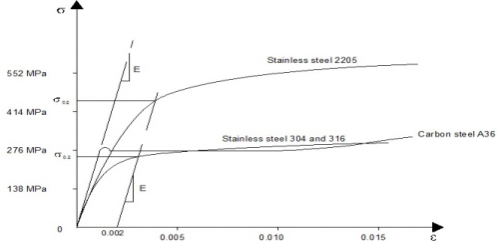

Ductility

Ductility is a degree of the diploma to which a fabric can pressure or elongate between the onset of yield and eventual fracture below tensile loading as demonstrated withinside the discern below. The fashion dressmaker is based on ductility for some of aspects of layout, which include redistribution of pressure on the final restrict state, bolt organization layout, decreased danger of fatigue crack propagation and withinside the fabrication processes of welding, bending and straightening. The diverse requirements for the grades of metallic withinside the above desk insist on a minimal fee for ductility so the layout assumptions are legitimate and if those are exact efficaciously the fashion dressmaker may be confident of their good enough performance.

Weldability

All structural steels are basically weldable. However, welding includes locally melting the metal, which ultimately cools. The cooling may be pretty fast due to the fact the encompassing cloth, e.g., the beam, gives a big warmness sink and the weld (and the warmth introduced) is typically incredibly small. This can lead to hardening of the warmth affected zone (HAZ) and to reduced toughness. The more the thickness of cloth, the more the reduction of toughness.

The susceptibility to embrittlement additionally relies upon at the alloying factors principally, however now no longer exclusively, the carbon content. This susceptibility may be expressed because the Carbon Equivalent Value (CEV), and the various product standards for carbon steels trendy supply expressions for figuring out this fee.

Other mechanical homes of structural metal which can be essential to the fashion dressmaker include:

Durability

A similarly essential assets is that of corrosion prevention. Although unique corrosion resistant steels are to be had those aren't typically utilized in building creation. The exception to this is weathering metal.

The maximum not unusual place way of providing corrosion safety to creation metal is through painting or galvanizing. The kind and diploma of coating safety required relies upon at the diploma of exposure, location, layout life, etc. In many cases, beneath Neath inner dry conditions no corrosion safety coatings are required aside from appropriate hearthplace safety. Detailed facts at the corrosion safety of structural metal are to be had.

Structures are designed in keeping with a standardized code which have homes (or specific standards) that want to be met for the duration of the layout procedure. The restrict kingdom of a shape is whilst the shape is going past the required standards and it ‘breaks. Limit kingdom layout can consequently be described as the method of designing a shape in order that it doesn’t smash and stays fit for its designed use.

There are several layout philosophies utilized by civil engineers. The 3-maximum prominent, as observed via research, can be in brief discussed. These are:

1. Working Stress Method (WSM)

2. Ultimate Load Method (ULM)

3. Limit State Method (LSM).

The Working Stress Method assumes that all cloth used withinside the layout behaves in a linear elastic way and calculations are primarily based totally on carrier situations. The predicted running hundreds at the shape are triggered as stresses at the shape for the duration of the layout and those are restricted (to be under the permissible stresses) to make certain ok protection. The thing of protection is the ratio of the power of the cloth to the permissible pressure. However, as running hundreds can't be stored in the permissible stresses this technique isn't always continually viable.

The assumption withinside the Ultimate Load Method is that the cloth isn't always linear-elastic which means that extraordinary hundreds can have extraordinary protection elements. Calculations are primarily based totally on closing load situations and the pressure situations on the web page of failure or approaching crumble is analysed. This effects in extra slender (consequently extra economic!) sections. However, this technique can bring about cracks and deflections which can be excessive because of the serviceability homes now no longer being met.

In the Limit State Method (aka as Limit State Design), the layout of the shape is taken into consideration for each the serviceability and closing load kingdom. This is consequently the higher layout philosophy to employ. The extraordinary restrict states are the Ultimate Limit State (ULS) and the Serviceability Limit State (SLS), for which distinction are made withinside the code SANS10160: five.1.3... These states every have their own minimal degree of reliability - that's colloquially called the Safety Index.

The extraordinary restrict states of Limit State Design:

Ultimate Limit State offers with states simply earlier than the shape collapses. This pertains to the protection of human beings and the protection of the shape (power, fatigue, bucking, sliding and overturning). It has a protection index of β= 3. five.

Serviceability Limit State offers with functioning of the shape, acceptability of protection and look of the shape (deflections, crack width, malfunction and lack of durability). This has a protection index β= 1. five.

Calculations regarding the impact of a carried-out load and the power or resistance of the shape have to fall in the Safety Index. This is executed through way Partial Safety Factors. Partial protection elements have emerged inside restrict kingdom layout as a method of adjusting parameters to account for versions in order that the best values are used for layout purposes. Partial protection elements are derived from thinking about a frequency distribution statistical evaluation of movements on a shape. Nominal hundreds, observed on symmetric bell curves, have an opportunity of being handed through five%. The overlap of nominal loading of imply load and imply power curves describes the failure condition. This suggests the need of getting a cloth/resistance partial protection thing.

For every layout technique and restrict kingdom, an extraordinary set of layout parameters are used. In the Ultimate Load Method for strengthened concrete layout, partial protection elements of 1. five for concrete and 1.15 for metal are used. While withinside the Working Stress Method, the protection thing is regularly known as being the ratio of the power of the cloth to the permissible pressure. However, withinside the Ultimate Limit State: protection elements of 1.2 instances the useless hundreds, 1.6 instances the stay hundreds and 1.3 instances the wind hundreds are implemented.

This philosophy is a development over the conventional layout philosophies. It considers the protection on the closing load and serviceability on the running load, form of extension of the WSM and ULM.

“Limit kingdom is the kingdom of approaching failure, past which a shape ceases to carry out its meant characteristic satisfactorily, in phrases of both protection or serviceability.”

There are 2 sorts of restrict states

It makes use of more than one protection elements for the desired protection and serviceability on the closing load and running load respectively through thinking about all restrict states. These are called “partial protection elements”.

Partial protection thing for materials:

The power of concrete in real shape is taken as (0. sixty-seven *function power), i.e., 0. sixty-seven fck. The partial protection thing (for closing restrict kingdom) for concrete is 1. five and that for metal is 1.15. The fee is better for concrete as its miles predicted to have extra variability as compared to metal. The partial protection thing (for serviceability restrict kingdom) for concrete and that for metal is taken as 1.0. This is taken as solidarity as we're interested by estimating the real deflections are crack width for the duration of carrier hundreds.

Partial protection thing for hundreds:

Various load combinations are laid out in IS 456 are

For Ultimate limit states

The load factor of 1.2 is considered for the combination of three because the probability of the three loads reaching its peak together is less.

For serviceability limit states

The load factor is taken as 0.8 in the third case as the probability of wind load or earthquake load acting with the peak of live load is less. For all cases the safety factor is taken as 1.0 as we are considering the serviceability of structure here.

Where DL is dead load, LL is live load and QL is earthquake/wind load.

Methods of Steel Structure Design

Simple Design of Steel Structure.

Simple layout is the maximum conventional technique and remains usually used.

Continuous Design of Steel Structure. In non-stop layout, its miles assumed that joints are inflexible and switch second among participants.

Semi-Continuous Design of Steel Structure.

Following are the techniques of structural metallic layout:

1. Simple Design of Steel Structure

Simple layout is the maximum conventional technique and remains usually used. It is thought that no second is transferred from one connected member to another, besides for the nominal moments which rise up as an end result of eccentricity at joints. The resistance of the shape to lateral hundreds and sway is typically ensured via way of means of the supply of bracing or, in a few multi-story buildings, via way of means of concrete cores. It is crucial that the fashion dressmaker recognizes the assumptions concerning joint reaction and guarantees that the detailing of the connections is such that no moments expand which can adversely have an effect on the overall performance of the shape. Many years of enjoy have established the varieties of information that fulfill this criterion and the fashion dressmaker must refer to the same old connections on joints in easy construction.

2. Continuous Design of Steel Structure

In non-stop layout, its miles assumed that joints are inflexible and switch second among participants. The balance of the body towards sway is via way of means of body action (i.e., via way of means of bending of beams and columns). Continuous layout is greater complicated than easy layout consequently software program is usually used to examine the body. Realistic combos of sample loading have to be taken into consideration whilst designing non-stop frames. The connections among participants have to have special traits relying on whether or not the layout approach for the body is elastic or plastic. In elastic layout, the joints have to own enough rotational stiffness to make certain that the distribution of forces and moments across the body aren't notably special to the ones calculated. The joint has to be capable of convey the moments, forces and shears springing up from the body evaluation. In plastic layout, in figuring out the remaining load capacity, the energy (now no longer stiffness) of the joint is of high importance. The energy of the joint will decide whether or not plastic hinges arise withinside the joints or withinside the participants, and could have a huge impact at the disintegrate mechanism. If hinges are designed to arise withinside the joints, the joint have to be targeted with enough ductility to accommodate the ensuing rotations. The stiffness of the joints will be crucial whilst calculating beam deflections, sway deflections and sway balance.

3. Semi-Continuous Design of Steel Structure

True semi-non-stop layout is greater complicated than either easy or non-stop layout because the actual joint reaction is greater realistically represented. Analytical workouts to comply with the actual connection behaviour intently are fantastically worried and mistaken for ordinary layout, as they require the usage of state-of-the-art laptop programs. However, simplified approaches do exist for each braced and unbraced frame; those are in brief referred to below. Braced frames are the ones wherein the resistance to lateral hundreds is supplied via way of means of a bracing device or a core; in unbraced frames this resistance is generated via way of means of bending moments withinside the columns and beams.

The simplified approaches are:

The wind second approach, for unbraced frames. In this procedure, the beam/column joints are assumed to be pinned whilst considering gravity hundreds. However, beneath Neath wind loading they're assumed to be inflexible, which method that lateral hundreds are carried via way of means of body action. A fuller description of the approach may be discovered in reference.

(ii) Semi-non-stop layout of braced frames. In this procedure, account of the actual joint behaviour is taken to lessen the bending moments carried out to the beams and to lessen the deflections. Details of the approach may be discovered in reference.

Analytical Methods

To carry out an accurate evaluation a structural engineer has to decide data including structural hundreds, geometry, aid situations, and fabric properties. The consequences of such an evaluation generally encompass aid reactions, stresses and displacements. This data is then in comparison to standards that suggest the situations of failure. Advanced structural evaluation can also additionally examine dynamic reaction, balance and non-linear behavior. There are 3 tactics to the evaluation: the mechanics of substances technique (additionally referred to as energy of substances), the elasticity idea technique (that is simply a unique case of the greater widespread area of continuum mechanics), and the finite detail technique. The first employ analytical formulations which observe in most cases easy linear elastic models, main to closed-shape answers, and might frequently be solved via way of means of hand. The finite detail technique is simply a numerical approach for solving differential equations generated via way of means of theories of mechanics including elasticity idea and energy of substances. However, the finite-detail approach depends closely at the processing energy of computer systems and is greater relevant to systems of arbitrary length and complexity.

Regardless of technique, the formula is primarily based totally at the equal 3 essential family members: equilibrium, constitutive, and compatibility. The answers are approximate whilst any of those family members are simplest about satisfied, or simplest an approximation of reality.

Limitations

Each approach has noteworthy limitations. The approach of mechanics of substances is restrained to very easy structural factors beneath Neath noticeably easy loading situations. The structural factors and loading situations allowed, however, are enough to remedy many beneficial engineering troubles. The idea of elasticity lets in the answer of structural factors of widespread geometry beneath Neath widespread loading situations, in principle. Analytical answer, however, is restrained to noticeably easy cases. The answer of elasticity troubles additionally calls for the answer of a device of partial differential equations, that is extensively greater mathematically disturbing than the answer of mechanics of substances troubles, which require at maximum the answer of a normal differential equation. The finite detail approach is possibly the maximum restrictive and maximum beneficial on the equal time. This approach itself is based upon different structural theories (including the alternative mentioned here) for equations to remedy. It does, however, make it generally feasible to remedy those equations, regardless of fantastically complicated geometry and loading situations, with the restrict that there's constantly a few numerical errors. Effective and dependable use of this approach calls for a stable understanding of its limitations.

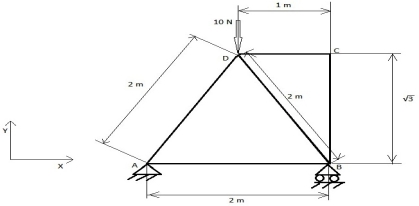

Example

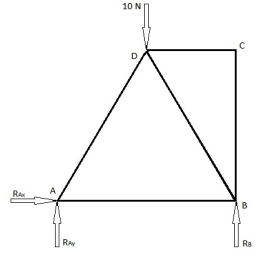

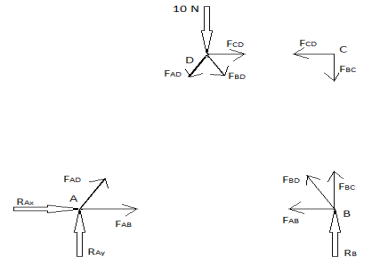

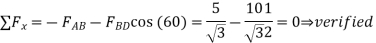

There are 2 commonly used methods to find the truss element forces, namely the Method of Joints and the Method of Sections. Below is an example that is solved using both of these methods. The first diagram below is the presented problem for which we need to find the truss element forces. The second diagram is the loading diagram and contains the reaction forces from the joints.

Since there is a pin joint at A, it will have 2 reaction forces. One in the x direction and the other in the y direction. At point B, we have a roller joint and hence we only have 1 reaction force in the y direction. Let us assume these forces to be in their respective positive directions (if they are not in the positive directions like we have assumed, then we will get a negative value for them).

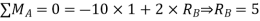

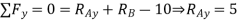

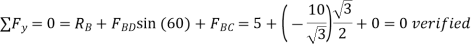

Since the system is in static equilibrium, the sum of forces in any direction is zero and the sum of moments about any point is zero. Therefore, the magnitude and direction of the reaction forces can be calculated.

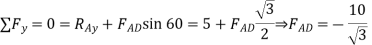

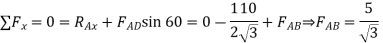

Method of joints

At D,

At C,

Although we have found the forces in each of the truss elements, it is a good practice to verify by completing force balances.

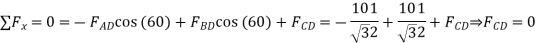

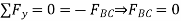

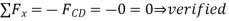

At B,

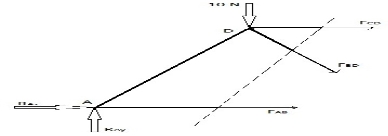

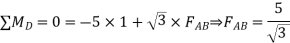

Method of sections

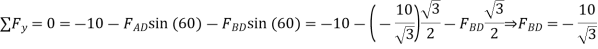

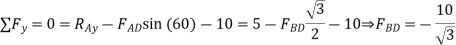

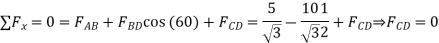

This method can be used when the truss element forces of only a few members are to be found. This method is used by introducing a single straight line cutting through the member whose force wants to be calculated. However, this method has a limit in that the cutting line can pass through a maximum of only 3 members of the truss structure. This restriction is because this method uses the force balances in the x and y direction and the moment balance, which gives us a maximum of 3 equations to find a maximum of 3 unknown truss element forces through which this cut is made. Let us try to find the forces FAB, FBD and FCD in the above example

This section provides information on the default load combinations (technically, loading combinations) that RAM Concept creates when you start a new IS 456 files. The purpose and origin of each load combination are given. You can remove or modify any of these load combinations. You can also add load combinations. The load combinations are from IS 456: 2000 unless noted otherwise.

Combinations as per IS 456:

For Limit State of Collapse:

Load Combination | DL | LL | WL/EL |

DL+LL | 1.5 | 1.5 | - |

DL+WL/EL | 0.9/1.5 | - | 1.5 |

DL+LL+WL/EL | 1.2 | 1.2 | 1.2 |

For Limit State of Serviceability:

Load Combination | DL | LL | WL/EL |

DL+LL | 1.0 | 1.0 | - |

DL+WL/EL | 1.0 | - | 1.0 |

DL+LL+WL/EL | 1 | 0.8 | 0.8 |

For Foundation Design:

Load Combination | DL | LL | WL | EL |

DL+LL | 1.0 | 1.0 | - | - |

DL+LL+WL | 0.8 | 0.8 | 0.8 | - |

DL+LL+EL | 0.8 | 0.8 | - | 0.8 |

The load aggregate (Dead load + stay load + wind load or seismic load) can be left out in design & first load aggregate i.e. Dead load + Live Load will be in comparison with secure bearing potential because of shear criteria & allowable bearing potential due agreement criteria wherein wind or seismic load is much less than 25 percentage of that because of useless and stay hundreds. Where wind or seismic load is extra than 25 percentage of that because of useless and stay hundreds, foundations can be so proportioned that the strain because of aggregate of load (useless + stay + wind load) does now no longer exceed the secure bearing potential with the aid of using extra than 25 percentage. When seismic forces are considered, the secure bearing potential will be accelerated as laid out in IS: 1893-1984.

Net secure SBC for (DL+LL +EQ) comb = SBC*(A) A = 150% for footing with tie beams on Rock and difficult soil A = 125% for footing with tie beams on medium soil /or gentle soil A = 150% for footing without tie beams on Rock and difficult soil A = 125% for footing without tie beams on medium soil A = 0.00% for footing without tie beams on gentle soil

For both Earthquake and Wind Loads

Load Cases

For Earthquake Load

Load Cases

For Wind Load

For Live Load

Concept of Wind Load Analysis:

Buildings are difficulty to horizontal hundreds because of wind strain appearing at the buildings. Wind load is calculated as in step with IS 875(Part III)-1987. The horizontal wind pressures act on vertical outside partitions and uncovered location of the buildings. Some of the strain appearing on uncovered surfaces of structural partitions and columns is directly resisted with the aid of using bending of those members. The infill partitions act as vertical plate supported at pinnacle and backside with the aid of using ground beams, accordingly shifting the hundreds at slab degree. The parapet wall is at terrace transfers the wind hundreds to the floor slab with the aid of using cantilever action. For simplicity, the wind hundreds appearing on uncovered surfaces of a given story are idealized to be supported with the aid of using higher and lower floors.

Wind load evaluation as in step with IS 875 (Part three)-1987:

Wind forces appearing on a given floor is same to the wind pressures expanded with the aid of using the effected location.

Design wind velocity

(Vz): Design wind velocity is given with the aid of using the equation

Vz= Vb K1 K2 K3

wherein Vz =Design wind speed (m/sec)

Vb= Basic wind velocity in m/sec (Based on Appendix -A of diverse towns in IS 875 –Part three)

Basic wind velocity Vb, relies upon at the place of the building.

For this purpose, the use of a is split in to six zones with detailed wind speeds starting from 33m/s to fifty-five m/s. Basic wind velocity is primarily based totally on gust speed averaged over a quick time c programming language of three seconds at 10m peak from imply floor degree in an open terrain and for fifty years return period. Appendix A (Fig.1) of the code detailed for a few crucial towns/ cities is given.

Vb has 6 values 33, 39,44,47,50 & fifty-five m/sec.

APPENDIX A (Clause 5.2)

Basic Wind Speed at 10m Height for some Important Cities/Towns

City/Town | Basic Wind Speed (m/s) | City/Town | Basic Wind Speed (m/s) |

Agra | 47 | Jodhpur | 47 |

Ahmedabad | 39 | Kanpur | 47 |

Ajmer | 47 | Kohima | 44 |

Almora | 47 | Kurnool | 39 |

Amritsar | 47 | Lakshadweep | 39 |

Asansol | 47 | Lucknow | 47 |

Aurangabad | 39 | Ludhiana | 47 |

Bahraich | 47 | Madras | 50 |

Bangalore | 33 | Madurai | 39 |

Barauni | 47 | Mandi | 39 |

Bareily | 47 | Mangalore | 39 |

Bhatinda | 47 | Moradabad | 47 |

Bhilai | 39 | Mysore | 33 |

Bhopal | 39 | Nagpur | 44 |

Bhubaneshwar | 50 | Nainital | 47 |

Bhuj | 50 | Nasik | 39 |

Bikaner | 47 | Nellore | 50 |

Bokaro | 47 | Panjim | 39 |

Bombay | 44 | Patiala | 47 |

Calcutta | 50 | Patna | 47 |

Calicut | 39 | Pondicherry | 50 |

Chandigarh | 47 | Port Blair | 44 |

Coimbatore | 39 | Pune | 39 |

Cuttack | 50 | Raipur | 39 |

Darbhanga | 55 | Rajkot | 39 |

Darjeeling | 47 | Ranchi | 39 |

Dehradun | 47 | Roorkee | 39 |

Delhi | 47 | Rourkela | 39 |

Durgapur | 47 | Simla | 39 |

Gagtok | 47 | Srinagar | 39 |

Gauhati | 50 | Surat | 44 |

Gaya | 39 | Tiruchirappalli | 47 |

Gorakhpur | 47 | Trivandrum | 39 |

Hyderabad | 44 | Udaipur | 47 |

Imphal | 47 | Vadodara | 44 |

Jabalpur | 47 | Varanasi | 47 |

Jaipur | 47 | Vijayawada | 50 |

Jamshedpur | 47 |

|

|

Jhansi | 47 |

|

|

K1=Risk Coefficient (Table 1 of IS875-part3)

Table 1 Risk Coefficients for different glasses of structures in different wind speed zones (Clause 5.31)

Class of Structures | Mean Propable Design Live of Structure in Years |

| |||||

33 | 49 | 44 | 47 | 50 | 55 | ||

All general buildings and structures | 50 | 1.0 | 1.0 | 1.01 | 1.0 | 1.0 | 1.0 |

Temporary sheds, structures such as those used during construction stages and boundary walls. | 5 | 0.82 | 0.76 | 0.73 | 0.71 | 0.70 | 0.57 |

Buildings and structure presenting a low degree of hazard to life and property in the Event of failure. Such as isolated towers in wooded areas, farm buildings other than residential buildings

| 25 | 0.94 | 0.92 | 0.91 | 0.90 | 0.90 | 0.89 |

Important buildings and structures such as hospitals communication buildings/towers, power plant structures.

| 100 | 1.05 | 1.06 | 1.07 | 1.07 | 1.08 | 1.03 |

The danger coefficient k1 takes in to account the diploma of reliability required and the anticipated existence of shape.

1.All trendy homes (Design existence 50 years)

2.Temporary sheds (Design existence five years)

3.Less vital Buildings (Design existence 25 years)

4.Important Buildings (Design existence a hundred years)

K2=Terrain, top and shape length element (Table 2)

It relies upon of Terrain class and constructing class/length of shape. Four terrain classes are particular with the aid of using the code protecting at the availability of obstruction to the glide of wind.

Category 1: Refers to no obstructions to be had to the constructing (e.g.) sea coasts and flat treeless plains wherein different systems if any have heights much less than 1.5m.

Category 2: Refers to open terrain with scattered obstructions of 1.5m to 10m top. (e.g.) commercial location.

Category 3: Refers to regions of closed spaced homes of top as much as 10m (e.g.) homes at outskirts of metropolis

Category 4: Refers to location with particularly closed homes of massive heights (e.g.) dense metropolis location. K2 element additionally relies upon at the dimensions of the constructing beneath Neath considerations. Based on size of constructing, the systems are categorized as Class A, Class B, Class C

List of general codes for the deliver, fabrication and shipping of structural metallic and miscellaneous metallic gadgets for the paintings are given right here.

1. I.S. 226: Structural metallic (general quality)

2. I.S. 808: Rolled metallic beams, channel and angles sections.

3. I.S. 1099: Structural metallic (normal quality)

4. ASTM 06: General necessities for shipping of rolled metallic plates, sheet piling and bars for structural use.

five. I.S. 1367: Technical deliver situations for threaded fasteners.

6. I.S. 3757: High tensile friction grip fasteners for structural engineering purposes.

7. I.S. 814: Specifications for protected electrodes for steel arc welding for moderate metallic.

8. I.S. 3613: Acceptance tests for twine flux aggregate for submerged-arc welding.

19. I.S. 816: Code of exercise to be used of steel arc welding for trendy production.

20. I.S. 4353: Recommendations for submerged arc welding of moderate metallic and occasional alloy metallic.

21. I.S. 823: Code of method for guide steel arc welding of moderate metallic.

22. I.S. 817: Codes of exercise for education and welding of steel arc welders.

24. I.S. 1182: Recommended exercise for radiographic exam of fusion-welded butt joints in metallic plates

25. I.S. 5334: Codes of exercise for magnetic particle flaw detection of welds

30. I.S. 1477: Code of exercise for portray of ferrous metals in constructing all allied finishes.

31. I.S. 1161: Steel Tubes for structural purposes

32. IS:1363: Hexagon Head Bolts, Screws and Nuts of product (Part I to III)

33. I.S. 1852: Rolling and Cutting Tolerances for Hot Rolled Steel Products

34. I.S. 3502: Steel Chequered Plate

35. I.S. 3757: High Strength Structural Bolts

36. I.S. 1200: Method of Measurement

Indian general code for structural metallic layout for all kinds of systems are given below. These are the codes which may be referred at some point of layout of metallic systems. Following are the codes commonly used, for any specialised layout, every other code will also be referred that are not indexed right here.

IS: 800: 2007 - Code of Practice for trendy production in Steel

IS: 802 Part 2: 1978 - Code of Practice to be used of Structural Steel in Overhead Transmission Towers-Fabrication, Galvanizing, Inspection and Packing

IS: 806: 1968 - Code of Practice for USE OF Steel Tubes in General Building Construction

IS: 808: 1989 - Dimensions for Hot Rolled Steel Beam, Column, Channel and Angle Sections

IS:814: 2004 - Covered Electrodes for Manual Metal Arc Welding of Carbon and Carbon Manganese Steel Specification

IS:816: 1969 - Code of Practice to be used of Metal Arc Welding for General Construction in Mild Steel.

IS:1161: 1998 - Specification for Steel Tubes for Structural Purposes.

IS:1182: 1983 - Recommended exercise for radiographic exam of fusion welded butt joints in metallic plates

IS:1363 Part 1 & 3: 2002 - Black Hexagonal Headed Bolts, Screws, Nuts & Locknuts of Product Grade C- Hexagon Head Bolts (M5-M64)

IS:1367 Part 1 To 3 & five to 7: 2002 - Technical Supply Conditions for Threaded Steel Fasteners

IS:1852: 1985 - Rolling and Cutting Tolerances for Hot Rolled Steel Products

IS:2062: 1999 - Steel for General Structural Purposes- Specification

IS:3502: 1994 - Specification for Steel Chequered Plates

IS:3658: 1999 - Code of Practice for Liquid Penetrant Flaw Detection

IS:3757: 1985 High Strength Friction Grip Structural Bolts

IS:4260: 2004 - Recommended Practice for Ultrasonic Testing of Butt Welds in Ferritic Steel

IS:5334: 2003 - Code of Practice for Magnetic Flaw Detection of Welds

IS:5369: 1975 - General Requirements for Plain Washers and Lock Washers.

IS:5372: 1975- Specification - Taper Washers for Channels.

IS:5374: 1975 - Specification - Taper Washers for I – Beams

IS:6639: 2005 - Specification for Hexagon Bolts for Steel Structures

IS:7205: 1974 Safety Code for Erection of Structural Steel Work

IS:7215: 1974 - Tolerances for Fabrication of Steel Structures

IS:7307 Part 1 - 1974 - Approval Tests for Welding Procedures Part 1- Fusion Welding of Steel

IS:7310 Part 1: 1974 - Approval Tests for Welders running to Approved Welding Procedures Part 1- Fusion Welding of Steel

IS:7318 Part 1: 1974 - Approval Tests for Welders while Welding Procedure Approval isn't always required. Part 1- Fusion Welding of Steel

IS:8500: 1991 - Weldable structural metallic (Medium and High Strength qualities)

IS:9595: 1996 Recommendation for steel arc welding of carbon manganese metallic

IS:12843: 1989 - Tolerances for Erection of Steel Structures.

slender sections

Plate factors of a cross-phase can also additionally buckle domestically because of compressive stresses. The nearby buckling may be prevented earlier than the restriction nation is performed with the aid of using restricting the width to thickness ratio of every detail of a cross-phase subjected to compression because of axial force, second or shear. When plastic evaluation is used, the contributors will be able to forming plastic hinges with enough rotation potential (ductility) without nearby buckling, to permit the redistribution of bending second required earlier than formation of the failure mechanism. When elastic evaluation is used, the member will be able to growing the yield strain beneath Neath compression without nearby buckling. On foundation of the above, Cl. 3.7 of IS 800:200 categorizes the sections in to 4 training as follows.

When extraordinary factors of a cross-phase fall beneath Neath extraordinary training, the phase will be categorised as ruled with the aid of using the maximum vital detail. The most price of restricting width to thickness ratios of factors for extraordinary classifications of sections are given in Table 2 of IS 800:2007 that is reproduced right here as Table 3.

1. Class 1 (Plastic)

Cross-sections which could broaden plastic hinges and feature the rotation potential required for failure of the shape with the aid of using formation of plastic mechanism fall beneath Neath this class. The width to thickness ratio of plate factors will be much less than that particular beneath Neath Class 1 (Plastic), in Table 2 of IS 800:2007.

2. Class 2 (Compact)

Cross-sections which could broaden plastic second of resistance, however have insufficient plastic hinge rotation potential for formation of plastic mechanism, because of nearby buckling come beneath Neath this class. The width to thickness ratio of plate factors will be much less than that particular beneath Neath Class 2 (Compact), however more than that particular beneath Neath Class 1 (Plastic), in Table 2 of IS 800:2007.

3. Class 3 (Semi-compact)

Cross-sections wherein the intense fiber in compression can attain yield strain however can't broaden the plastic second of resistance, because of nearby buckling. The width to thickness ratio of plate factors will be much less than that particular beneath Neath Class 3 (Semi-compact), however more than that particular beneath Neath Class 2 (Compact), in Table 2 of IS 800:2007.

4. Class 4 (Slender)

Cross-sections wherein the factors buckle domestically even earlier than achieving yield strain. The width to thickness ratio of plate factors will be more than that particular beneath Neath Class 3 (Semi-compact), in Table 2 of IS 800:2007. In such cases, the powerful sections for layout will be calculated both with the aid of using following the provisions of IS 801 to account for the post-nearby-buckling electricity or with the aid of using deducting width of the compression plate detail in extra of the semi-compact phase restriction.

Key Takeaways:

References:

1. McCormac, J.C., Nelson, J.K. Jr., Structural Steel Design. 3rd edition. Prentice Hall, N.J., 2003.

2. Galambos, T.V., Lin, F.J., Johnston, B.G., Basic Steel Design with LRFD, Prentice Hall, 1996

3. Segui, W. T., LRFD Steel Design, 2nd Ed., PWS Publishing, Boston.

4. Salmon, C.G. and Johnson, J.E., Steel Structures: Design and Behavior, 3rd Edition, Harper & Row, Publishers, New York, 1990.

5. Related Codes of Practice of BIS

6. NBC, National Building Code, BIS (2017).

7. ASCE, Minimum Design Loads for Buildings and Other Structures, ASCE 7-02, American Society of Civil Engineers, Virginia, 2002.

8. Subramanian, N. (2010). Steel Structures: Design and Practice, Oxford University Press.

9. Duggal, S.K. (2014). Limit State Design of Steel Structures, McGraw Hill.