Unit - 1

Introduction to energy & power scenario of world

Developing countries desires for economic growth. However, the relationship between the economic growth and the increased energy demand is not always a straightforward linear one.

Example: In the present scenario 6% increase in India's Gross Domestic Product (GDP) would impose an increased demand of 9 % on its energy sector.

In this context, the ratio of energy demand to GDP is a useful indicator. A high ratio reflects energy dependence and a strong influence of energy on GDP growth.

The developed countries, by focusing on energy efficiency and lower energy-intensive routes, maintain their energy to GDP ratios at values of less than 1. The ratios for developing countries are much higher. The ratios for developing countries are much higher.

India's Energy Needs

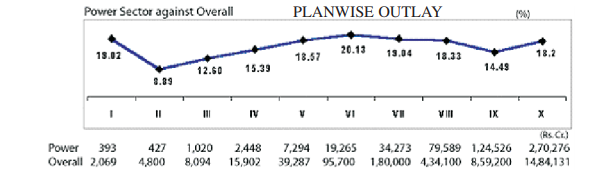

The plan outlay vis-à-vis share of energy is given in Figure. As seen in the figure 18.0% of the total five-year plan outlay is spent on the energy sector.

Per Capita Energy Consumption

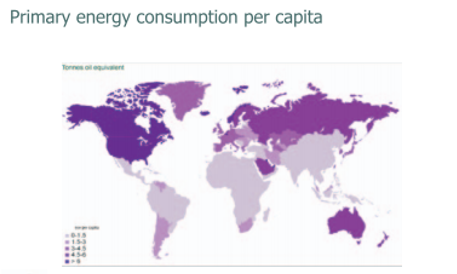

The per capita energy consumption as shown in the figure is too low for India as compared to developed countries. It is just 4% of USA and 20% of the world average. The per capita consumption is likely to grow in India with the growth in economy and thus increasing the energy demand.

Short term and long-term policies

Long Term Policies

- Efficient generation of energy resources

- Improving energy infrastructure

- Deregulation and privatization of energy sector

Short Term Policies

Short term policies are ideally annual work plans drawn from long term policies during each financial year. Investment must increase for clean energy.

Energy Sector Reforms

Since the initiation of economic reforms in India in 1991, there has been a growing acceptance of the need for deepening these reforms in several sectors of the economy which were essentially in the hands of the government for several decades.

The major focus is:

- Private participation in exploration marketing and distribution-NELP.

- Many construction companies went into generation of electricity.

- Electricity trading exchange is also established.

- Establishing competitive electricity markets, adopting market pricing mechanisms, and regulating monopolies

- Encouraging private sector participation, particularly public-private partnerships

- Adopting tariff structures to promote energy conservation.

Energy Security

Energy security is defined as “the continuous availability of energy in varied forms, in sufficient quantities, and at affordable prices”. In terms of energy security, the key issue is resource availability, which is the actual physical amount of the resource available around the world that is the long-term security.

Another aspect of energy security is the need for system reliability, such as the continuous supply of energy, particularly electricity, to meet consumer demand at any given time that is short-term security.

There are many drivers governing the secure supply of energy:

- Diversification of generation capacity—to allow prices to remain reasonably stable

- Prices—energy must be affordable

- Levels of investment required—a significant investment is needed to meet the forecast growth in energy demand and the availability of that investment can be problematic in developing countries

- Ease of transport—energy must be readily available

- Concentration of suppliers—the reliance on imported fuels from a limited number of suppliers increases the risk of adverse market influence

- Availability of infrastructure expertise—countries must have access to different energy sources to achieve a diverse energy mix

- Interconnection of energy systems—the interconnection of energy systems, particularly electricity, must be considered

- Fuel substitution—diversification in the uses of fuels may also be important for energy security

- Political threats—the energy supply system can be vulnerable to disruptions caused by political interests and terrorist attacks.

Energy is central to sustainable development and poverty reduction efforts. It affects all aspects of development-social, economic, and environmental-including livelihoods, access to water, agricultural productivity, health, population levels, education, and gender related issues. None of the Millennium Development Goals (MDGs) can be met without major improvements in the quality and quantity of energy services in developing countries. Some of the common energy sources are coal, petroleum, natural gas, nuclear fuels, and biomass. Of all these, the most widely used energy sources are the hydrocarbon compounds or fossil fuels which account for more than 80% of global primary energy consumption. Depending on their sustainability, energy resources can be broadly classified as either renewable (flowing water, wind, geothermal, solar, hydrogen, biomass) or non-renewable (petroleum, coal, natural gas, uranium). The non-renewable energy resources account for 82% of the world's energy consumption (76% from fossil fuel and 6% from nuclear power) while the remaining 18% comes from renewable energy sources such as biomass (11%), hydropower (4.5%) and geothermal, wind and solar energy (2.5%).

A. Non-Renewable Energy Resources-

1) Petroleum or crude oil: As petroleum or crude oil or conventional or light oil comes out from the ground, it is a thick and gooey liquid consisting of hundreds of combustible hydrocarbons along with small amounts of sulphur, oxygen, and nitrogen impurities. The crude oil is dispersed in pores and cracks in underground rock formations somewhat like water saturating a sponge. In the process of drilling and transporting the oil around the World, some oil spills on land and on aquatic environment, thereby causing land, air and water pollutions. Geologists opine that known and projected global reserves of oil, coal and natural gas are expected to be 80% depleted within 40 years to the point that it would be uneconomical to continue exploration of these natural resources. A serious problem associated with the use of conventional crude oil or any carbon-containing fossil fuel is that it releases CO2 into the atmosphere thereby promoting climate change from global warming. Currently, burning oil mostly as gasoline and diesel fuel for transportation accounts for 43% of global CO2 emission. Climate change undermines power and energy production by increasingly depleting renewable and non-renewable sources, creating resources scarcity and damage to infrastructure. It also undermines environmental dimensions by increasing sea-level rise, extreme weather events and land degradation and pollution. In reducing climate induced threats on power sector, efforts should be geared towards ensuring that the energy sector withstand the changes to climate that are already underway by optimizing energy mix, developing low carbon and renewable energy, formulating relevant laws and regulations as well as promoting technology advancement and economic engineering.

2) Natural Gas: Natural Gas is a mixture of 50-90% by volume of methane (CH4), the simplest hydrocarbon and smaller amounts of heavier gaseous hydrocarbons (higher alkanes) such as ethane (C2H6), propane (C3H8) and butane (C4H10) as well as even smaller amounts of carbon dioxide, nitrogen and highly toxic hydrogen sulphide (H2S). It is a fossil fuel formed when layers of buried plants, gases, and animals are exposed to intense heat and pressure over thousands of years. The energy that the plants originally obtained from the sun is stored in the form of chemical bonds in natural gas. Natural gas is an energy source often used for heating, cooking, and electricity generation. It is also used as fuel for vehicles and as a chemical feedstock in the manufacture of plastics and other commercially important organic chemicals.

3) Coal: Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or veins called coal beds or coal seams. The harder forms, such as anthracite rock can be regarded as metamorphic rock because of later exposure to elevated temperature and pressure. Coal is composed primarily of carbon along with variable quantities of other elements, chiefly hydrogen, sulphur, oxygen, and nitrogen. Coal is an abundant energy resource that is burned mostly to produce electricity and steel. Coal is a solid fossil fuel that was formed in several stages as the buried remains of land plants that lived 300- 400 million years ago were subjected to intense heat and pressure over many millions of years. Coal is mostly carbon but contains small amounts of sulphur, which are released into the atmosphere as sulphur dioxide when the coal burns. Burning coal also releases trace amounts of toxic mercury and radioactive materials. Coal is burned to generate 62% of the world's electricity (52% in the United States) and to make three-fourths of its steel. Coal is the world's most abundant fossil fuel. According to the U.S. Geological Survey, identified and unidentified supplies of coal could last for 125 - 214 years, depending on our rate of usage. The United States has one-fourth of the world's proven coal reserves, Russia has 16%, and China has 12%. In 2004, slightly more than half of global coal consumption was split almost evenly between China and the United States. China has enough proven coal reserves to last 300 years at its current rate of consumption. According to the U.S. Geological Survey, identified U.S. Coal reserves should also last about 300 years at the current consumption rate, and unidentified U.S. Coal resources could extend those supplies for perhaps another 100 years).

4) Nuclear Energy: In conventional nuclear reactor, isotopes of uranium and plutonium undergo controlled nuclear fission. The resulting heat produces steam that in turn spins turbines to generate electricity. To evaluate the advantages and disadvantages of nuclear power, we must know how a conventional nuclear power plant work and its accompanying nuclear fuel cycle work.

5) Radioactive Decay: Natural radioactive decay is a nuclear change in which unstable isotopes spontaneously emit fast moving chunk of matter (alpha or beta particles), or high-energy radiation (gamma-ray), or both at a fixed rate. The unstable isotopes are called radioactive isotopes or radioisotopes. Radioactive decay of these isotopes into other isotopes continues until it produces a stable isotope that is not radioactive. The rate of decay of radioisotope can be expressed in terms of half-life: the time needed for one half-life of the nuclei in a given quantity of a radioisotope to decay and emit their radiation to form a different isotope. As a rule (rule of thumb) such decay takes about 10 half-life, iodine 131 for example has a half-life of 8 days (i.e., 80 days). Plutonium 239 which is produced in nuclear reactor and used as the explosive in some nuclear weapons has a half-life of 24,000 years (i.e., 240,000 years) - about four times longer than human beings (Homo sapiens sapiens) have existed. It can cause lung cancer when its particles are inhaled even in minute amounts. Exposure to alpha particles, better particles, or gamma rays can alter DNA molecules in cells and in some cases lead to genetic defects in the next generation of offspring or several generations later. Such exposure can also damage body tissues and cause burns, miscarriages, eye cataracts, and certain cancers. Nuclear fission is a nuclear change in which the nuclei of certain isotopes with large mass numbers (such as uranium235) are split apart into lighter nuclei when struck by neutrons; each fission releases two or three more neutrons plus energy. Each of these neutrons, in turn, can trigger an additional fission reaction. For multiple fissions to take place, enough fissionable nuclei must be present to provide the critical mass needed for efficient capture of these neutrons. Multiple fissions within a critical mass produce a chain reaction, which releases an enormous amount of energy. In an atomic bomb, an enormous amount of energy is released in a fraction of a second in an uncontrolled nuclear fission chain reaction. In the reactor of a nuclear power plant, the rate at which the nuclear fission chain reaction takes place is controlled. The heat released produces high-pressure steam to spin turbines, thereby generating electricity.

Nuclear fusion is a nuclear change in which two isotopes of light elements, such as hydrogen, are forced together at extremely high temperatures until they fuse to form a heavier nucleus. A tremendous amount of energy is released in this process. In fact, fusion of hydrogen nuclei to form helium nuclei is the source of energy in the sun and other stars. Light-water reactors (LWRs) produce 85% of the world's nuclear-generated electricity (100% in the United States). Unlike other energy resources, nuclear energy produces highly radioactive materials that must be stored safely for 10,000-240,000 years until their radioactivity falls to safe levels. In addition, once a nuclear reactor comes to the end of its useful life (after 40-60 years), it cannot be shut down and abandoned like a coal-burning plant. It contains large quantities of intensely radioactive materials that must be kept out of the environment for many thousands of years. In evaluating the safety and economic feasibility of nuclear power, energy experts and economists caution us to look at the entire nuclear fuel cycle, not just the nuclear plant itself.

B. RENEWABLE ENERGY RESOURCES- One of the keys to sustainability based on learning from nature, is to rely mostly on renewable solar energy directly from the sun or indirectly from moving water, wind, and biomass. Two other forms of renewable energy are geothermal energy from the earth's interior and use of renewable energy to produce hydrogen fuel from water. These renewable energy resources are otherwise called sustainable energy.

1) Solar Energy- Buildings could be heated by either orienting them toward the sun (passive solar heating) or pumping a liquid such as water through roof top collectors (active solar heating). Several solar thermal systems can collect and transform radiant energy from the sun into high-temperature thermal energy (heat), which can then be used directly or converted to electricity. These approaches are used mostly in desert areas with ample sunlight. Solar cells that convert sunlight to electricity can be incorporated into roofing materials or windows, and the currently high cost of doing so are expected to fall.

2) Producing Electricity from Flowing Water- Dams, Tides, and Waves. Water flowing in rivers and streams can be trapped in reservoirs behind dams and released as needed to spin turbines and produce electricity. Solar energy evaporates water and deposits it as water and snow in other areas through the water circle. Water flowing from higher to lower elevations in rivers and streams can be controlled by dams and reservoirs and used to produce electricity. This indirect form of renewable energy is called hydropower, in 2003, hydropower supplied about one-fifth of the world electricity. We can also produce electricity from water flows by tapping into the energy from tides and waves. Most analysts expect these sources to make little contribution to world electricity production because of high costs and lack of enough areas with the conditions.

3) Wind Energy- The greater heating of the earth at the equator than at the poles and the earth's rotation set of flows of air called wind. This indirect form of solar energy can be captured by wind turbines and converted into electricity. Since 1990, wind power has been the world's fastest growing source of energy with it use increasing almost sevenfold between 1995 and 2004. Europe is leading the way into the age of wind energy. Still much of the world potentials for wind power remains untapped.

4) Solid Biomass Energy- Plant materials and animal wastes can be burned to provide heat or electricity or converted into gaseous or liquid bio-fuels. Biomass consists of plant materials (such as wood and agricultural waste) and animal wastes that can be burned directly as a solid fuel or converted into gaseous or liquid biofuels. Biomass is the first-ever fuel used by humankind and is also the fuel which was the mainstay of the global fuel economy till the middle of the 18th century when fossil fuels took over because they were not only more abundant and denser in their energy content, but also generated less pollution when burnt compared to biomass. In recent years, there is a resurgence of interest in biomass energy because biomass is perceived as a carbon-neutral source of energy unlike net carbon-emitting fossil fuels of which copious use has led to global warming and ocean acidification. Biomass is an indirect form of solar energy because it consists of combustible organic compounds produced by photosynthesis. Burning wood and animal manure for heating and cooking supplies 11% of the world's energy and 30% of the energy used in developing countries.

Almost 70% of the people living in developing countries heat their homes and cook their food by burning wood or charcoal. However, 2.7 billion people in these countries cannot find, or are too poor to buy, enough fuel wood to meet their needs. Bacteria and various chemical processes can convert some forms of biomass into gaseous and liquid bio fuels. Example is biogas (a mixture of 60% methane and 40% CO2), liquid ethanol, and liquid methanol.

5) Geothermal Energy- Geothermal energy consists of heat stored in soil, underground rocks, and fluids in the earth's mantle. We can tap into this stored energy to heat and cool buildings and to produce electricity. Geothermal heat pumps can exploit the difference between underground and surface temperature in most places and use a system of pipes and ducts to heat or cool building. A related way to heat or cool a building is geothermal exchange or geo exchange. Buried pipes filled with a fluid move heat in or out of the ground or from nearby bodies of water, depending on the season and the heating requirements. Geothermal exchange is said to be the most energy-efficient, cost-effective, and environmentally clean way to cool or heat a building.

6) Hydrogen- When oil is gone or when the remaining oil costs too much to use, how will we fuel our vehicles, industries, and buildings? Many energy experts say the fuel of the future is hydrogen gas. When hydrogen gas burns in air or in fuel cell, it combines with oxygen gas in the air to produce non-polluting water vapour. Widespread use of hydrogen as a fuel would eliminate most of our current air pollution problems and greatly reduce the threats from global warming because it does not emit CO2 as long as the hydrogen is not produced from fossil fuel or other carbon containing compounds. Three problems arise in turning the vision of widespread use of hydrogen as a fuel into reality. First, hydrogen is chemically locked up in water and in organic compounds such as methane and gasoline. Second, it takes energy and money to produce hydrogen from water and organic compounds. In other words, hydrogen is not a source of energy-it is a fuel produced by using energy. Third, fuel cells are the best way to use hydrogen to produce electricity, but current versions are expensive.

1.If you consider any industry the topmost operating expenses include energy labour and materials. If we were to compare the cost or potential of each of these components, then energy emerges to the top. Therefore, energy management constitutes a strategic area for reduction in cost.

2.It helps us to understand the way energy and fuel are used in industry. It helps in identifying the areas where waste can occur areas of improvement.

3.It depicts a positive orientation regarding cost reduction, preventive maintenance and quality control program which are vital for production and utility activities.

4.Energy audit provides a benchmark for managing energy in organization. It provides basis for effective planning and use of energy in organization.

5.Determine ways to reduce energy consumption per unit of product output.

Type 1 / Level 1 - Basic Energy Audit

Type I audit provides quantitative overview that is suitable for smaller sites with lower energy consumption. It defines the minimum detail of level for an audit required to comply with the standard.

It provides a quantitative overview of energy performance and identifies low cost and no-cost opportunities with payback period up to 2 years.

The accuracy and cost benefits are sufficient for low-cost operational expenditures.

Type 2/ Level 2- Detailed Energy Audit

Type 2 provides the detailed analysis of energy performance to quantify full range of opportunities for a site.

It defines a detailed level of audit involving comprehensive review and analysis of equipment, systems and characteristics of whole building to enable quantifiable energy savings.

Type-2 are required to include financial analysis of recommended energy performance improvement actions using estimates that are of required accuracy for operational expenditures.

Type 3/ Level 3: Precision Subsystem Audit

These include additional data gathering and measurement to provide high accuracy. They focus on processor sub-system rather than a whole site.

It involves onsite measurements to monitor energy data over long periods to capture various operating conditions in order to quantify costs and benefits to sufficient level.

Methodology-

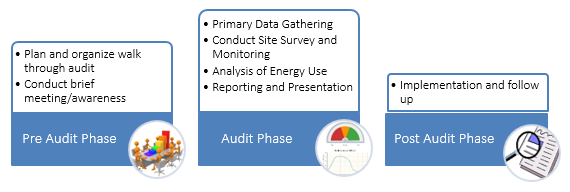

Energy Audit is conducted to determine ways to reduce energy consumption per unit of product output and/or to lower operating costs for facilities. The audit consists of three phases which namely the Pre-Audit Phase, Audit Phase and Post Audit Phase.

1.Pre-Audit Phase

Pre-Audit Phase focuses on the planning for audit process. An energy audit team is established at this stage to ensure coordination during audit activities. Details of facilities are identified thoroughly to be included in the scope of audit process. A Kick off meeting is carried out to discuss on any first-hand observation and assessment on prevailing operation levels and pre-defined practices on certain facilities.

2.Audit Phase

There are a few steps in Audit Phase specified in the following:

(i) Gathering Primary Data

Data collection of energy usage on facilities will be gathered. Data may include facilities drawings, electricity supply, metering, energy consumption and production details. Some qualitative method such as questionnaires/ surveys may be conducted by the auditor to the operation team. This enables the auditor to grasp a better understanding on the facilities performance.

(ii) Conduct Site Survey, Monitoring and Measuring

A site survey will be conducted to identify the source of supply to the facilities. Supply facilities includes the loads (i.e., motors, lighting, compressor etc.) as well as its condition. A measurement of power consumption (i.e., Nominal Current) of the loads will be collated for analysis purposes.

(iii) Analysis of Energy Use

The result of site survey together with the collection of primary data will be utilized as a basis of analysis for energy consumption. This stage is intended to identify areas of concern. Some example analysis result can be presented in an energy analysis or energy waste/loss analysis.

(iv) Reporting and Presentation

The energy audit report will be presented in the following structure:

- Summary

- Description of Facility

- Historical Data of Energy Use of Facility

- Current Energy Use

- Energy Saving Measures (Including implementation of cost and estimated saving)

- Strategy for Implementation (Recommended energy saving plan/ action plan)

- Expectation (achieved saving after implementation of the action plan together with calculated profitability)

3.Post Audit Phase

Monitoring actions and measurements will take place to ensure action plan is fulfilled. Schedule for implementation will be recorded and reviewed periodically.

Barriers –

The barriers of energy auditing are-

A. Missed Opportunities- The most widespread problem in energy audits as identified by Shapiro is missed opportunities. Shapiro argues that comprehensiveness is widely recognized as a critical feature of all high-quality energy audits. He provides a list of possibilities which he feels should be covered in every energy audit: high efficiency HVAC, domestic hot water and lighting; lighting power density; lighting controls; wall or roof insulation; motors/drives; HVAC controls; and fenestration opportunities. While we agree that all energy audits should provide clients with a reasonable selection of options for implementation, his study combined results from energy audits of both residential and commercial buildings.

B. Equipment and Project Life - This is as a result of overestimated or omitted material and project life. Equipment or project life is so critical to accurate life-cycle cost analysis. Missing or incorrect information regarding project life can lead to poor measure prioritization. It is essential to include projects or equipment life in all NPV, and IRR analysis, calculating it for every measure is recommended.

C. Life-cycle Costing- Failure to provide clients with the "whole picture" afforded by Life-cycle costing. Unlike simple payback, life-cycle costing offers a holistic perspective on potential measures and helps clients and energy auditors make better decisions about which projects to pursue. In an energy audit, in addition to providing simple payback metrics, it is advisable also to calculate the Internal Rate of Return (IRR) and Net Present Value (NPV) for all measures, as well as for the report as a whole. All of these figures are captured in a high-level overview table in the report summary to allow for easier decision making on the part of the client. This information helps clients to make the most effective business case to senior management, for the implementation of the energy-saving measures.

D. Energy Savings Measure Selection- Selecting the wrong measure due to missing or incorrect information can distort the energy audit result. The most common reason that energy auditors do a poor job of identifying and recommending energy-saving measures is due to missing or inaccurate information. For example, one of the most common errors is to suggest an action with a longer payback than the expected life of the project. Other mistakes happen when energy auditors make biased assumptions, do not use life-cycle costing, or underestimate equipment or installation costs.

E. Building Description- Building components poorly described or missing entirely. All energy audits should include a detailed description of all parts of a building. Description and analysis of components for commercial and industrial buildings will be different for residential energy audits. HVAC and lighting systems for commercial, institutional and multi-unit residential buildings, offer the best opportunities for energy savings in these building types.

F. Billing Analysis- Inadequate billing analysis for measures and projects can affect the result of the energy audit. The ASHRAE Standard is to study at least one year of monthly energy data. This gives the clients a better understanding of the consumption patterns and energy costs of their buildings. Regression analysis can be run, provided better and further particulars are available on the billing pattern. This will determine the relationships between variables to predict future energy use. Again, it will allow us to correctly understand how the variables that affect energy use, such as weather or occupancy patterns over a particular period, affect energy consumption. This will provide the client with a baseline standard against which to measure energy consumption in subsequent years.

G. Energy Savings Estimation- The overestimation of energy savings is another critical issue. When making energy savings calculations, it is impossible to account for all factors that affect energy savings. However, Shapiro found that over half of the energy audits studied had savings that were twice as high as could be reasonably expected. High energy savings estimates can create unreasonable expectations and may lead to poor prioritization of measures.

The role of an Energy Manager (EM) involves facilitating energy conservation by identifying and implementing various options for saving energy, leading awareness programs, and monitoring energy consumption. As such, EMs play a critical role in the successful implementation of energy conservation and demand management programs within the industry.

1. Saving Energy

EM duties revolve around the identification, reporting and implementation of energy savings opportunities. For quick reference, the responsibilities identified in the EM Agreement are summarized below:

- Electrical Energy Saving Project Implementation

- Energy Tracking & Monitoring

- Primary Assessment

- Maintenance and Operating Schedules

- Energy Savings Opportunities & Action Plan

- Measurement & Verification Strategy

- Energy Management Behaviour and Business Process Improvements

- Employee Awareness Programs

- Assistance to IESO Projects

- Reporting

Continuation of funding is primarily decided on the basis of energy savings target achievement and future savings potential.

2. Annual Savings Targets

EMs must meet two targets as laid out in the IAP Energy Manager Funding Agreement

- Minimum 2,000 MWh Annual Savings Target

- Minimum 10% of Annual Savings Target attributed to Projects not financed by IESO incentives (non-incented)

Understanding that it can be challenging to reach the targets in the first year of the agreement, if the EM does not meet the Annual Savings Target in the first twelve-month period of the Agreement, the shortfall will be added to the Annual Savings Target for the second twelve-month period. There is no adjustment in the maximum funding amount if some of the missed target in the first year is carried over to the second year. And the transfer of the target is only available in the first year.

Performance will be assessed based on Quarterly Reports submitted by EMs.

3. Reporting

Energy management activities and conservation measures must be reported in Quarterly Reports. Quarterly Reports are submitted to the IESO for review and approval under the EM Funding Agreement.

As part of the reporting requirements under the EM Funding Agreement, EMs are required to prepare the following reporting documents:

- Quarterly Reports within 30 days of the end of each quarter.

- EMs are encouraged to provide the Quarterly Reports as close to the end of each quarter as possible.

- It is recommended that the Quarterly Report be maintained as a living document and used for project tracking purposes, such that it can be provided to the IESO at any time, without need of significant updates.

- An Energy Management Plan (EMP) for each Facility occupied by the Participant, no later than six (6) months after the EM’s employment start date, unless an EMP already exists.

- An updated EMP is required for each subsequent twelve (12) month term.

4. Quarterly Report Reviews

- Each Quarterly Report will be reviewed by the IESO’s Technical Reviewer so that the likelihood of targets being met can be assessed.

- Mid-term technical review of non-incented Measures can be valuable to IESO accounting.

- Quarterly Reports should include all Measures to date, including those in previous reports and those that have been reviewed.

- Quarterly Reports should also include Projects planned for the next term that show the potential to meet the next term’s targets.

5. Annual Reviews

- At the end of the fourth quarter of each EM term, an annual review will be performed by the IESO’s Technical Reviewer to determine whether targets have been met.

- The annual review is based on the fourth Quarterly Report, which should identify all Projects that are complete and in-service such that they can be counted towards the current term’s Annual Savings Target.

The requirement for an energy audit such as identification and quantification of energy needs various measurements and these measurements can be obtained with the use of instruments. The parameters monitored during the energy audit include basic electrical parameters in AC and DC systems and parameters of importance other than electrical such as temperature & heat flow, radiation, air and gas flow, liquid flow.

In order to obtain accurate operating conditions and performance of equipment/systems, the auditor should have the necessary measuring instruments to take readings of corresponding parameters such as temperature, pressure, flow, lighting lux level, running current, etc.

These instruments must be portable, durable, easy to operate and relatively inexpensive. The parameters generally monitored during energy audit include the following:

Electrical Measuring Instruments

These instruments are used for measuring major electrical parameters such as kVA, kW, PF, Hertz, kVAr, Amps and Volts. They can also be used to measure harmonics.

The instruments applied on-line that is running motors, where there is no need to stop the motor. Instant measurements can be taken with hand-held meters. More advanced ones facilitate cumulative readings with print outs at specified intervals.

Typical Electrical Instruments

Voltmeter

An inexpensive voltmeter is useful for determining operating voltages on electrical equipment, and especially useful when the nameplate has worn off of a piece of equipment or is otherwise unreadable or missing. The most versatile instrument is a combined volt-ohm ammeter with a clamp-on feature for measuring currents in conductors that are easily accessible. This type of multimeter is convenient and relatively inexpensive.

Wattmeter/Power Factor Meter

A portable hand-held wattmeter and power factor meter is handy for determining the power consumption and power factor of individual motors and other inductive devices. This meter typically has a clamp-on feature which allows an easy connection to the current-carrying conductor and has probes for voltage connections.

Clamp- On Ammeter

These are used for measuring current in a wire without any live electrical connections. The clamp is opened and put around one insulated conductor, and the meter reads the current in that conductor. An idea of the level of harmonics in a load can be estimated from using an old non-RMS ammeter, and then a true RMS ammeter to measure the current. If there is more than a five to ten percent difference between the two readings, there is a significant harmonic content to that load.

Lux meters

A lux meter is a device for measuring brightness. It measures specifically the intensity with which the brightness appears to the human eye. This is different from the measurements of actual light energy produced by or reflected from an object or light source.

Figure. Lux meter

A lux meter works by using a photocell to capture light. The meter then converts this light to an electrical current. Measuring this current allows the device to calculate the lux value of the light it captured.

Temperature Measuring Instruments

Several temperature measuring devices are required to measure temperatures in offices and other work areas, and to measure the temperature of operating equipment. Knowing the process temperatures allows the auditor to determine process equipment efficiencies and identify waste heat sources for potential heat recovery programs. Some typical temperature measuring instruments used for energy audit are:

Contact Thermometer

Figure. Contact Thermometer

These are thermocouples which measures for example flue gas, hot air, hot water temperatures by insertion of probe into the stream. For surface temperature, a leaf type probe is used with the same instrument.

Infrared thermometer

An infrared thermometer is a thermometer which infers temperature from a portion of the thermal radiation called blackbody radiation emitted by the object being measured. They are sometimes called laser thermometers if a laser is used to help aim the thermometer, or non-contact thermometers to describe the device's ability to measure temperature from a distance. By knowing the amount of infrared energy emitted by the object and its emissivity, the object's temperature can often be determined. Infrared thermometers can be used to serve a wide variety of temperature monitoring functions.

Figure. Infrared Thermometer

Pressure and Flow Measuring Instruments

One of the energy auditor’s tasks is measuring air flow from heating, air conditioning or ventilating ducts, or from other sources of air flow. Airflow measurement devices can be used to identify problems with air flows, such as whether the combustion air flow into a gas heater is correct. Some of the typical instruments measuring air and water pressure, flow rates include:

Pitot Tube and manometer

Air velocity in ducts can be measured using a pitot tube and inclined manometer for further calculation of flows.

Anemometers

Two types of anemometers are available for measuring airflow: vane and hot-wire. The volume of air moving through an orifice can be determined by estimating the free area of the opening and multiplying by the air speed. This result is approximate due to the difficulty in determining the average air speed and the free vent area.

Water flow meter

This non-contact flow measuring device using Doppler effect / Ultra sonic principle. There is a transmitter and receiver which are positioned on opposite sides of the pipe. The meter directly gives the flow. Water and other fluid flows can be easily measured with this meter.

Flowmeters are used in fluid systems (liquid and gas) to indicate the rate of flow of the fluid. They can also control the rate of flow if they are equipped with a flow control valve.

Miscellaneous Instruments

Combustion Analyzer

Combustion analysers are portable devices capable of estimating the combustion efficiency of furnaces, boilers, or other fossil fuel burning machines. Two types are available: digital analysers and manual combustion analysis kits. Digital combustion analysis equipment performs the measurements and reads out in percent combustion efficiency.

The manual combustion analysis kits require multiple measurements including exhaust stack: temperature, oxygen content, and carbon dioxide content. The efficiency of the combustion process can be calculated after determining these parameters. The manual process is lengthy and prone to human error frequently.

Fyrite Gas Analysers

They are fast, accurate and easy to use instruments for measuring and analysing carbon dioxide or oxygen. Fyrite absorbing fluid is selective in the chemical absorption of carbon dioxide or oxygen, respectively. Therefore, the Fyrite’s accuracy, which is well within the range is required for industrial and professional applications.

Tachometers

A simple tachometer is a contact type instrument mainly used for direct access possibility. The more sophisticated and safer ones are non-contact instruments such as stroboscopes. Mechanical stroboscopic instruments are instruments with mechanical shutters (choppers) in the form of disks or hollow cylinders with slits through which the object is observed. By measuring the disk’s speed of rotation at which the object viewed through the shutter appears stationary, the frequency of the periodic motion of the object can be determined. Such instruments are called stroboscopic tachometers.

Leak Detectors

Compressed air is one of the costliest utilities in a facility today. A simple program of leak inspection and repair can go a long way towards reducing excessive energy costs.

Ultrasonic instruments are available which can be used to detect leaks of compressed air and other gases which are normally not possible to detect with human abilities.

Ultrasonic Leak Detector is a complete kit, the high- quality flexible sensor mounted on the end of a flexible steel pipe so that the ultrasonic sound sensor can access hard reach areas. The unit converts the ultrasonic noise of a leak into a sound, humans can here hissing sound with some beeping sound or LED display.

References:

1. Witte L.C., Schmidt P.S. And Brown D.R., Industrial Energy Management and Utilization, Hemisphere Publ., Washington,1988.

2. Callaghan P.W., Design and Management for Energy Conservation, Pergamon Press, Oxford, 1981.

3. Murphy W.R. And McKay G., Energy Management, Butterworths, London,1987.