Unit - 4

Energy Conservation in major utilities

(A) Energy conservation at household level

In all country residential demands constitute major part of total energy used. When comparing an average house to our energy efficient house, it is possible to reduce annual energy bills up to 40%. We should develop an energy conservation plan for our house. This is both an environment friendly and economically sound action. The steps in developing an energy conservation plan for our home are

(1) identify the problem areas where energy is being lost or inefficiently used. (2) to prioritize the problem areas according to how much energy is being lost or inefficiently used and

(3) systematically correct the prioritized problems according to the limits of our household energy improvement budget.

Apart from lights and fans, several other household appliances have flooded the market. A cautious operation and use of good quality electrical appliances (with five-star rating) not only enhance their life but also save energy. Some energy conservation activities are mentioned below:

(i) Major appliances for domestic use

Large appliances are the major consumers of energy and improving the operating efficiency of such household appliances will significantly reduce the overall consumption of electricity.

(a) Refrigerator

Do you know that refrigerators account for the consumption of a huge amount of energy? Condenser is found either behind the fridge or underneath the fridge and helps in maintaining its lower temperature. We can conserve energy while using refrigerator in the following ways:

- It should be maintained at 37ºF- 400 0 F and freezer section at 500F and should have automatic moisture control.

- We should keep the fridge as full as possible and it should be kept in that position that its outside surface is not exposed to direct sunlight.

- If the door of the fridge is not closed properly it will consume much more energy. Uncovered liquids should not be put in the refrigerators as it will give extra workload to the compressor.

- Before putting food in the refrigerator, it should be cooled up to room temperature.

- Door of the fridge should not be opened several times.

(b) Ovens/Microwave oven

To conserve energy while using ovens we should keep in mind the following:

- We should use microwaves as they consume 50% less energy than conventional ovens.

- The oven door should not have any cracks or tears in it.

- We should use “lids-on” cooking to permit temperature overheating.

- Keep reflector pans beneath stove top heating elements bright and clear.

- Carefully measure water used for cooking to avoid having to heat needed.

- Begin cooking on highest heat until liquid begins to boil. Then lower the settings and allow food to simmer until fully cooked.

- One should cook as much of the meal in the oven at one time as possible.

- Rearrange oven shelves before turning your oven on and do not peep in oven. Every time the oven is opened temperature is lowered by 4° - 5°C.

- When preheating an oven for baking, time the preheat period carefully, minutes should be sufficient.

- For large items, stove-top cooking is most efficient, especially with gas.

(c) Ironing

Every day we iron our clothes. It consumes approximately 1000-watt energy, which is a huge amount. But we can save energy by ironing clothing in bulk and not just one or two at a time. Ensure that the thermostat on the iron is working and set the right temperature for the clothing being ironed.

(d) Cooking

Major part of energy is consumed during cooking. It can be saved during cooking by using all these measures. Use a cooking pan that is slightly bigger than your cooker plate, coil or burner. Keep saucepan lids on. Turn down the heat once food starts boiling.

(e) Washing machines

Washing machines consume 20% of the electricity. Energy can be conserved during the use of working machine in the following ways:

- We should try to use cold water while working and rinsing as almost 90% of the energy consumed by washing machine is used to heat the water.

- Follow detergent instructions carefully. Adding too much detergent for effective working action may require more energy.

- Wash only full loads of clothing but do not overload machine.

- Soak or prewash the clothes for effective cleaning as well as to reduce energy consumption.

(ii) Lighting

Increasing energy demand the world over and the ever-increasing prices of energy have provided a justifiable reason for improving energy efficiencies of all energy intensive technologies. Some methods of saving energy during lighting are as follows:

- Light should be turned off when not in use.

- Maximum sunlight should be used during the day. Bulbs and tube lights should not be used during day.

- Use task lighting whenever possible instead of brightly lighting an entire area or room.

- Use compact fluorescent lamps (CFL) in place of incandescent bulbs. A 23-watt compact fluorescent bulb can replace a 90 or 100 watt.

- Use dim light in galleries, lobbies; balconies etc.

- Do not keep computer, TV, tape recorder, music system in standby mode. Do you know how much electricity you can conserve by turning off the TV instead of keeping it on stand-by? You can save 70-kilowatt hour per year.

- Geysers consume the maximum amount of electricity. Thermostat can be set to a lower temperature 45oC to 50oC.

- Lamps should be put in those corners of the rooms where they can reflect many light surfaces instead of one.

- Use dimmable bulbs wherever possible.

(iii) Electricity conservation

With the growing awareness about the depletion of global energy reserves and adverse environmental impacts of energy use, now efforts are underway to develop energy efficient machines and technologies to reduce energy expenditure and to minimize environmental hazards. Some such steps are as follows: • Use ISI marked appliances and equipment’s.

- Substitute bulbs with tungsten filaments lamps (TLP) tubes.

- CFL (compact fluorescent lamps) should be used as they use comparatively less electricity and last longer.

- Electric geyser can be replaced by gas geyser to save electricity.

(iv) Others

Some other methods by which energy can be saved are as follows:

- Adjust the flame of gas cooking appliances, so that the flame remains blue not red or yellow.

- Shut down computers when not in use.

- Select appliances (i.e., curling irons, coffee pots, irons) with time limited shut off switches.

- Replace aging old appliances, TVs and VCRs when needed, with energy efficient models.

(v) Cooling

A huge amount of energy is wasted in cooling.

Following cooling measures can be taken to conserve energy:

- We should open windows at night, to bring cool air inside. • Windows should be closed during daytime.

- West facing windows should be shaded. A whole house fan can be used to draw cool night air into the house.

- An evaporative cooler should be installed.

- Use room air conditioning only where needed and install energy efficient models. Cooling in air-conditioned houses should be maintained at 25°F.

- Regular cleaning of filter in air conditioning systems and cleaning of condenser conserve energy.

(B) Energy conservation at community level

Energy conservation is a very sensitive issue throughout the world. In a society where money and especially saving of financially advantageous options are available to us, we should follow the following measures to reduce energy consumption-

- All unnecessary lights should be turned off especially when conference rooms etc. are not in use.

- Energy uses should be minimized during peak demand hours.

- Set computers, monitors, photocopiers and other business equipment’s to their energy saving mode. Turn them off during long idle hours such as lunch breaks.

- Skylights should be used for warehouses.

- Ensure that offices having air conditions have proper windows and all doors are closed when the air conditioner is in use.

(i) Use of renewable energy resources

Alternative resources i.e., renewable energy sources should be used in place of non-renewable energy sources e.g., solar energy, biogas, wind energy etc. Energy audits of homes, buildings, hotels and factories should be done at regular interval.

Demonstration of projects involving the introduction of appropriate, renewable solar technologies at the community level like solar pumps for water purification and irrigation of lawns, play grounds, gardens, community centres, as well as solar energy for cooking and heating should promoted. Projects involving wind-generated energy for community and municipal needs should be demonstrated to the whole community. Demonstration of biogas programmes (see lesson 30) is also required to tell people for the efficient used of it. Collaborative community/ academic research and development in order to produce low cost, sustainable energy options should be given priority.

Environment friendly public transport system should be promoted to reduce the use of individual motorized transport. For a single purpose minimum number of vehicles should be used. It will be also helpful in reducing CO2 emission.

(ii) Energy conservation at community level for housing complexes

We require energy for all kinds of work. Cooking, lighting, cooling, transportation etc. But often the amount of energy which we use is comparatively much less than the amount of energy which is wasted. As the energy sources are fast depleting, it is necessary for us to save energy. At the community level following measures can be used:

- Installation of photoelectric controls or timers should be used to make sure that outdoor lighting is sufficient during the day. Open area or yard area lightings should be switched off after sunrise and again switched on only after sun sets. Tube lights in common area and staircase landings should be reduced and twin tube light should be replaced by one tube light. Number of electrical lighting points could be reduced to one point per room. All additional fittings may be removed permanently or switched off.

- Water pumps should be switched off during non-peak utility hours

- Elevators/lifts should be used for going up beyond three floors and for coming down the usage of lifts may be reduced. Whenever two elevators/lifts are provided in a building only single should be operated during “non-peak” hours. Do not allow children to play with elevators.

- Environmentally sustainable transport will promote more mileage less pollution by GHC gases.

- Conservation and sustainable use of water bodies, including watersheds, rivers barriers and coastal zones will be helpful in the energy conservation at community level.

- Training programme about energy efficient repairs should be organized to conserve energy at community level. Advocacy to remove subsidies to inefficient and polluting sources of energy should become essential. Locally manufactured, improved cook stoves should be introduced to reduce charcoal/fuel consumption.

(C) Energy conservation in industry and other places

Energy conservation is the practice of decreasing the quantity of energy used. It may be achieved through efficient energy use, in which case energy use is decreased while achieving a similar outcome, or by reduced consumption of energy services. At different places such as factories, business centres, transportation sector and construction activities, it can be saved in the following ways:

(i)At factories and business centres including shops

(a) Auditing

Regular monitoring and audit of energy consumption results in energy conservation.

(b) Process modification

Process modification means replacement of old and more energy consuming processes by the new energy efficient processes. Old factories should now employ process modification.

(c) Improved measuring instruments

We can use new technologies and energy efficient instruments and processes to conserve energy.

(d) Energy loss reduction

A lot of energy is wasted every day. We can reduce energy loss by using following measures, for example: thermal insulation of fuel tanks can be done, Ceramic fibre sealing of furnaces, electrical tracing of liquid fuel lines instead of conventional steam heating.

(e) Light load reduction

A significant amount of energy can be saved by reducing light load. Bulbs have been replaced by tube lights. Nowadays CFLs have proved very helpful in reducing energy needs for lighting purposes.

(D) Energy conservation in transportation sector

Transportation includes all vehicles used for personal or freight transportation. Do you know of the energy used in this sector, approximately 65% is consumed by gasoline powered vehicles, primarily personally owned? Diesel powered transport (trains, merchant ship, heavy trucks etc.) consume about 20% and air traffic consumes most of the remaining 15%. Energy can be conserved in transportation by the following ways:

(i) Reduction of fuel consumption

Fuel consumption can be reduced in the following ways:

- Use public transportation as much as possible instead of using own vehicles.

- Car speed should be maintained as far as possible 50 to 60 km/hr.

- Do not use choke unless necessary, when choke is used, put it off as soon as engine is warmed up, if there is a starting trouble, press clutch to start the engine.)

- Avoid free frequent starts and stops to reduce fuel consumption. Release clutch pedal gradually and simultaneously press accelerator to racing and or jerking.

- Never race engine when declutched. Declutch fully when changing gears on clutch pedal because this increases clutch wear and fuel consumption.

- Do not run-on hand brake and preferably install a warming light device. Apply brakes gradually as far as possible. Anticipate need for braking. Switch to lower gears on gradients (up/down) at the right time. All these will be helpful in reducing fuel consumption

- If possible, it is always better to live near workplace.

(ii) Fuel economy- maximizing behaviour

Fuel economy maximizing behaviour describes techniques that drivers can use to optimize their automobile fuel economy. The energy in fuel consumed in driving is lost in many ways including engine inefficiency, aerodynamic drag, rolling friction and kinetic energy lost due to braking. They include following measures-

- Moderate driving

- Driving at lower speeds

- Using cruise control (speed control or auto cruise controls speed and maintains steady speed by the driver).

- Turning off a vehicles engine at stops rather than idling;

- a vehicles gas mileage decreases rapidly at highway speeds, normally above 55 miles per hour (though the exact number varies by vehicle).

There are numerous pumps in the system and all play a part in energy savings. When operating at below full capacity, the amount of refrigerant and cooling liquids required to be moved through the system is reduced. This is accomplished by controlling the pump system. Traditional means of controlling the pump output involve dissipating or diverting the output of the pump running at full speed by means of bypass and throttle valves, which meant that the pump was still running at full load or close to full load. VSD drives allow flow control by varying the speed or other parameters of the pump to achieve the required flow rate.

The latest improvements in smart VSDs factor in the effects of speed on the pump’s hydraulic performance to better control processes. This is accomplished through embedded pump-specific algorithms that use information such as torque, speed and power received from the VSD to escalate KPIs specifically related to pumps and pump systems. An example is smart VSDs controlling processes using torque rather than speed.

Energy saving on fans is much greater than on other equipment. On fan loads, the power requirement varies as the cube of the speed, so the slower the fan speed, the less energy required. A fan running at 80% speed will consume 50% of the energy at 100% speed. Modern fan controls consist of much more than just speed controls and variable speed drives.

Key to identifying the energy savings opportunities of VSDs in HVAC systems is an understanding of the operating cycle of the system versus the heating and cooling needs actually required. Most HVAC systems are designed to keep the building cool on the hottest days and warm on the coldest days. Therefore, the HVAC system only needs to work at full capacity on those days.

For the rest of the year, the HVAC system can operate at reduced capacity. This is where a variable air volume system with variable speed drives (also-called variable frequency drives, or VFDs) can be used to match air flow to actual heating and cooling demands. The VSD can reduce the motor speed when full flow is not required, thereby reducing the power and the electrical energy used.

This can result in significantly improved process control compared to traditional speed control when controlling pumps with relatively flat performance curves. Because of the significant advancements in drive technology and the information’s accuracy and reliability, industry professionals can better estimate pump performance parameters such as flow and head solely by using drive output torque and speed data. VSD controllers available today offer features unique to HVAC systems that can schedule the operation of multiple pump installations with rotation of the duty pump, ensuring maximum service life and system efficiency.

A blower is a device that pushes out gases by imparting energy to increase its pressure and speed.

They range from the large blowers found in applications such as production machinery and clean rooms, to the small blowers built into devices such as home appliances or personal computers, and are used to blow air for exhausting ventilation or cooling.

How blowers work

There are a variety of different types of blowers. The following example is of a brushless DC blower from ASPINA.

This blower is a centrifugal turbo type and is shaped like a snail shell. This blower contains a cylindrical impeller. The air is drawn in is pressurized by the centrifugal force imparted by the impeller rotation, and this pressurized air is then discharged.

History of blowers

Historically, among the very first blowers were the bellows used to supply air during the smelting of iron. Mentions of these bellows can be found in the literature of ancient Rome and China. Bellows were at first manually operated, then underwent various enhancements over time including the use of water power, evolving into an efficient means of supplying air.

In more recent times, the arrival of new power sources such as steam and electricity led to the development of a variety of other pneumatic (air-driven) equipment. Example applications include air brakes in steam locomotives and the opening and closing of automatic doors.

Nowadays, blowers and compressors used in various industries, and are built into equipment such as sorting or transportation machines, and processing or assembly, and packaging equipment. They are also found in products such as computers and home appliances, where they facilitate size reduction and performance enhancement.

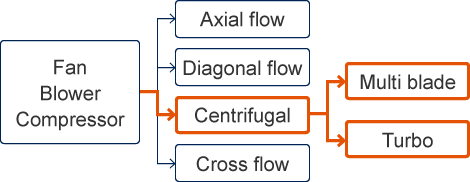

Types of blowers

While blowers come in many different types, ASPINA supplies centrifugal blowers; mainly multi blade or turbo types.

Multi blade type

The air flow is perpendicular to the axis of rotation, and the blades are typically angled forward in the direction of rotation. These types tend to be mid-range in terms of flow rate and pressure, and are used in applications such as duct ventilation, air conditioning, and cooling.

Turbo type

The air flow is perpendicular to the axis of rotation and the blades are typically angled backward with respect to the direction of rotation. These types tend to feature a low flow rate and high pressure, and are used in applications such as vacuum cleaners and dryers.

A compressed air system is much more than just an air compressor. A basic compressed air system is made up of the following components:

- The Air Intake Filter is a device composed of fibrous materials designed to trap atmospheric airborne particles such as dust, pollen, mold, etc. before they can reach the compressor.

- The Air Compressor is a machine used to convert power (usually from an electric motor, a diesel engine or a gasoline engine) into kinetic energy by compressing and pressurizing air, which, on command, can be released in quick bursts. There are several different types of air compressors, including reciprocating, rotary screw, and rotary centrifugal.

- The Aftercooler cools the system lubricant and discharged air.

- The Air Receivers provide compressed air storage capacity to meet peak demand events and help control system pressure by controlling the rate of pressure change in the system.

- The Air Dryer removes condensation from compressed air in order to prevent damage to the system.

Compressed air systems last 10 to 15 years on average. The top two causes of premature system failure are improper installation and improper maintenance.

Components of a compressed air system

Compressed air systems usually consist of the following components:

- Compressor

- Air cooler

- Air receiver tank

- Filter

- Dryer

- Condensate trap

- Distribution system

The compressor produces compressed air at the required pressure.

The air receiver tank acts as a reservoir to store and cool the compressed air and helps make sure the system can cope with variations in demand.

The air cooler, filter and dryer all treat the air at different points in the system. They remove impurities such as water, dirt and oil from the air taken in by the compressor, as well as those added by the compressor.

Compressed air may be fed to various uses on a site via a distribution system. These distribution systems can be relatively straightforward or very complex. Some businesses use portable units, which consist of all of these components in a compact package. Portable units are usually used for small-scale applications, or when a mobile source of compressed air is needed.

Literal meaning of refrigeration is the production of cold confinement relative to its surroundings. In this, temperature of the space under consideration is maintained at a temperature lower than the surrounding atmosphere. To achieve this, the mechanical device extracts heat from the space that has to be maintained at a lower temperature and rejects it to the surrounding atmosphere that is at a relatively higher temperature. Since the volume of the space which has to be maintained at a lower temperature is always much lower than the environment, the space under consideration experiences relatively higher change in temperature than the environment where it is rejected. The precise meaning of the refrigeration is thus the following: Refrigeration is a process of removal of heat from a space where it is unwanted and transferring the same to the surrounding environment where it makes little or no difference. To understand the above definition, let us consider two examples from the daily life.

It is a well-known fact that the spoilage of food and many other items reduces at a lower temperature. At a lower temperature, molecular motion slows down and the growth of bacteria that causes food spoilage also retards. Thus, to preserve many types of perishable food products for a longer duration, we use refrigerators in our homes, canteens, hotels, etc. The temperature of the food products has to maintained at a level below that of surroundings. For this we keep the food products in a refrigerator. The inside volume of the refrigerator where we store food products or any other items is much less than the volume of the room where the refrigerator is kept. The room in this case is the surrounding environment. Food products in the refrigerator initially were at a higher temperature than desired temperature, meaning that it had some unwanted heat. If its heat is removed, its temperature will decrease. The refrigerator removes unwanted heat from the food products and throws away that heat to the room – the surrounding environment of the refrigerator. The amount of heat makes a big difference in temperature inside the refrigerator and almost little or no difference in the temperature of the room.

Air Conditioning

Merely lowering or raising the temperature does not provide comfort in general to the machines or its components and living beings in particular. In case of the machine components, along with temperature, humidity (moisture content in the air) also has to be controlled and for the comfort of human beings along with these two important parameters, air motion and cleanliness also play a vital role. Air conditioning, therefore, is a broader aspect which looks into the simultaneous control all mechanical parameters which are essential for the comfort of human beings or animals or for the proper performance of some industrial or scientific process. The precise meaning of air conditioning can be given as the process of simultaneous control of temperature, humidity, cleanliness and air motion. In some applications, even the control of air pressure falls under the purview of air conditioning. It is to be noted that refrigeration that is control of temperature is the most important aspect of air conditioning. To understand the above definition in a better way, let us consider one example. In the summer, the temperature in Delhi is about 10 oC higher than in Kolkata where temperature varies in the range of 32 oC to 35 oC. We feel uncomfortable in both places. Weather in Delhi is hot and dry (moisture content in the air is low) whereas in Kolkata it is (mild) hot but humid (moisture content in the air is very high). If we go to a hill-station, say Shillong in the summer, we feel comfortable there. Temperature there remains about 25 oC and relative humidity of the air is also in the comfortable range, say about 65%. In Delhi, temperature is very high and humidity is low, whereas in Kolkata, temperature is low but humidity is high. In Delhi if there is a rain, we feel more comfortable whereas in Kolkata even with rain, the relative comfort is less. In Delhi temperature falls down and humidity also increases towards the comfortable value. In Kolkata, temperature falls down but humidity still remains on the higher side. Thus, for comfort, both temperature and humidity have to be in the specified range. This is true for both human beings and scientific processes. Apart from the above two, from intuition one can also say that purity or cleanliness of the air is an essential item for the comfort and it has been established that the air motion is also required for the comfort condition.

Depending upon the requirement, air conditioning is divided into the summer air conditioning and the winter air conditioning. In the summer air conditioning, apart from cooling the space, in most of the cases, extra moisture from the space is removed, whereas in the winter air conditioning, space is heated and since in the cold places, normally the humidity remains low, moisture is added to the space to be conditioned. The summer air conditioning thus uses a refrigeration system and a dehumidifier. The winter air conditioning uses a heat pump (refrigeration system operated in the reverse direction) and a humidifier. Depending upon the comfort of the human beings and the control of environment for the industrial products and processes, air conditioning can also be classified as comfort air conditioning and industrial air conditioning. Comfort air conditioning deals with the air conditioning of residential buildings, offices spaces, cars, buses, trains, airplanes, etc. Industrial air conditioning includes air conditioning of the printing plants, textile plants, photographic products, computer rooms, etc.

It has been mentioned above that the refrigeration and air conditioning are related. Even when a space has to be heated, it can be done so by changing the direction of flow of the refrigerant in the refrigeration system, i.e., the refrigeration system can be used as a heat pump. However, some section of the people, treat refrigeration exclusively the process that deals with the cooling of the space. They treat heating operation associated with the heat pump.

Cooling towers may also both use the evaporation of water to take away method warmness and funky the operating fluid to close to the wet-bulb air temperature or, with inside the case of closed circuit cooling towers or dry cooling towers, depend entirely on air to chill the operating fluid to close to the dry-bulb air temperature the use of Common programs encompass cooling the circulating water utilized in oil refineries, petrochemical and different chemical flowers, thermal electricity stations, nuclear electricity stations and HVAC structures for cooling homes.

The category is primarily based totally at the form of air induction into the tower: the primary styles of cooling towers are herbal draft and triggered draft cooling towers.

Cooling towers range in length from small roof-pinnacle gadgets to very huge hyperboloid systems (as with inside the adjoining image) that may be as much as 2 hundred meters (660 ft) tall and one hundred meters (330 ft) in diameter, or square systems that may be over forty meters (a hundred thirty ft) tall and eighty meters (260 ft) long.

Hyperboloid cooling towers are regularly related to nuclear electricity flowers, even though they're extensively utilized in a few coal-fired flowers and to a point in a few huge chemical and different business flowers.

Although those huge towers are very prominent, the good-sized majority of cooling towers are a good deal smaller, inclusive of many gadgets established on or close to homes to discharge warmness from air conditioning.

This reduces the returned pressure, which in flip reduces the steam consumption, and as a consequence the gasoline consumption, at the same time as on the identical time growing electricity and recycling boiler-water.

While water utilization isn't always a trouble with marine engines, it paperwork a substantial difficulty for plenty land-primarily based totally structures.

By the flip of the twentieth century, numerous evaporative strategies of recycling cooling water have been in use in regions missing a longtime water deliver, in addition to in city places in which municipal water mains might not be of enough deliver; dependable in instances of demand; or in any other case ok to fulfill cooling needs. In regions with to be had land, the structures took the shape of cooling ponds; in regions with confined land, including in cities, they took the shape of cooling towers.

These early towers have been placed both at the rooftops of homes or as free-status systems, provided with air with the aid of using fanatics or counting on herbal airflow.

At the pinnacle is a fixed of dispensing troughs, to which the water from the condenser has to be pumped; from those it trickles down over "mats" fabricated from wood slats or woven cord screens, which fill the gap with inside the tower.

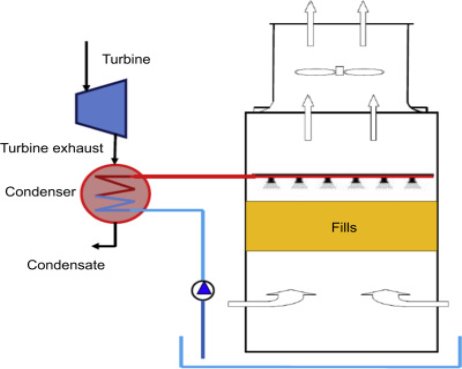

Wet cooling towers

Wet Cooling Towers are those houses wherein the water that have become heated via commercial enterprise or power technology approaches is cooled, again.

The warmth is given off to the environment. Wet cooling towers are a critical part of the thermodynamic circle. The water to be cooled is sprayed and disbursed over the splash fills.

As a quit end result the water temperature drops at the same time as the evaporation warmth is withdrawn and the air gets mummified.

The required air float for the cooling is produced via ventilators which is probably mounted on an output shaft of the system unit.

To permit the FLENDER Wet Cooling Tower Gear Units to take with inside the giant air float forces the system devices are prepared with an in addition axial bearing. Therefore, most effective application-tailor-made 2-staged bevel helical system devices are used to satisfy the precise requirements of this application.

The motor is mounted outside the door. He is robotically linked to the equipment unit this is located proper within side the center of the diffuser of the cooling tower thru lengthy Composite Couplings. These unique couplings also are determined within side the FLENDER product range. Your blessings at a glance

- Low noise emission because of torsion ally inflexible housings

- Variable dimensions of the output bearings for the distinct ventilator types (consistent with the ventilating rail)

- Highest operational reliability because of one-element housings, bolstered bearings, centrifugal discs at the ventilator shaft

- Additional cooling found out through fan cooler at the enter shaft

- Long carrier existence because of optimized equipment unit choice and use of high-grade materials

- Complete force device from an unmarried source

Applications

- Power producing industries, like:

- Biomass energy plant

- Gas energy plant

- Waste incineration plant

- Oil energy plant

A cooling tower is designed to cast off warmth from a constructing or facility through spraying water down via the tower to trade warmth into the interior of the constructing.

Air is available in from the perimeters of the tower and passes via the falling water.

As the air passes via the water, warmth is exchanged and a number of the water evaporates.

This warmth and evaporated water go with the drift out the pinnacle of the tower within side the shape of an exceptional cloud-like mist.

The cooled water is amassed at the lowest of the tower and pumped again into the plant or constructing for reuse.

Cooling towers offer big scale air-conditioning wherein land and (or) water are expensive, or policies limit the go back of once-via cooling waters

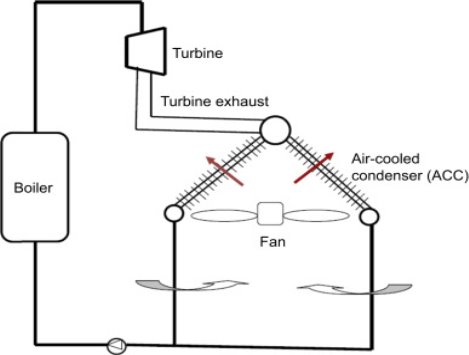

Dry cooling towers

Dry cooling towers are the various cooling towers designed to attain the equal cause as different towers: disposing of the extra warmness as plenty as viable.

The more warmness from machines and business methods may be dangerous to the performance of the machine and can even result in risk and risk our personal protection. So, it’s essential to pick out the proper one to your particular utility to now no longer best make certain your protection, however additionally preserve your machine’s performance as excessive as viable and keep time and money in the end as nicely. In this newsletter from Liquid, we can speak the fundamentals of dry cooling towers, in which you could use them, how they function, and so on.

Cooling towers are taken into consideration as gadgets that assist reject the extra warmness to the atmosphere. This method occurs with the assist of a water movement that acts as a medium to switch the warmth.

There are unique forms of cooling tower that could attain one of these causes. Though the fundamentals are the equal for all of them, however every of them is particular for particular packages consisting of massive scale or small scale, etc. Each cooling tower layout belongs to a selected category.

This categorization may be primarily based totally on unique parameters consisting of shape, warmness switch approach, etc. and Dry cooling towers additionally belong to a specific category.

Dry cooling towers are one of the sorts beneath the warmth switch approach category. They are recognized for his or her particular manner of shifting the warmth.

They function through warmness switch thru a floor keeping apart the ambient air from the running fluid. The medium utilized in dry cooling towers is both water and an aggregate of water-glycol.

The precept of warmth switch is used on this machine which takes vicinity through a warmness exchanger with prolonged fins. In dry cooling towers, the air may be brought through herbal draft or mechanical draft to transport the air thru the air-cooled warmness exchangers/ACC.

Unlike different towers, they don’t use evaporation and as a result, the intake of make-up water in those structures is minimal; plus, the fan on this machine makes use of an electric powered motor to run, so it’s every other plus factor for this kind.

This machine features with air cooling generation and the flow of warm water from the condenser thru skinny tubes permits the warmth alternate for the reason that tubes are uncovered to ambient air flowing round them.

The low air temperature absorbs the warmth from the water to chill it right all the way down to the favored degree.

The boom of volumetric waft charge of the air thru the warmth exchangers has an enhancing impact at the overall performance, which relies upon at the air dry-bulb temperature.

But one of the dangers of such gadgets is their decrease performance whilst the ambient air temperature is excessive. In order to offer uniform warmness switch and an easy and easy internal tube floor for water pressure-drop, this tower has been designed with managed growth among the tube and fin.

Plus, to preserve the performance excessive, the cars are designed to face up to rain, moisture, and dust.

And the low velocity of the motor allows boom the performance and minimizes the noise.

There are unique overall performance levels for this machine, and you could pick out the proper one to your particular utility.

It is ranged from about five to 2,000 kW performances.

These structures have unique noise degrees and have to be used for out of doors installation.

Dry cooling towers may be used for the sun industry, plastic industry, information middle cooling, manufacturing unit cooling, electricity plant, and plenty of different packages.

You can use dry coolers in pc room air con structures, in cooling manufacturing gadget structures, in water-cooled chilled water air con structures, in garage refrigeration structures, and additionally in cooling diesel generator sets.

This tower kind works top notch for locations in which water sources are limited.

They can without problems assist to cast off the extra warmness without negative the out of doors surroundings and make certain your protection and your gadgets’ protection all yr. Long.

Keep in thoughts which you want to set an appointment for everyday protection to make certain your dry cooling tower works nicely and permits you to get the maximum from your machine.

The everyday protection allows keep away from compressor failure too.

Plus, whilst the machine is efficient, the fees of strength intake and protection will lower through the years even as preserving excessive performance.

On the opposite hand, their simplistic layout in addition to different factors that we referred to above, are the motives that this kind is famous for each residential and business makes use of.

Now which you’ve examine this newsletter, you could without problems communicate approximately dry cooling towers, how they function, and in which they’re used.

You can without problems comprehend what the distinction among this one and the opposite numbers is and whether or not it fits your wishes or now no longer.

Cooling ponds

A cooling pond is a synthetic frame of water more often than not fashioned for the reason of cooling heated water and/or to keep and deliver cooling water to a close-by strength plant or business facility along with a petrol refinery, pulp and paper mill, chemical plant, metallic mill or an herbal or synthetic open reservoir used to chill the new circulating water

The water is cooled within side the pond mainly via evaporation and convective warmness switch (water to air).

The temperature of the cooled water relies upon on meteorological situations—the temperature and humidity of the atmospheric air, the overall cloud cover, and the wind speed—and at the temperature of the incoming warm water.

Cooling ponds are noticeably easy to operate, and at some point, of the extra a part of the year, particularly within side the winter, they are able to offer a decrease water temperature than different coolers.

With a cooling pond there may be no want to boost the water to a full-size height, as, for example, with cooling towers; accordingly, much less electric strength is expended in riding the circulating pumps.

A drawback is the noticeably low precise warmness switch from the pond’s floor, a reality that necessitates the advent of a good-sized floor vicinity for the pond.

River floodplains that may be spanned via way of means of dams are used within side the production of cooling ponds, as are lakes and dike-enclosed regions outdoor of watercourses.

Cooling ponds are commonly huge our bodies of water that could seem extra like a lake or massive pond. They historically are used to method and funky the nice and cozy water created via way of means of an business method along with: Power plant operations [nuclear plants, coal-fired plant] Refineries Mills [paper, steel etc.] & Chemical flora Food processing plants The cooling method is finished thru warm/warm water from the method being pumped into the pond, which then might be allowed to glide certainly to permit cooling thru radiation, evaporation, and conduction earlier than being recirculated again into the cooling device thru the device pumps.

For an example, seek advice from Lake Anna, wherein Dominion Energy operates the North Anna Nuclear Generating Station, imparting strength for 450,000 homes. Due to the warmth switch inefficiencies via way of means of the usage of this method, a massive water floor is required.

Advantages of Cooling Ponds

- Construction prices are pretty low, wherein land and soil situations permit

- They can function a settling pond for any suspended solids produced via way of means of the water being cooled

- Limited cooling water makeup required, may be replenished via way of means of rain

Disadvantages of Cooling Ponds

They additionally be aware the subsequent disadvantages:

- Large vicinity of land needed

- Low soil permeability

- Issues if there may be ice

- Can purpose fog

In case the desired quantity of water isn't to be had at steam energy plant site, both the cooling ponds and cooling towers are constructed.

The technique of cooling the recent water via way of means of cooling ponds as compared to cooling towers is easy and cheaper however it's miles much less efficient.

The schematic diagram of a cooling pond is proven in Figure.

The floor location required for cooling pond may be very large, its miles approximately 30 to 50 instances the dimensions of a cooling tower.

The incoming condensate from condenser is sprayed within side the cooling pond thru nozzles.

These nozzles are stored at a distance to every different in order that there's no interference among Sprays.

The spray nozzles are stored at a peak of one to two m above the floor degree for powerful cooling.

The quantity of water misplaced via way of means of evaporation and via way of means of the wind blowing throughout the cooling pond.

Key Takeaways:

- Cooling towers offer big scale air-conditioning wherein land and (or) water are expensive, or policies limit the go back of once-via cooling waters

- In dry cooling towers, the air may be brought through herbal draft or mechanical draft to transport the air thru the air-cooled warmness exchangers/ACC.

- Dry cooling towers may be used for the sun industry, plastic industry, information middle cooling, manufacturing unit cooling, electricity plant, and plenty of different packages.

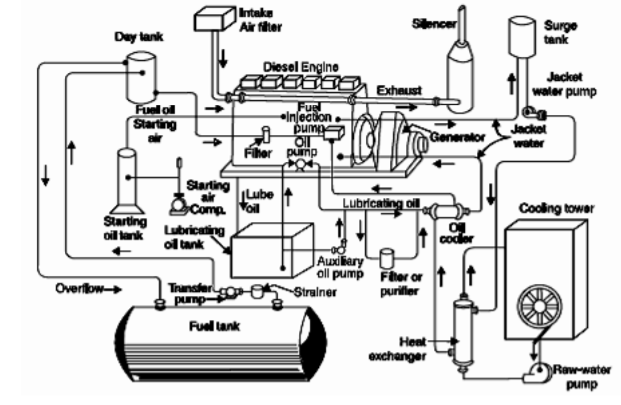

Diesel Power Plant / DG Set: A power plant that uses a diesel engine as a prime mover to generate electrical energy is known as a diesel power plant / DG set. Diesel engines are used as prime movers in diesel power plants. Diesel burns in the engine, and the product of this combustion acts as a "hydraulic" to produce mechanical energy. Diesel engines drive alternators that convert mechanical energy into electrical energy. Due to the high price of diesel, the cost of generating electricity is quite high, so such power plants are only used to generate a small amount of electricity. Thermal and hydroelectric power plants are always used to generate large volumes at low cost, but diesel power plants have low electricity demand, lack of sufficient coal and water, and lack of transportation facilities. It is preferred in places where you are. Not enough. These plants are also used as standby sets to continue to supply critical points such as hospitals, radio stations, cinemas and telephone exchanges.

Advantage:

The design and layout of the plant is very simple.

- Due to the small number and size of auxiliary devices, it occupies less space.

- It can be placed anywhere.

- It can be started quickly and the load can be picked up in a short time.

- There is no standby loss.

- The amount of water required for cooling is small.

- The overall cost is much cheaper than a thermal power plant of the same capacity.

- The thermal efficiency of the plant is higher than the thermal efficiency of the steam power plant.

- The number of operation staff required is small.

Cons: Disadvantages:

- The fuel used (diesel, etc.) is expensive, so the operating cost of the plant is high.

- The plant does not function well for a long period of time under overload conditions.

- The plant can only generate a small amount of electricity.

- The cost of lubrication is generally high.

- Generally, maintenance costs are high. Schematic Layout of Diesel Power Plants Figure shows the schematic layout of a typical diesel power plant. Apart from the diesel generator set, the plant has the following auxiliary equipment:

Fuel Supply System. It consists of a storage tank, strainer, fuel transfer pump and all-day fuel tank. Fuel oil is supplied by rail or road on the factory premises. This oil is stored in a storage tank. From the storage tank, oil is pumped to smaller all-day tanks daily or at short intervals. From this tank, fuel oil passes through the strainer to remove airborne impurities. Clean oil is injected into the engine by a fuel injection pump.

Intake system. This system provides the engine with the air needed to burn the fuel. It consists of pipes to supply fresh air to the engine manifold. Filters are provided to remove dust particles from the air, which can act as an abrasive in the engine cylinder.

Exhaust system. This system guides engine exhaust to the outside of the building and releases it into the atmosphere. Silencers are usually built into the system to reduce noise levels. Figure-5.1 Schematic layout of diesel generator set

Fig. Schematic arrangement of Diesel Generator Set

Cooling system. The heat released by the combustion of fuel in the engine cylinder is partially converted to work. The rest of the heat can pass through cylinder walls, pistons, rings, etc. and damage the system. Cooling is provided to keep the temperature of engine components within safe operating limits. The cooling system consists of a water source, a pump and a cooling tower. The pump circulates water through the cylinder and head jacket. Water draws heat from the engine and becomes hot in itself. Hot water is cooled in a cooling tower and recirculated to cool.

Lubrication system. This system minimizes wear on the friction surface of the engine. It consists of a lubricating oil tank, a pump, a filter, and an oil cooler. Lubricating oil is pumped out of the lubricating oil tank and passed through a filter to remove impurities. Clean lubricating oil is sent where lubrication is needed. The oil cooler built into the system keeps the oil temperature low.

Engine starting system. This is the arrangement that first spins the engine during start up until firing begins and the unit operates at its own power. Small sets are manually started by the handle, but for larger units, compressed air is used for starting. In the latter case, high pressure air flows into several cylinders, which act as reciprocating air motors to rotate the engine shaft. The fuel is put into the remaining cylinders and the engine starts on its own.

Alternator. The alternator is a salient synchronous generator that is self-excited and self-regulated by the excitation unit. The excitation unit consists of a choke, CT, a diode, and a capacitor. The voltage can be adjusted within 2.5% of the nominal voltage from load up to full load with o-rated pf. The choke is for adjusting the terminal voltage when there is no load. CT is for adjusting the terminal voltage under load.

Key takeaways:

- Diesel Power Plant / DG Set: A power plant that uses a diesel engine as a prime mover to generate electrical energy is known as a diesel power plant / DG set.

- Diesel engines are used as prime movers in diesel power plants. Diesel burns in the engine, and the product of this combustion acts as a "hydraulic" to produce mechanical energy.

- Due to the small number and size of auxiliary devices, it occupies less space.

- The plant can only generate a small amount of electricity.

- The alternator is a salient synchronous generator that is self-excited and self-regulated by the excitation unit.

References:

1. Witte L.C., Schmidt P.S. And Brown D.R., Industrial Energy Management and Utilization, Hemisphere Publ., Washington,1988.

2. Callaghan P.W., Design and Management for Energy Conservation, Pergamon Press, Oxford, 1981.

3. Murphy W.R. And McKay G., Energy Management, Butterworths, London,1987.