Unit - 2

TQM principles

TQM prescribes a series of ways for organizations to accomplish this, with the pathway to successful continuous improvement centred on the use of strategy, data and effective communication to instil a discipline of quality into the organization's culture and processes.

More specifically, TQM puts a spotlight on the processes that organizations use to produce their products, and it calls for organizations to define those processes, continuously monitor and measure their performance, and use that performance data to drive improvements. Furthermore, it calls for all employees, as well as all organizational departments, to be part of this process.

TQM's objectives are to eliminate waste and increase efficiencies by ensuring that the production process of the organization's product (or service) is done right the first time.

This management framework was initially applied to companies in the manufacturing sector, but, over the decades, organizations in other sectors have adopted it, as well.

The role of leadership in quality management forms the backbone of any improvement strategy. Leaders provide a unity of purpose, while also establishing the direction of the organisation. As such, the responsibility of leaders consists of creating and maintaining the internal environment. In this environment, employees are able to become completely involved in achieving the organisation’s goals and aims. In this way, good leadership is essential in order to improve quality across the organisation, as the leading force that sets objectives and assists employees to implement these objectives.

11 Tips to Improve Quality Management Leadership and Management-

Be proactive and lead through example rather than dictating – true leaders lead in a way that is active in implementing and following through on actions, rather than simply dictating actions without leading by example.

Understand and react to fluctuations in the external environment – the external environment is every bit as important as the internal environment, which is why leaders need to fully comprehend and correctly react to various changes within this environment.

Consider the wants of ALL stake holders, from customers to owners, employees, suppliers, local communities and the general public – these stake holders form a vital part of the quality management process, and can greatly affect the organisation’s success if there is no relationship and understanding from a leadership point of view.

Establish a clear view of the organisation’s prospects – a clear view of the organisation’s future is essential in order to accurately plan ahead, by continuously changing goals and milestones in the future.

Establish common values and ethical role models throughout the organisation – leaders instil a sense of values and ethics that are entrenched in the organisation’s mission statement, acting as role models to inspire employees to be a part of quality management initiatives based on these common values.

Develop trust and eradicate fear – a good company relies on effective leadership to develop trust across internal and external environments, without the need to use fear as a motivating factor.

Equip employees with the needed resources and freedom to strive for duty and accountability – with a well-developed range of strategies that include all levels within the organisation, along with resources that equip employees to meet the organisation’s goals, the entire organisation can be involved in improving quality across the board.

Inspire, motivate and recognise contributions from all levels of employees – the ability to inspire and motivate staff across all levels allows employees to be actively involved and invested in quality management initiatives.

Foster open and honest communication – communication is essential in order for all levels within the organisation to work together to implement improvement strategies, and as leader, the role is to foster open communication from all employees.

Teach, train and coach employees – through learning and coaching on various improvement strategies and other initiatives, employees are able to garn a better understanding not only on what they are doing, but why they are performing their tasks.

Develop challenging objectives and targets – through goal setting, leaders are able to foster constant growth and development across the organisation, by continually improving the standards of goals within each department.

There are seven basic steps to strategic quality planning. The process starts with the principle that quality and customer and customer satisfaction are the centre of an organization's future. It brings together all the key stake holders.

1. Customer Needs

The first step is to discover the future needs of the customer.

- Who will they be?

- Will your customer base change?

- What will they want?

- How will the organization meet and exceed expectations of customer?

2. Customer Positioning

The planners determine where the organizations want to be in relation to the customers.

Do they want to retain, reduce, or expand the customer base?

Products or services with poor quality performance should be targeted for break-through or eliminated. The organization needs to concentrate its effort on areas of excellence.

3. Predict the Future

Rate of change is continuously changing; hence the planners must be able to predict the future conditions that will affect their product or service. Demographic, economic, forecasts, and technical assessments or projections are tools that help predict the future.

4. Gap Analysis

This step requires the planners to identify the gaps between the current state and the future state of the organization. Statistical analysis, brainstorming are the tools for future predictions and gap identification, can be used.

5. Closing the Gap

By establishing goals and responsibilities are necessary to fill the gap.

6. Alignment

As the plan is developed, it must be aligned with the mission, vision and core values and concepts of the organization.

7. Implementation

This step is the most difficult step in strategic planning. Resources must be collecting data, designing, changes, and overcoming resistance to change. Also part of this step is the monitoring activity to ensure that progress is being made. The planning group should meet at least once a year to assess progress and take any corrective action.

Strategic planning can be performed by any organization. It can be highly effective, allowing organizations to do the right thing at the right time, every time.

A quality council is established to provide overall direction.

The council is composed of

1. Chief Executive Officer

2. Senior Managers

3. Coordinator or Consultant

4. A representative from the Union Duties of the council is

5. Develop the core values, vision statement, mission statement and quality policy statement

6. Develop the strategic long-term plan with goals and Annual Quality Improvement Program with objectives

7. Create the total education and training plan

8. Determine and monitor the cost of poor quality

9. Determine the performance measures

10. Determine projects those improve the process

11. Establish multifunctional project and work group teams

12. Revise the recognition and rewards system

A typical meeting agenda will have the following items

- Progress report on teams

- Customer satisfaction report

- Progress on meeting goals

- New project teams

- Benchmarking report

Within three to five years, the quality council activities will become ingrained in the culture of the organization.

Motivation-

Motivation is achieved through various means — posters, publicity, voluntary pledges by workers, visits of customers to the plant, etc. The thrust is on each worker fixing his own defectives-reduction goal by himself (not by the supervisor, although the supervisor may help him in the process). Before such pledges and other motivational techniques, it is necessary to generate a good awareness about the product amongst workers, such as, what is the product, where is it used, etc. It is also necessary to generate an awareness of the performance of the product quality in the past. Such an awareness campaign should precede the actual implementation of the Zero Defects Program.

Organization of the ZD Program: The Zero Defects Program should be a separate activity coordinated probably by an administrator with the help of a number of Zero Defects representatives working in various functional areas and manufacturing departments of the company. The Zero Defects Administrator may report to the Quality Manager of the organization. Top management support is absolutely essential for implementing a radical program such as Zero Defects.

Removal of Errors: For the actual implementation of the Zero Defects Program, in addition to the positive motivation of the worker to do a better job, it is also essential to probe, by various means, the causes of the defects or errors. One such vital components of the Zero Defects Program is the Error Cause Removal campaign. Suggestions are invited from all, in writing, as to how the errors are caused in his/her own work as well as in other areas of work in the company. Of course, not all the causes could be genuine. But the idea here is to encourage all suggestions, because some small things may be causing large errors. The Zero administrator with the help of others might sift through these suggestions and implement only a few, but it is necessary that he give positive recognition to all the workers who have shown interest in the Zero-Defect Programs; it could be certificate, it may be some sort of publicity in the company magazine, or it may simply be a pat on the back. But such feedback to the workers is important to keep up the tempo of ZD.

Criticism of the ZD Program; The Zero Defects Program is, therefore, basically a motivational program where the worker is made more responsible, more achievement-oriented and prouder of their work. It cannot be a short-term program; it has to be long term program. Because of this, some think that interest in ZD may be lost in the long term. Such apprehensions are not warranted, provided (a) the management (including the top management) is itself not de-motivated towards ZD, and (b) provided that all the important precautions regarding implementing the Zero-Defect Program are properly taken care of. To explain the latter: if a company has a large component of brought-out parts in its final product, it goes without saying that the Zero Defects Program should be applicable and operating in the vendor organization also. Although many feel that it is conceptually impossible to have zero defects, nevertheless, benefits from ZD in terms of improved quality are substantial in the light of the cost associated with the Zero Defects Program. In many organizations abroad, the benefits-to-cost ratio has been said to be as high as 70 to 1. In addition to the benefits in terms of better quality of product, there are many indirect benefits such as improved industrial relations, better plant utilization, etc. On the whole, the Zero Defects Program, if properly applied can produce results on a long-term basis.

Team and Teamwork-

Teams are formed when individuals with a common taste, preference, liking, and attitude come and work together for a common goal. Teams play a very important role in organizations as well as our personal lives.

“Coming together is a beginning. Keeping together is progress. Working together is success-Henry Ford”

The above proverb by Henry Ford can very well highlight the importance of working together in teams.

Every employee is dependent on his fellow employees to work together and contribute efficiently to the organization. No employee can work alone; he has to take the help of his colleagues to accomplish the tasks efficiently. It has been observed that the outcome comes out to be far better when employees work in a team rather than individually as every individual can contribute in his best possible way. In organizations, individuals having a similar interest and specializations come together on a common platform and form a team.

A sales team has employees inclined towards branding and marketing activities to promote their brand. An individual with a human resource specialization would be out of place in such a team. Research supports that organizations with clearly defined teams are more successful as compared to those with a one man show.

Team work is essential in corporates for better output and a better bonding among employees.

- No organization runs for charity. Targets must be met and revenues have to be generated. Tasks must not be kept pending for a long time and ought to be completed within the desired timeframe. A single brain can’t always come with solutions or take decisions alone. He needs someone with whom he can discuss his ideas. In a team, every team member has an equal contribution and each team member comes out with a solution best suited to the problem. All the alternatives can be explored to come out with the best possible solution. Thoughts can be discussed among the team members and the pros and cons can be evaluated.

- Tasks are accomplished at a faster pace when it is done by a team rather than an individual. An individual will definitely take more time to perform if he is single handedly responsible for everything. When employees work together, they start helping each other and responsibilities are shared and thus it reduces the work load and work pressure. Every team member is assigned one or the other responsibility according to his specialization, level of interest and thus the output is much more efficient and faster.

- Work never suffers or takes a backseat in a team. Mike was taking care of an important client and was the only one coordinating with them. Mike took a long leave and there was no one else who could handle the client in his absence. When he joined back after a long vacation, the organization had already lost the client. Had Mike worked in a team, others could have taken the charge when he was not there. In a team, the other team members can perform and manage the work in the absence of any member and hence work is not affected much.

- There is always a healthy competition among the team members. Competition is always good for the employee as well as the organization as every individual feel motivated to perform better than his other team member and in a way contributing to his team and the organization.

- Team work is also important to improve the relations among the employees. Individuals work in close coordination with each other and thus come to know each other better. Team works also reduces the chances of unnecessary conflicts among the employees and every individual tries his level best to support his team member. The level of bonding increases as a result of team work.

- Team members can also gain from each other. Every individual is different and has some qualities. One can always benefit something or the other from his team members which would help him in the long run. Everyone is hungry for recognitions and praises. One feel motivated to work hard in a team and to live up to the expectations of the other members. Each member is a critic of the other and can correct him whenever the other person is wrong. One always has someone to fall back on at the time of crisis.

Team and team work must be encouraged at workplace as it strengthens the bond among the employees and the targets can be met at a faster pace. Workload is shared and individuals feel motivated to perform better than his team members.

Employee involvement-

At the heart of the TQM is the concept of intrinsic motivation-involvement in decision making by the employees. Employee involvement is a process for empowering members of an organization to make decisions and to solve problems appropriate to their levels in the organization.

The Lean (Toyota) systems, utilizing JIT techniques are more productive, smaller and more efficient, increases worker pride and involvement on shop floor.

Employee empowerment-

The dictionary definition of empowerment is to invest people with authority

Empowerment should not be confused with delegation or job enrichment. Delegation refers to distributing and entrusting work to others. Employee empowerment requires that he individual is held responsible for accomplishing the whole task. The employee becomes process owner- thus the individual is not only responsible but also accountable. Employee empowerment requires that the individual is held responsible for accomplishing a whole task.

Quality circle is a people building philosophy based on the premise that an employee doing a particular job is biggest expert of that field and thus is in a better position to identify, analyse and resolve the work-related problems through their innovative and unique ideas. In fact, it is a practical application of McGregor’s Theory ‘Y’ that if given the right environment and decision-making power, people will enjoy and take pride in their work thus leading to enrichment of their work life.

By solving their work-related problems, the employees reduce the rejection rate, rework and thus their mental tensions are reduced, enabling them to work with total commitment and dedication.

It is a voluntary group of employees, who are doing the same or similar type of job, meet together on a regular’ basis to identify, analyse and solve their work-related problems leading to improvement in their work, performance and- enrichment of their work life. The number of circle members could vary from 5 to 15 but the ideal size of a circle is 7 or 8 members. The number of members should be such that the circle is effective.

Quality Circle – 7 Important Objectives

The important objectives of quality circles are:

(i) To develop, enhance and utilize human resources effectively;

(ii) To improve quality of products/services, productivity and reduce cost of production per unit of output;

(iii) To satisfy the workers’ psychological needs for self-urge, participation, recognition etc., with a view to motivating them. Accomplishment of this objective will ensure enhancement of employee morale and commitment;

(iv) To improve various supervisory skills like leadership, problem solving, inter-personal and conflict resolution; and

(v) To utilize individual imaginative, creative and innovative skills through participation, creating and developing work interest, including problem solving techniques etc. Achievement of these objectives effectively requires the use of certain techniques.

(vi) To make use of the knowledge and skills of the workers.

(vii) To develop good relations between workers and managers and create cordial industrial relations.

Recognition is a process whereby management shows acknowledgement of an employee’s outstanding performance. Recognition is a form of employee positive motivation. Recognition of employees is highly essential as people find themselves in a accepted and winning role. To sustain employee’s interest and to propel them towards continuous improvement, it is essential to recognize

The people. This acknowledgement may be of financial, psychological or both in nature.

Ways to recognize people

Send letters to improve team members when they establish a team thanking them for their involvement.

1. Develop a behind the scenes awards specifically for those whose actions are not usually in the lime light, make sure such awards are in the lime light.

2. Create best ideas of the year booklet and include everyone’s picture name and description of their best ideas.

3. Feature the quality team of the month and put their picture in a prominent place.

4. Honor peers who have helped you by recognizing them at your staff meetings.

5. Let people attend meetings, committees etc; in your place when you are not available.

6. Involve teams with external customers and suppliers, sending them on appropriate visits to solve problems and look for opportunities.

7. Invite a team for coffee or lunch at any time, not necessarily when you need them for something.

8. Create a visibility wall to display information, posters, and pictures, thanking individual employees and their teams, and describing their contributions.

9. When you are discussing an individual or group ideas with other people, peers, or higher management make sure that you give them credit.

WHY SHOULD ONE RECOGNISE PEOPLE?

1. improve employees morale

2. show the company’s appreciation for better performance

3. create satisfied workplace

4. Create highly motivated workplace.

5. Reinforce behavioural patterns.

6. Stimulate creative efforts.

REWARD

MEANING:

Reward is a tangible one, such as increased salaries, commissions, cash bonus, gain sharing, etc; to promote desirable behaviour.

TYPES OF REWARDS:

- Intrinsic rewards

- Extrinsic rewards

Intrinsic rewards are related to feelings of accomplishment of self-worth.

INTRINSIC REWARDS

1. Non-monetary forms of recognition to acknowledge achievement of quality improvement goals.

2. Celebration to acknowledge achievement of quality improvement goals.

3. Regular expressions of appreciation by managers and leaders to employees to acknowledge achievement of quality improvement goals.

4. 360-degree performance appraisals feedback from co-workers’ subordinates to customers are incorporated into performance appraisals.

EXTRINSIC REWARDS:

1. Profit sharing

2. gain sharing

3. employment security

4. compensation time

5. individual based performance systems

6. quality-based performance appraisals

Recognition is a process by which management shows acknowledgement of an employee’s outstanding performance.

Various ways for Recognition and Rewards are

1. Recognition can be expressed using verbal and written praise.

2. Rewards may be in the form of certificates and plaques.

3. Reward is normally in the form of cinema tickets, dinner for family etc.

4. The financial compensation (for recognition) can be paid in terms of increased salaries, commissions, gain sharing etc.

5. The efforts of employees can be recognized by promotions, special job assignments etc.

6. A letter of appreciation from the CEO or the Top Management will increase the employee’s involvement.

7. Reward may be delayed but recognition should be in a timely basis.

8. Rewards should be appropriate to the improvement level.

9. People like to be recognized than any reward.

10. Special forms of recognition include pictures on the bulletin board, articles in newsletters, letter to families etc.

11. Supervisors can give on-the-spot praise for a job which is done well.

EFFECTS OF RECOGNITION AND REWARD SYSTEM

1. Recognition and reward go together for letting people know that they are valuable members for the organization.

2. Employee involvement can be achieved by recognition and reward system.

3. Recognition and reward system reveals that the organization considers quality and productivity as important.

4. It provides the organization an opportunity to thank high achievers.

5. It provides employees a specific goal to achieve.

6. It motivates employees to improve the process.

7. It increases the morale of the workers.

Performance Appraisal is the systematic evaluation of the performance of employees and to understand the abilities of a person for further growth and development. Performance appraisal is generally done in systematic ways which are as follows:

- The supervisors measure the pay of employees and compare it with targets and plans.

- The supervisor analyses the factors behind work performances of employees.

- The employers are in position to guide the employees for a better performance.

Objectives of Performance Appraisal

Performance Appraisal can be done with following objectives in mind:

- To maintain records in order to determine compensation packages, wage structure, salaries raise, etc.

- To identify the strengths and weaknesses of employees to place right men on right job.

- To maintain and assess the potential present in a person for further growth and development.

- To provide feedback to employees regarding their performance and related status.

- To provide feedback to employees regarding their performance and related status.

- It serves as a basis for influencing working habits of the employees.

- To review and retain the promotional and other training programmes.

Advantages of Performance Appraisal

It is said that performance appraisal is an investment for the company which can be justified by following advantages:

- Promotion: Performance Appraisal helps the supervisors to chalk out the promotion programmes for efficient employees. In this regards, inefficient workers can be dismissed or demoted in case.

- Compensation: Performance Appraisal helps in chalking out compensation packages for employees. Merit rating is possible through performance appraisal. Performance Appraisal tries to give worth to a performance. Compensation packages which include bonus, high salary rates, extra benefits, allowances and pre-requisites are dependent on performance appraisal. The criteria should be merit rather than seniority.

- Employees Development: The systematic procedure of performance appraisal helps the supervisors to frame training policies and programmes. It helps to analyse strengths and weaknesses of employees so that new jobs can be designed for efficient employees. It also helps in framing future development programmes.

- Selection Validation: Performance Appraisal helps the supervisors to understand the validity and importance of the selection procedure. The supervisors come to know the validity and thereby the strengths and weaknesses of selection procedure. Future changes in selection methods can be made in this regard.

- Communication: For an organization, effective communication between employees and employers is very important. Through performance appraisal, communication can be sought for in the following ways:

a) Through performance appraisal, the employers can understand and accept skills of subordinates.

b) The subordinates can also understand and create a trust and confidence in superiors.

c) It also helps in maintaining cordial and congenial labour management relationship.

d) It develops the spirit of work and boosts the morale of employees.

All the above factors ensure effective communication.

6. Motivation: Performance appraisal serves as a motivation tool. Through evaluating performance of employees, a person’s efficiency can be determined if the targets are achieved. This very well motivates a person for better job and helps him to improve his performance in the future.

Continuous process improvement (CPI) is the practice of making incremental changes to your business processes to improve efficiency and quality.

Continuous process improvement is sometimes also known as ‘continual process improvement’. Not to be confused with business process reengineering (BPR), continual improvement invites you to make incremental changes to your processes rather than scrapping everything to completely redesign a new process.

This ongoing effort to improve existing business processes can consist of small changes that tweak the workflow or bigger ‘breakthrough’ improvements that encourage innovation.

Your CPI program should aim to boost efficiency, effectiveness, output quality, and flexibility. It’s a key component of achieving operational excellence.

Lots of organizations use workflow analysis software like frevvo to help with this process. Tools like this make it easy to track performance and spot areas for improvement.

What are the Benefits of Continuous Process Improvement?

Conducting continuous process improvement will allow your business to spot inefficiencies and open the door to rectify them.

As such, there are multiple benefits that can come from this practice. Some benefits include:

- Reduced costs

- Less errors

- Better outcomes

- More efficient processes

- Reduced bottlenecks

- More satisfied customers

- More productive and happy employees

The impact of continuous process improvement and its related benefits will depend on where you choose to focus. It will also depend on your current operations and processes because they define the room for improvement.

The great news is that no matter how big or small your improvements may be, they have the potential to have an impact on your employees, as well as your customers.

What are the 4 Steps of Continuous Process Improvement?

As one of the most popular tools for continuous process improvement, many rely on the plan-do-check-act (PDCA) cycle. This stands for:

1. Plan:

Identify an opportunity for change.

2. Do:

Implement the change on a small scale to test.

3. Check:

Review results by analysing data to determine if the change was successful. One of the easiest ways to approach this step is by leveraging a data automation software solution that can showcase real-time data and analytics as processes run their cycles.

4. Act:

If the change proves successful based on the data, then it’s time to implement it on a broader scale. If it wasn’t as effective as hoped for, later only, try again!

PDCA Cycle (also known as PDSA Cycle or Deming Cycle), is a problem-solving method used for the continuous learning and improvement of a process or product.

There are 4 basic steps in PDCA Cycle:

- Plan: identify a problem and possible solutions

- Do: execute the plan and test the solution(s)

- Check: evaluate the results and lessons learned

- Act: improve the plan/process for better solutions

These four steps incorporate inductive-deductive interplay and have been a simple and scientific approach for problem-solving (process-improving). It follows the curve of how we acquire knowledge through constant reflection, standardization, and modification.

The PDCA framework begins with a planning phase where a problem or a process to be improved is identified. This involves not only the goal setting and finding possible solutions, but also hypothesizing methods that can be used to reach the ultimate goal. Another thing that needs special attention is defining the success metrics. This simply means a clear evaluation matrix is ideally to be set beforehand.

Then, the solution(s) will be tested in the Do process. To detach the Do, there could be two steps: making the Do multiple To-Dos by splitting the task and defining them with a specific time, personnel, and steps, and collecting real-time data and feedback.

Check includes analysing the results and comparing them to the hypothesis in the Plan stage: how well the solution worked, how much the goal has been achieved, and whether the methods were proven feasible. If there are any unexpected issues, you may also need to find the causes and possible solutions. Note that there might be forth and back between Do and check.

The Act step closes the cycle, which involves adjustment on the initial goal or solutions and integration of all key learnings by the entire process, to standardize successful parts and avoid error recurrence. In a nutshell, the Act phase summarizes the current cycle and prepares for the next.

However, the PDCA cycle doesn’t stop here. Instead, it can repeat from the beginning with a modified version of the Plan. There is no end to it and sustainability should be its main pitch.

Benefits of PDCA Cycle

Among all those other methods, why does the PDCA model shade some lights in the history, especially known for the “Japanese Quality” and is still widely used today? Some key benefits of it need to be valued.

PDCA methodology emphasizes minimizing errors and maximizing outcomes. When applied to business development, e.g., a product’s iterations, it could ensure a developing path where the product is shaped better and better to the market and customers. It’s the same when it comes to personal growth. It also leaves space for constant check and reflection, which can avoid wasting time on the mistakes or making the same mistakes.

PDCA framework follows a learning curve and enhances the learning-improvement process continually. This is the key factor defining PDCA as a scientific and methodical way to gain knowledge. With knowledge building up, people’s ability goes up.

PDCA model encourages a growth mindset. Seeing continuous improvements is a good way to enhance individuals’ self-esteem levels and bring a great sense of accomplishment. People tend to find meaning in the things they do. Imagine if one stops making progress, they would stay in the static and lose meaning in repetitive work and life.

5S-

5S is a system for organizing spaces so work can be performed efficiently, effectively, and safely. This system focuses on putting everything where it belongs and keeping the workplace clean, which makes it easier for people to do their jobs without wasting time or risking injury.

5S Translation

The term 5S comes from five Japanese words:

- Seiri

- Seiton

- Seiso

- Seiketsu

- Shitsuke

In English, these words are often translated to:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

The Origins of 5S – 5S & Lean Manufacturing

5S began as part of the Toyota Production System (TPS), the manufacturing method begun by leaders at the Toyota Motor Company in the early and mid-20th century. This system, often referred to as Lean manufacturing in the West, aims to increase the value of products or services for customers. This is often accomplished by finding and eliminating waste from production processes.

Lean manufacturing involves the use of many tools such as 5S, kaizen, kanban, jidoka, heijunka, and poka-yoke. 5S is considered a foundational part of the Toyota Production System because until the workplace is in a clean, organized state, achieving consistently good results is difficult. A messy, cluttered space can lead to mistakes, slowdowns in production, and even accidents, all of which interrupt operations and negatively impact a company.

By having a systematically organized facility, a company increases the likelihood that production will occur exactly as it should.

Kaizen

Kaizen is a Lean manufacturing tool that improves quality, productivity, safety, and workplace culture. Kaizen focuses on applying small, daily changes that result in major improvements over time. Kaizen first surfaced during the effort to rebuild Japan after World War II. At the time, several U.S. Business consultants collaborated with Japanese companies to improve manufacturing. The collaboration resulted in the development of several new management techniques, one of which was Kaizen.

Kaizen (改善) comes from two Japanese words: Kai (improvement) and Zen (good), which translates to “continuous improvement”. In business, Kaizen refers to activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. Kaizen’s strength comes from having all workers participate and make suggestions to improve the business. The purpose of Kaizen goes beyond simple productivity improvement. When done correctly, the process humanizes the workplace, eliminates overly hard work, and teaches people how to spot and eliminate waste in business processes.

The Kaizen philosophy states that our way of life - be it our working life, our social life, our home life - deserves to be constantly improved. Kaizen is about achieving improvements by taking small steps instead of drastic, rigorous changes. Although improvements under Kaizen are small and incremental, the process brings about dramatic results over time. Additionally, Kaizen is a low-risk and an inexpensive approach. It involves process improvements that do not require a large capital investment. As a result, Kaizen encourages workers to experiment and try out new ideas. If an idea does not work, they can always revert the changes without incurring large costs.

Benefits of Kaizen

Beyond the obvious benefit of improving processes; Kaizen engenders teamwork and ownership. Teams take responsibility for their work and are able to make improvements to enhance their own working experience. Most people want to be successful and proud of the work that they do and Kaizen helps them to achieve this while benefitting the organization.

A Gallup poll of US workers in 2015 showed that just 32% of employees were engaged. A majority of employees (50.8%) were “not engaged”, while 17.2% were “actively disengaged”. One of the main benefits of Kaizen is getting employees actively involved and engaged with the company. Having more engaged workers leads to more efficient processes, lower turnover, and higher rates of innovation. Engaged employees feel that they have an impact on the company’s performance and are more likely to try out new ideas. Additionally, organizations with more engaged employees can achieve higher competitiveness, enhance customer satisfaction, and have an improvement culture of solving problems through teamwork.

The Kaizen Process

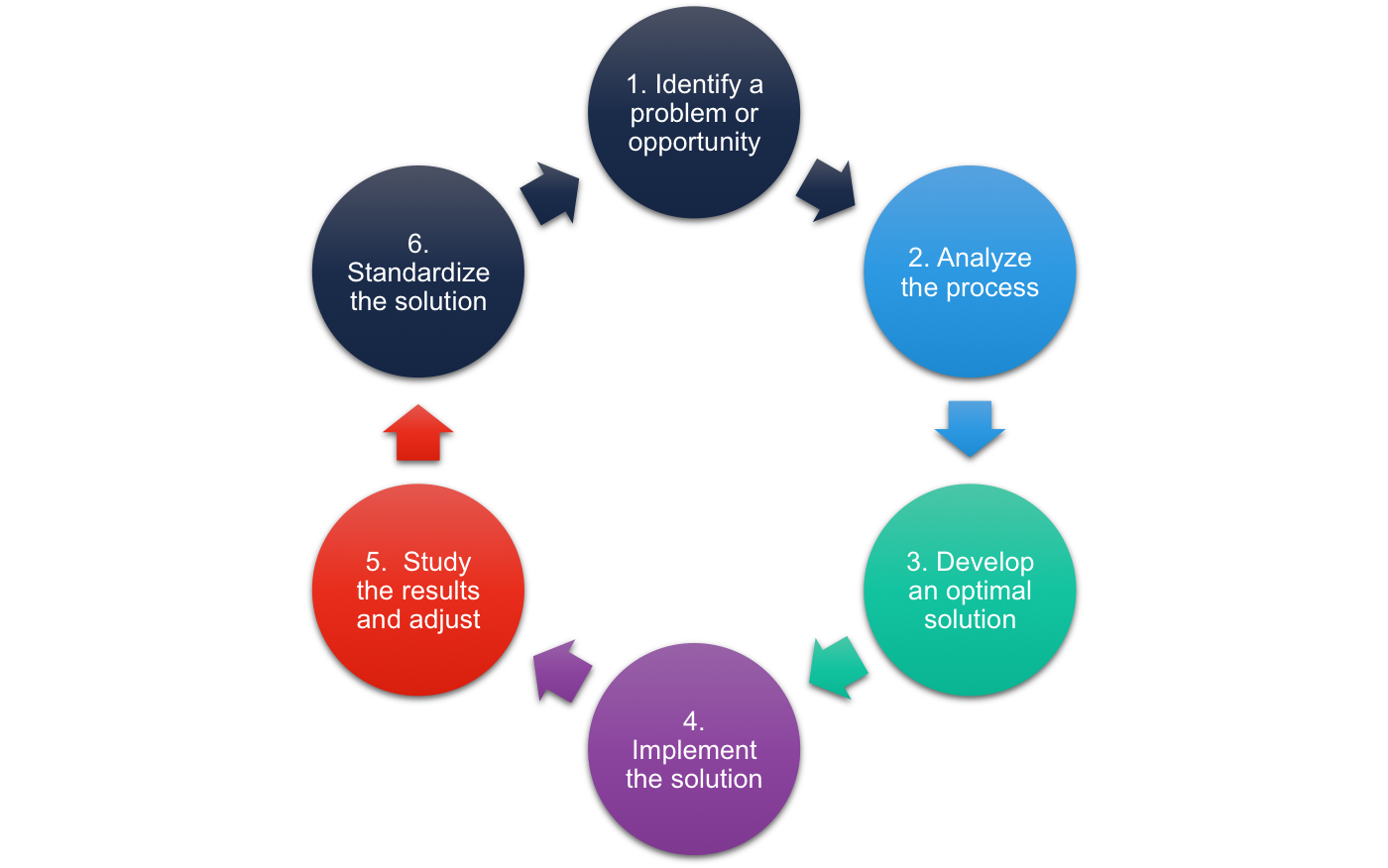

The continuous cycle of Kaizen activity has six phases:

1. Identify a problem or opportunity

2. Analyze the process

3. Develop an optimal solution

4. Implement the solution

5. Study the results and adjust

6. Standardize the solution

Continuous Improvement Cycle

Kaizen starts with a problem, more precisely the recognition that a problem exists and that there are opportunities for improvement. Once problems are identified, the organization needs to enlist the cross-functional personnel to understand the underlying cause of it. The proposed solution is then tested on a small-scale. Using data, the team makes adjustments to the solution. And finally, the results are spread across the organization and the solution is standardized.

Getting Started with Kaizen

As a Lean business practice, Kaizen succeeds when all employees look for areas to improve and provide suggestions based on their observations and experience. To facilitate this, management’s role is to communicate the need to change, demonstrate a personal commitment to process improvement, educate and train staff in Kaizen, and manage the improvement process. When first getting started with Kaizen, here are some things to keep in mind:

Start with training: Everybody needs to know what Kaizen is and how it can benefit the workplace culture.

Support Kaizen from the top: Employees need to know that they will get support when they need it.

Get ideas flowing: Use Kaizen boards, quality circles, and suggestion boxes. Employees need a way to communicate effectively and document their ideas for improvement.

Keep ideas coming: Let employees implement their own suggestions when possible. This will encourage participation.

Remove barriers: Kaizen boards and software are especially useful here. They allow workers to post ideas, track their progress, and see the benefits of each improvement.

Measure impacts: By keeping track of the beneficial results from the kaizen process, the company is more likely to continue investing in it and sustaining it.

Kaizen is a long-term strategy and the goal is to develop the capabilities and confidence of workers. As a strategy, Kaizen works when employees at all levels of the company work together proactively to achieve regular, incremental improvements. In a sense, it combines the collective talents within a company to create a powerful engine for improvement.

By having the right system in place, management can help their Kaizen program gain momentum and succeed. Workers will gain a sense of ownership over their tasks and become more involved in every aspect of the business. This will ultimately lead to better processes, higher customer satisfaction, and a more profitable business.

Partnering is a defined as a continuing relationship, between a buying firm and supplying firm, involving a commitment over an extended time period, an exchange of information, and acknowledgement of the risks and rewards of the relationship. The relationship between customer and supplier should be based upon trust, dedication to common goals and objectives, and an understanding of each party’s expectations and values.

Benefits of Partnering

The benefits of partnering include:

- Improved quality;

- Reduced cost;

- Increased productivity;

- Increased efficiency;

- Increased market share;

- Increased opportunity for innovation; and

- Continuous improvement of products / services.

Key Elements to Partnering

The three important elements to achieve the customer / supplier partnering relationship are:

1. Long-term commitment: Long-term commitment provides both customer and supplier the much-needed environment to achieve the planned objectives. Because to set up and solve the problem of continuous improvement, both parties may require the sufficient time.

2. Trust: Mutual trust between two parties forms the basis for a strong working relationship. Trust enables the partners to effectively combine their resources and knowledge. It results in a ‘win-win’ situation for both partners.

3. Shared vision: Both the customers and suppliers have the common goal i.e., to satisfy the end user. In order to ensure this goal, both particles should share and understand their goals and objectives.

Three types of supplier sourcing are:

- Sole sourcing;

- Multiple sourcing, and

- Single sourcing.

1. Sole Sourcing

Sole sourcing is the use of only one supplier for the organization. The organization does not have any choice. It is forced to use only one supplier. This forced situation is because of the following factors: patents, technical specifications, raw material location, only one organization producing the item, etc.

2. Multiple Sourcing

Multiple sourcing is the use of two or more suppliers for an item. The basic concept of multiple sourcing is that competition will result in better quality, lower costs, and better service. (The selection of suppliers from various alternatives is based on their performance in terms of prices, quality and delivery.

3. Single Sourcing

Single sourcing is the use of one supplier for an item when several sources are available. It leads to long-term partnering relationship.

The suppliers should be treated as partners to achieve the same quality level as attained within the organization.

The following forces need Supplier Partnership to improve quality, reduce costs and increase market share.

- Deming Philosophy (Deming’s 4th point)

- Just-in-time

- Continuous process improvement

- ISO 9000

When a supplier completes the “evaluation” steps and becomes a fully approved supplier, then on-going monitoring and rating will be implemented. The rating may make comparisons between various suppliers who are concurrently providing similar products or services, or may be focused on measuring changes in individual supplier performance over time, versus expected performance demands.

Supplier rating may be in the form of some of the following: the number of pass/fails received, the number of defects within each unit on average received, the number of defects per million for high volume suppliers. The rating system selected should provide a clear picture of supplier performance and be able to offer a trend over time, for example, month by month trends in performance.

The first step in developing a supplier rating process is to identify the key performance characteristics in the product or service provided. The key performance characteristics may relate to product quality, meeting delivery requirements, reliability expectations, cost.

Once the key performance characteristics are known then methods of measurement need to be identified and implemented. The measurement methods must themselves be reliable and consistent. There should be no room for unknown variation otherwise the rating system may itself by questioned and will lose value in the eyes of the supplier.

Finally, the supplier performance reports need to be published on a regular basis. Ideally, feedback should be relatively prompt, therefore depending on the products or services being performed, feedback may be provided weekly, monthly, quarterly. In the interval between performance report issue, individual instances of performance failure should be relayed back to the supplier, so that immediate action can be taken to understand and address.

Supplier Rating is done

- To obtain an overall rating of supplier performance.

- To communicate with suppliers regarding their performance.

- To provide each supplier with a detailed and true record of problems for corrective action.

- To enhance the relationship between the buyer and the supplier.

Let’s discuss the 5 steps you should take in order to make the correct decisions in supplier selection.

Step 1 – Supplier Selection Scorecard

The first step in the supplier selection process is to create a supplier selection scorecard.

The supplier selection scorecard contains all the important elements you require in a supplier. It has long been stated, “That which does not get measured, does not get done”.

Your scorecard should be quantifiable and include:

- Supplier characteristics

- The important strategic alignment factors you value

- Applicable business policies

- Any constraints – management directives, government regulations, contracts already in place, and other commitments

At this step, make sure you are prioritizing your needs. All of the above may be important but some are more important than others.

For example, quality may be most important. Surprising to some, cost is often a low priority. Think about it…if a supplier offers poor quality, long lead time, late deliveries, etc. Does it really matter how low the price is? It simply won’t do!

Step 2 – Identify Suitable Suppliers

Once you have the selection criteria in place, you must create the pool from which you will select a supplier. During this part of the process, you will want to consider:

- Current suppliers – Starting with suppliers you have experience with and established relationships is generally a good idea

- Past suppliers – Depending upon the reasons why they are ‘past’ and not ‘current’

- Competitors – You may be in a position to buy from a competitor if it is ethical and low-risk

- Industry groups – many of which are non-profit and maintain data bases of member companies

- Recommendations and prior business relationships – perhaps created while working at other companies

- Internet – which offers myriad opportunities to find, research, and contact potential suppliers

Step 3 – Scorecard Ranking

Next, gather information from the identified suitable suppliers – perhaps in the form of a Request for Quote (RFQ) or Request for Proposal (RFP).

Tabulate the information you collect and use the scorecard to rank the potential suppliers.

Depending upon the complexity and/or criticality of the product or service, you may:

- Select the highest-ranking supplier – Recognize that while you are not required to pick the top scorer, moving too far down the list is a red flag, indicating the process was flawed

- Choose more than one for further qualification – May include interviews, site visits, etc.

If all that work did not identify a clear winner, you may need to review your criteria and/or expand your search.

Step 4 – Negotiate

After you have narrowed the list to a manageable number of best options, possibly just one, let the negotiations begin!

Depending on the critical good or service, you may negotiate with just the top supplier on your scorecard, even if others remain on the list of potentials.

These others, of course, are not told they are not #1 until after you have completed negotiations and agreements are completed.

Based upon the complexity of the situation, lawyers may be involved.

Step 5 – Create Contract

Once an agreement is reached, a contract is created and signed.

For many transactions, the purchase order is the contract. For complex situations, you may have a contract and then create a separate purchase order.

Creating the purchase order will include activating your procurement system. This should be a standard operating procedure and include getting your accounts payable process ready to process the supplier invoice.

References:

1. Course Notes - National Institute of Technology, Calicut

2. Production and Operation Management - DDCE Utkal University