Unit - 4

Unconventional Machining Processes

In Unconventional machining processes, there is no physical contact between the tool and work piece. Although in some non-traditional processes tool wear exists, its rarely is a significant problem.

Construction:

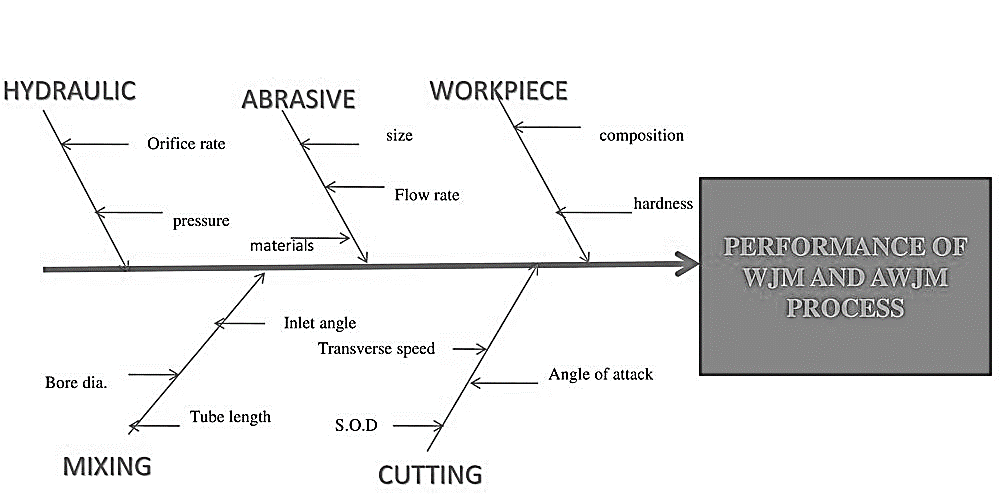

Fig. Process Parameters

Reactive force = Mass flow rate (m) X jet velocity (v)

Hence,

MRR α m α v

Working of Abrasive jet machining (AJM):

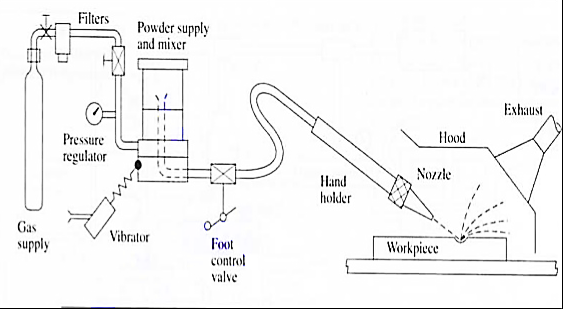

Fig. Abrasive jet machining

Typical AJM Parameters

2. Size

3. Quantity

4. Medium

5. Nozzle

6. Factors affecting MRR:

The nozzle is one of the most vital elements controlling the process characteristics. Since it is continuously in contact with the abrasive grains flowing at a high speed, the material must be hard to avoid any significant wear.

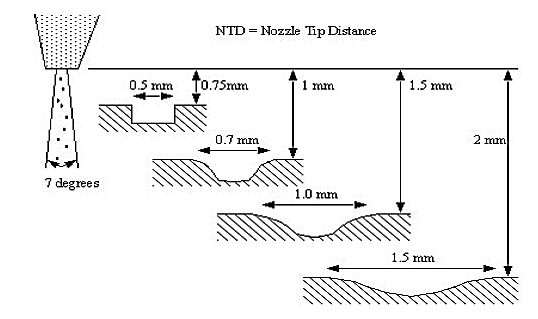

One of the most important factors in AJM is the distance between the work surface and the tip of the nozzle, normally called the nozzle distance

Fig. Nozzle Tip Distance

Applications: -

Limitations: -

Advantages: -

Disadvantages: -

Principle of Ultrasonic machining (USM):

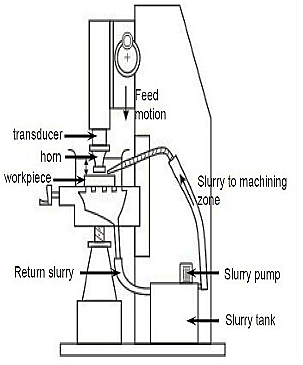

In this method with the help of piezoelectric transducer tool is vibrate at high frequency in a direction normal to the surface being machined abrasive slurry are used for the remove the metal from work piece.

Working of USM:

Fig. Ultrasonic machining

Applications: -

Advantages: -

Disadvantages: -

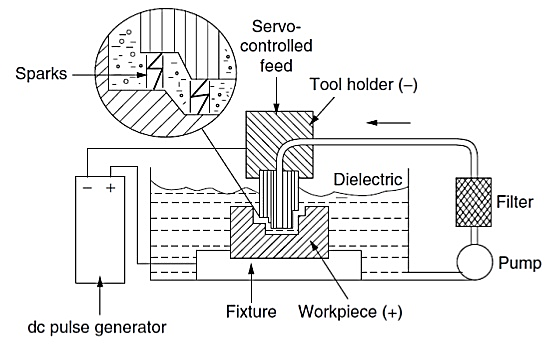

Principle of EDM:

Electrical discharge machining (EDM), sometimes also referred to as spark machining, spark eroding, burning, die sinking, wire burning or wire erosion, is a manufacturing process whereby a desired shape is obtained using electrical discharges (sparks).

Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a die-electric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the "tool" or "electrode", while the other is called the workpiece- electrode, or "workpiece".

Working of EDM:

Fig. Electrical discharge machining

Advantages: -

Disadvantages: -

Surface finish:

The outermost boundary of a body adjacent to the air is called surface. When this surface deformed by a sharp cutting edge, the term surface finish describes the boundary.

A good surface is affected by many variables in single or multiple point machining.

Surface finish is defined in terms of 4 factors:

Tool wear:

Tool subjected to:

1. Forces

2. Temperature

3. Sliding action

1. Loss of dimensional accuracy

2. Increased surface roughness

3. Increased power requirement

4. Excessive vibration and abnormal sound (Chatter)

5. Total breakage of the tool

Tool is replaced or reconditioned usually by grinding.

Tool Wear depending factors:

1. Type of tool material and its hardness

2. Type and condition of work piece material

3. Dimensions of cut (Feed and depth of cut)

4. Cutting speed

5. Tool geometry

6. Tool temperature (function of cutting speed, feed and depth of cut)

7. Type of cutting fluid

Classification of Tool Wear

1. Flank wear

2. Crater wear on tool face

3. Localized wear such as the rounding of Cutting edge

4. Chipping of the cutting edge

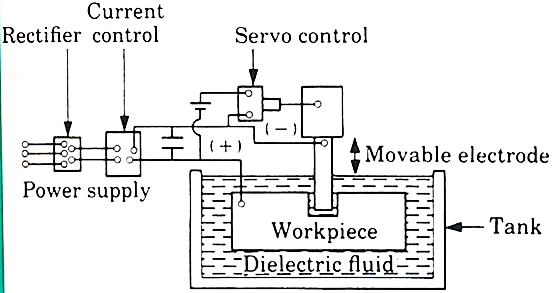

The main components in EDM:

Working Principle:

Fig. EDM Schematic

Power & Control Circuits:

Two broad categories of generators (power supplies) are in use on EDM. Commercially available: RC circuits based and transistor-controlled pulses.

In the first category, the main parameters to choose from a setup time are the resistance(s) of the resistor(s) and the capacitance(s) of the capacitor(s).

In an ideal condition, these quantities would affect the maximum current delivered in a discharge.

Current delivery in a discharge is associated with the charge accumulated on the capacitors at a certain moment.

Little control is expected over the time of discharge, which is likely to depend on the actual spark-gap conditions.

Advantage: RC circuit generator can allow the use of short discharge time more easily than the pulse-controlled generator.

Also, the open circuit voltage (i.e., voltage between electrodes when dielectric is not broken) can be identified as steady state voltage of the RC circuit.

In generators based on transistor control, the user is usually able to deliver a train of voltage pulses to the electrodes.

Each pulse can be controlled in shape, for instance, quasi-rectangular.

In particular, the time between two consecutive pulses and the duration of each pulse can be set.

The amplitude of each pulse constitutes the open circuit voltage.

Thus, maximum duration of discharge is equal to duration of a voltage pulse. Maximum current during a discharge that the generator delivers can also be controlled.

Details of generators and control systems on EDMs are not always easily available to their user.

This is a barrier to describing the technological parameters of EDM process. Moreover, the parameters affecting the phenomena occurring between tool and electrode are also related to the motion controller of the electrodes.

A framework to define and measure the electrical parameters during an EDM operation directly on inter-electrode volume with an oscilloscope external to the machine has been recently proposed by Ferri et al.

This would enable the user to estimate directly the electrical parameter that affect their operations without relying upon machine manufacturer's claims.

When machining different materials in the same setup conditions, the actual electrical parameters are significantly different.

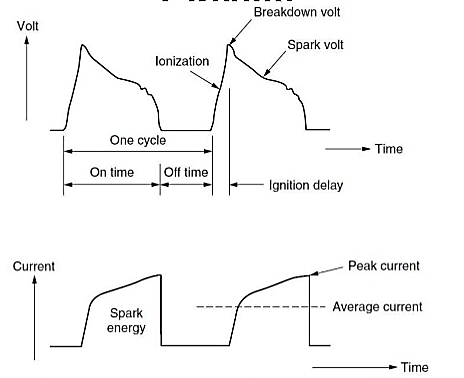

When using RC generators, the voltage pulses, shown in Fig. are responsible for material removal.

Fig. Voltage and current waveform during EDM

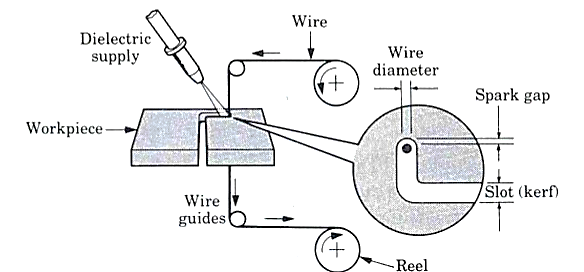

Wire EDM:

Fig. Wire EDM

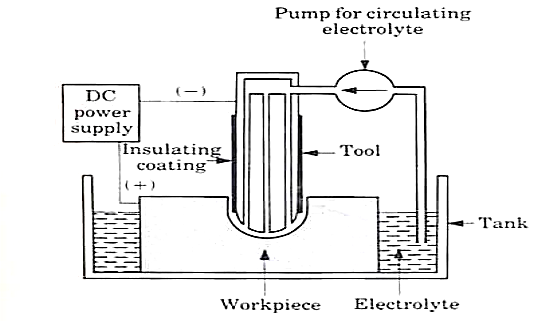

Working of ECM:

Fig. Electro-chemical machining

Advantages of ECM:

Types of masks used in Chemical machining:

2. Screen resist maskants:

3. Photo resist maskants:

The general requirements of tool material in ECM are:

1. It should be conductor of electricity.

2. It should be rigid enough to take up the load due to fluid pressure.

3. It should be chemically inert to the electrolyte.

4. It should be easily machinable to make it in the desired shape.

Process Parameter:

S.no | Parameters | Values |

1. | Power Supply |

|

| Type | Direct Current |

| Voltage | 2 to 35 V |

| Current | 50 to 40,000 A |

| Current Density | 0.1 A/mm2 to 5 A/mm2 |

2. | Electrolyte |

|

| Material | NaCl and NaNO3 |

| Temperature | 20 oC to 50 oC |

| Flow rate | 20 lpm/100 A current |

| Pressure | 0.5 to 20 bars |

| Dilution | 100 g/l to 500 g/l |

3. | Working gap | 0.1 mm to 2mm |

4. | Overcut | 0.2 mm to 3 mm |

5. | Feed rate | 0.5 mm/min to 15 mm/min |

6. | Electrode material | Copper, brass and bronze |

7. | Surface roughness (Ra) | 0.2 to 1.5 μm |

Material removal rate (MRR):

MRR = m / tρ = IA / Fρν

where m = ItA/Fv = mass of material dissolve

I = current

A = Atomic weight

v = valency

F = Faraday’s constant = 96500 coulombs

ρ = density of the material

Power Supply:

1. Type: direct current

2. Voltage: 2 to 35 V

3. Current: 50 to 40,000 A

4. Current density: 20 A/cm2 to 300 A/cm2

Surface finish is defined in terms of 4 factors:

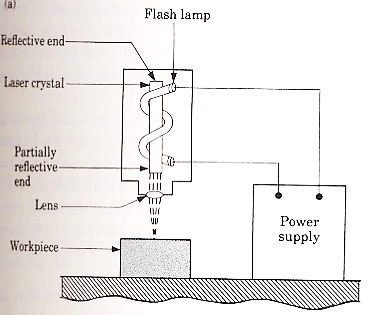

Lasers can be used to cut, drill, weld and mark. LBM is particularly suitable for making accurately placed holes.

Principle of Laser beam machining (LBM):

Working of LBM

Fig. Laser Beam Machining

Applications: -

Limitations: -

Advantages: -

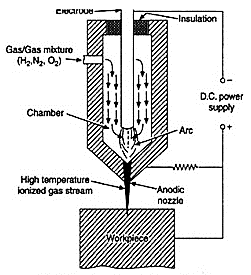

When a gas or air is heated at a temperature of more than 5000 °C, then it will start getting ionized into positive ions, negative ions and neutral ions. When the gas or air is ionized its temperature reaches from 11000 °C to 28000 °C and this ionized gas is called plasma.

The gas or air is heated with arc and the plasma produced by heating gas is used to remove material from the workpiece. So, the whole process is called Plasma Arc Machining.

Fig. Plasma Arc Machining

Mechanism of Metal Removal:

Advantages of Plasma arc Machining:

2. Wide Range of Materials and Thickness:

3. Easy to Use:

4. Economical:

Disadvantages of Plasma Arc Machining:

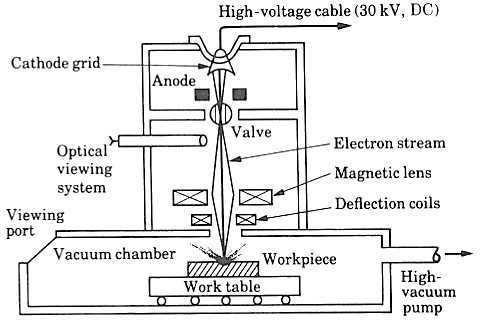

Working of EBM

Fig. Electron Beam Machining

Applications: -

Limitations: -

Advantages: -

References:

1. Kalpakjian and Schmid, Manufacturing processes for engineering materials (5th Edition)-Pearson India, 2014.

2. Taha H. A., Operations Research, 6th Edition, Prentice Hall of India, 2003.

3. Shenoy G.V. and Shrivastava U.K., Operations Research for Management, Wiley Eastern,1994.

4. P. K Mishra, Non- conventional machining, Narosa Publishing House