Unit - 3

Soil Compaction

- This is the simplest method of increasing the performance, characteristics, especially bearing capacity of soil.

- In this method, by the application of force or vibrations, the soil particles are more closely packed thereby increasing the density and hence bearing capacity of the soil.

- Increasing the density of soil by application of mechanical energy is called compaction.

- Compaction is also defined as the process where the density is increased by reducing air voids. It may involve modification of water content or gradation of soil or both.

- The theory of compaction was first developed by R.R. Proctor while building a dam in the USA.

- The principles of compaction developed by him were published in a series of articles in Engineering News record in 1933.

Purpose of Compaction

Compaction of soil is undertaken for a number of purposes. These are listed below:

- To increase density and thereby shear strength and bearing capacity of soil, this is required in the case of slope stability improvement.

- To decrease the permeability of soil, this is required for earth dams.

- To reduce the settlement of structures after construction.

- To reduce danger of piping, this is required for seepage control of earth dam.

- To increase resistance towards erosion of soil by rain and other causes.

Field Situations Where Compaction is Required:

As already stated above compaction is required in tl. Following field situations:

- When sufficient bearing capacity is not available even at a greater depth.

- When the soil is totally cohesionless like dry sand.

- When the soil is highly pervious and is used in water retaining structures.

- In economical foundation design.

- In tunnels, roads etc.

- In special soil types.

Key Takeaways:

This is the simplest method of increasing the performance, characteristics, especially bearing capacity of soil. In this method, by the application of force or vibrations, the soil particles are more closely packed thereby increasing the density and hence bearing capacity of the soil.

- The precept of compaction become advanced via way of means of R. R. Proctor in 1933 throughout production of earth dams in California. The goal of compaction is to reap most viable dry density of the compacted soil. The water content material used for compaction controls the dry density performed.

- At low water content material, the soil is stiff and the debris provide resistance to return back closer, ensuing in low dry density. As the water content material is increased, water bureaucracy a lubricating movie round debris inflicting them to be compacted to a better kingdom of touch ensuing in better dry density. The dry density will increase with boom withinside the water content material till most dry density (MDD) is reached.

- At this stage, the soil debris come to the nearest viable kingdom of touch. On boom of water content material past most desirable moisture content material (OMC), the quantity of soil does now no longer lower in addition via way of means of compaction and water begins off evolved to occupy extra area inflicting a boom withinside the quantity of voids and the whole quantity, and ensuing in a lower in dry density.

- The water content material at which the dry density is most after compaction is referred to as most desirable moisture content material or most desirable water content material. In general, water same to OMC is brought withinside the area for powerful compaction, besides in a few unique cases. Compactive attempt or compaction strength additionally controls the effectiveness of compaction. Higher the compactive attempt, better could be the dry density performed for the equal soil.

- The form of soil and its gradation and plasticity traits additionally impact the diploma of compaction performed. Coarse-grained soils may be compacted to a better dry density than fine-grained soils. Cohesionless soils may be further compacted to a better dry density than cohesive soils. A well-graded soil is compacted greater correctly in comparison to a poorly graded soil. Addition of fines to a coarse-grained soil, via way of means of a quantity simply required to fill the prevailing voids, significantly complements the dry density.

- For the compaction of a given soil, the pattern of soil is compacted withinside the laboratory making use of general compaction strength at exceptional water contents. The dry density of the compacted soil at every of the water content is decided and a graph is plotted with the water content material at the x-axis and the dry density at the y-axis.

- The water content material similar to most dry density is decided, which offers most desirable water content material. For the compaction of soil withinside the area, water same to OMC, or less (dry of OMC) or greater (moist of OMC) water is used relying at the goal of compaction and form of production. Same compaction strength according to unit quantity of soil, as used withinside the laboratory compaction test, is used to compact the soil withinside the area.

- Laboratory compaction tests provide the basis for determining the soil compaction needed to achieve the required engineering properties of soil at site. The aim of these tests is to determine the maximum dry unit weight that can be obtained for the given soil sample with a standard amount of compactive effort.

- The proctor test is used to achieve compaction by impact energy. A hammer is dropped several times on a sample of soil kept in a mould. Standard values of the weight of the hammer, height of blows, number of blows, volume of mould etc are given in the IS Codes for different proctor tests.

- According to R.R. Proctor, the compaction of a soil mass depends on the following 4 factors:

- Type of Soil

- Moisture Content

- Compactive Effort

- Dry Density of the Soil

Standard Proctor test:

The stepwise procedure of standard proctor test is given below:

Preparation of specimen:

- Take 16 kg of air-dried sample passing through 20 mm 15 sieve.

- Apply water to bring water content to about 10 percent, less than the estimated optimum water content.

- Keep the soil in an air tight tin for about 20 hours to ensure thorough mixing of the water with the soil.

- Divide the sample in six equal parts.

Compaction test procedure:

- Clean the mould and weigh it to nearest gram.

- Apply grease to inside of mould, base plate and collar.

- Assemble the mould and base plate together on the floor.

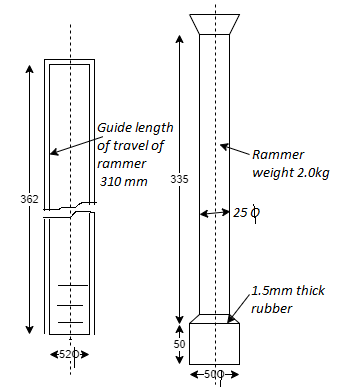

- Take one part of sample and fill the mould in 3 layers giving 25 blows to each layer with the 2.6kg hammer dropping from 310 mm.

- Scratch with spatula each layer before putting in the next layer.

- Remove the collar and trim the compacted soil flush with the top of mould with a straight edge.

- Weigh the mould with the soil to nearest gram. Extract the soil from mould with the extruder.

- Cut the soil sample in the middle and take representative sample in an air tight container from middle of the cut surface.

- Determine the water content.

- Calculate bulk density.

- Calculate dry density using bulk density and water content values by using,

=

=

- Repeat steps 4 to 11 by taking 2 to 3% more water than preceding test.

- For all six samples, record the readings and plot moisture content against dry density.

- Find out dry density corresponding to the maximum point of the curve and corresponding moisture content.

- This dry density is known as maximum dry density (MDD) and the corresponding water content is known as the optimum moisture content (OMC).

Fig 1: Rammer for light compaction for SPT

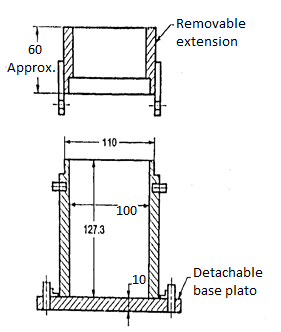

Fig 2: Mould for compaction of SPT

Uses of the Test:

- To obtain OMC and MDD of a given soil sample.

- To get relation between dry density and moisture content for a soil sample.

- To achieve controlled compaction of soil in the field.

Key Takeaways:

- Preparation of specimen

- Compaction test procedure

Modified Proctor Test:

- This Proctor test is used for situations where heavy compaction is indicated.

- The test procedure is almost identical except the three factors, viz: number of layers, weight of hammer and the distance through which the hammer falls. A comparison of standard and modified tests is given below:

Sr no. | Feature | Standard proctor test | Modified proctor test |

1 | Weight of hammer. | 2.6 kg | 4.89 kg |

2 | No. Of layers in which soil is filled in the mould. | 3 | 5 |

3 | Vertical drop of hammer before striking the soil | 310mm | 450mm |

- Mould size in both tests is, 12.73 mm height and 100 mm diameter cylindrical mould and number of blows given in tests is 25.

- Modified Proctor test gives 5 to 10% higher value of dry density and 2 to 3% less OMC as compared to standard test provided that both tests are performed on the same soil.

Key Takeaways:

It is used for situations where heavy compaction is indicated. The test procedure is almost identical except the three factors, viz: number of layers, weight of hammer and the distance through which the hammer falls.

Following factors affect the compaction of soil and the maximum dry density which can be achieved by compaction

- Type of Soil: For the same compactive effort, a well graded coarse-grained soil can be compacted to higher MDD than a uniformly graded soil. As the grain size decreases the OMC values goes on increasing and the MDD values goes on decreasing

- Amount of compaction: If the compactive effort is increased, MDD increases and OMC decreases. But the increase in MDD is not linear with increase in energy.

- Water content: As is evident, if water content goes on increasing the maximum density of compacted soil goes on increasing upto a certain water content. If water content is further increased, the density goes on decreasing.

- Admixtures: Various admixtures like lime, calcium chloride, aggregates in various proportions etc. are used to improve the compaction properties of soil. Lime can increase the dry density by about 5 to 10%

Key Takeaways:

- Type of Soil

- Amount of compaction

- Water content

- Admixtures

- The objective of compaction test is to improve some desirable properties of the soils such as reduction of compressibility, water absorption, permeability, increase in soil strength, bearing capacity etc. and change in swelling and shrinkage characteristics.

Compressibility:

- Saturated clayey sample, compacted on the wet side of optimum, is more compressible than another sample of the same soil, having the same voids ratio, but compacted dry of optimum, when the applied pressure is in low pressure range. This is so because the sample compacted dry of optimum has flocculated structure and requires extra pressure to cause parallel orientation of particles. However, in the high-pressure range, a sample compacted dry of optimum is more compressible than the one compacted wet of the optimum.

Water absorption:

- As optimum moisture content is achieved in soil, its further water absorption characteristic reduces.

Permeability:

- As the density of soil increases, permeability decreases. This is due to increase in compactive efforts and reduction in void ratio. For the same density, fine grained samples compacted dry of optimum are more permeable than those compacted wet of optimum. This is so because these soils have flocculated structure when compacted dry of optimum, and have dispersed structure when compacted wet of optimum.

Shear strength:

- In general, at low strains, strength of cohesive soils compacted dry of optimum is higher than those compacted wet of optimum. Shear strength of compacted clays depend upon dry density. Moulding w/c, soil structure, compaction method, strain used to define strength, drainage condition and type of soil.

Shrinkage:

- Sample compacted dry of optimum shrink less than that of wet of optimum because the soil particles having parallel orientation can pack more efficiently.

Swelling:

- A clayey soil sample compacted dry of optimum water content has high water deficiency and flocculated structure, and hence exert greater swelling pressure and swell to higher water content than the sample of the same density obtained from wet side compaction.

Key Takeaways:

Effects of Compaction on soil properties are as follows:

- Compressibility

- Water absorption

- Permeability

- Shear strength

- Shrinkage

- Swelling

Smooth-wheel (or smooth-drum) rollers

- Suitable for proof-rolling of sub-grades and finishing operations of fills with sandy and clayey soils.

- These rollers provide 100% coverage under wheels with ground contact pressure as high as 310-380 KN/m2.

- Not suitable for the application of high weights of compaction when used on thicker layers.

Pneumatic rubber-tired rollers

- Better than smooth-wheel rollers as they have several rows of closed spaced tires (4 to 6 in a row).

- Used for sandy and clayey soil compaction.

- Compaction action consists of combination of pressure and kneading action.

Sheep foot rollers

- Consist of drums with large number of projections, with area of each projection ranging from 25-85 cm2.

- Effective in compacting clayey soils.

- Contact pressure ranges from 1400-7000 KN/m2.

Vibratory rollers

- These are extremely efficient in compacting granular soils.

- Vibrators can be attached to smooth-wheel, pneumatic rubber-tired, or sheepsfoot rollers to provide vibratory effect to the soil.

- Vibration effect is produced by rotating off-centre weights.

References:

- Principles of Geotechnical Engineering by Braja M. Das, Cengage learning

- Soil Mechanics and Foundation Engineering by K.R. Arora, Standard Publishers

- Soil mechanics and Foundation Engineering by B.N.D. Narsingarao, Wiley India Pvt. Ltd.

- Basic and applied soil mechanics, by Gopal Ranjan, A.S.R Rao, New age International publishers