Unit - 5

Basic of microbiology

- Microbiology is the observe of microscopic organisms (microbes), which can be described as any residing organism this is both a unmarried mobileular (unicellular), a mobileular cluster, or has no cells at all (acellular).

- This consists of eukaryotes, which includes fungi and protists, and prokaryotes. Viruses and prions, eleven though now no longer strictly classed as residing organisms, also are studied.

- Microbiology generally consists of the observe of the immune system, or immunology.

- Generally, immune structures have interaction with pathogenic microbes; those disciplines regularly intersect that is why many faculties provide a paired diploma which includes “Microbiology and Immunology.”

- Microbiology is an extensive time period which incorporates virology, mycology, parasitology, bacteriology, immunology, and different branches. A microbiologist is an expert in microbiology and those associated topics.

- Microbiological methods typically ought to be aseptic and use a number of equipment which includes mild microscopes with a aggregate of stains and dyes. As microbes are in reality required for maximum aspects of human life (together with the air we breathe and the meals we eat) and are capacity reasons of many human diseases, microbiology is paramount for human society.

- Research withinside the microbiology subject is expanding, and withinside the coming years, we must see the call for microbiologists withinside the personnel increase.

- It is predicted that simplest approximately one percentage of the microorganisms found in a given environmental pattern are culturable and the range of bacterial cells and species on Earth continues to be now no longer viable to be determined.

- Recent estimates imply that this range is probably extraordinarily excessive at 5 to the strength of thirty. Although microbes had been without delay found over 3 hundred years ago, the best determination, quantitation, and outline of its capabilities is some distance from complete, given the overpowering variety detected with the aid of using genetic and culture-unbiased means.

Key Takeaways:

Microbiology is the observe of microscopic organisms (microbes), which can be described as any residing organism this is both a unmarried mobileular (unicellular), a mobileular cluster, or has no cells at all (acellular).

The secondary treatment of the sewage is biological treatment. For that the following units are used which can treat not only the domestic sewage but also industrial effluent.

Biological Units Used for the Secondary Treatment of Sewage:

- The biological methods used for the secondary treatment of the sewage are :

A: Activated Sludge Limits

B: Aerated Lagoons

C: Bio towers

D: Solid Contact Basins

E: Trickling Filters

F: Rotating Bio contactors

Key Takeaways:

The secondary treatment of the sewage is biological treatment. For that the following units are used which can treat not only the domestic sewage but also industrial effluent.

- An Aerobic process refers to a procedure that calls for the presence of oxygen or air instead of an anaerobic procedure that doesn't require it. An instance of a cardio procedure is cardio breathing.

- The organic cellular conducts breathing in a procedure known as mobile breathing. It is a sequence of metabolic methods that take vicinity inside a cellular wherein biochemical power is harvested from natural substance (e.g. Glucose) and saved as power carriers (ATP) to be used in power-requiring sports of the cellular.

- The cellular appears to “respire” in a manner that it takes in molecular oxygen (as an electron acceptor) and releases carbon dioxide (as an give up product).

- Since the procedure takes place withinside the presence of oxygen it's miles stated to cardio. Conversely, mobile breathing takes vicinity in different organisms that employ different molecules as electron acceptor in place of oxygen.

- In this case, the very last electron acceptor isn't oxygen and consequently the procedure is defined as anaerobic. The cardio kind is greater green than the anaerobic procedure with regards to the variety of ATP internet gain.

Key Takeaways:

An Aerobic process refers to a procedure that calls for the presence of oxygen or air instead of an anaerobic procedure that doesn't require it. An instance of an cardio procedure is cardio breathing.

- The Activated sludge process was developed in the year 1914 in England, by Ardern and Lockett. It was named so, because the process is involved in the production of an activated mass of micro-organism, which is capable of stabilizing the waste aerobically, through a lot of modifications have taken place in the process the fundamental principles have remained the same.

- The term Activated sludge, indicates that the sludge is obtained, by settling the sewage in presence of abundant oxygen.

- The sludge is biologically active and it has a number of aerobic bacteria and some other micro-organism having an unusual property of oxidising the organic matter.

Properties of Activated Sludge:

- A: They have the fertilizing constituents

- B: The degree of aeration is indicated by the colour of the activated sludge. i.e. Light brown colour indicates, under aerated sludge. Golden brown colour indicates, well-aerated sludge and Muddy-brown colour indicates, over-aerated sludge.

- It can hold the moisture up to 95% to 97%/

Process of Activated Sludge:

- Step 1: The activated sludge is mixed with raw or partially treated sewage.

- Step 2: When the activated sludge is mixed properly with the sewage having sufficient quantity of oxygen, the micro-organisms in the activated sludge, go on multiplying vary rapidly.

- Step 3: This helps to oxidize the organic solids in the sewage.

- Step 4: Suspended and colloidal matter the sewage, gets coagulated to form a readily settle able precipitate.

- Step 5: When the precipitate settles down, the effluent is cleared from any type of organic matter; so if required the effluent is given the treatment chlorination. The part of the sludge is sent for recirculation and the remaining sludge goes to the digestion tanks.

- Step 6: This digested sludge is totally harmless and can be sent to the drying beds.

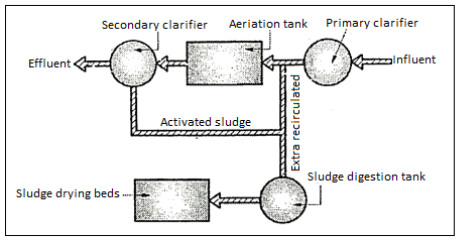

Flow Chart of the Activated Sludge Process:

Fig 1: Flow Chart of Activated sludge process

- The flow chart of the activated sludge. Process indicates the stages of purification of the effluent as given below.

- Step 1: The influent is sent to the primary clarifier for proper mixing of the activated sludge and the raw or the settled sewage.

- Step 2: A part of this well mixed sewage is sent to sludge digestion tank for extra recirculation, through which it is sent to the drying beds.

- Step 3: The remaining well-mixed sewage is sent to the Aeration Tank (or Aeration Chamber) for proper agitation

- Step 4: The agitated or aerated sewage and sludge is sent to the 2nd clarifier. In this secondary clarifier the sludge is allowed to settle down. A part of this activated sludge is sent back to the process of recirculation (to be carried in the sludge digestion tank) and through that it goes to the final sludge drying beds and the effluent is sent to natural stream (which is harmless and does not pollute the natural surface stream).

Operational Problems and Maintenance in ASP:

- Many problems in the operation process of ASP can be developed which affect the quality of the effluent. The main function of the A.S.P system is to develop and to maintain the mixed microbial culture called as the Activated Sludge.

- The failure of A.S.P. Efficiency is due to two major operational problems.

- Rising sludge

- Bulking sludge

- Let us discuss these problems and find out the means to control them for better maintenance.

(A) Rising sludge

- This is commonly referred as clumping or ashing or rising sludge.

- The floating solids are usually the result of high sludge age ie there are too many solids in the systems or the long detention for the solids in the final clarifier.

Solution:

- Decrease the solid inventory 1.e. By increasing wasting rate

- Remove the solids from the final clarifier quickly.

(B) Bulking sludge

- It is caused by overloading of siudge i.e. high organic loading.

- The changes in the pH, low dissolved oxygen level. Seasonal variation or improper balance among Carbon Nitrogen and Phosphorous in the waste etc. are some of the other causes of bulking of sludge.

Solution

- The problem of bulking of sludge is not easy to deal because it is not easy to find out the cause of bulking The careful review of the operational records with respect to pH loading or D. O. Level is always useful to find out the cause of bulking causing poor operational conditions.

- If the bulking of sludge is caused by overloading the best method which can be used to reduce the overloading is the prechlorination of the primary tank influent.

- The chlorination of return activated sludge can control the filamentous bulking.

- This would help to the sludge volume index. The extensive wasting of biological sludge also helps to control the bulking of sludge.

Key Takeaways:

The Activated sludge process was developed in the year 1914 in England, by Ardern and Lockett. It was named so, because the process is involved in the production of an activated mass of micro-organism, which is capable of stabilizing the waste aerobically, through a lot of modifications have taken place in the process the fundamental principles have remained the same.

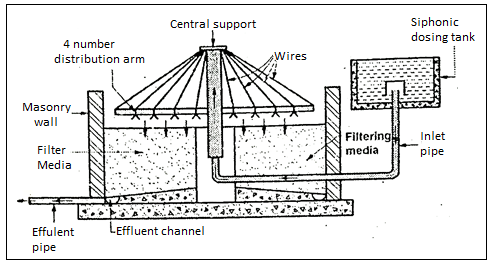

The Principles of Trickling Filters:

- These filters by the functions, also are known as sprinkling filters.

- The sewage is allowed to sprinkle or trickle over the bed of hard, rough and coarser material.

- The waste which has been filtered is collected through the under drainage system.

- Under the aerobic conditions, the organic matter is oxidized.

- A bio-film i.e. bacterial film is developed around the particles of the filtering media.

- The colour of this film is varied i.e. in some cases it is blackish and in other cases it is greenish or yellowish. The film consists of microorganisms like bacteria, algae, fungi, protozoa, lichens etc.

Fig 2: Circular Type Trickling Filter

Types of Trickling Filters:

- On the basis of the rate and capacity, these filters can be divided into two types, such as,

- Standard rate trickling filters.

- High rate or high capacity trickling filters

- On the basis of their shape we can classify them into two as

- Circular type trickling filters.

- Rectangular type trickling filters

On the basis of stages Trickling filters can be classified as:

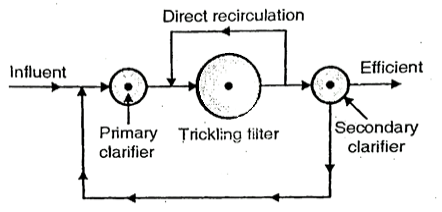

a) The single stage trickling filter

Fig 3: The single stage trickling filter (flow diagrams)

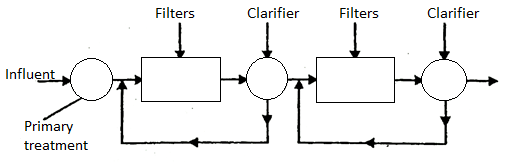

b) Two stage Trickling Filter or high rate trickling filter

Fig 4: The two stage trickling filter [flow Diagram]

Material used for Trickling Filters or Different T.F Media:

- Crushed stones or clinkers or specially manufactured material is used as the filter media.

- The cubical shaped and uniformed sized media is used. Generally the size of the media varies between 30 and 80 mm.

- The R.C.C floor with a thickness of 10 to 15 cm. Is constructed with a slope towards the central drain and the sewage is collected through the under-drainage system.

- Fixed or movable distributers are provided to have even distribution of the influent over the media. For these trickling tanks automatic closing tanks are provided.

- The application of the sewage is totally discontinued for a period of 3 to 10 minutes.

- The working of trickling tank is simple the maintenance cost is less and it gives the best results, as the outflow is highly nitrified and it is stabilized.

- The only drawback of this system has that it needs a huge space; and the construction cost of the trickling tank is high. It can treat the sewage which already has got the primary treatment.

Treatment Procedure of Sewage:

The treatment of sewage is carried in three stages; as given below:

- Primary sedimentation

- Filtration

- Post filtration treatment

A: Primary sedimentation

- In this stage the large, suspended particles are removed from the sewage.

- This helps to avoid clogging of the media. It also helps to have better oxidation of finely derived matter of sewage in the filter.

B: Filtration

- The trickling filters remove the total solids of the sewage, but we must know that the purpose of the trickling is to change the characteristics of the suspended solids, rather than to remove them totally from the sewage.

C: Post Filtration treatment

- The secondary clarifiers are located after the units of secondary treatment, known as tricking filters or activated sludge process units.

- So, the secondary clarifiers are provided for post filtration treatment or for treating the treated sewage, for making it good, to discharge it into the natural surface stream.

- These secondary clarifiers are also called as 'final clarifiers' to indicate the post filtration treatment.

Design Aspect of Trickling Filters:

- Following are the design aspects of the trickling filters

- Depth

- Numbers

- Rate of filtration loading

- The Emperical Relationship

A: Depth

- The effective depth is kept between 1.8 meters and 2.4 meters.

- If it is more than 2.4 meters it does not give any additional advantage and under special conditions (to avoid pumping) the depth is kept below 1.8 meters.

B: Numbers

- To have continuous functioning it is better to have a stand-by unit So, for the purpose of rearing, one of the two units can be taken out without interrupting the process

C: Rate of filtration loading

- The following units of measurements are used for calculating the loading of trickling filters.

- Kg of BOD, per volume of filter bed:

i.e. 1000 to 2200 kg of BOD per ha-metre/per day

B. Kg of BOD per volume of filter media

i.e. 15 to 30 Kg of BOD. Per day/per 100 m3 of filter media.

C. Surface area of filter bed

i.e 25 to 40 million litres, per ha/per day.

D. Volume of filter bed

i.e. 7.50 to 22.50 million liters/per ha meter/per day

D: The Emperical Relationships

- Generally the Trickling Filter Design is based on the empirical relationship, to find the required filter volume, for at designed degree of wastewater treatment.

- Following are some of the equations used to calculate the required filter volume.

A: NRC Equation (National Research Council)

B: Ranking Equation

C: Eckentilder Equation.

D: Galler and Gotaas Equation

- Among the above, NRI Rankines equations are generally used. N.R.L. Equations give satisfactory values, when there is no re-circulation.

- When seasonal variations in temperature, are not large and fluctuations with high organic loading Rankin's equation is mainly used for high rate filter.

NRC Equations

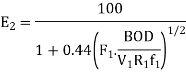

- These are applicable to both, high rate and low rate filters. The efficiency of single stage or first stage of two stage filter (E₂) is given by

- For second stage filter the Efficiency (E3) is calculated by

Where in

% of Efficiency in BOD removal of single or first stage of two stage filter

% of Efficiency in BOD removal of single or first stage of two stage filter

=% of Efficiency of second stage filter

=% of Efficiency of second stage filter

BOD loading of settled raw sewage in single stage of the two stage filter (in kg/d)

BOD loading of settled raw sewage in single stage of the two stage filter (in kg/d)

=

= BOD loading on second stage filters.

BOD loading on second stage filters.

Rf₁ =Recirculation factor for the first stage.

Rf₂ = Recirculation factor for the second stage.

R₁ = Recirculation Ratio for the first stage filter.

R₂ = Recirculation Ratio for the second stage filter.

Rankin's Equation

- It is also known as, Tentative Method of Ten States in U.S.A with wide variation in the temperature conditions from Atlantic coast to pacific coast of U.S.A.

Advantages of Trickling Filters:

- The effluent is highly nitrified and it is stabilised. So, for the dilution a small quantity of water is needed.

- As these filters do not have many mechanical equipment, the maintenance cost is less.

- The moisture contents of the sludge is about 99%, obtained from the tricking filters.

- For running the mechanical equipments less power (electric power) is needed.

- These filters can deal with sewage of different composition and different concentration because their flexible nature in operation.

- They can reduce about 75% of B.O.D. And about 80% of colloidal matter from the sewage.

- No skilled supervision is needed, as its working is very simple.

Disadvantages of Trickling Filters:

- The construction cost is high.

- The loss of head, through the filter is high, so it is necessary to install the siphonic dosing tanks.

- It may cause, bad odour and may develop house flies. So, it is necessary to use insecticides to control the house-flies.

- It needs to have the primary treatment of the sewage. So the raw sewage can not be treated directly in this method.

- It needs larger areas (than the activated sludge process) So it can not be applied in the urban areas, where the land-cost is too high.

Key Takeaways:

These filters by the functions, also are known as sprinkling filters. The sewage is allowed to sprinkle or trickle over the bed of hard, rough and coarser material

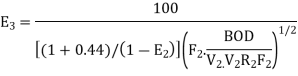

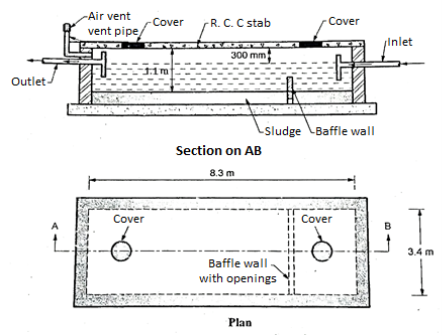

Fig 5: Rotating Biological Contactor

- Rotating biological contactor (RBC) is a biological treatment process.

- It is used in the treatment of wastewater. It is used to move the pollutants before the wastewater is discharged into the stream river or lake. In this process the wastewater is allowed to come in contact with the biological medium for this removal. So, R.B.C is a Secondary Biological Process.

- The microorganisms observed in the aerated and facultative ponds are very much diverse than those observed in many other biological treatment processes, because of the varying environmental conditions.

- We can form three functional groups of the microorganisms,They are all aerobic bacteria,

- Freely Dispersed, Single Bacteria

- Flock Forming Bacteria

- Filamentous Bacterial

- All the above microbes present in aerobic conditions have the same function i.e. Oxidize Organic Carbon i.e. the using D.O. For B.O.D. And produce CO, and also to produce new bacteria.

Key Takeaways:

Rotating biological contactor (RBC) is a biological treatment process.

- Anaerobic wastewater remedy is a organic procedure in which microorganisms degrade natural contaminants withinside the absence of oxygen.

- In a fundamental anaerobic remedy cycle, wastewater enters a bioreactor receptacle. The bioreactor includes a thick, semi-strong substance called sludge, that is made out of anaerobic micro organism and different microorganisms.

- These anaerobic microorganisms, or “anaerobes,” digest the biodegradable count gift withinside the wastewater, ensuing in an effluent with decrease organic oxygen demand (BOD), chemical oxygen demand (COD), and/or overall suspended solids (TSS), in addition to biogas byproducts.

- Anaerobic wastewater remedy is used to deal with numerous business effluent streams from agricultural, meals and beverage, dairy, pulp and paper, and fabric industries, in addition to municipal sewage sludge and wastewater.

- Anaerobic technology are normally deployed for streams with excessive concentrations of natural material (measured as excessive BOD, COD, or TSS), regularly previous to cardio remedy.

- Anaerobic remedy is likewise used for specialised applications, consisting of remedy of waste streams with inorganics or chlorinated organics, and is well-appropriate for treating heat business wastewater.

Key Takeaways:

Anaerobic wastewater remedy is an organic procedure in which microorganisms degrade natural contaminants withinside the absence of oxygen.

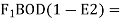

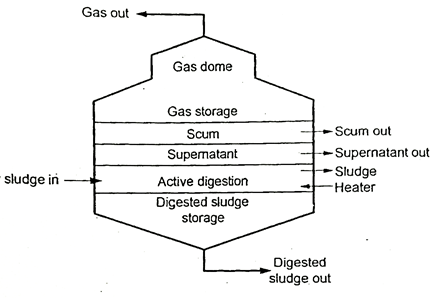

- It is series of biological processes in which microorganisms break down.

- The biodegradable material in absence of oxygen (So, it is called as "Anaerobic Digestion!") one of the important end product in Biogas which is used for generating electricity and heat.

- It can be processed into renewable natural gas and a transportation fuel. In this process separated digested solids can be used as green manual.

Fig 6: Conventional Sludge Digestor

Biological Process

- The digestion process starts with the bacterial hydrolysis of the input material, to breakdown the insoluble organic polymers e.g. carbohydrates to make them available for other bacteria.

- Acidogenic bacteria convert, the sugars and amines acids into carbon dioxide hydrogen ammonia and other organic acids.

- Then the acetogenic bacteria these acids into acetic acid together with additional ammonia and carbon dioxide.

- Finally, metnanogens convert these conducts is to methane and carbon dioxide.

Types of Anaerobic Digesters

- Four commonly used digesters are as follows,

- Fixed Dome Digester

- The Flexible Bag Digester

- The Floating Gas Holder Digester

- The prototype digester

- High Rate Digester

1. Fixed Dome Digester

- It is a very popular type of biogas digester as:

- It has very low cost of construction

- The local material can be used for the construction.

- It has low maintenance cost:

- To avoid the formation of crack and leakage of gas, it is always better to seal the inside of the dome with appropriate living material.

2. The Flexible Bag Digester

- It is rarely used in India. It may be used in India in future due to less operational problem easy and low cost of installation.

- It has a high durability and it gives stable gas pressure.

3. The Floating Gas Holder Digester

- It has cost its popularity due to its high construction cost and its corrosion and leakage problem of gas.

4. The prototype digester

- This type of digester is cheap and small in size where the final product i.e. the bio-gas generation is not very important this type of digester is used.

5. High Rate Digester

- High Rate Anaerobic Digester, realizing anaerobic bacteria, through a variety of means.

- The process decouples the Hydraulic Retention Time (H.R.T) from the Solid Retention Time (S.R.T). This process of S.R.T/H.R.T ratio, can be improved by producing a concentrated recycle stream without adversely affecting the anaerobic bacterial consortia.

Design Parameters of an Anaerobic Digester:

- As already stated, the anaerobic digestion depends upon the biological activities of relatively slowly reproducing methanogenic bacteria. So sufficient time must be given for the reproduction of these bacteria.

- The size of the digester should be designed such to get, maximum biogas with minimum capital investment.

- It must have to give optimum performance in summer and also in winter and must be enough large to avoid washout'

- The main criteria for designing the digester is the mean solid resistance time which is defined as

- "It is the mass of bacterial cells, in a digester, divided by the mass of cells, removed from the digester per day,"

- This is generally equivalent to the Hydraulic Retention Time (HR.T)

- The volume, the temperature, the PH, the velocity; material to be digested are the major parameters to be considered while designing the Anaerchic Digester.

Capacity of the Digester:

The digester capacity is based on the following factors:

- The digestion period i.e. The cell residence time or the solid retention time.

- The volumetric loading

- The population to served

- The observed volume reduction

Let us discuss the factors, mention above in brief

1.The digestion period i.e. The cell residence time or the solid retention time

- Generally the standard rate digesters are designed for the digestion period, varying between 30 and 60 days.

- The high rate anaerobic digester are designed for a period of 10 to 20 days as, the solid are adequately stabilized in this period.

2. The volumetric loading

- The volumetric loading is expressed in kg. Total volatile solids added per day per m³ of the digester capacity.

3. The population to be served

- On the total population the capacity of digester capacity can be calculated on the basis of average 120 grams solids/ capita/day.

- This has a variation from a community to community.

- It depends upon the standard of living and the economic activity of the community.

4. The observed volume reduction

- In the process of digestion, the volume of the treated solids is reduced as some of it is returned back the plant.

- After considering the above factors the capacity of the digester to be fit for a community is decided.

Key Takeaways:

It is series of biological processes in which microorganisms break down. The biodegradable material in absence of oxygen (So, it is called as "Anaerobic Digestion!") one of the important end product in Biogas which is used for generating electricity and heat.

- High Rate Anaerobic Digester, realising anaerobic bacteria, through a variety of means.

- The process decouples the Hydraulic Retention Time (H.R.T) from the Solid Retention Time (S.R.T).

- This process of S.R.T/H.R.T ratio, can be improved by producing a concentrated recycle stream without adversely affecting the anaerobic bacterial consortia.

- The anaerobic sludge digestion process is carried out by microorganisms under anaerobic conditions i.e. in this process oxygen is not used.

- In this process the sludge is treated to reduce the organic waste so it becomes easy to dispose the sludge the anaerobic digestion is more economical than aerobic digestion.

Steps of Sludge Digestion:

- The process of Anaerobic digestion has three steps or stages. They are as follows

- Step No. 1: It involves liquifying of the solid material in the sludge. This process is called as hydrolysis.

- Step No. 2: It is rapid and it involves the digestion of the soluble solids. The process is carried out at molecular level by acid i.e. Acetic propionic and Butyric acid etc.

- Step No. 3 or final step: It is known as gasification stage, the organic acid produced in the 2nd step is used by some microbes to produce gases such as methane and carbon dioxide. So the process is also known as methanogenesis as it produces methane.

- The anaerobic digestion takes place at 30° to 38° degree Celsius. All the stages either can be carried in single stage digestion system or in two stage digestion system.

Key Takeaways:

The anaerobic sludge digestion process is carried out by microorganisms under anaerobic conditions i.e. in this process oxygen is not used.

- The sludge or the garbage needs to be disposed very carefully to avoid any type of pollution and to avoid any unhygienic conditions and to prevent any type of public health problems.

- The method to be used for disposing the sludge depends upon its nature (quality) and its volume.

- It is necessary to have a careful analysis of the sludge before any method of disposal of that sludge is selected.

- Following are the methods used to disposed off the dry sludge and the garbage.

- Controlled tipping

- Disposal into sea

- Filling of the low-lying areas.

- Incineration

- Mechanical compost plant

- Pulverization

- Trenching

Controlled Tipping:

- In this methods the sludge is tipped in hollows to a depth of about one to two metres.

- In these hollows the coarse material is tipped at their bottoms and finer material at their tops. These tips are covered by ash or earth for about one day.

- This leads to the action of fermentation through the anaerobic bacteria under the seal and this action is completed within a period of one year.

- After the process of fermentation is completed, the site of disposal of sludge is free from any type of germs and the site is available for any future development. Generally for a depth of about 2 meters, for the controlled tipping.

- The requirement of area is about 0.50 m² and it may vary upto 0.60 m²/per capita/per year.

Disposal into Sea Advantages:

- It can be used by the settlements which are located near the sea coast. It is a cheap method but it needs a careful disposal of the sludge into the sea. Following point, must be observed before disposing the garbage or sludge into the sea.

- A: It must be discharged at such point and at such time that due waves, currents tides it should not return to the coast.

- B: It must be carried away from the coast for about 15 to 20 km away and the depth of the sea-floor must be atleast 30 metres or more, where in the sludge is not be disposed off. The direction of the ocean current also should be thought about.

- It is a cheap, easy method to dispose off the sludge, but is has following disadvantages.

Disadvantages of Disposal into Sea:

High tide conditions

- During the high tides, the bulky but light material, which float on the surface of sea water are brought back on the coast.

Transport of garbage or sludge

- The sludge is needed to be transported into the deep sea for getting it disposed off.

- During the S.W. Monsoon season it becomes difficult for the ships or barges to carry out the transport in the stormy weather conditions.

- Under such conditions, the sludge is required to be stored (till the sea/weather conditions calm down) or to be treated by some other methods.

Filling of Low-lying Areas

- In this method the sludge is collected, conveyed and dumped in the areas which are low lying, near the locations.

- It is covered with a blanket of ash or earth to avoid the flies and vermin. If, the low lying area is available in ample this method can be applied which is a cheap method.

Advantages of filling methods:

- No separation of sludge is required.

- It is most economical method and still a simple method.

- By using this method, the areas under, water logging conditions can be reclaimed.

- No by products are developed so no further methods of disposal or treatment is required.

Disadvantages of filling method

- The insecticides are to be used to prevent fly nuisance.(This adds to the cost).

- If the garbage or sludge has undesirable matter like plastic, unused medicine, paints, sanitary material etc, it creates a problem to the nearby settlements, as some of the soluble toxic material may step down to pollute the underground water, which is used for drinking and other domestic requirements and can create the health problem.

- Low-lying areas are not easily available.

- Due to mixing of material a gas is developed which is called as fill gas. It has a foul odour and it may explode.

Incineration Method

- In the incineration plant the refuse is burnt. It is used for the hazardous waste.

- The initial cost of incineration plant is high still it has a lot of advantages as given below.

Advantages:

- It needs less labour supply.

- The heat generated through the incineration can be used for some other purpose.

- It takes the care of the public health.

- The cost goes reducing as it is used for a longer period of time.

Disadvantages:

- If it is not operated properly it may lead to develop smoke, odour, and ash.

- Skilled labour is required to run the plant.

- It needs to be located away from the settlements to avoid the air-pollution, but, so it adds to the transport cost.

Mechanical Composting Plant:

- It converts the waste into the useful manure. The purpose of this method is to develop a plant which can produce methane to support the chemical fertilisers. (to reduce the cost of agricultural inputs). It has following advantages.

Advantages of composting

- There are no health hazards.

- Certain plant-diseases can be put under control.

- By using the composing method, the soil properties can be improved. e.g. It has 0.3% of nitrogen, 0.5 to 0.8% of phosphorus, 0.6 to 0.9% of potassium. So, it enriches soil to be used for cultivation.

- Cost of compost is lesser than the chemical fertilisers.

Pulverisation:

- Without changing its chemical composition, in this method, it is converted into powder, which can be used as a fertiliser.

- It has a high density so the transport cost is reduced.

- It can also be used for land re-claimation.

Trenching:

- In this method, the dry refuse is dumped into trenches and it is converted into compost. These trenches are about 3 to 12 metres long, 2 to 3 metres wide and 1 to 2 metres deep.

- The compost developed through this method may prove to be harmful to the soil (if the original refusal has harmful contents).

- Still it is a popular method to dispose off the garbage and other refuse as it is a simple and cheap method of treatment.

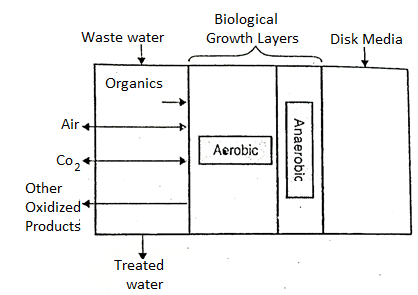

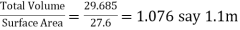

Q. Design a septic tank for a hostel housing 125 persons. Also design the soil absorption system for the disposal of the septic tank effluent, assuming the percolation rate as 20 min per cm. Desludging period once in a year.

Soln.:

Given data:

Number of persons= 125;

Desluding pericd= 1 year

Percolation rate = 20 min/cm

1. Surface area

The estimated peak discharge for 125 persons

The estimated peak discharge for 125 persons = 300 lpm

Surface area of tank @ 0.92 m² for every 10 1pm=

2. Total depth of septic tank

Assume depth of tank for sedimentation = 0.3 m

Provide free board = 0.3 m.

Total volume of tank:

(i) Volume for sedimentation : 27.6 x 0.3= 8.28 m²

(ii) Volume for digestion: 0.032 × 125 = 4.00 m3

(iii) Volume for sludge storage: (7.3/100)x 125= 9.125 m²

(iv) Volume for Free board: 27.6 x 0.3= 8.28 m²

Total volume = 8.28 +4.00 +9.125 +8.28 = 29.685 m²

Total depth of tank =

∴Provide depth =1.1m

3. Dimension of septic tank

Consider L/B ratio as 2.5,

∴L/B = 2.5

2.5B X B = 27.6

∴B = 3.32 m say 3.4m

Provide B = 3.4 m and L = 8.3 m

Hence septic tank dimensions are 8.3 m x 3.4 m x 1.1 m

Fig. Shows the septic tank with design dimensions.

Design of absorption system

We know,

=

= =29.07 lpd/m2

=29.07 lpd/m2

Assume sewage flow @150 lpcd.

Total flow per day=120 x 150 = 18000 lpd

Total trench area=18000/ 29.07 = 619.2 m²

Fig 7: Septic Tank

- Sewerage (or sewage machine) is the infrastructure that conveys sewage or floor runoff (stormwater, meltwater, rainwater) the use of sewers.

- It encompasses additives inclusive of receiving drains, manholes, pumping stations, hurricane overflows, and screening chambers of the mixed sewer or sanitary sewer.

- Sewerage ends on the access to a sewage remedy plant or on the factor of discharge into the environment. It is the machine of pipes, chambers, manholes, etc. that conveys the sewage or hurricane water.

- In many cities, sewage (or municipal wastewater) is carried collectively with stormwater, in a mixed sewer machine, to a sewage remedy plant. In a few city areas, sewage is carried one after the other in sanitary sewers and runoff from streets is carried in hurricane drains.

- Access to those systems, for renovation purposes, is commonly thru a manhole. During excessive precipitation intervals a sewer machine might also additionally enjoy a mixed sewer overflow occasion or a sanitary sewer overflow occasion, which forces untreated sewage to waft immediately to receiving waters. This can pose a critical chance to public fitness and the encompassing environment.

Key Takeaways:

Sewerage (or sewage machine) is the infrastructure that conveys sewage or floor runoff (stormwater, meltwater, rainwater) the use of sewers.

Biological Units Used for the Secondary Treatment of Sewage:

- The biological methods used for the secondary treatment of the sewage are:

A: Activated Sludge Limits

B: Aerated Lagoons

C: Bio towers

D: Solid Contact Basins

E: Trickling Filters

F: Rotating Bio contactors

Steps of Sludge Digestion

- The process of Anaerobic digestion has three steps or stages. They are as follows

- Step No. 1: It involves liquifying of the solid material in the sludge. This process is called as hydrolysis.

- Step No. 2: It is rapid and it involves the digestion of the soluble solids. The process is carried out at molecular level by acid i.e. Acetic propionic and Butyric acid etc.

- Step No. 3 or final step: It is known as gasification stage, the organic acid produced in the 2nd step is used by some microbes to produce gases such as methane and carbon dioxide. So the process is also known as methanogenesis as it produces methane.

- The anaerobic digestion takes place at 30° to 38° degree Celsius. All the stages either can be carried in single stage digestion system or in two stage digestion system.

References:

- Environmental Enginnering, Peavy and Rowe, MC Graw hill Publications

- Optimal Design of Water distribution networks, P.R.Bhave, Narosa Publishing house

- Water supply Engineering, Harold Eaton Babbit & James Joseph Doland, Tata MC Graw Hill