Unit - 1

Industrial Control examples

A control system is a set of mechanical or electronic devices which control the other devices. In control system behaviours of the system is desired by differential equations.

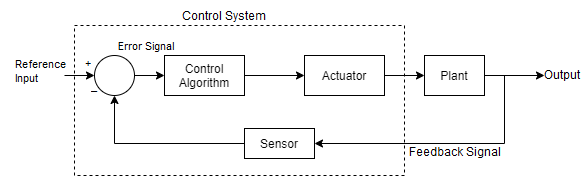

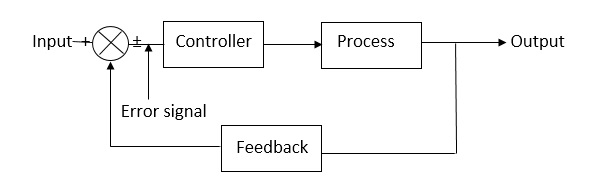

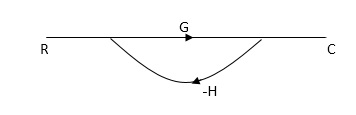

Fig 1 Block diagram for closed loop control system

The above figure shows a feedback system with a control system. The components of control system are:

i) The actuator takes the signal transforms it accordingly and causes some action.

Ii) Sensors are used to measure continuous and discrete process variables.

Iii) Controllers are those elements which adjust the actuators in response to the measurement.

Key takeaway:

1) The feedback control system is having a sensor.

2) These sensors help to improve accuracy by generating error signal.

Electrical System

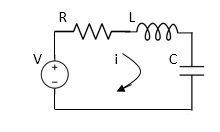

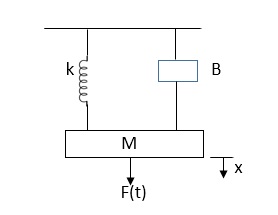

Fig 2 RLC Circuit

Example-1 For circuit shown above find value of current I?

Applying Kirchoff’s voltage Law

V= Ri +Ldi/dt +1/c

V= Rdq/dt + L d2q/dt2+q/c

Now By kirchoff’s current low

I= V/R+ 1/L  + cdv/dt

+ cdv/dt

But V= dø/dt

I= 1/R dø/dt + 1/L ø+cd2ø/dt2

But v= dø/dt

I= 1/R dø/dt+ 1/L. ø+c d2ø/dt2

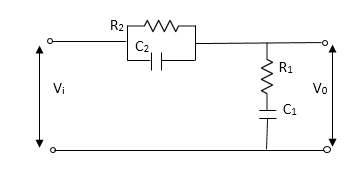

Example-2 For the given mechanical system below draw the analogus system (force. Voltage )& find V0(s)/V1(s)

Soln.

Let Z1 = R2 11 1/c2

=R2*1/c2s/R2+1/c2s

Z1= R2/1+R2c2s

Let Z2 = R1+1/c1s

Z2= 1+R1c1s/c1s

V0(s)/vi(s) = z2/z1+z2

= 1+R1c1s/c1s/R2/1+R2c2s+1+R1c1s/c1s

V0(s)/v0(s) =(c1+R1c1s) (1+R2c2s)/R2c1s+1+sR1c1s2R1R2c1c2

Mechanical System

(a) Translational system

(b) Rotational system

Translational system

The motio that takes place along a straight line is called translational the forces that resist motio are

- Inertia: A body with mass ‘N’ acceleration ‘a’ will produce inertia fm(t)= malt N’ acceleration ‘a’ will produce inertia

fm(t)= M a(t)

In terms of velocity

Fm(t) = M dv(t)/dt

In terms of displacement

Fm(t)= Md2/dt2µt

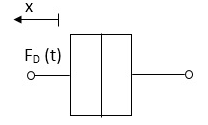

- Damping force: The damping force is proportional to velocity for vis case function

F0(t) = B(t) = B dx(t) /dt

B Damping coefficient N/M sec

Fig 3 Damping Force

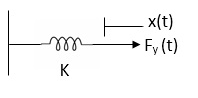

- Spring force: A spring stores potential energy. The releasing force of a string is proportional to the displacement.

Fk(t)  x(t)

x(t)

Fk(t) = k x (t)

Fig 4 Spring Constant

Fk(t) = k

K = string constant N/m.

(b)Rational System:- The motion of a body about a fixed axis is called as Rotational motion. The types of lorques which can resist the motion are

i) Inertial Torque:- The inertial torque is the product of moment of inertia I and angular acceleration .

TI(t) = J (t)

(t)

TI(t) = Jd/dt w(t)

TI(t) = Jd2ø(t)/dt2(N-m)

W (t) – Angular velocity

Ø(t) = Angular displacement

(ii) Damping Torque :- it is product of damping efficient B and angular velocity w

T0 (t) = B w(t)

T0(t) = B d/dt ø(t)

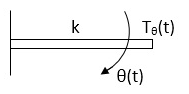

(iii) Spring Torque :- It is the product of torsional stiffness and angular displacement

Tø(t) = k ø(t)

K = N.m/rad

Fig 5 Rotational Spring Constant

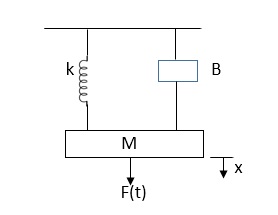

D’Alembert’s Principle

For anybody, the algebraic sum of externally applied forces and the forces resisting motion in any given direction is zero.

Ex.

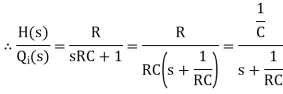

Fig 6 Mechanical System

In above figure applying D’Alemberts principle to write the equation of motion

As force f(t) acts downwards all other forces (of k,B,x)acts Opposite to it to considering f(t) as the and all other forces negative.

F(t)+fm (t) + fD(t) +fx(t) =0

f(t)- M d2x(t)/dt2+B dx(t)/dt +x(t)

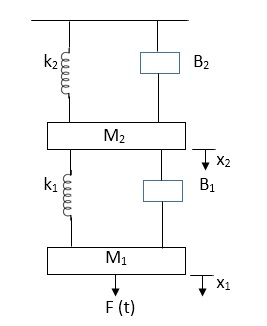

Example-1 Draw the free body diagram and write the differential equation for system below.

Fig. 7

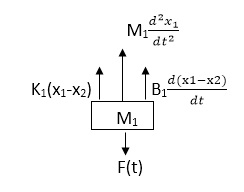

Soln: The free body diagram for M1 will be

Fig 8 FBD for Mechanical System

F(t) = M1 d2/dt2x1+ B1 d/dt (x1-x2)+ k1(x1-x2)

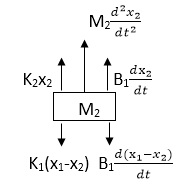

Similarly for M2we have

Fig 9 FBD for Mechanical System

K1(x1-x2) + B1d/dt(x1-x2) = k2x2+M2d2/dt2+B2dx2/dt

Thermal

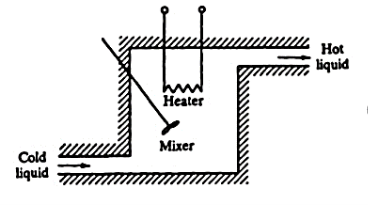

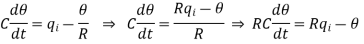

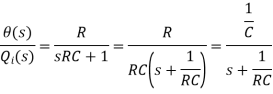

Thermal systems are those that involve the transfer of heat from one substance to another. The model of thermal systems is obtained by using thermal resistance and capacitance which are the basic elements of the thermal system. The thermal resistance and capacitance are distributed in nature. But for simplicity in analysis lumped parameter models are used.

Consider a simple thermal system shown in the below figure. Let us assume that the tank is insulated to eliminate heat loss to the surrounding air, there is no heat storage in the insulation and liquid in the tank is kept at uniform temperature by perfect mixing with the help of a stirrer. Thus, a single temperature is used to describe the temperature of the liquid in the tank and of the out flowing liquid. The transfer function of thermal system can be derived as shown below.

Fig 10 Thermal System

Let θ1 = Steady state temperature of inflowing liquid, °C

θ0 = Sandy state temperature of outflowing liquid, °C

G = Steady state liquid flow rate, Kg/sec

M = Mass of liquid in tank, Kg

c = Specific heat of liquid, Kcal/Kg °C

R = Thermal resistance, °C - sec/Kcal

C = Thermal capacitance, Kcal/°C

Q = Steady state heat input rate, Kcal/Sec

Let us assume that the temperature of inflowing liquid is kept constant. Let the heat input rate to the thermal system supplied by the heater is suddenly changed from Q to Q + q1. Due to this, the heat output flow rate will gradually change from Q to Q + q0. The temperature of the outflowing liquid will also be changed from θ0 to θ0 + θ.

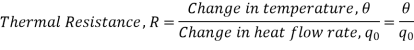

For this system the equation for q0, C and R is obtained as follows,

Change in output heat flow rate  = Liquid flow rate, G × Specific heat of liquid, c × Change in temperature θ

= Liquid flow rate, G × Specific heat of liquid, c × Change in temperature θ

Thermal capacitance, C = Mass, M x Specific heat of liquid, c = Mc

On substituting for qo from equation (1) in equation (3) we get,

On substituting for qo from equation (1) in equation (3) we get,

In this thermal system, rate of change of temperature is directly proportional to change in heat input rate.

The constant of proportionality is capacitance C of the system.

Equation (5) is the differential equation governing system. Since, equation (5) is of first order equation, the system is first order system.

From equation (3) , R = θ/q0

q0 = θ/R

On substituting for q0 from equation (6) in equation (5) we get,

Let, L {θ} = θ(s); L{dθ/dt} = sθ(s) ; L{q1} = Q1(s)

On taking Laplace transform of equation (7)

RC s θ(s) + θ(s) = R Q1(s)

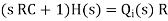

θ(s) [sRC + 1] = R Q1(s)

θ(s)/Q1(s) is the required transfer function of thermal system.

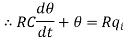

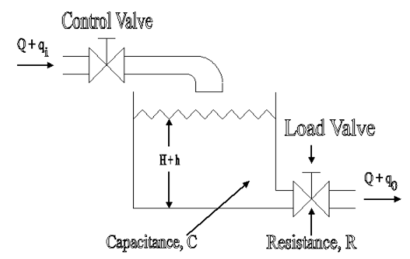

Hydraulic

The Hydraulic system of interest to control engineers may be classified into,

1.Liquid Level system

2.Hydraulic devices

The liquid level system consists of storage tanks and connecting pipes. The variables to be controlled are liquid height in tanks and flow rate in pipes. The driving force is the relative difference of the liquid heights in the tanks. The Hydraulic devices are devices using incompressible oil as their working medium. In this we will be learning transfer function of hydraulic system.

These devices are used for controlling the forces and motions. The driving force is the high-pressure oil supplied by the Hydraulic pumps. Liquids are slightly compressible at high pressures.

In hydraulic system, the compressibility effects may be neglected and conservation of volume is used as the basic physical law. The variables of hydraulic system are volumetric flow rate, q and pressure, R The volumetric flow rate, q is through variable and it is analogous to current. The pressure, P is across variable and it is analogous to voltage.

Three basic elements of hydraulic systems are the Resistance, Capacitance and inertance. The liquid flowing out of a tank can meet the resistance in several ways. Liquid while flowing through a pipe meet with resistance due to the friction between pipe walls and liquid. Presence of valves, bends, coupling of pipes of different diameter also offer resistance to liquid flow.

The capacitance is an energy storage element and it represents storage in gravity field. The inertance represents fluid inertia and is derived from the inertia forces required to accelerate the fluid in a pipe. It is also an energy storage element. But the energy storage due to inertance element is negligible compared to that of capacitance element.

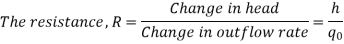

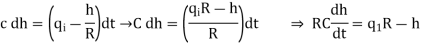

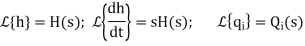

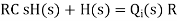

Consider the flow through a short pipe connecting two tanks. The Resistance, R for liquid flow in such a pipe or restriction, is defined as the change in the level difference, necessary to cause a unit change in the flow rate.

R = Change in level difference/Change in flow rate

The Capacitance, C of a tank is defined to the change in quantity of stored liquid necessary to cause in the potential (head).

C = Change in liquid stored/Change in head

A simple liquid level system is shown in the below figure with steady flow rate, Q and steady state head, H.

Fig 11 Liquid Level System

Let Q = Steady state flow rate(before any change has occured)

qi = Small deviation of inflow rate from its steady-state value

qo = Small deviation of outflow rate from its steady-state value

H = Steady state head (before any change has occurred)

h = Small deviation of head from its steady state value

Let the system be considered linear. The differential equation governing the system is obtained by equating the change in flow rate to the amount stored in the tank. In a small time interval dt, let the change in flow rate be (qi - qo) and the change in height be dh.

Now, Change In storage = Change in flow rate

C dh = (qi - qo) dh

Qo = h/R

On substituting for qo, we get,

RC dh/dt + h = qi R

RC dh/dt + h = qi R

The above equation is the differential equation governing the system. The term RC is the time constant of the system .On the Laplace's transform of above equation we get,

The above equation is the required transfer function of the Hydraulic system.

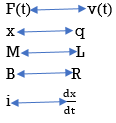

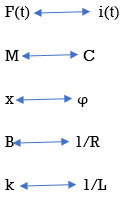

Analogy Between Electrical and Mechanical System:

Force -voltage | Force -current | Mechanical Translatory | Mechanical Rotational |

1.Voltage (v) | Current | Force (f) | Torque (T) |

2.Charge(q) | Flux (ø) | Displacement(x) | Angular Displacement(ø) |

3.current. | Voltage | Velocity v(t) | Angular velocity(w) |

4.Inductance(l) | Capacitance(c) | Mass (m) | Moment of inertia (J) |

5. Resistance(R) | Conductance G= (1/R) | Damping coefficient (B) | Damping Coefficient (B) |

6.Reciprocal of capacitance(1/c) | Inverse of Inductance (1/L) | Stiffness (K) | Stiffness(K) |

Examples

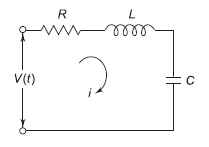

Q1) Explain force-voltage analogy?

Sol: If the dynamic characteristics of an electrical system is identical to that of a mechanical system, then the electrical system is said to be analogous to the mechanical system. This can be done by comparing the mathematical models of both the systems.

Fig 12 Mechanical System

The equation for above mechanical system is given by

f(t) = M  +B

+B  +kx (1)

+kx (1)

For series RLC circuit the mathematical equation is given as

Fig 13 Electrical System

V(t)= Ri + L  +

+

i =

V(t) = L  + R

+ R +

+  (2)

(2)

Comparing 1 and 2 we see that

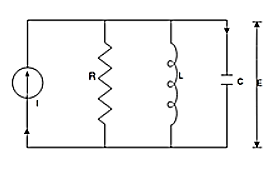

Q2) Explain force-current analogy?

Sol: For parallel RLC circuit shown below the KCL equation is written as

Fig 14 Electrical Circuit

i(t) = C  +

+  +

+

v =

i(t) = C  + R

+ R +

+  (3)

(3)

Comparing 1 and 3 we find that

Key takeaway

Hydraulic fluid acts as a lubricant and coolant. Comparatively small sized hydraulic actuators can develop are forces or torques. Hydraulic actuators can be operated under continuous, intermittent, reversing, and called conditions without damage. Hydraulic actuators have a higher speed of response. They offer fast starts, stops and speed reversals. With availability of both linear and rotary actuators, the design has become more flexible.

Servomechanism is also called servo which is a device usually error sensing device connected as a feedback element to correct the action of a mechanism. Here instead of controlling a device by variable input signal, the device is controlled by feedback signal.

The input signal applied to such systems generate the required output which is compared again to the input signal. If the device achieves its desired output, there will be no longer the logical difference between the two signals. Hence, the primary task of servomechanism is to maintain the output of a system at the desired value in the presence of disturbances.

Servomotors: These motors are used in feedback control system. These are also known as control motors. These motors should have low rotor inertia and high speed of response. The servomotors used in the feedback control systems should have linear control signal and rotor speed.

Types of Servomotors:

(a). A.C. Servomotors

(b). D.C. Servomotors

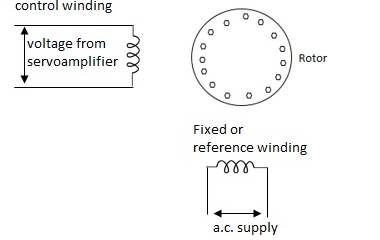

(a). A.C. Servomotors:

A.C servomotor is a two-phase ac induction motor. There are two windings in this motor, one is fixed or reference winding is supplied with a fixed voltage and frequency from a constant voltage source. Second winding is control winding with variable supply voltage of same frequency as reference winding but having a phase displacement of 900 electrical. A flux is induced due to the phase change which cuts the conducting bars of rotor and causes a time varying current, this current produces a time varying flux and reacts with the stator flux causing the rotor to rotate.

Fig 15 AC Servomotor

The rotor of A.C. Servo motors are of two types,

(a). Squirrel Cage Rotor

(b). Drag cup type rotor

(a). Squirrel cage rotor: They have high resistance as the rotor is having large length and small diameter. The air gap here is kept small.

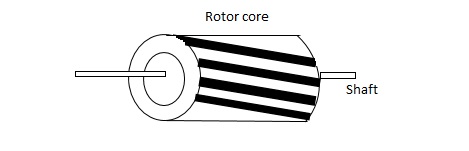

Fig 16 Squirrel cage rotor

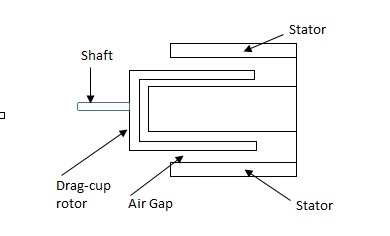

(b). Drag cup type motor: For the drag cup rotor there are two air gaps. For the rotor a cup of non-magnetic conducting material is used. A stationary iron core is placed between the conducting cup to complete the magnetic circuit. The resistance of drag cup type is high and therefore, has high starting torque. Generally aluminium is used for cup.

Fig 17 Drag Cup type rotor

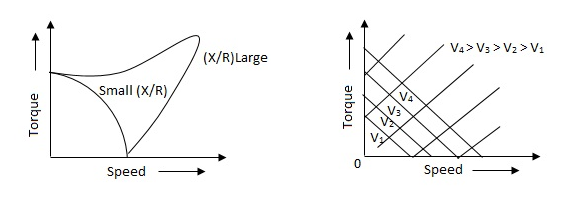

Torque-speed characteristic:

The torque speed characteristics of the two phase servomotor depends on ratio of reactance to resistance(X/R).

Fig 18 The torque speed characteristics of the two phase servomotor

(i). For high ‘R’ and low X, the characteristic is linear and

(ii). For high X and low R, it becomes non-linear.

Fig 19 torque-speed characteristic for various voltage

The torque-speed characteristic for various voltage is almost linear.

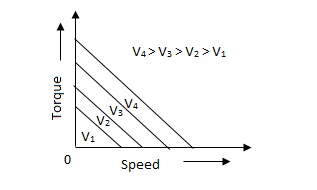

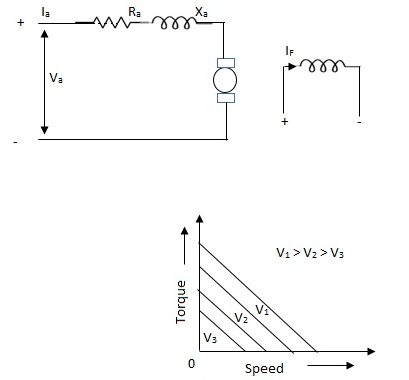

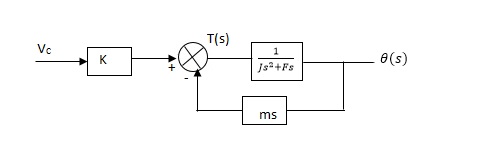

(b). D.C. Servomotor:

D.C. Servomotor are separately excited or permanent magnet dc servomotors. The armature of D.C. Servomotors is having large resistance and hence torque-speed characteristic is linear.

Fig 20 (a) DC Servomotor (b) Torque-speed characteristics

The above graph fig (b), clearly shows that the torque-speed characteristics is a function of control winding voltage as shown below.

T = mw + KVc -- (1)

Where T = Torque developed by motor

w = angular velocity

Vc = control winding voltage

Taking Laplace of above equation (1),

T(S) = mS Q(S) + KVc - - (2)

T(S) = JS2Q(S) + FSQ(S) - - (3)

Above equation(3) is the dynamic equation with,

J – moment of inertia

F – coefficient of friction of motor

From equation (2) and (3) the block diagram will be,

Fig 21 Block Diagram of DC Servomotor

Q(S)/Vc = K/Js + F + m - - (4)

Stepper Motors

It is a device whose output is completely controlled by the input pulses. There are two types of stepper motors:

a) Variable Reluctance

b) Permanent Magnet

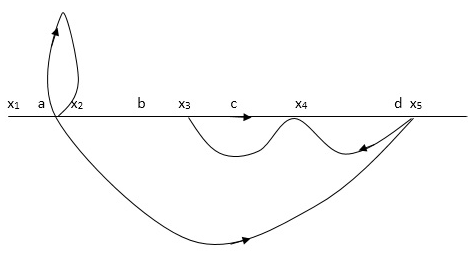

A variable reluctance stepper motor consists of stator having a common frame and rotate n a common shaft. Rotor and stator have toothed structure and teeth are of same size so that it can be aligned on same axis. The stator re pulse excited while the rotor is unexcited. When stator is excited stator and rotor teeth are aligned to minimum reluctance position. The stator torque of the rotor depends on the displacement  .

.

There are two positions of zero torque:

i) For  =0 when rotor and stator are aligned is called stable position because slight disturbance from this position in either direction brings the rotor back to its original position.

=0 when rotor and stator are aligned is called stable position because slight disturbance from this position in either direction brings the rotor back to its original position.

Ii) For  = 180/T when tooth and stator are aligned is called unstable position. This is because of slight disturbance from this position in either direction makes the rotor move away from it.

= 180/T when tooth and stator are aligned is called unstable position. This is because of slight disturbance from this position in either direction makes the rotor move away from it.

For multiple stack stepper motor, Step angle  = 360/nxT

= 360/nxT

n: number of stacks

T: number of rotor teeth

These motors are used in computer peripherals.

Tacho Generators

These are electromechanical devices which convert mechanical input at their shaft to corresponding electrical output. It is basically used to measure speed of motor. It has negative feedback. These devices are most commonly used to find speed of any rotating machine.

| D.C. Tachometer | A.C. Tachometer |

1. | They convert rotational speed into a proportional dc voltage. | They convert the rotational speed into a proportional ac voltage. |

2. | It uses a permanent magnet for producing magnetic field. It contains iron core rotor. | It works on principle of induction generator. |

3. | The permanent magnet controls the magnetic field therefore the induce voltage at terminal of armature is proportional to shaft speed. | The reference winding is supplied by reference voltage and the output voltage is induced across the output winding. |

4. | The polarity depends on direction of rotation. | The amplitude and phase depends on the direction of rotation. |

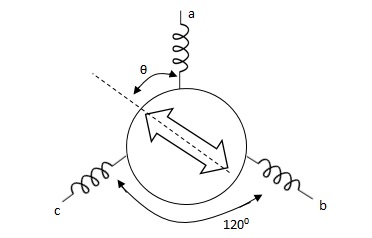

Synchros

Its construction is similar to a three-phase alternator. The stator is made of laminated silicon steel and rotor is dumbbell shaped magnet with a single winding.

Fig 22 Synchros

Let the applied a.c. Voltage to the rotor is,

er = ErSinwot

Let the rotor be at angle of ϴ, then voltage in each stator coil with respect to neutral,

Ean = KErSinwot cos(ϴ)

Ebn = KErSinwotcos(ϴ + 1200)

Ecn = KErSinwotcos(ϴ + 2400)

Magnitude of stator terminal voltage,

Ecb = Ecn – Ebn

= KErSinwot[cos(ϴ + 2400) – cos(ϴ + 1200)]

= KErSinwot(√3 Sinϴ)

Ecb = √3KErSinwot Sinϴ

Similarly,

Eac = √3KErSinwot Sin(ϴ + 1200)

Eba = √3KErSinwot Sin(ϴ + 2400)

When ϴ = 0, Ecb, Ean = 0

Hence, input to the synchro transmitter is the angular position of motor shaft and output are three phase voltage which are function of shaft position.

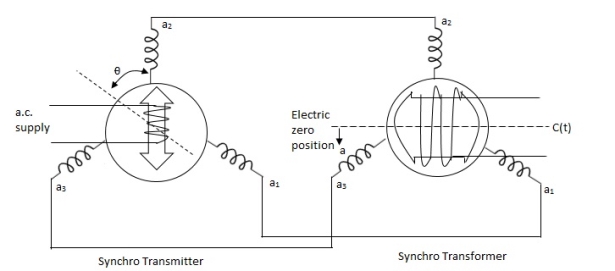

Synchro Transformer:

Its basic working principle is similar to the synchro transformer. Here the rotor is cylindrical type. It is an electromechanical device. The combination of synchro transmitter and synchro transformer is used as an error detector.

The basic diagram is shown below,

Fig 23 Synchros Transformers

Let transmitter rotate at an angle ϴ and control transformer rotor rotate in same direction through α. Then,

φ = (90 - ϴ + α)

Voltage across rotor terminal is given as,

e(t) = K1Vrcos ϴSinwot

e(t) = K1VrSin(ϴ - α) Sin wot

From above equation we can conclude that when two rotor shafts are not aligned, the rotor voltage of transformer is a sine function of difference between two angles.

For small angular displacement between two rotor position,

e(t) = K1Vr(ϴ - α)Sinwot

Magnetic Amplifiers, Servo Amplifiers

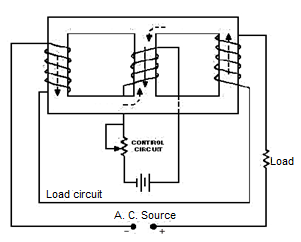

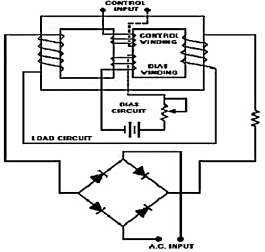

Magnetic Amplifiers: They are basically electromagnetic device used for amplification of electrical signals. The basic working of this amplifier depends on the saturation of core principle. It consists of two cores connected in opposite phases, with control and AC winding. By applying small amount of DC currents on control winding large amount of current on AC winding can be controlled. They are of two types

a) Half wave magnetic amplifier: When DC supply is given to the control winding the magnetic flux is generated in the iron core. As flux increases the output impedance decreases and the current through AC winding in output increases. Here only half cycle of AC is utilised.

Fig 24 Half wave magnetic amplifier

If the current through the control winding is zero, then the impedance of the output winding will be very high making no current to flow through the load or output winding. A diode is connected to the output winding which acts as a rectifier, used for reversing the polarity of the AC supply constantly from cancelling out control winding flux.

b) Full wave magnetic amplifier: It utilizes both the half cycles of the AC supply. Due to wound of the two halves of the output winding the direction of magnetic flux created by these two halves in centre leg is same as direction of control winding flux

Fig 25 Full wave magnetic amplifier

No control voltage is supplied there will be some flux present in magnetic core, hence impedance of the output winding will never attain its maximum value and current through load never attain its minimum value. The operation of the amplifier can be controlled by using the bias winding.

Servo Amplifiers: It is an electronic amplifier used to power servomechanism. It monitors the feedback signal and adjusts the deviation if present. When input is applied from control system the servo amplifier amplifies the signal and transmits electric current to a servo motor producing motion proportional to the command signal.

Key takeaway

Comparison between A.C. Servomotor & D.C. Servomotor

| A.C. Servomotor | D.C. Servomotor |

|

|

|

1. | They are less efficient | They are more efficient |

2. | They have low power output | They have high power output |

3. | No noise so has smooth operation | These motors have noisy operation |

4. | They do not have any radio frequency noise | These motors have brushes so produce radio frequency noise |

5. | They are maintenance free because of no brushes and slip rings | For these motors, maintenance is required. |

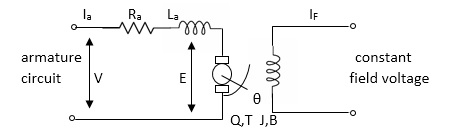

Armature Controlled dc motor:

In armature controlled motors the time constant is small and hence response is last The efficiency is better than field cannot. The transfer function is calculated below.

Fig.26 Armature controlled D.C Servomotor.

Applying kVL in armature circuit

V = Raia+ Ldia/dt +E-----(5)

Where

V= applied voltage

Ra = armature resistance

La = Armature inductance

Ia= Armature current

If= field current

E= Induced emf in armature

T= Torque developed by motor

But E= Kb w

E= kbdø/dt --------(6)

W =angular velocity

Kb= back emf

T= k ia-----(7)

The equation for torque will be

T= Jd2ø/dt2+Bdø/dt --------(8)

Taking Laplace of equation (5), (6), (7), (8)

V(S) – E(S) = I1(s) (Ra+sLa)

E(s) = kb s (s)

(s)

T(s) = k Ia (s)

T(S)= (s2J+SB)  (S)

(S)

T(S) = (SJ+B) s (S)

(S)

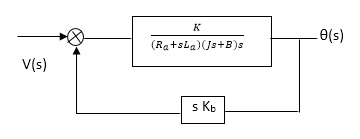

(S)/v(s) k/(Ra+sla) (Js +B) s+ kkbs ------(a)

(S)/v(s) k/(Ra+sla) (Js +B) s+ kkbs ------(a)

The Block diagram representation for above equation (a) is shown below.

Fig. 27 Block diagram for Armature controlled D.C motor

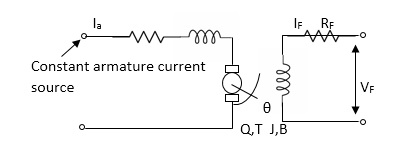

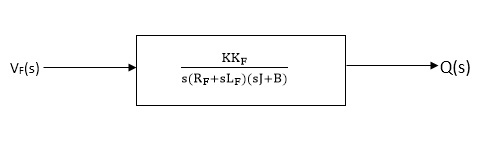

Field controlled D.C Servomotor:

For field-controlled D.C motor the ratio L/R is large which means time controller for field circuit is large

Fig.28 circuit for field-controlled D.C motor

Applying KVL in field circuit

Vf= Rf If +Lf d If/dt------(10)

T = k øIa

ø If

ø= kfIf

:. T= kkfIa If

Let k, = KIa

T= k’ Kf If --------(11)

Dynamic equation for torque is

T= Jd2 /dt2 +Bd

/dt2 +Bd /dt ------- (12)

/dt ------- (12)

Taking Laplace of above equations

Vf(s) = Rf If (c)+SLf If(s) [Rf+SLf]

If= Vf(S)/Rf+ SLf--------(13)

T(s) = (S) [s2J+SB] --------(14)

(S) [s2J+SB] --------(14)

T(S) = kkfVf(s)/Rf+SLf------ (15)

From equation (14) and (15) we get

(s)/ vf(s) = kkf/s (sJ+B) (Rf+sLf)

(s)/ vf(s) = kkf/s (sJ+B) (Rf+sLf)

The block diagram representation of above equation (16) is shown in figure below

Fig. 29 Block diagram for field-controlled d.c servomotor

Key takeaway

A.C Servomotor | D.C Servomotor |

1) Low power output of about 0.5 W to 100 W. | 1) Deliver high power output |

2) Efficiency is less about 5 to 20%. | 2) High efficiency |

3) Due to absence of commutator maintenance is less. | 3) More problems of stability |

4) Stability problems are less. | 4) More problems of stability |

5) No radio frequency noise. | 5) Brushes produce radio frequency noises. |

6) Relatively stable and smooth operation | 6) Noisy operation |

7) A.C. Amplifier used have no drift. | 7) Amplifier used have a drift. |

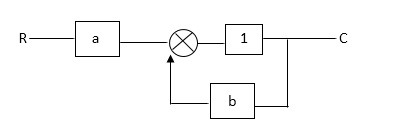

Open loop systems:

This is the loop of control system without any feedback. In this the control action is not dependent on the desired output.

Fig. 30 open loop control system

Example of open Loop systems are the traffic signals, Automatic washing machine and in fields control d.c. Motor.

G(s) = c(s)/R(s) -------(1)

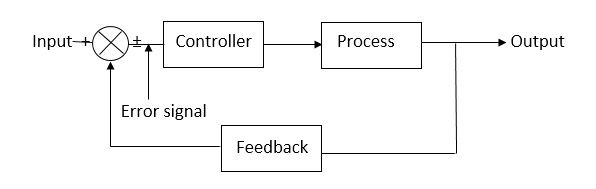

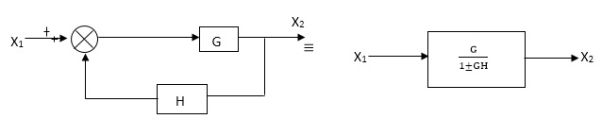

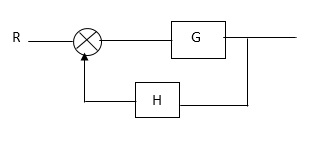

Closed loop systems:

This is a type of control system with feedback. In this type of system. The control action is dependent on the desired output.

Fig 31 Closed Loop control system

The error signal is again fed to controller to the error and get desired output.

G(s) – forward amplification

H(s) _ Reverse amplification

Above system is with negative feedback.

Positive feedback is used only in oscillators and other use is not known as discussing only negative feedback.

[ R(s) – c(s) H (S) ] G(s) = c(s)

R (s) G(s) = [1+G(s) H(s)] c(s)

C(s)/R(S) = G(S)/1+G(s) H(s)

S0, the transfer function of closed Loop system is

C(s)/ R(S) = G(s)/ 1+G(S) H(S) --------(2)

If numerator of above equation (2) is equalized to zero we get zeros of closed Loop Transfer function [G(S) = 0]

If dominator of equation (2) is equaled to zero we get polls of the closed loop transfer function [ 1+G(s) H(S) = 0]

1+ G(S) H(s) = 0 [ characteristic Equation]

Stability of the system is determined by the location of its poles.

Comparisons between open Loop and Closed Loop system

Open Loop System | Closed Loop system |

1.It does Not have any feedback. | 1. This system comprise of feedback |

2.As no feedback so easier to build. | 2.As it has feedback so difficult to build |

3.Theaccuracy of this system depends on the calibration of input. | 3.They are accuracy because of the feedback. |

4.Open Loop system are more stable. | 4.In closed Loop system stability depends on system components. |

5.optimization is not possible | 5. Optimization is possible |

6.These systems are not reliable. | They are more reliable |

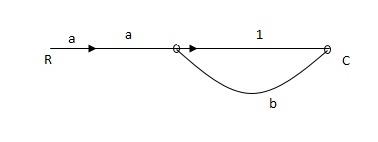

There are two types of feedbacks

i) Positive Feedback

Fig 32 Closed Loop control system

In positive feedback systems the feedback signal is added to the input signal. The positive feedback is used only in oscillators. The transfer function is given as

C(s)/ R(S) = G(s)/ 1-G(S) H(S)

Ii) Negative Feedback

In negative feedback the error signal is inverted at the input signal. The discussion in this unit is based on this negative feedback systems only. The transfer function is given by

C(s)/ R(S) = G(s)/ 1+G(S) H(S)

Key takeaway

Parameter | Positive feedback | Negative Feedback |

Overall phase shift | 0 or 360  | 180  |

Input and Output Voltage , noise | Increases due to Feed back | Decreases due to Feed back |

Feedback Signal and Input signal | In phase | Out of phase |

Stability | Becomes poor | Becomes better |

Applications | Oscillators | Amplifiers |

Advantages of Block diagram reduction technique:

- Very simple to Construct the Block diagram of complicated electrical & mechanical systems.

- The function of individual element can be visualized form block diagram

- Individual as well as overall performance of the system can be studied by the figure shown in Block diag.

- Overall CLTF can be easily calculated by Block diagram reduction rules.

Disadvantages of Block diagram reduction technique:

It does not include any information above physical construct of system (completely mathematical approach). Source of energy is generally not shown in the block diagram so diff. Block diagram can be drawn for the same function.

CLTf: -ve feedback

C(s)/R(s)= G(s)/1+G(s)H(s)

CLTF: +ve feedback

C(S)/R(S) = G(S)/1-G(s)H(S)

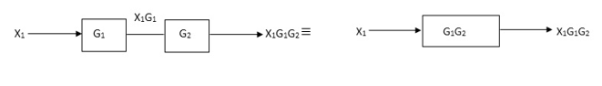

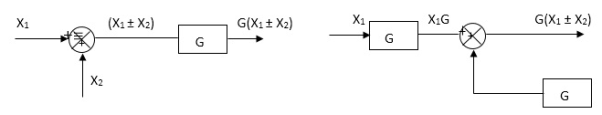

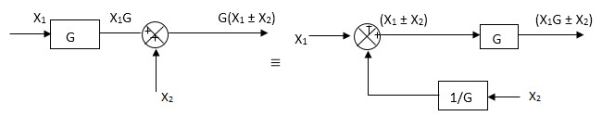

Rules of Block diagram Algebra:

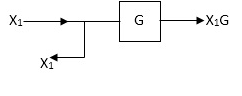

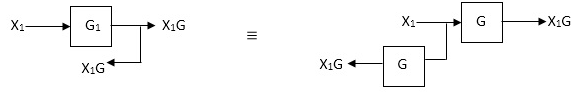

Block in cascade

Moving summing point after a block

Moving summing point after a block

Moving summing point ahead of block

Moving summing point ahead of block

Moving take off point after a block

Moving take off point ahead a block

Eliminating a feedback Loop

Practice Problems

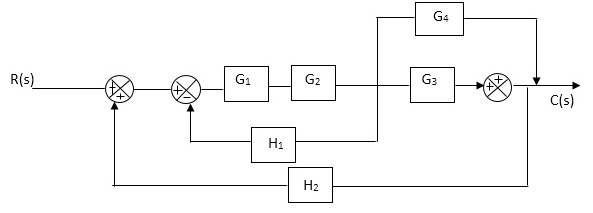

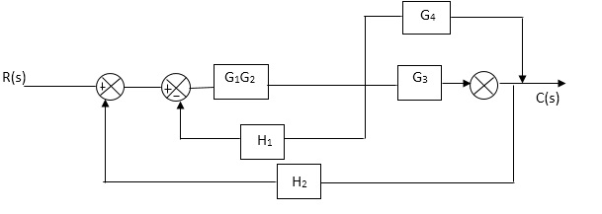

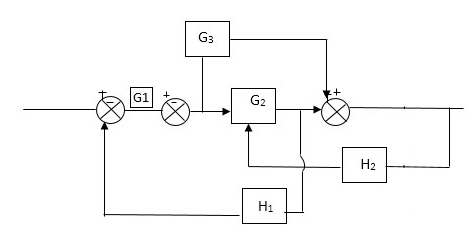

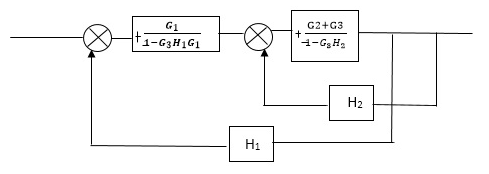

Q1. Reduce given B.D to canonical (simple form) and hence obtain the equivalent Tf = c(s)/ R(S)?

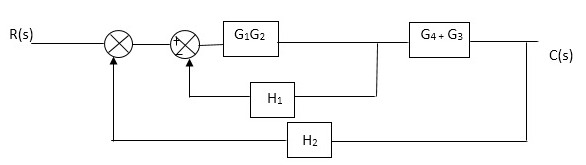

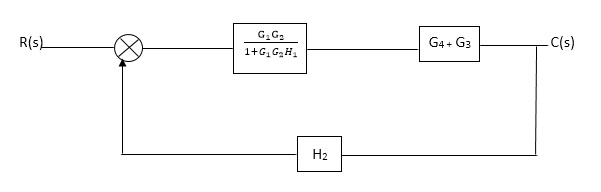

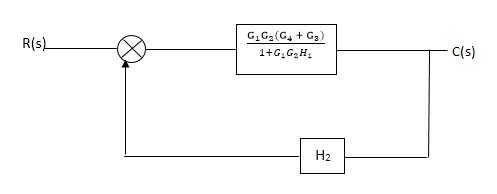

Sol:

Sol:

C(S)/R(S) = (G1G2) (G3+G4)/1+G1G2H1)/1-G1,G2(G3+G4) H2/1+G1G2H1

= G1G2(G3+G4)/1+G1G2H1-G1G2H2(G3+G4)

=G1G2(G3+G4)/1+(H1-H2)(G1G2) (G3+G4)

C(s)/R(S) = G1G2(G3+G4)/1+(H1-H2(G3+G4)) G1 G2

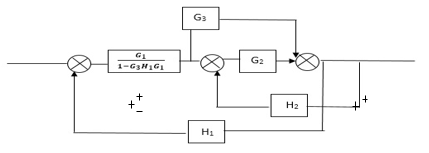

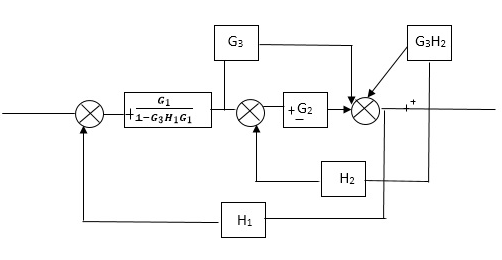

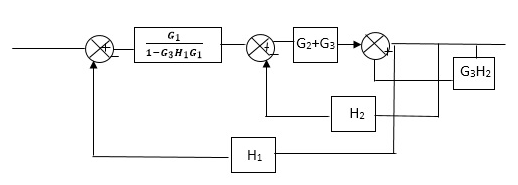

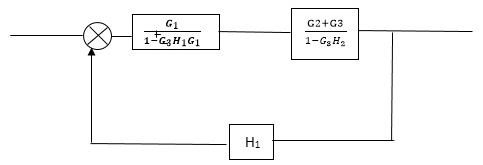

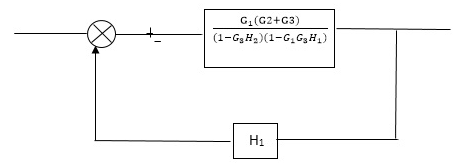

Q2) Reduce the Block diagram

Sol:

C(s)/R(s)= G1(G3+G2)/(1-G1G3X1) (1-G2X2) H1

= G(G3+G2)/(1-G3G1H1) (1-G2H2) + G1H1(G3+G2)

= G1(G3+G2)/1-G3G1H1-G2H2+G1H1(G3+G2H1

=G1(G3+G2)/1-G3H2+G1G2H1(1+G3H2)

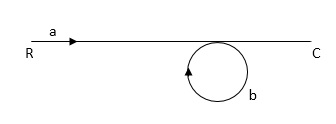

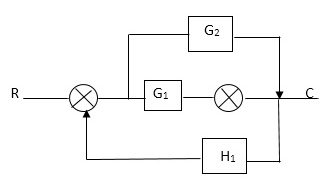

As we already know that Block Diagram is represented as shown below

SFG

RULES:

1) The signal travels along a branch in the direction of an arrow.

2) The input signal is multiplied by the transmittance to obtain the o/p.

3) I/p signal at a node is sum of all the signals entering at that node.

4) A node transmits signal at all branches leaving that node.

Practice Problem

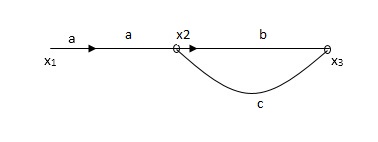

Q: For given block diagram draw the SFG?

Ra+cb =c

c/R= a/1-b

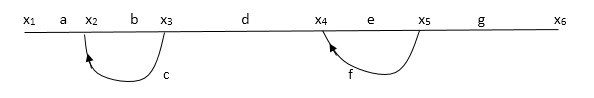

Q. The SFG shown has forward path and singles isolated loop determine overall transmittance relating X3 and X1?

Soln:

X1- I/p node

X2-Intenmediale node

X3- o/p node

Ab- forward path (p)

Bc- 1 loop (L)

At node XQ:

X2 = x1a + x3c [Add i/p signals at node]

At node x3:

x2b =x3

(x1a+x3c) b = x3

X1ab = x3 (1-bc)

X1 = x3 (1-bc)/ab

Ab/(1-bc) = x3/x1

T= p/1-L

X1: I/p node x2, x3, x4, x5, Qnlexmedili node

X0: o/p node abdeg:- forward path

Bc, ef: Loop [isolated]

x2 = ax1+c x3

x3= bx2

x4 = d x3+f x5

x5 = e x4

x6= g x5

x6 = g(e x4) = ge [dx3+ e f x5]

xb = ge [d (bx2) + f (e x4)]

xb = ge [ db (ax1+cx3) + fe (dx3+ fx5)]

xb = ge [db (ax1+cb (ax1+x3) +fe[cdbx2]+

f(e [db (ax1+ cx3)

x2 = ax1 + cb (x2) x4 = d bx2 + f exq

x2 = ax1 + cbx2 = db (d4) + fe/1-cb

x2 = ax1/(1-cb) xy = db x2 + f x6/g

xy = db [ax1]/1-cb + f xb/g

x5 = c db ( ax1)/1-cb + efxb/g

xb = gx5

= gedb (ax1)/1-cb + g efxb/g

Xb = gx5

Gedb (ax1)/1-cb + g efxb/g

(1- gef/g) xb = gedb ax1/1-ab

Xb/x1 = gedb a/ (1- ef – bc + beef

Xb/x1 = p/ 1- (L1+L2) + L1 L2 for isolated loops

MASON’S GAIN FORMULA

T=

The overall transmittance Coverall gain can be determined by Masks formula.

Explanation

Pk forward path transmittance of k+n path from a specified i/p node to n o/p nods

forward path transmittance of k+n path from a specified i/p node to n o/p nods

While calculating ipnode to n o/p nods.

While calculating ip no node should be encountered (used) more than ones.

it is the graphics determined which involves of transmittances and multiple increases b/w non touching loops.

it is the graphics determined which involves of transmittances and multiple increases b/w non touching loops.

= 1- [sum of all individual loop transmitting]

= 1- [sum of all individual loop transmitting]

+[ sum of loop transmittance product of all possible non- touching loops]

-[sum of loop transmittance of all possible triples of non- touching loops]

path factor associated with concerned path & involves all a in the graphic which are isolated from forward path under consideration.

path factor associated with concerned path & involves all a in the graphic which are isolated from forward path under consideration.

The path factor  for kth is equal to graph determinant of SFG which effect after erasing the kth path from the graph

for kth is equal to graph determinant of SFG which effect after erasing the kth path from the graph

Q. Draw SFG for given block diagram?

Sol:

P1= G1 p2 =G2 Delta1 =1

L1= -G1 H1

= 1-(-G1H1)

= 1-(-G1H1)

= 1+G1H1

T= G1+G2/1+G1H1

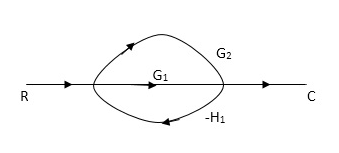

Q: Determine overall gain x5 and x1 Draw SFG

X2 = ax1+ f x2

X3= bx2 +exy

X4 = cx3+hx5

X5 =dx4 + gx2

P1 = abcd p2 = ag

L1 = f L2 = ce, L3= dh

1 = 1

1 = 1

2= 1-ce

2= 1-ce

= 1-[L2+L2+L3] + [L1 L2 +L1 L3]

= 1-[L2+L2+L3] + [L1 L2 +L1 L3]

= 1-[f+ le = dh] + [fce +fdh]

T= abcd+ ag (1-ce)/1-[ftce + dh ] + (fce + fdh)

Key takeaway

- The function of individual element can be visualized from block diagram

- The signal travels along a branch in the direction of an arrow.

- The input signal is multiplied by the transmittance to obtain the o/p.

References:

[1] I. J. Nagrath and M. Gopal, “Control Systems Engineering”, New Age International,

2009.

[2] K. Ogata, “Modern Control Engineering”, Prentice Hall, 1991

[3] M. Gopal, “Control Systems: Principles and Design”, McGraw Hill Education, 1997.

[4] B. C. Kuo, “Automatic Control System”, Prentice Hall, 1995.