UNIT 5

New Materials

The designing and making up of anything whose use depends on the specific structure at nano scale. These posses the different properties at reducing scale. The measurement can be taken in notice at 100 nanometers and lesser is called as the nanotechnology. This includes the materials made by the manipulation of up of atoms or molecules. They are composed up of metals, ceramics, polymers, organic materials in simpler way these all are made up of carbon compounds. The technology that we deal with in taking the consideration up of the Nano material is called as the nanotechnology.

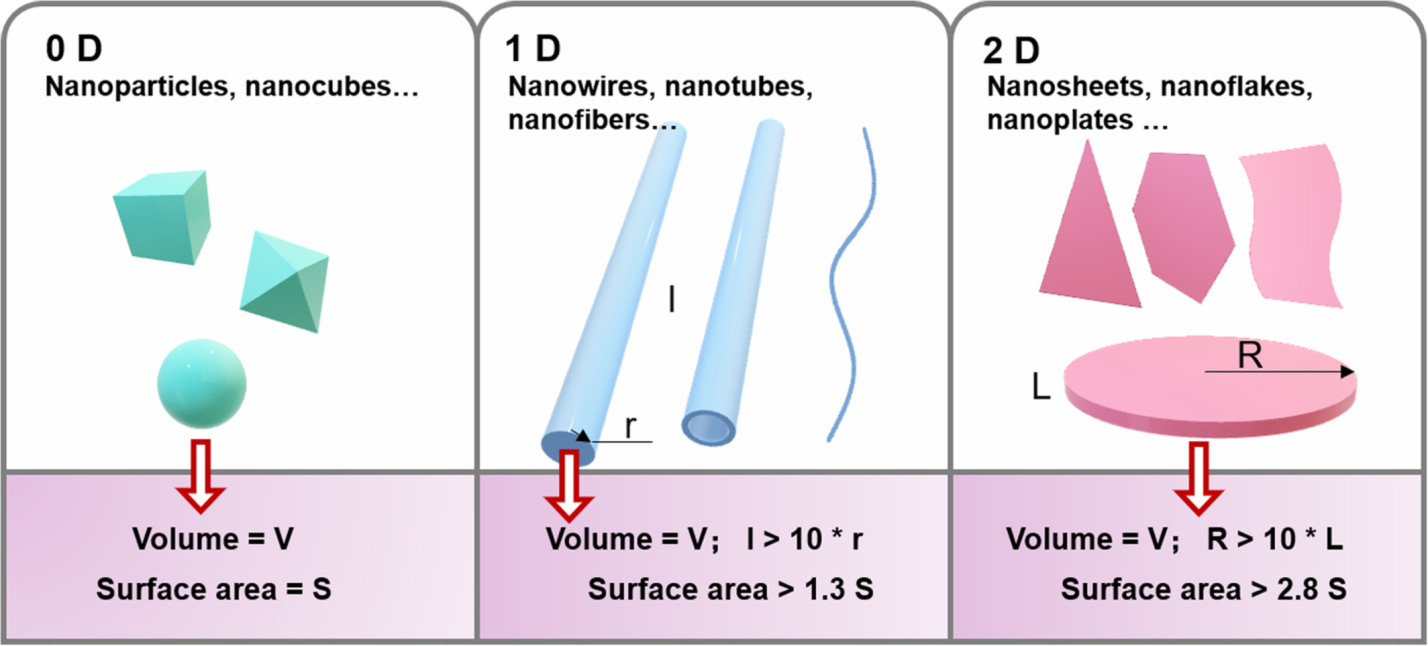

This classification is based on the number of dimensions of a material, which are outside the nano scale (<100 nm) range.

In zero-dimensional (0D) nano materials all the dimensions are measured within the nano scale (no dimensions are larger than 100 nm). Most commonly, 0D nano materials are nano particles.

In one-dimensional nano materials (1D), one dimension is outside the nano scale. E.g.; nano tubes, nano rods, and nano wires.

In two-dimensional nano materials (2D), two dimensions are outside the nano scale. This class exhibits plate-like shapes. E.g.; graphene, nano films, nano layers, and nanocoatings.

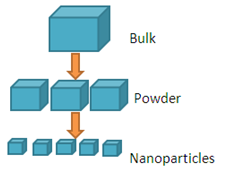

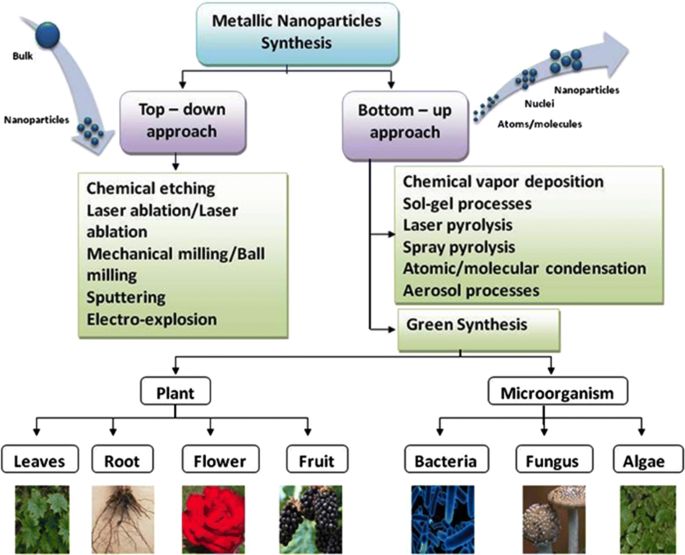

Top Down Approach

Top down approach deals with the breaking down of bulk material into nano sized particles. Top-down synthesis techniques are extension of those that have been used for producing micron sized particles. Top-down approaches are inherently simpler and depend either on removal or division of bulk material or on miniaturization of bulk fabrication processes to produce the desired structure with appropriate properties. The biggest problem with the top-down approach is the imperfection of surface structure. E.g.: nano wires made by lithography are not smooth and may contain a lot of impurities and structural defects on its surface.

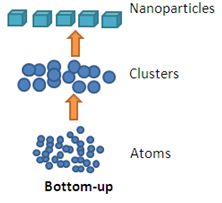

Bottom Up Approach

Bottom –up approach refers to the build-up of a material from the bottom: atom-by-atom, molecule-by-molecule or cluster-by-cluster. This route is more often used for preparing most of the nano-scale materials with the ability to generate a uniform size, shape and distribution. It effectively covers chemical synthesis and precisely controlled the reaction to inhibit further particle growth. Although the bottom-up approach is nothing new, it plays an important role in the fabrication and processing of nanostructures and nano materials.

5.5 Introductory idea on synthesis of nano materials via green synthetic route

Green synthetic route is a environment friendly way of synthesizing nano particles. This method does not require expensive, harmful and toxic chemicals. Synthesis can be done in one step using biological organisms such as bacteria, action-bacteria, yeasts, molds, algae and plants, or their products. Molecules in plants and micro-organisms, such as proteins, enzymes, phenolic compounds, amines, alkaloids and pigments perform nano particle synthesis by reduction. As of rapid development, affordable culture costs and easy control and manipulation of growth environment, bacteria are clearly targets in the production of nano particles. At the same time, it is known that some species of bacteria have special mechanisms to suppress the toxicity of metals or heavy metals. Bacteria preferred for these properties, can perform nano particle synthesis in-situ and ex-situ. Through the use of biochemical pathways and reducing agents such as proteins, enzymes, etc. which present in the bacteria, metal ions can be reduced and precipitated for nano particle production. Actino bacteria, which perform the production of secondary metabolites such as antibiotics, are aerobic, immobile, and mostly filamentous gram-positive bacteria. They are resistant to the most toxic heavy metals owing to their detoxification property. Soluble toxic metal ions are detoxified by either being degraded by intracellular or extracellular reduction or precipitation. Thus, nano particles being antibacterial, antifungal, anticancer, antioxidant, anti-bio contamination and having catalytic activity can be produced. Synthesis of nano particles can be done as extra-cellular or intra-cellular with enzymes by employing simply-cultured and fast-breeding eukaryotic yeasts and molds with easy biomass design, as. The incubation conditions and the metallic ion solutions used influence the size of the nano particles produced. Being pathogenic for humans limits the use of some molds in nano particle production. Plants, which have great potential for detoxification, reduction and accumulation of metals, are promising, fast and economical in removing metal-borne pollutants. Metallic nano-particles having various morphological characteristics can be produced intra cellularly and extra cellularly. Synthesis process; is initiated by addition of extracts obtained from plant parts such as leaves, roots and fruits into the aqueous solution of metal ions. With the materials present in the plant extract, such as sugar, flavonoid, protein, enzyme, polymer and organic acid, acting as a reducing agent, takes charge in bio-induction of metal ions into nano particles.

Application of nano material in environmental field:

Application of nano material in electronic devices: