UNIT – 3

DC DC buck converter

A chopper is a DC equivalent to an AC transformer having continuously variable turn ratio. Like a transformer, a it can be used to step up or step down the fixed DC input voltage. On this basis, there are two types of chopper: Step-up and Step-down Chopper. A chopper whose average value of DC output voltage is more than the fixed DC input voltage is called Step-up Chopper. While, a chopper whose average value of DC output voltage is less than the DC input voltage is called Step-down chopper.

Working Principle of Chopper:

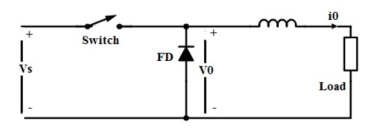

A chopper is a high speed ON/OFF switch. It connected source to load and disconnects the load from the source at a fast speed. Figure below represents the simple circuit to show its working principle.

Figure 1. Chopper

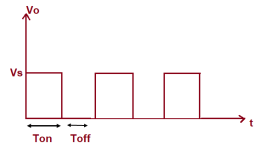

In this circuit, the switch SW is chopper. This switch can be made ON and OFF at a very high speed. In this way, the load may be connected and disconnected from the supply source Vs. When the switch is ON, the load voltage is equal to the source voltage Vs and when the switch is OFF, load voltage becomes equal to ZERO. Thus, a chopped voltage across the load is obtained. The output voltage i.e. voltage across the load is shown in figure below.

Figure 2. Output waveforms

It should be noted here that, when the switch SW is made OFF, the load current finds its path through free- wheeling diode D. Therefore, diode D acts as a short and hence the voltage across the load becomes zero. Inductor in the chopper is an essential thing. This inductor makes diode D forward biased when the switch SW is OFF.

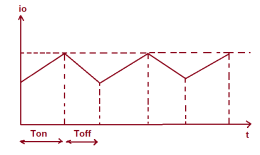

It should also be noted that, even though the switch SW is made OFF, the load current doesn’t become zero. Rather, it flows through the free- wheeling diode, inductor L and load. In fact, the load current is continuous as shown below.

Figure 3. Load current

It may be seen from the above waveform of output current of chopper that, during ON time, the current rises whereas during OFF time, the load current io decays.

The time for which chopper connects the load from source is called ON time i.e. TON. Whereas, the time for which load is disconnects from source is called OFF time i.e. TOFF.

Duty Cycle:

Duty cycle of chopper is defined as the ratio of ON time to the total time period. It is denoted by symbol α. Total time period is the sum of ON and OFF time.

Duty Cycle = TON / (TON+TOFF)

Assuming (TON+TOFF) = T, duty cycle is given as below.

Duty Cycle, α = (TON / T)

Calculation of Output Voltage:

The average output voltage of chopper may be find from the output voltage waveform. It is clear from the o/p voltage waveform that, voltage Vo is available only for TON time period in the total time (TON+TOFF). Therefore, average output voltage Vo may be calculated as shown below.

Vo = TON Vs / (TON+TOFF)

But, TON / (TON+TOFF) = α

Hence,

Vo = αVs

Thus, the output voltage may be controlled by controlling the duty cycle. This duty cycle may be controlled in various ways which we will discuss in the next post. From the expression of ouput voltage, it is also clear that, the output voltage is independent of the load current.

The expression for chopper output voltage may also be written as below.

Vo = TON Vs / (TON+TOFF)

= Vs TON / T

Assuming 1/T = Chopping frequency

Vo = f Vs TON.

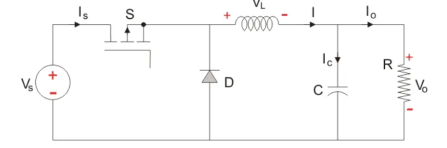

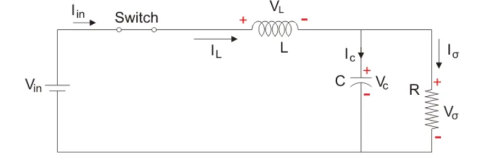

A typical Buck converter is shown below.

Figure 4. Buck converter

The input voltage source is connected to a controllable solid- state device which operates as a switch. The solid-state device can be a Power MOSFET or IGBT.

The second switch used is a diode. The switch and the diode are connected to a low-pass LC filter which is appropriately designed to reduce the current and voltage ripples. The load is a purely resistive load.

The input voltage is constant and the current through load is also constant. The load can be seen as current source.

The controlled switch is turned on and off by using Pulse Width Modulation(PWM).

PWM can be time based or frequency based.

The Buck converter has two modes of operation. The first mode is when the switch is on and conducting.

Mode I : Switch is ON, Diode is OFF

Figure 5. Buck converter circuit(Switch ON)

The voltage across the capacitance in steady state is equal to the output voltage.

Let us say the switch is on for a time TON and is off for a time TOFF. We define the time period, T,

T = TON + T OFF

and the switching frequency

fswitching = 1/T .

Let us now define another term, the duty cycle,

D = TON/T

Let us analyze the Buck converter in steady state operation for this mode using KVL.

Vin = VL + Vo

diL/dt = ∆ iL/∆t = ∆iL/DT = Vin-Vo/L

Since the switch is closed for a time Ton = DT we can say that ∆t=DT

(∆ iL ) closed= (Vin - Vo/L) DT

While performing the analysis of the Buck converter, we have to keep in mind that

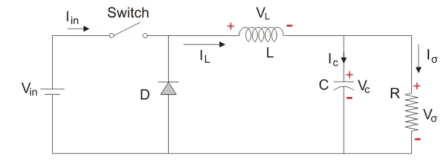

Mode II: Switch is OFF, Diode is ON

Figure 6. Switch off

Here, the energy stored in the inductor is released and is ultimately dissipated in the load resistance, and this helps to maintain the flow of current through the load. But for analysis we keep the original conventions to analyse the circuit using KVL.

Let us now analyse the Buck converter in steady state operation for Mode II using KVL.

0 = VL + Vo

VL = L diL/dt = -VO

diL/dt = ∆ iL/∆t = ∆ iL / (1-D) T = -Vo/L

Since the switch is open for a time

TOFF = T – TON = T -DT = (1-D) T

We can say that

∆t = (1-D) T

(∆ iL) open = ( -Vo/L) (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo) /L . DT + (-Vo/L) DT =0

Vo /Vin = 1/ 1-D

Since the switch is open for a time

TOFF = T – TON = T – DT = (1-D) T

We can say that

∆t = (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero.

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo/L) (1-D) T + (-Vo/L) (1-D)T =0

Vo /Vin = D

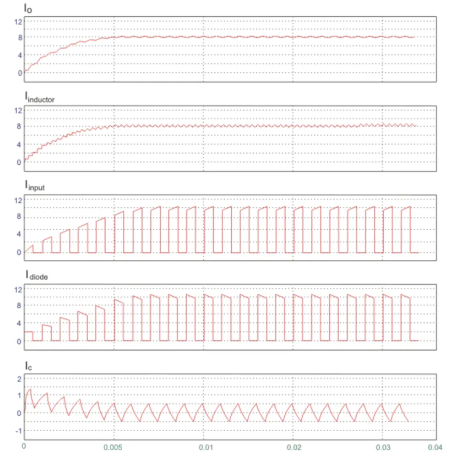

A circuit of a Buck converter and its waveforms is shown below.

The inductance , L, is 20mH and the C is 100µF, and the resistive load is 5Ω. The switching frequency is 1 kHz. The input volatgeis 100V DC, and the duty cycle is 0.5.

The voltage waveforms are as shown above and the current waveforms are as shown in the figure below.

Figure 7. Output waveforms

Figure 7. Duty ratio

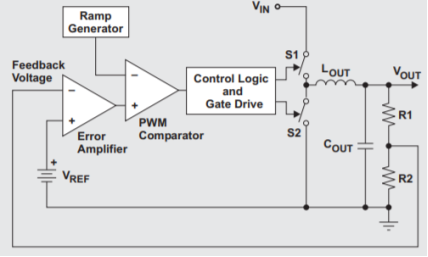

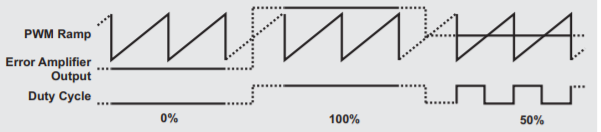

The buck converter is used to generate a lower output voltage from a higher DC input voltage. If the losses in the switch and catch diode are ignored, then the duty cycle, or the ratio of ON time to the total period, of the converter can be expressed as (1) The duty cycle is determined by the output of the error amplifier and the PWM ramp voltage as shown in Figure 2. The ON time starts on the falling edge of the PWM ramp voltage and stops when the ramp voltage equals the output voltage of the error amplifier. The output of the error amplifier in turn is set so that the feedback portion of the output voltage is equal to the internal reference voltage.

Figure 8. Output of error amplifier

References: