Unit - 2

Operating Principles & Relay Construction

The design of protective relay is normally divided into the following stages:

(a) Selection of the operating characteristics

(b) Selection of proper construction

(c) Design of the contact moment from the point of view of utmost reliability.

The relay operating characteristic must match with the abnormal operating characteristics of the system i.e., it should clearly show the conditions for tripping under various abnormal operating conditions. The most important considerations in the design for construction are:

- Reliability

- Simplicity of construction

- Circuitry

The construction of the relay is divided into the following:

- Contacts- Contact performance is probably the most important item affecting reliability of the relay. Corrosion or dust deposit can cause non-operation of relay. Thus, material and shape of relay are of considerable importance. A good contact system design provides restricted contact resistance, reduced contact wear. The contact material used is gold, gold alloy, platinum, pelledium and silver. The selection of the contact material depends on a number of factors like:

(a) The voltage per contact break

(b) The current to break

(c) The type of atmospheric pollution under which the contacts are operate

The following factors are to be considered for selecting a suitable contact material: 1) The nature of the current to be interrupted (ac or dc) 2) Voltage at break and make operation 3) Value of current magnitude 4) Frequency of operation 5) The actual speed of contact at make or break 6) Contact shape

- Bearing-

(a) Single ball bearing

(b) Multi ball bearing

(c) Pivot and jewel bearing – This is the most common type for precision relay

- Electromechanical design- It consists of the design of the magnetic circuit and the mechanical features of core, yoke, and armature. The reluctance of the magnetic path is kept to a minimum by enlarging the pole face which makes the magnetic circuit more efficient.AC electromagnets made from soft iron, low carbon steel core having a slot for mounting shaded rings are more common. The relay coil current is usually limited to 5A and the coil voltage to 220 V but the insulation for the relay coil is designed to withstand at least 4kV.The relay coil is designed to carry about 15 times the normal current foe one second.

- Termination & housing- Material used for springs are stainless steel; nickel steel, phosphorous bronze and Beryllium copper. The spring is insulated from the armature by molded blocks. For moulded blocks nylon is used.

The actuating quantity is normally in electrical signal. Sometimes the actuating quantity may be pressure and temp. Protective relay can be classified as

- According to the function in protection scheme.

- According to the nature of actuating quantity.

- According to the connection of the sensing element

- According to the method by which the relay acts upon the circuit breaker

Generally, the electrical protective relays can be broadly classified in two categories

(a) Electromagnetic relays- Electromagnetic relays are those relays which are operated by electromagnetic action. Modern electrical protection relays are mainly microprocessor based, but still electromagnetic relay holds its place. It will take much longer time to be replaced the all electromagnetic relays by microprocessor based static relays. So before going through detail of protection relay system we should review the various types of electromagnetic relays.

(b) Static relays- A relay in which the measurement or comparison of electrical quantities are done in a static network. The output signal operates a tripping device which may be electronic, semiconductor or electromagnetic. The static relays are classified according to the types of measuring units or the comparator 1) Electronic relays 2) Transducer (magnetic amplifier relay) 3) Rectifier bridge relay 4) Transistor relay 5) Hall effect relay 6) Gauss effect relay

Depending upon working principle the electromagnetic relays can be divided into following types of electromagnetic relays.

i. Attraction Armature Type Relay

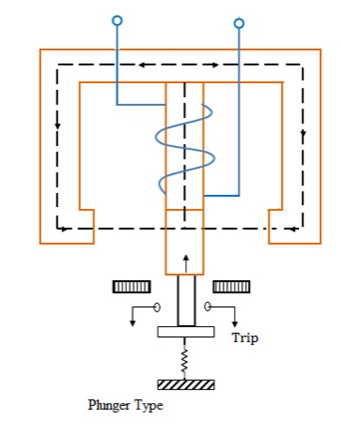

This has four types i.e., plunger, hinged armature, balanced beam and moving iron polarized. These are the simplest types which responds to AC and DC.

The force of attraction is given by-

Where K is a constant &  is pulsating

is pulsating

The coil is energized by current or voltage, a proportionate operating quantity, which produces a magnetic flux, thereby creating an electromagnetic force. This force is proportional to the square of the flux in the air gap or square of the current. This force increases, as the armature approaches the pole of electromagnet. This type of relay is used for protection of small machines and also used for auxiliary relays such as indicating relays (flags) alarm and annunciator relays etc.

Ii. Induction Disc Type Relay

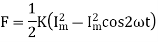

a. Watt Meter Type or Non-Directional Relay- It has a metallic disc free to rotate between the poles of two electro magnets. The spindle of this disc carries a moving contact which bridges two fixed contacts when the disc rotates through an angle, which is adjustable between 0o to 360o. By adjusting this angle, the travel of moving contact can be adjusted so that the relay can be given any desired time setting which is indicated by a pointer. The dial is calibrated from 0-1. The relay time from name plate cure is to be multiplied by time multiplier setting.

The upper magnet has two windings. The primary coil is connected to the secondary of CT through tappings in it. These tappings are connected to plug Settings Bridge. The secondary is connected to the lower electro magnet. The torque exerted on the disc is due to the interaction of eddy current produced therein by the flux from the upper EM and the lower EM. The relay setting is 50% to 200% in steps of 25%.

b. Shaded Pole Type or Non-Directional Relay

The rotating disc is made of aluminum. In the above type one half of each of electromagnet shown in fig, is surrounded by a copper band called as the shading ring. The shaded portion of the pole products a flux which is displaced in space and time w.r.t the flux produced by the unshaded portion of the pole. These two alternating fluxes cut the disc and produce eddy currents in it. Torques are produced by the interaction of each flux with the eddy current produced by the other flux. The resultant torque causes the disc to rotate.

A spring is used to supply the resetting torque. A permanent magnet is employed to produce eddy current braking to the disc. The braking torque is proportional to the speed of the disc. When the operating current exceeds pick-up value, driving torque is produced and the disc accelerates to a speed where the braking torque balances the driving torque. The disc rotates at a speed proportional to the driving torque.

At a current below the pick-up value, the disc remains stationary by the tension of the control spring acting against the normal direction of disc rotation. The disc rests against a backstop. The position of the back-stop is adjustable. So that the relay-contacts travel distance can be varied according to need. This is called time-setting of the relay.

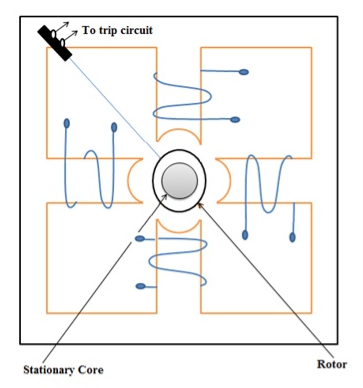

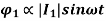

Iii. Induction Cup Type Relay

It is a double actuating quantity relay (current & voltage) which is highly sensitive, high speed, steady & non-vibrating torque and ration of re-set to pick up is high (above 95%) as well as it has operating time less than 0.01 seconds.

The operating is similar to induction motor. It consists of a stationary rotor iron core and moving rotor conductor (cup). The moving element is a hollow cylinder or cup which turns on its axis. The driving element is a four or eight pole structure placed radially around the outside of the cylinder and joined by a yoke. To shorten the air-gap, a stationary iron core is placed inside the rotate cylinder.

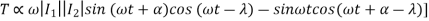

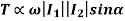

It is a high-speed induction relay since inertia is less. The two pairs of coils are displaced by 90o. When these coils are excited, a rotating magnetic field is produced. The rotor cuts the magnetic field and an emf is induced in the rotor. Which results in a current due to short circuit nature of the rotor. A torque is produced due to the interaction between the rotating flux and the induced current which causes the rotation of the cylinder. The movement of the rotor closes the trip circuit. The torque produced is proportional to |I1||I2| sin α or Φ1 Φ2 sin α, where Φ1 Φ2 are the fluxes due to excitation currents I1 and I2 of coil pairs and α is the phase difference between the two fluxes.

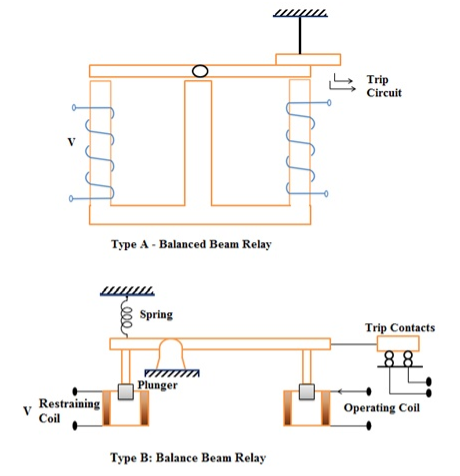

Iv. Balanced Beam Relay

All these relays have the same principle. That is electromagnetic force produced by the magnetic flux which in turn is produced by the operating quantity. The force exerted on the moving element is proportional to the square of the flux in the air gap or square of the current. In DC electromagnetic relays this force is constant. If this force exceeds the restraining force, the relay operates.

This type of balanced beam relay has a fixed beam and an electromagnet (EM) as shown in the figure. The EM has two windings, one is energized by the voltage and the other energized by the current. Under normal conditions, the pull due to the voltage (restraint quantity) will be high and hence the contact remains open. When a fault occurs, the current increases, the pull due to current will be more than the pull due to voltage. This closes the contacts of the trip circuit.

This balanced beam type relay shown in the figure consists of a horizontal beam pivoted centrally, with one armature attached to either side. There are two coils, one on each side. The beam remains horizontal till the operating force becomes greater than the restraining force. Current in coil gives the operating force and in the other, the restraining force. When the operating force or torque increases, the beam tilts and then the contact closes. The relay then actuates the tripping mechanism of the circuit breaker controlling the line / equipment.

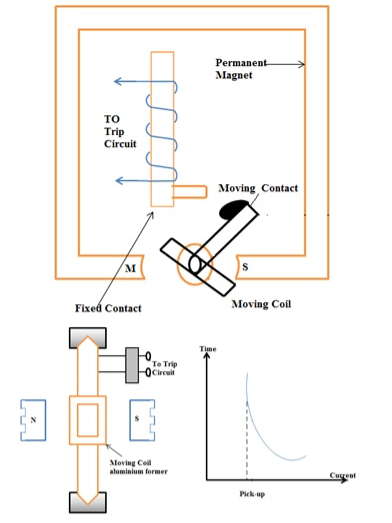

v. Moving Coil Relays

It is of two types

a. Rotary Moving Coil

It consists of a permanent magnet coil wound on a non-magnetic former, spring, spindle etc. as shown in the fig. The coil is energized by the fault current. Due to the interaction of the permanent magnetic field and the field due to the coil, moving torque is developed. Due to this the spindle rotates and closes the trip circuits. It has negative time-current characteristics as shown in the figure. It has high torque / weight ration.

F α NHIL

Where F = Force, N= No. Of turns, H=Magnetic Field, I=Current in the coil, L=Length of coil

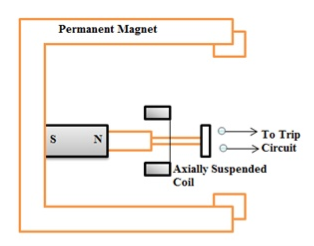

b. Axial Moving Coil

It has axially suspended coil wound on a former. The coil has only axial movement. When the coil is energized by the current, magnetic field is developed and this magnetic field is repelled by the already existing permanent magnet. Due to this, contacts get closed.

This relay is more sensitive and faster than the rotary moving coil relay. This relay has inverse operating time-current characteristics.

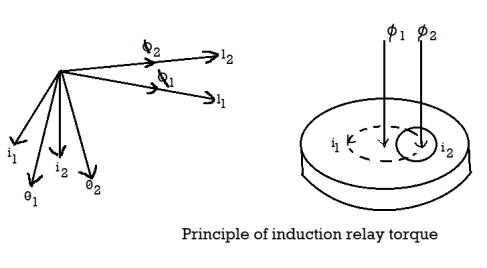

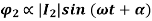

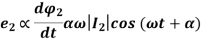

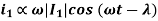

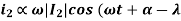

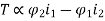

In Induction Relay Torque Equation, two magnetic fluxes Φ1 and Φ2 differing in time phase penetrate through a disc. These alternating fluxes induce emfs e1 and e2 in the disc which lag their respective fluxes by 90°. These emfs lead to the flow of eddy currents i1 and i2. By the interaction of Φ1 with i2 and Φ2 with i1 a driving torque is produced.

The currents i1 and i2 lag the voltages e1 and e2 by the impedance angle λ of the disc. Below figure shows the vector diagram.

Let,

Therefore, the resultant torque is given as-

Thus, the induction relay is a sine comparator in which the maximum torque is developed when α is 90° or 270° and zero torque when α is 0° or 180°.

Equation for Comparators

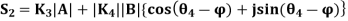

Let us first derive the general threshold equation assuming that there are two input signals S1 and S2 such that when the phase relationship or magnitude relationship fulfills pre-determined threshold conditions, tripping is initiated. The input signals are derived from the system through instrument transformers (CTs and/or PTs). In case the two quantities to be compared are different (i.e., voltage and current), some form of mixing device, such as current voltage transactor, is required.

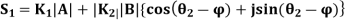

Let the two input signals be represented as –

Where, A and B are the primary system quantities, K1 and K3 are the scalar numbers and |K2|and | K4| are the complex numbers with angles θ2 and θ4 respectively. Taking A as the reference phasor and phasor B to lag A by an angle ɸ. Then the above equation can be rewritten as –

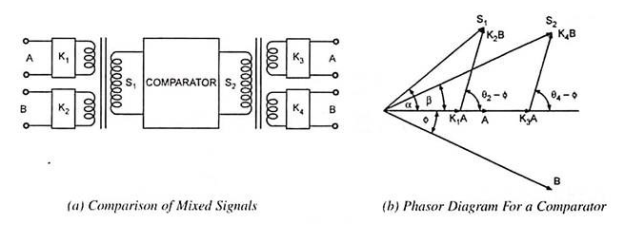

Equation for Electromagnetic Relay

When not more than two quantities are involved, the equation for the characteristic of the relay at the threshold of operation under steady state conditions, when plotted on complex planes is a circle. The General Equation for Electromagnetic Relay can be represented in a general form as-

Where, |A| & |B| are two quantities being compared

= Electrical Angle between A & B

= Electrical Angle between A & B

= Relay characteristic angle, which is the value of

= Relay characteristic angle, which is the value of  for maximum torque

for maximum torque

K & K’ = Scalar Constants

K’’ = Mechanical restraining toque

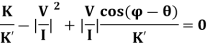

If the two input quantities are current I and voltage V then the equation for threshold operation becomes:

Which can also be explained as: the current winding produces a torque KI2 and the potential winding a torque K’V2, while the torque due to interaction of current and potential windings will be VI cos (Φ-θ).

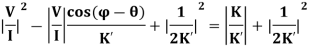

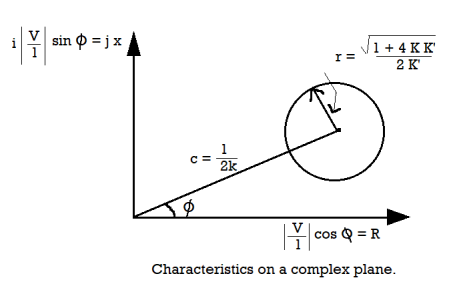

K” is finite only in singe quantity relays, where it is used as a level indicator; it is made negligibly small in relays with more than one input so K” = 0 and dividing throughout by K′ |I|2

It can be represented as a circle on a complex plane, having

As coordinates, i.e., on the R-X plane as shown in the figure below

In an over current relay or o/c relay the actuating quantity is only current. There is only one current operated element in the relay, no voltage coil etc. are required to construct this protective relay.

In an over current relay, there would be essentially a current coil. When normal current flows through this coil, the magnetic effect generated by the coil is not sufficient to move the moving element of the relay, as in this condition the restraining force is greater than deflecting force. But when the current through the coil increases, the magnetic effect increases, and after a certain level of current, the deflecting force generated by the magnetic effect of the coil, crosses the restraining force. As a result, the moving element starts moving to change the contact position in the relay. Although there are different types of over current relays but basic working principle of over current relay is more or less same for all.

Types of Over Current Relays

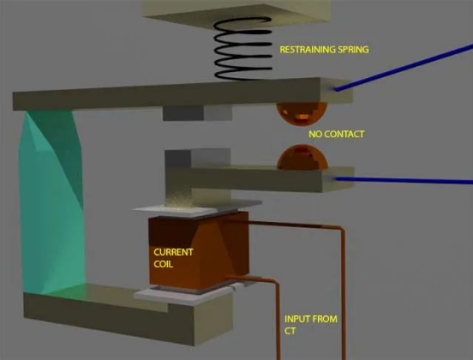

(i) Instantaneous Over Current Relay

Construction and working principle of instantaneous over current relay is quite simple.

Here generally a magnetic core is wound by a current coil. A piece of iron is so fitted by hinge support and restraining spring in the relay, that when there is not sufficient current in the coil, the NO contacts remain open. When the current in the coil crosses a preset value, the attractive force becomes enough to pull the iron piece towards the magnetic core, and consequently, the no contacts get closed.

We refer the pre-set value of current in the relay coil as pickup setting current. This relay is referred as instantaneous over current relay, as ideally, the relay operates as soon as the current in the coil gets higher than pick upsetting current. There is no intentional time delay applied. But there is always an inherent time delay which we cannot avoid practically. In practice, the operating time of an instantaneous relay is of the order of a few milliseconds.

(ii) Definite Time Over Current Relay

This relay is created by applying intentional time delay after crossing pick up the value of the current. A definite time overcurrent relay can be adjusted to issue a trip output at an exact amount of time after it picks up. Thus, it has a time setting adjustment and pickup adjustment.

(iii) Inverse Time Over Current Relay

Inverse time is a natural character of any induction type rotating device. Here, the speed of rotation of rotating part of the device is faster if the input current is more. In other words, time of operation inversely varies with input current. This natural characteristic of electromechanical induction disc relay is very suitable for overcurrent protection. If the fault is severe, it will clear the fault faster. Although time inverse characteristic is inherent to electromechanical induction disc relay, the same characteristic can be achieved in microprocessor- based relay also by proper programming.

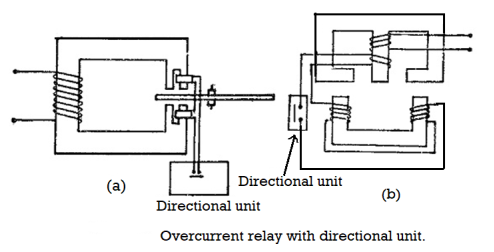

Selective protection cannot be achieved with time graded overcurrent protection systems in ring or loop systems as well as in radial circuits with two end power supply. A directional feature is incorporated in the Directional Relays as shown in Fig.

Figure (a) shows how an induction disc type over current relay with split-pole magnet, having in addition a directional unit consisting of capacitance or a resistance capacitance circuit works. Figure (b) shows the watt metric type of induction disc relay. Here the directional unit controls the angle between the two fluxes by varying the RX parameters of the lower electromagnet.

Another method of control in the watt metric element is to supply the lower winding from a separate voltage source. When the voltage of this source is equal and opposite to the output of the upper magnet secondary winding there is no current in the lower coil, and therefore no torque is produced. If it opposes and is less than the secondary output, or if it assists the secondary output, there is an operating torque. Conversely, if this source voltage opposes and exceeds the secondary output the current in the lower coif is reversed, giving a reverse torque. This latter method of control is the basis of the Translay balanced-voltage unit protection.

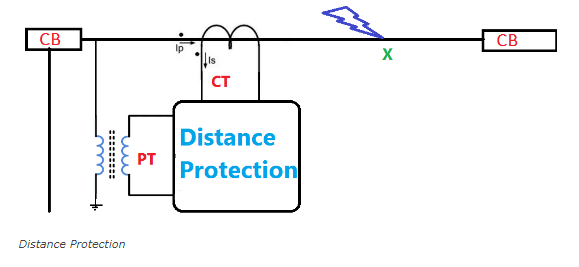

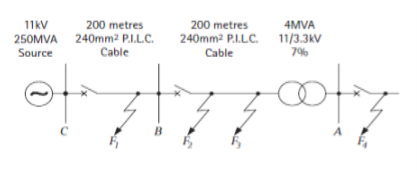

Distance protection relay is the name given to the protection, whose action depends on the distance of the feeding point to the fault. The time of operation of such protection is a function of the ratio of voltage and current, i.e., impedance. This impedance between the relay and the fault depends on the electrical distance between them. The principal type of distance relays is impedance relays, reactance relays, and the reactance relays. Distance protection relay principle differs from other forms of protection because their performance does not depend on the magnitude of the current or voltage in the protective circuit but it depends on the ratio of these two quantities. It is a double actuating quantity relay with one of their coils is energized by voltage and the other coil is energized by the current. The current element produces a positive or pick-up torque while the voltages element has caused a negative and reset torque.

The relay operates only when the ratio of voltage and current falls below a set value. During the fault the magnitude of current increases and the voltage at the fault point decreases. The ratio of the current and voltage is measured at the point of the current and potential transformer. The voltage at potential transformer region depends on the distance between the PT and the fault.

If the fault is nearer, measured voltage is lesser, and if the fault is farther, measured voltage is more. Hence, assuming constant fault impedance each value of the ratio of voltage and current measured from relay location comparable to the distance between the relaying point and fault point along the line. Hence such protection is called the distance protection or impedance protection.

Distance zone is non-unit protection, i.e., the protection zone is not exact. The distance protection is high-speed protection and is simply to apply. It can be employed as a primary as well as backup protection. It is very commonly used in the protection of transmission lines.

Distance relays are used for both phase fault and ground fault protection, and they provide higher speed for clearing the fault. It is also independent of changes in the magnitude of the short circuits, current and hence they are not much affected by the change in the generation capacity and the system configuration. Thus, they eliminate long clearing times for the fault near the power sources required by overcurrent relay if used for the purpose.

The relay whose operation depends on the phase difference of two or more electrical quantities is known as the differential protection relay. It works on the principle of comparison between the phase angle and the magnitude of the same electrical quantities. For example: Consider the comparison of the input and output current of the transmission line. If the magnitude of the input current of the transmission line is more than that of output current that means the additional current flows through it because of the fault. The difference in the current can operate the differential protection relay.

The following are the essential condition requires for the working of the differential protection relay.

- The network in which the relay use should have two or more similar electrical quantities.

- The quantities have the phase displacement of approximately 180º.

The differential protection relay is used for the protection of the generator, transformer, feeder, large motor, bus-bars etc. The following are the classification of the differential protection relay.

- Current Differential Relay

- Voltage Differential Relay

- Biased or Percentage Differential Relay

- Voltage Balance Differential Relay

(i) Over Current relay for Feeder Protection

It is customary to have two elements of over current and one element of earth fault protection system in the most elementary form of protection of three phase feeders. Different types of feeders employ the over current protection along with the directional relay so that proper discrimination of an internal fault is possible. Some examples are illustrated below.

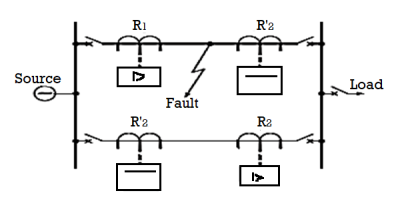

(a) Application of directional relays to parallel feeders

It may be seen from the below given parallel feeders that the relays placed at the load side of both the lines use directional element which respond to a direction away from the bus bars. Similarly, the relays placed at the source side do not require any directional element.

(b) Application of directional relays to ring mains

A similar concept of discrimination is also utilized in the below given ring main feeder and a feeder fed from both the sides. It can be observed that relays placed near the bus connecting the sources, don’t have any directional feature, whereas the rest of the buses, respond to a direction always away from the source. It is good practice to locate a fault anywhere among different sections of the feeders and check whether that particular section only is isolated without disrupting the power flow in other sections.

(c) Over current protection radial system

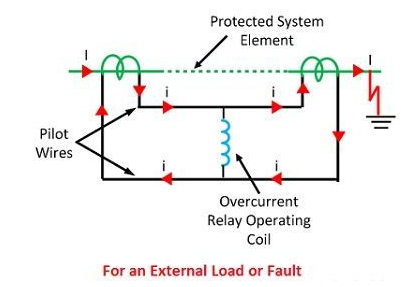

(ii) Pilot Wire Schemes for Feeder Protection

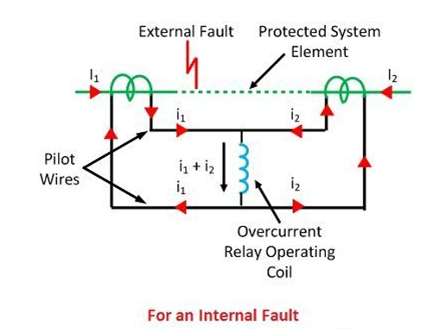

In differential protection scheme, the current entering at one end of the line and leaving from other end of the line is compared. The pilot wires are used to connect the relays. Under normal working condition, the two currents at both ends are equal and pilot wires do not carry any current, keeping relays inoperative. Under an internal fault condition, the two currents at both the ends are no longer same, this causes circulating current flow through pilot wires and makes the relay to trip. The various schemes used with this method of protection are,

1. Merz-Price Voltage Balance System

2. Translay Scheme

(iii) Distance Relay for Feeder Protection

One of the important protections in Power System Protection is Feeder Protection.

Different types of relays are used for feeder protection like electromagnetic type relays, static type relays etc. But now a day we are using Numerical relays for all protections.

The benefits of Numerical relays are,

- Accurate tripping,

- Less tolerance,

- Fault events and counter storage

- Display of fault parameters on screen

(Fault parameters means current, voltage, resistance and reactance values during fault and fault distance, Numerical relays can store thousands of tripping events).

The main inputs needed for distance protection is Voltage and Current from corresponding feeder PT and CT.

According to site conditions we will set certain impedance values in relay settings (i.e., R and X values) for fault detection. Relay will monitor Current and Voltage in the feeder line (PT and CT secondary), and from these values, the relay will calculate Impedance value Z. i.e., Z = V/I. In normal load condition the impedance values on line will be high. But when fault comes on the feeder line, the impedance will decrease and becomes less than the impedance setting in the relay, then the distance relay will trip with in 40 ms in zone 1 (different zones are there and that will be explained later) and isolate power equipment’s from fault. I.e., during fault, relay will trip and show the fault parameters like fault current, voltage, reactance, resistance and fault distance on relay screen.

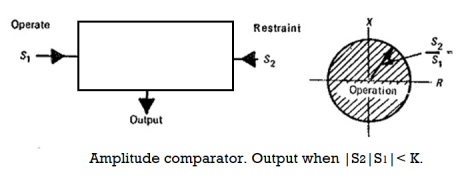

a) Amplitude Comparator

Amplitude comparator compares the amplitudes of two (or more) input quantities. The phase angle between the quantities under comparison (inputs) is not recognized or noticed by the amplitude comparator.

If the two input signals are S1 and S2 (say S1 the operating and S2 restraining), the amplitude comparator gives positive output only if –

S2/S1 < K.

The function is represented by a circle in the complex plane with its centre at the origin. This defines the boundary of the marginal operation. The main purpose of amplitude comparators is to provide direction and distance protection.

Mainly there are three types of amplitude comparators

- Integrating Comparators

- Instantaneous Comparators

- Sampling Comparators

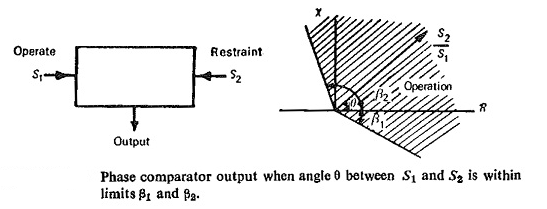

b) Phase Comparator

Phase Comparator Circuit technique is the most widely used for all practical directional, distance, differential and carrier relays. If the two input signals are S1 and S2 the output occurs when the inputs have a phase relationship lying within specified limits.

Both inputs must exist for an output to occur; ideally, operation is independent of their magnitudes, and is dependent only on their phase relationship.

Figure below illustrates the Phase Comparator Circuit in its simple form. The function as defined by the boundary of marginal operation is represented by two straight lines from the origin of the complex plane.

The condition of operation can be put mathematically as

Where θ is the angle by which S2 leads S1. If β1=β2=90° the comparator is known as cosine comparator and if β1=0 and β2=180° it is a sine comparator.

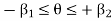

c) Coincidence Phase Comparator

The basic concept of phase comparison is simpler in that it is possible to deal with signals of equal strength whose coincidence (or non-coincidence) is readily measurable. Considering two sinusoidal signals S1 and S2, the period of coincidence of S1 and S2 will depend on the phase difference between S1 and S2. Figure below illustrates the coincidence of signals for different phase relationships in Coincidence Type Phase Comparator.

It can be seen that the period of coincidence is equal to the period of non-coincidence for a phase difference of ±90°, the period of coincidence is less than the period of non-coincidence and vice versa when the phase difference is less than ±90°.

Depending upon the phase relation of the input signals it is possible to design the circuit to give an output a Yes or a No, by measuring the period of Coincidence Type Phase Comparator. The period of coincidence of two signals with a phase difference of θ is ψ=180-θ.

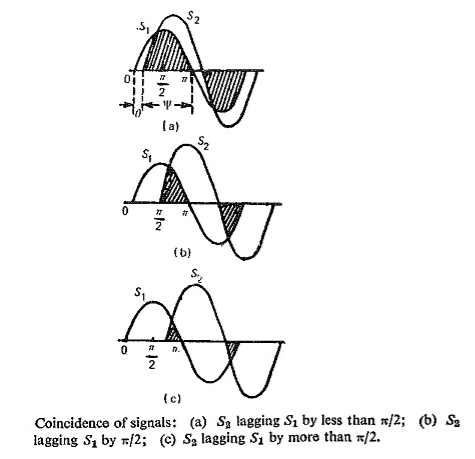

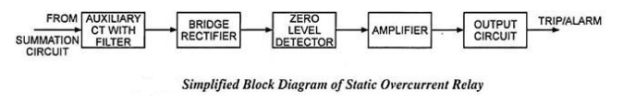

d) Basic Elements of Static Relays

The static relay is the combination of both the static and the electromagnetic relay. In this relay, there is no armature and moving contacts and response is developed by the components without mechanical motion. The solid-state components used are transistors, diodes, resistors, 0and capacitor and so on. In the static relay, the measurement is performed by electronic, magnetic, optical or another component without mechanical motion.

Static relay consists of the following functional circuits:

- Input stage with CT’s and PT’s:

The input to the relay is obtained from the CT/PT. This output of CT/PT is given to the auxiliary CT/PT. The input stage has CT’s and PT’s, summation units, auxiliary CT’s and PT’s, filter.

- Rectifiers and smoothing circuits:

In these circuits, the input given from auxiliary CT/PT is given to the single bridge rectifier to rectify the fluctuating quantities. This rectifier output is then smoothened to avoid any ripples and is provided it to a level detector which levels the quantities.

- Comparator:

The output which is smoothened is given to the comparator to compare it with a fixed input. Thus, the output is then fed to the measuring unit. The comparators used are of amplitude, hybrid and phase comparators.

- Measuring unit:

If the input of the comparator is above the threshold value, then the level detector gives an output otherwise it doesn’t produce output if it’s below the threshold value.

There are amplifiers, logic circuits as well as level detector circuits to complete the job.

- Output stage:

The output of the level detector is then fed to the output stage of the relay in which it has a PMMC (Permanent magnet moving coil) relay, a Thyristor in series with the trip coil and auxiliary switch.

Whenever there is a fault the relay operates, and it gives gate signal to the Thyristor which then energizes the trip coil so that the circuit breaker contacts get open and the circuit is tripped. These relays do not have any arcing problems as all the entire relay system is static.

Advantages of Static Relay:

- Consumption of power is low.

- The selectivity of the system can be improved by using special circuits.

- There are no moving parts thus arcing and contact bounce is not present which saves a lot of money.

- Vibrations and effects of gravity is not present in operation of static relays.

- These relays are compact.

- These relays have high speed.

- The relays can be programmed according to the needs.

- The settings of the relay can also be changed if the line carries charge.

- Only one relay is sufficient for several functions.

Limitations of Static Relay:

- Some components are sensitive to electrostatic discharges. Even small charges can damage the components, and therefore precautions are necessary for the manufacturing of static relays to avoid components failures due to electrostatic discharges.

- Static relays are sensitive to voltage spikes or voltage transients. Special measures are taken to avoid such problems.

- The reliability of the system depends on a large number of small components and their electrical components.

- The static relay has low short-time overload capacity as compared to electromagnetic relays.

- Static relays are costlier, for simple and single function than their equivalent electromechanical counterparts. But for multi-functional protection, static relay proves economical.

- Highly trained personnel are required for their servicing.

- Static relays are not very robust in construction and easily affected by surrounding interference.

e) Over Current Relays

The over current relays, even though simplest of all types of electromechanical relays, are the most difficult static relays. This is because the induction disc characteristics of the over current relays (inverse characteristics) are not amenable to simple mathematical analysis. The first static relays developed were the high-speed differential relays and the distance relays.

Fault current level detectors are termed over current relays. They are more complicated in static form as compared to their electromagnetic counterparts.

However, static over current relays offers several advantages over the electromagnetic form:

1. Low CT burden – The VA consumption of static overcurrent relays is quite low (7 mVA to 100 mVA) as compared with that of electromagnetic relays (1VA to 3VA) so that smaller CTs are required. The performance of CT under short-circuit condition is also improved.

2. Compact in size – The size of a single three-phase overcurrent relay may be about one-fourth of three electromagnetic relays. Hence less panel space is required in case of static overcurrent relays.

3. Possibility of Instantaneous Reset. In case of static overcurrent relays instantaneous reset is possible. This is due to the absence of moving parts, which facilitates the application of automatic reclosing of breakers.

4. No over-reaching tendencies and more accurate time-current characteristic.

5. Less maintenance, long life and not affected by shock and vibration.

The technique of over current relaying is still widely used as a means of fault detection on distribution system and on transmission lines supplied from one end. In the case of transmission lines supplied from both ends, it is employed with directional relays. Over current relays are also employed in conjunction with distance relays to provide backup protection. The protective relays are either single actuating quantity relays such as over current, under-voltage, earth fault relay or double actuating quantity relays such as distance relays, differential relays.

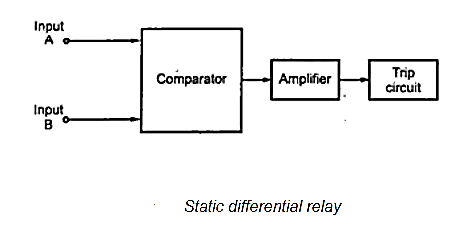

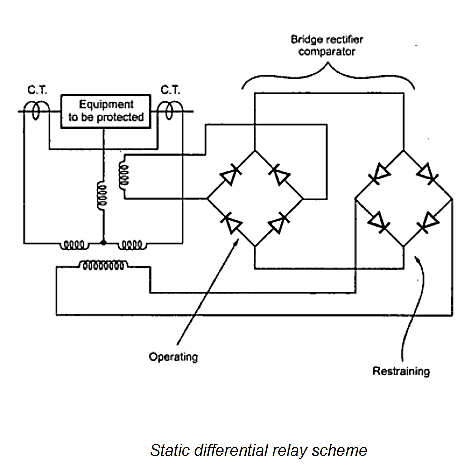

f) Differential Protection

A differential relay is the relay which operates when the phasor difference of two or more similar electrical quantities exceeds a predetermined value.

In static differential relay, two similar quantities either voltages or currents are compared. The comparator measures the vector difference between the two similar input signals. The rectifier bridge type comparator is generally used in the static differential relay. The block diagram is shown in the figure

In normal conditions, the two quantities balance each other and the comparator output is zero and the relay us inoperative.

For any internal fault conditions, the comparator senses the phase difference between the two quantities and produces the output. This is amplified and given to the trip circuit which operates the relay. This scheme is used for protection of the generators and transformers against any type of internal fault.

The various advantages of static differential relay over electromagnetic differential relay are, highly sensitive, compact, and very fast in operation, low power consumption, less burden on input CTs and inrush current proof characteristics.

The basic static differential relay scheme is shown in the above figure.

Let no and nr be the number of turns of operating and restraining coils respectively. Then the relay operates when,

K1 no Io > K2 nr Ir + K'

Where k1 and k2 are design constants while K' is the spring control torque.

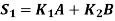

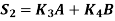

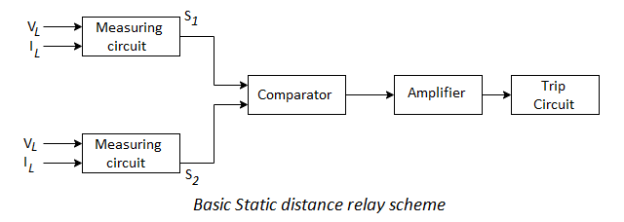

g) Static Distance Protection

In the distance relay, the operation is dependent on the ratio of the voltage and current, which is expressed intends of impedance. The relay operates when the ratio V/I i.e., impedance is less than a predetermined value. The distance relays include impedance, reactance and admittance relays. In static relays the comparison of voltage and current is achieved by electronic comparator circuits.

The basic block diagram of static distance relay is shown in the Fig

The line voltage VL and line current IL are given as the inputs to the two measuring circuits. The circuits produce the outputs S1 and S2 depending upon their characteristics. Thus,

S1= K1 VL + K2 IL

S2= K3 VL + K4 IL

Where K1, K2, K3 and K4 are to be selected according to the requirement of the characteristics.

Now depending upon whether the comparator is amplitude or phase comparator and the constants K1 to K4, the various characteristics of the distance relay can be obtained. The static distance relays are used popularly for protection of medium and long transmission lines, parallel feeders and interconnected and T connected lines.

References:

1. Power System Protection and Switchgear – B. Ravindranath & M. Chander–New Age International Publishers (Second Edition)

2. Electrical Power System - C.L. Wadhwa New Age International Publishers. (Sixth Edition).

3. Power System Engineering - M.L. Soni, P.V. Gupta, U.S. Bhatnagar, A. Chakrabarti, Dhanpat Rai & Co. (P) Ltd.

4. Switchgear and Protection – Sunil S Rao, Khanna Publishers, New Delhi.