Unit - 1

Mechanical engineering design

The engineering layout method is a not unusual place collection of steps that engineers use in developing useful merchandise and processes.

The method is distinctly iterative - components of the method frequently want to be repeated regularly earlier than any other may be entered - eleven though the part(s) that get iterated and the wide variety of such cycles in any given challenge can also additionally vary.

Among the essential factors of the layout method are the status quo of targets and criteria, synthesis, analysis, construction, checking out and assessment.

It's essential to apprehend that there are numerous framings/articulations of the engineering layout method.

Different terminology hired can also additionally have various tiers of overlap, which influences what steps get said explicitly or deemed "excessive level" as opposed to subordinate in any given model.

This, of course, applies as an awful lot to any precise instance steps/sequences given here. One instance framing of the engineering layout method delineates the subsequent stages: studies, conceptualization, and feasibility assessment, setting up layout requirements, initial layout, designated layout, manufacturing making plans and device layout, and manufacturing.

Others, noting that "one-of-a-kind authors (in each studies literature and in textbooks) outline one-of-a-kind levels of the layout method with various sports going on inside them," have recommended greater simplified/generalized models - including trouble definition, conceptual layout, initial layout, designated layout, and layout communication.

Another précis of the method, from European engineering layout literature, consists of explanation of the task, conceptual layout, embodiment layout, element layout.

In those examples, different key aspects - including idea assessment and prototyping - are subsets and/or extensions of 1 or greater of the indexed steps.

1. Define the Problem

The engineering layout procedure begins off evolved while you ask the subsequent questions on issues which you observe:

What is the trouble or need?

Who has the trouble or need?

Why is it essential to solve?

[Who] need(s) [what] because [why].

For unique assist with this step, use those resources:

Define the Problem

Design Notebook

Mind Mapping

2. Do Background

Research Learn from the reports of others — this may assist you discover approximately present answers to comparable issues, and keep away from errors that had been made with inside the past.

So, for an engineering layout project, do history studies in foremost areas:

Users or customers

Existing answers

For unique assist with this step, use those resources:

Background Research Plan for an Engineering Design Project

3. Specify Requirements

Design necessities country the essential traits that your answer need to meet to succeed. One of the first-class methods to pick out the layout necessities on your answer is to research the concrete instance of a comparable, present product, noting every of its key features.

For unique assist with this step, use those resources:

Specify Requirements

Design Requirement

Examples

How to Analyze a Physical Product How to Analyze a Software Product or Website How to Analyze an Environment How to Analyze an Experience How Many Design Requirements?

4. Brainstorm Solutions

There are usually many precise opportunities for fixing layout issues. If you consciousness on simply one earlier than searching on the alternatives, it's far nearly sure which you are overlooking a higher answer.

Good designers try and generate as many viable answers as they can. For unique assist with this step, use those resources:

Brainstorm Multiple Solutions

5. Choose the Best Solution

Look at whether or not every viable answer meets your layout necessities. Some answers probable meet greater necessities than others.

Reject answers that don't meet the necessities.

For unique assist with this step, use those resources:

Choose the Best Solution

6. Develop the Solution

Development includes the refinement and development of an answer, and it maintains for the duration of the layout procedure, frequently even after a product ships to customers.

For unique assist with this step, use those resources: Development Work Drawing Storyboards

7. Build a Prototype

A prototype is a running model of an answer. Often it's far made with one of a kind substances than the very last model, and usually it isn't always as polished.

Prototypes are a key step with inside the improvement of a very last answer, permitting the clothier to check how the answer will work.

For unique assist with this step, use those resources: Prototyping

8. Test and Redesign

The layout procedure includes a couple of iterations and redesigns of your very last answer.

You will in all likelihood take a look at your answer, discover new issues, make changes, and take a look at new answers earlier than selecting a very last layout.

For unique assist with this step, use those resources: Test and Redesign

9. Communicate Results

To whole your project, talk your consequences to others in a very last document and/or a show board.

Professional engineers usually do the same, very well documenting their answers in order that they may be synthetic and supported.

For unique assist with this step, use those resources: Final Report Abstract Display Board Science Fair Judging

Code and Standardization:

A code is a hard and fast of guidelines and specs for the suitable techniques and substances utilized in a positive product, constructing or process. Codes may be accepted through local, country or federal governments and might deliver the pressure of law.

The predominant reason of codes is to shield the general public through putting in place the minimal appropriate degree of protection for buildings, merchandise and approaches.

It is often a formal file that establishes uniform engineering or technical criteria, techniques, approaches and practices. Standards permit for interchangeability of parts, machine interoperability, and that they make sure quality, reliability and protection.

Standards, codes, specs are extraordinarily important - regularly essential - technical files in engineering and associated technical fields.

Standards

A technical popular is a longtime norm or requirement. The files organized through an expert organization or committee that are believed to be excellent and right engineering practices and which comprise obligatory requirement.

Codes

A code is a hard and fast of guidelines and specs or systematic techniques for design, fabrication, set up and inspection techniques organized in this kind of way that it could be followed through prison jurisdiction.

The PFI standards contain minimum requirements; however, the designer or fabricator may consider specifying additional requirements beyond the scope of PFI publications. The use of PFI standards or bulletins is voluntary. A listing of PFI publications follows.

Engineering and Fabrication

- ES2

Method of Dimensioning Piping Assemblies - ES7

Minimum Length and Spacing for Welded Nozzles - ES16

Access Holes, Bosses, and Plugs for Radiographic Inspection of Pipe Welds - ES26

Welded Load Bearing Attachments to Pressure Retaining Piping Materials - ES36

Branch Reinforcement Work Sheets - ES40

Method of Dimensioning Grooved Piping Assemblies - ES44

Drafting Practices Standard

Welding and Fabrication

- ES1

Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds - ES21

Internal Machining and Fit-up of GTAW Root Pass Circumferential Butt Welds - ES24

Pipe Bending Methods, Tolerances, Process and Material Requirements - ES35

Nonsymmetrical Bevels and Joint Configurations for Butt Welds - ES45

Recommended Practice for Local Post-Weld Heat Treatment - ES47

Welding of Internally Clad Piping - ES49

Guidelines for Installation of Integrally Reinforced Branch Connection Outlet Fitting

Cleaning, Painting, and Shipping

- ES5

Cleaning of Fabricated Piping - ES29

Internal Abrasive Blast Cleaning of Ferritic Piping Materials - ES31

Standard for Protection of Ends of Fabricated Piping Assemblies - ES34

Temporary Painting/Coating of Fabricated Piping - ES37

Standard for Loading and Shipping of Piping Assemblies

Quality Control

- ES3

Fabricating Tolerances - ES11

Permanent Marking on Piping Materials - ES22

Recommended Practice for Color Coding of Piping Materials - ES32

Tool Calibration - ES39

Fabricating Tolerances for Grooved Piping Systems - ES41

Standard for Material Control and Traceability of Piping Components - ES43

Standard for Protection of Austenitic Stainless Steel and Nickel Alloy Materials

Examination and Testing

- ES4

Hydrostatic Testing of Fabricated Piping - ES20

Wall Thickness Measurement by Ultrasonic Examination - ES27

"Visual Examination" The Purpose, Meaning and Limitation of the Term - ES42

Standard for Positive Material Identification of Piping Components using Portable X-Ray Emission Type Equipment - ES48

Random Examination

Interchangeability:

In device layout interchangeability refers back to the interchangeable components.

Interchangeable components are one this is made to almost equal in order that it could efficaciously replacement the same components and healthy into the meeting of the identical type.

Such randomly decided on additives can update some other with none custom fitting, which include filing.

In mass manufacturing, preserving length of the aspect inside a near diploma of accuracy is tough and time-consuming.

Even eleven though there might be a few variant. The motive for this inaccuracy can be because of mistakes in measuring, terrible alignment of work piece, machining mistakes, mistakes because of device wear, etc.

The accuracy of aspect is crucial in right functioning of mechanism, however it's miles vain to make components any such specific to satisfy the sensible requirement. Hence in mass manufacturing, its miles allowed to the additives have a few variant in its size, inside a positive limit.

The diagnosed variant in dimensions of additives promotes the performance of producing in addition to make random mating components healthy properly.

Whether absolutely the interchangeability relevant or not, relies upon the shape of various components and tolerance adopted.

In order to supply universally interchangeable components, the producing method, the gauges and slicing gear etc. should be standardized (global standards).

The fashionable specification made viable through the improvement of gauges, measuring gear (e.g. Caliper, sine bar), enterprise standards (e.g. Screw threads), jigs and fixtures.

Advantages of interchangeability

- Precise size isn't essential, produce aspect inside small size mistakes limit.

- Economic oriented.

- It permits mass manufacturing, reduces the manufacturing fee.

- Mating components can freely update without custom fittings like fillets.

- Readily to be had alternative aspect with inside the market.

- Assembly method calls for lesser skill.

- Reduce fee and hard work time through permitting smooth maintenance.

- Easy discipline repair.

Preferred numbers:

In business design, desired numbers (additionally referred to as desired values or desired collection) are general tips for selecting actual product dimensions inside a given set of constraints.

Product builders have to pick several lengths, distances, diameters, volumes, and different feature quantities.

While all of those picks are restrained through concerns of functionality, usability, compatibility, protection or cost, there commonly stays sizable leeway with inside the actual desire for lots dimensions.

Preferred numbers serve purposes:

Using them will increase the opportunity of compatibility among gadgets designed at specific instances through specific people.

In different words, it's miles one tactic amongst many in standardization, whether or not inside a corporation or inside an industry, and it also includes perfect in business contexts (until the aim is seller lock-in or deliberate obsolescence)

They are selected such that after a product is synthetic in lots of specific sizes, those will emerge as more or less similarly spaced on a logarithmic scale.

They consequently assist to decrease the wide variety of various sizes that want to be synthetic or saved in stock.

Preferred Numbers are a vital device which decrease useless versions in sizes.

The whole variety is blanketed through minimal wide variety of sizes that is fantastic for each manufacturer and customer.

With the recognition of standardization, there may be want to maintain the same old sizes or dimensions of element in discrete steps.

The sizes must be unfold over extensive variety and on the identical time, they must be spaced properly.

E.g. Diameters are to be standardized among 10mm to 25mm, then sizes must be 10mm, 12.5mm, 16mm, 20mm, and 25mm.

This cause use the geometrical collection called desired collection. It consists of S5, S10, S20, S40, S80 collection and every collection has a sequence factor. Series and collection factors

For organizing a sequence, first a variety of is taken. By multiplying this wide variety through a sequence factor, 2d wide variety is received.

Series | Multiplying Series Factor |

S5 |  |

S10 |  |

S20 |  |

S40 |  |

S80 |  |

Now through multiplying 2d wide variety through a sequence factor, 0.33 wide variety is received and so on.

Fits and Tolerances:

Fits

When elements are to be assembled the relation as a result of the distinction among their sizes earlier than meeting is referred to as an in shape.

The in shape indicates the variety of tightness or looseness which might also additionally end result from the software of a selected mixture of allowances and tolerances with inside the layout of mating elements.

There are 3 trendy sorts of in shape among the mating elements

1. Clearance in shape:

A clearance in shape is one having limits of length so prescribed that a clearance usually effects whilst mating elements are assembled.

2. Interference in shape:

An interference in shape is one having limits of length so prescribed that an interference usually effects whilst mating elements are assembled.

3. Transition in shape:

A transition in shape is one having limits of length so prescribed that both a clearance and interference might also additionally usually end result whilst mating elements are assembled.

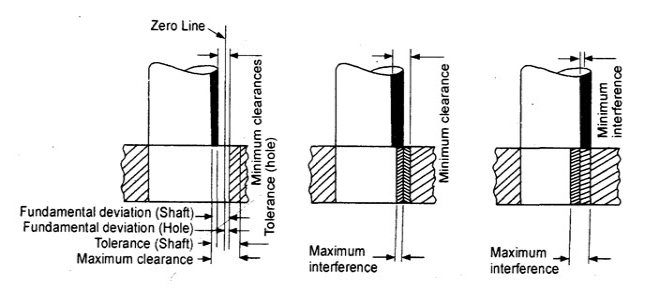

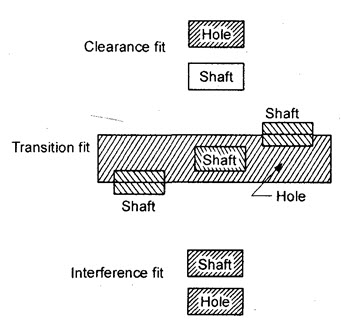

Types of Fits

The three types of fits are shown in Fig. 1.1 The disposition of tolerance zones for the three classes of fit are shown in Fig. 1.2.

Fig. 1 Types of fits

Fig. 2 Disposition of tolerance zones for the three classes of fit

Standard Tolerances

There are 18 standard grades of tolerances as specified by BIS with designations ITOI, ITO and IT to IT 16.

Standard tolerance unit, I = 0.45 D1/3 + 0.001D

Where i = standard tolerance unit in microns

D = diameter in mm

The standard tolerances for the various grades are given in Table 1.1 and tolerance grades for various manufacturing processes in Table 1.2

Table 1.1 Standard tolerances.

Grade | IT5 | IT6 | IT7 | IT8 | IT9 | IT10 | IT11 | IT12 | IT13 | IT14 | IT15 | IT16 |

Value | 7i | 10i | 16i | 25i | 40i | 64i | 100i | 106i | 200i | 400i | 640i | 1000i |

Table 1.2 Tolerance grade in various manufacturing processes.

Tolerance grade | Manufacturing process that can produce |

16 15 14 13 12 11 10 9 8

7

6

5 | Sand casting: flame cutting Stamping Die casting or moulding; rubber moulding Press work, tube drawing Light press work, tube drawing Drilling, rough turning, boring, precision tube drawing Milling slotting, planning, metal rolling, or extrusion. Worn capstan or automatic; horizontal or vertical boring Centre lathe turning and boring, reaming, capstan or automatic in good condition High quality turning, broaching, honing Grinding or Fine honing Machine lapping, diamond or fine boring, fine grinding |

Key Takeaways:

- It is often a formal file that establishes uniform engineering or technical criteria, techniques, approaches and practices.

- Such randomly decided on additives can update some other with none custom fitting, which include filing.

- Product builders have to pick several lengths, distances, diameters, volumes, and different feature quantities.

Engineering substances refers back to the organization of substances which are used with inside the production of artificial systems and components. The number one feature of an engineering cloth is to resist carried out loading without breaking and without showing immoderate deflection. The main classifications of engineering substances encompass metals, polymers, ceramics, and composites. The crucial traits of the substances inside every of those lessons are mentioned in this page, and tables of cloth homes also are provided.

Ferrous Alloys

Ferrous alloys have iron because the base detail. These alloys and encompass steels and solid irons. Ferrous alloys are the maximum not unusual place steel alloys in use because of the abundance of iron, ease of production, and excessive versatility of the cloth.

The largest downside of many ferrous alloys is low corrosion resistance. Carbon is a crucial alloying detail in all ferrous alloys. In general, better degrees of carbon growth electricity and hardness, and reduce ductility and weld ability.

Carbon Steel

Carbon steels are essentially simply combos of iron and carbon. They might also additionally comprise small quantities of different elements, however carbon is the number one alloying ingredient. The impact of including carbon is a growth in electricity and hardness.

Most carbon steels are undeniable carbon steels, of which there are numerous types.

Low-Carbon

Steel Low-carbon metallic has much less than approximately 0.30% carbon. It is characterized with the aid of using low electricity however excessive ductility. Some strengthening may be accomplished thru bloodless working, however it does now no longer reply properly to warmness treatment.

Low-carbon metallic could be very wieldable and is less expensive to produce. Common makes use of for low-carbon metallic encompass wire, structural shapes, gadget parts, and sheet steel.

Medium-Carbon

Steel Medium-carbon metallic incorporates among approximately 0.30% to 0.70% carbon. It may be warmness handled to growth electricity, in particular with the better carbon contents. Medium-carbon metallic is often used for axles, gears, shafts, and gadget parts.

High-Carbon Steel

High-carbon metallic incorporates among approximately 0.70% to 1.40% carbon. It has excessive electricity however low ductility. Common makes use of encompass drills, reducing tools, knives, and springs. Carbon Steel Materials Table The desk underneath offers consultant mechanical homes for numerous not unusual place carbon steels.

Non – Ferrous:

Non-ferrous metals and their uses

These metals consist of each metallic and alloy that doesn't include iron.

A quick listing of not unusual place non-ferrous metals will consist of:

Precious metals like silver, platinum, and gold Copper and its alloys like bronze and brass Nickel, Palladium, Platinum Titanium Aluminum Tin, Lead Zinc With this type of huge variety of substances on this grouping, the various mechanical houses that endorse iron may be found in non-ferrous metals.

For example, alloys of aluminum or titanium might be substituted for metallic in lots of cases, if it had been now no longer value-prohibitive to do so. Iron’s magnetic abilities might be emulated with nickel, cobalt, or uncommon earth factors alloyed with different metals.

However, due to the fact non-ferrous metals frequently value more, they have a tendency to be selected for his or her specific attributes, in place of for the approaches they are able to behave like metallic.

Lighter weights, conductivity, corrosion resistance, non-magnetic houses, subculture, or ornamental fee are a number of the motives to select a non-ferrous metallic. Some metals are prized precisely due to the fact they're uncommon: earlier than enormous aluminum production turned into possible, aluminum turned into a luxurious metallic utilized in high-stop tableware.

All varieties of specialized substances are forged. However, in conventional sand casting foundries, there are 3 noteworthy non-ferrous casting metals.

Bronze and brass

Bronze and brass had been the primary metals forged with the aid of using humanity with inside the Bronze Age, and those copper alloys are nonetheless sand casted today.

They’re melted at a whole lot decrease temperatures than ferrous substances, and that they forged element well, so they're frequently utilized in ornamental packages like statuary.

Bronze and brass are softer than metallic, however they're corrosion resistant even with inside the presence of salt, so those metals are utilized in popular marine packages like fittings on boats. Brass is likewise resistant to “galling,” that is the wear and tear of metallic towards itself, and so brass is now and again forged for mechanical parts, like marine propellers—or machined for bearings and zippers.

Both alloys are pretty luxurious as they depend upon copper, a metallic additionally in call for its electric houses.

Aluminum

Aluminum is a metallic with a miles decrease density than iron, making it a critical fabric in packages that want power without weight, along with the aerospace industry. It is corrosion resistant due to the fact aluminum, like stainless metallic, reacts to oxidization with the aid of using growing a metallic oxide shell that protects it.

Aluminum additionally has a decrease melting factor than the various steels or irons it'd replace, which makes it less difficult to forged than metallic, desiring much less oversight for complicated forms.

The largest drawback of aluminum is expense. Considering casting substances

When designing a casting, locating the correct metallic to stability fee and shape is an artwork and science. The proper metallic for a process will fulfill each the aesthetics and mechanical necessities of the software, and this may have an impact on the manufacturing strategies required to take a prototype to very last product.

Ferrous metals are the maximum not unusual place preference for castings, frequently picked for his or her value-performance and their mechanical houses. Sometimes it’s now no longer the power of a metallic that dictates the preference, however houses along with weight, corrosion resistance, or non-magnetism.

Non-ferrous alloys like bronze and brass also can be selected for subculture or for his or her beauty. Consultation with an engineer can assist a fashion dressmaker discover concord among the extraordinary components in their project, deciding on the correct metallic to honor each software and budget.

Non-metals:

Non-metal substances are the ones substances which lack metal attributes (lustrous, malleable, ductile, correct conductors of warmth and strength etc.). They are commonly utilized in engineering because of their flexibility, low price and resistance to warmth and strength.

Plastics

Plastics are artificial substances which may be molded into preferred shapes beneath pressure (without or with the utility of warmth).

Plastics are appreciably utilized in numerous business packages due to the fact of their corrosion resistance, pretty low price and dimensional stability.

Following are principal forms of plastics

Thermosetting plastic

Thermosetting plastic is a polymer that irreversibly turns into inflexible while heated. Thermoplastic is a polymer, which turns into gentle while heated and tough while cooled.

Rubber

Rubber has excessive bulk modulus. Rubber is utilized in force elements, vibration isolation, sealing and comparable packages

Leather

Leather is utilized in engineering because of its put on resistance and flexibility. Rubber is utilized in making washers and belt drives.

Timber

Timber is pretty low-price material. It is terrible conductor of each warmth and strength. It has correct elastic and frictional properties. Timber is broadly utilized in making foundry styles and transient gadget parts (like wheels, gears, shafts etc.).

Design requirements – properties of materials:

The layout necessities

Here is a listing of the types of the necessities to don't forget while deciding on a cloth for an aspect or a joint among additives:

- Performance requirements

- Selection criteria

- Reliability necessities

- Size, form, and mass necessities

- Cost necessities

- Manufacturing necessities

- Industry requirements

- Government policies

- Intellectual belongings necessities

- Sustainability necessities

Below is an evidence of every class of necessities

Performance Requirements

The overall performance necessities describe the attributes that the aspect or joint need to ought to feature as required. The attributes may be defined in phrases of mechanical, electromagnetic, thermal, optical, physical, chemical, electrochemical, and beauty houses.

Reliability Requirements

The reliability of an aspect or joint refers to its cap potential to feature as required over a particular use duration while uncovered to a particular set of use situations.

An aspect or joint fails as soon as the fabric degrades to the factor wherein the aspect or joint now no longer plays as required. The reliability necessities describe the use situations to which the substances may be uncovered and the predicted reaction of the substances to the use situations.

Examples of use situations are publicity to excessive temperatures, salt water (corrosion), and vibration.

Size, form, and mass necessities

The length, form, and mass necessities for an aspect or joint may have a big have an effect on at the substances that may be used. Consider an aspect that need to convey 5 amperes of present day without heating up via way of means of greater than 15o C above the ambient temperature.

The electric conductivity for an aspect with a 1 mm diameter need to be approximately 4 instances extra than the electric conductivity for an aspect that may be 2 mm in diameter.

A bicycle body that need to weight 10 kilos need to have body tubes fabricated from a decrease density fabric as compared to a 20 pound body.

For an aspect that need to aid 2 hundred kilos, the yield pressure for the fabric in an aspect that need to be 0.20 inches diameter need to be a lot extra as compared to the fabric in an aspect that may be 0.50 inches in diameter.

Cost necessities

The price to shape an aspect or joint or buy an aspect relies upon on

1) The substances that contain an aspect or joint,

2) The producing techniques used to shape a aspect or joint,

3) Whether or not an aspect is custom made or bought “off-the-shelf supplier”,

4) The amount of substances or additives being bought and

5) Nice issues related to a cloth or aspect.

If you need to lessen costs, don't forget what is going to be required from the substances engineering attitude to make production method adjustments that deal with gadgets 2 and 5.

Manufacturing necessities

Companies may also require that precise techniques be used for fabricating additives and constructing assemblies or sub-assemblies.

Perhaps an enterprise has inner production talents that need to be used or an enterprise is acquainted and cushy with aspect or joints fabricated the use of an acquainted production method.

Restrictions at the techniques that may be used to construct a product will restriction the substances that may be used to make additives due to the fact the substances need to be like minded with the techniques and different substances used to make the product.

For example, additives to be joined the use of a particular welding, brazing, or soldering method need to be fabricated from substances that permit suitable joints to be fashioned the use of the precise becoming a member of method.

This may also exclude off-the-shelf additives from one or greater providers due to the fact their additives are fabricated from substances which can be incompatible with the method.

For a custom aspect, the restrict may also require the usage of positive substances on the way to shape an excellent joint.

Restricting the producing method to best acquainted ones will restriction the alternatives of substances that may be used to shape an aspect or joint considering that many production techniques are restrained to processing positive substances.

In a few respects production constraints are acceptable, and can in truth be desirable, considering that the usage of acquainted techniques and substances reduces the hazard related to an alternate or new product. However, in instances while a brand new product is notably one of a kind than older products, the restrictions of the use of precise production techniques may also appear to be a burden.

Industry requirements

There are enterprise requirements worried with the overall performance and reliability of additives and joints. In a few instances, a particular trendy will talk aspect and joint necessities. For aspect precise requirements, the requirements talk

The length and form of additives used for precise applications.

The substances which can and can't be used for additives used for precise applications. The exams required to confirm the houses of the substances used to make an aspect.

Government policies

Policies concerning the substances utilized in a product are commonly associated with necessities at the substances from which additives and joints can and can't be made.

The necessities deal with the substances which can or can't be utilized in an aspect or joint and the predicted nice and reliability of the substances for precise applications. Every us of a has its very own set of policies.

Intellectual belongings necessities

There are many patents concerning the layout and manufacture of aspect or joints. If a patent is located this is relevant to the aspect or joint being decided on or designed, then the layout group has to determine whether or not to license the patent or engineer the aspect or joint order to keep away from war with the patent.

Sustainability necessities

These necessities restriction the substances that may be utilized in additives and joints to substances that may be re-used or recycled.

The necessities may also restriction the producing techniques than may be used to shape additives and joints to techniques that don't damage the surroundings and do now no longer use chemical substances and substances which can be synthetic the use of environmentally unfriendly techniques.

The sustainability necessities for a product emerge as the sustainability necessities for its additives and joints. Time and money;

Focus and discipline

This listing of various forms of necessities to don't forget may appear long. It may take a chunk of time to give you a whole description of all of the necessities in your subsequent project.

However, it'll accelerate the method of comparing substances and providers which can be recognized primarily based totally at the whole set of necessities.

Consider the money and time related to comparing substances and providers which can be located to be unsuitable.

Material selection:

Material choice includes a huge set of considerations. As a result, a correspondingly extensive kind of understanding is needed to make the perfect choice.

Oftentimes, substances engineers and scientists are relied upon to help. However, they're now no longer the most effective ones concerned with inside the choice making technique.

Purchasing experts, production engineers, layout engineers, clients and providers ought to doubtlessly be delivered in at some stage in the technique in order that the best choice is made.

Incorrect fabric choice will have a big effect on protection and alertness success.

An instance from a mechanical point of view is that if an aluminum alloy with a yield power of most effective 10 ksi is chosen while a metal with a yield power of fifty ksi is needed — then the element or shape being made ought to fail if the masses in anxiety are too great.

For a chemical and corrosion resistance instance, remember an austenitic chrome steel and ferritin chrome steel being located in a saltwater environment. Improper choice of the ferritin chrome steel could bring about heavy corrosion over time, while an austenitic 316 grade of chrome steel could face up to corrosion a great deal better.

In addition to thinking about how an unmarried fabric might also additionally behave in isolation at some stage in the fabric choice technique, it's also essential to remember how or extra substances may behave while in touch with every another.

A carbon metal element located in touch with a chrome steel element in an electrolytic answer will go through galvanic corrosion at a far quicker charge than it might if it became now no longer contacting the chrome steel element.

Use of Data books:

When you want to lay out a part/machine, you need to take below attention the modes of failure, the areas of strain concentrations and a few different essential elements. While designing, first you pick out a layout element (additionally known as because the element of protection sometimes) to get a concept of allowable stresses.

n=Sut÷σn

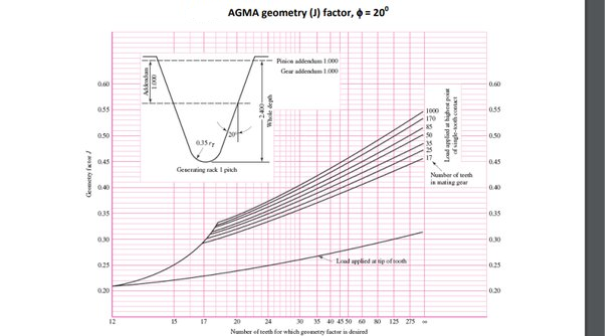

Where (Sut) is the Ultimate tensile electricity (or we use electricity in positive instances and (Sigma) is the allowable strain. Now, as an instance we ought to lay out an equipment. The AGMA equations to lay out an equipment set appearance fairly like this:

σ=Wt÷(FmJ)(Km)(Ko)(Kv)(Ks)(Ki)(Kb)

Where (Sut) is the Ultimate tensile electricity (or we use electricity in positive instances and (Sigma) is the allowable strain. Now, as an instance we ought to lay out an equipment. The AGMA equations to lay out an equipment set appearance fairly like this:

Table – 1. 3 Standard tooth system for spur gears

Item | 20 degree full depth | 20 degree stub | 25 degree full depth |

Addendum a | 1 m | 0.8 m | 1 m |

Debendum b | 1.25 m | 1 m | 1.25 m |

Clearance c | 0.25 m | 0.2 m | 0.25 m |

Working dept | 2 m | 1.6 m | 2m |

Whole depth h | 2.25 m | 1.8 m | 2.25 m |

Tooth thickness t | 1.57 1m | 1.57 1m | 1.57 1m |

Face width t | 9m – 14m | 9m – 14m | 9m – 14m |

Fillet radius min | 0.3 m | 0.3 m | 0.3 m |

Top land min | 0.25 m | 0.25 m | 0.25 m |

14.5° and 25° stub tooth systems have becomes obsolete now | |||

For example: For 20 deg full depth, F= 9m-14m. We select any value in this range.

We are given the amount of transmitted load.

We can further read J and other factors from the design data book as follows:

Table 1.4 – Overload factor K°

| Driven Machinery |

Source of power | Uniform | Moderate Shock | Heavy Shock |

Uniform | 1.00 | 1.25 | 1.75 |

Light shock | 1.25 | 1.50 | 2.00 |

Medium shock | 1.50 | 1.75 | 2.25 |

You are always given certain parameters when you select each factor from the design data book.

Key Takeaways:

- For example, alloys of aluminum or titanium might be substituted for metallic in lots of cases, if it had been now no longer value-prohibitive to do so. Iron’s magnetic abilities might be emulated with nickel, cobalt, or uncommon earth factors alloyed with different metals.

- The attributes may be defined in phrases of mechanical, electromagnetic, thermal, optical, physical, chemical, electrochemical, and beauty houses.

- A bicycle body that need to weight 10 kilos need to have body tubes fabricated from a decrease density fabric as compared to a 20 pound body.

Fundamentals of Machine Design: Types of load, Modes of failure, factor of safety concepts

Following are the overall issues in designing a system component:

a. Type of load and stresses resulting from the load.

The load, on a system component, might also additionally act in numerous methods because of which the inner stresses are set up.

b. Motion of the components or kinematics of the system.

The success operation of any system relies upon in large part upon the most effective association of the components so that it will provide the movement required.

The movement of the components can be:

(a) Rectilinear movement which incorporates unidirectional and reciprocating motions.

(b) Curvilinear movement which incorporates rotary, oscillatory and easy harmonic.

(c) Constant velocity.

(d) Constant or variable acceleration.

c. Selection of substances.

It is critical that a fashion dressmaker ought to have an intensive expertise of the homes of the materials and their behavior below operating conditions.

Some of the vital traits of substances are: strength, durability, flexibility, weight, resistance to warmth and corrosion, cap potential to cast, welded or hardened, machinability, electric conductivity, etc. The numerous kinds of engineering substances and their homes could be mentioned later.

d. Form and length of the components.

The shape and length are primarily based totally on judgment. The smallest plausible cross-segment can be used, however it can be checked that the stresses brought on with inside the designed cross-segment are fairly safe. In order to lay out any system element for shape and length, it's miles important to realize the forces which the element have to sustain. It is likewise vital to expect any all at once carried out or effect load which may motive failure.

e. Frictional resistance and lubrication.

There is continually a lack of strength because of frictional resistance and it ought to be referred to that the friction of beginning is better than that of strolling friction. It is, therefore, critical that a cautious interest have to accept to the problem of lubrication of all surfaces which flow in touch with others, whether or not in rotating, sliding, or rolling bearings.

f. Convenient and low-cost capabilities.

In designing, the running capabilities of the system ought to be cautiously studied. The beginning, controlling and preventing levers ought to be positioned on the idea of handy handling.

The adjustment for put on have to be supplied using the numerous take-up gadgets and arranging them in order that the alignment of components is preserved. If components are to be modified for exclusive merchandise or changed because of put on or breakage, clean get entry to ought to be supplied and the need of disposing of different components to perform this ought to be prevented if possible.

The low-cost operation of a system that's for use for manufacturing, or for the processing of cloth ought to be studied, for you to examine whether or not it has the most ability with the manufacturing of accurate work.

Types of load, Modes of failure, factor of safety concepts:

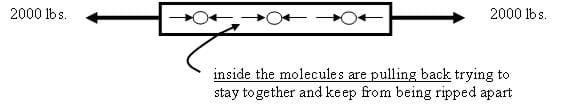

- Tension

Two pulling (opposing) forces that extend an item attempting to drag it aside (for instance, pulling on a rope, an automobile towing every other automobile with a chain – the rope and the chain are in anxiety or are "being subjected to a tensile load"). A drawing of a beam with 2,000 lbs. Of pressure pulling it aside from every end. Inside, molecules are pulling back, looking to live collectively and maintain from being ripped aside.

Figure 3. Tension.

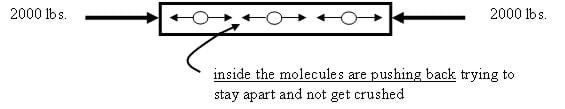

2. Compression:

Two pushing (opposing) forces that squeeze an item looking to compress it (for instance, status on a soda can, squeezing a bit of timber in a vise – each the can and the timber are in compression or are "being subjected to a compressive load").

A drawing of a beam with 2,000 lbs. Of pressure pushing on a beam from contrary ends. Inside, molecules are pushing back, looking to live aside and now no longer get crushed.

3. Shear:

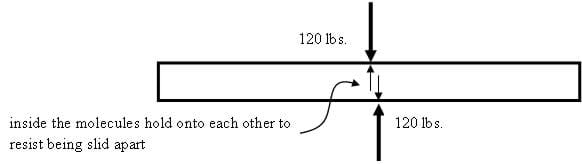

Two pushing or pulling adjoining forces, performing near collectively however now no longer immediately opposing every different.

A shearing load cuts or rips an item with the aid of using sliding its molecules aside sideways (for instance, pruning shears slicing thru a department, paper-cutter slicing paper - the department and paper are "subjected to a shear loading").

A drawing of a beam with a hundred and twenty lbs. Of pressure at the beam, now no longer pretty opposing every different. Inside, molecules keep onto every different to face up to being slid aside.

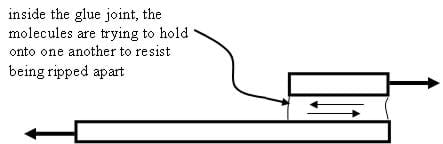

Another instance: Pulling on portions of timber which have been glued collectively; the glue joint is "being subjected to a shear loading.

Figure 4. Shear forces on glued wood.

A distinct drawing indicates glued timber beam below shear pressure. Inside the glue joint, the molecules attempt to keep onto each other to face up to being ripped aside. Figure 4. Shear forces on glued timber.

A Moment of a Force

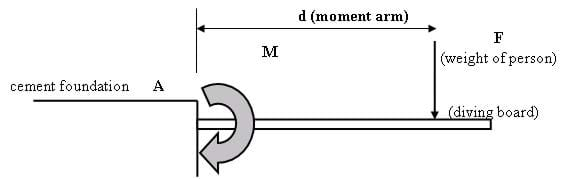

Understanding a second of a pressure is fundamental to knowledge the remaining varieties of loads. A second is a "turning pressure" due to a pressure performing on an item at far from a set point. Consider the diving board caricature in Figure 5. The heavier the person (pressure), and the farther they stroll out at the board (distance), the extra the "turning pressure," which acts at the concrete basis (constant point).

Figure 5. Moment of a force.

The pressure (F) produces a second or "turning pressure" (M) that attempts to rotate the diving board round a set point (A). In this case, the instant bends the diving board.

The more potent the pressure, and the extra the gap at which it acts, the bigger the instant or "turning pressure" it'll produce.

A second or "turning pressure" (M) is calculated with the aid of using multiplying a pressure (F) with the aid of using its second arm (d). The second arm is the gap at which the pressure is implemented, taken from the constant point:

M = F d

(As lengthy because the pressure performing at the item is perpendicular to the item.) If a pressure measured in Newton’s is elevated with the aid of using a distance in meters, then the devices for the instant are N-m (read "Newton-meters").

If the pressure is measured in kilos and multiply with the aid of using a distance in inches, then the devices are be lb-in (read "pound-inches"). Units for moments may be any pressure unit elevated with the aid of using any distance unit.

Bending:

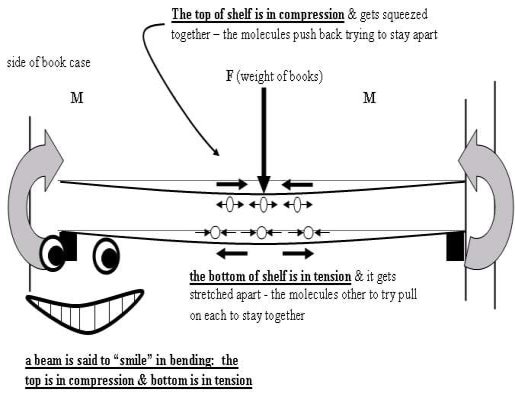

When a second or "turning pressure" is implemented to a structural member this is constant on each ends, along with a pole beam, making it deflect or bend. A second that reasons bending is referred to as a bending second. Bending produces anxiety and compression interior a beam or a pole, inflicting it to "smile. The molecules at the pinnacle of the smile get squeezed collectively, even as the molecules on the lowest of the smile get stretched out. A beam or pole in bending will fail in anxiety (spoil at the aspect this is being pulled aside) (for instance, a shelf in a bookcase, and the sooner diving board scenario).

Figure 6. A bookcase example of bending.

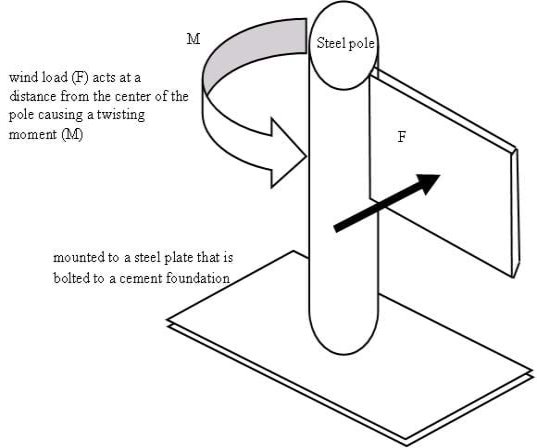

5. Torsion (Twisting):

Created while a second or "turning pressure" is implemented to a structural member (or piece of material) making it deflect at an angle (twist). A second that reasons twisting is referred to as a twisting or torsional second. Torsion produces shear stresses in the material. A beam in torsion will fail in shear; the twisting motion reasons the molecules to be slid aside sideways (for instance, a pole with a signal striking off one aspect). A drawing of a metallic pole set up to a metallic plate this is bolted to a concrete basis. Wind load (F) acts at a distance from the middle of the pole, inflicting a twising second (M).(for example, a pole with a sign hanging off one side).

Figure 7. Torsion.

Modes of failure:

In order to reply the “why did it fail?” query in a beneficial manner, we want to decide the series of occasions that cause the failure. The root purpose evaluation is a manner to decide this chain of occasions.

The purpose can be defective fabric or assembly, harm or layout blunders. It may additionally encompass bad selections and human blunders. Generally, we search for the bodily or chemical cause for the failure.

We must additionally discover the layout, assembly, deliver chain, and purchaser associated strategies for wherein did a blunders or weak point with inside the manner make a contribution to the failure.

Failure mechanisms are the fabric or code faults that cause failure. Thin insulation main to dialectic breakdown, infection main to corrosion, defective code main to an over voltage command.

The concept is the real factors of the product that if averted or prevented could keep away from the failure from occurring.

Types of screw ups and timing Products fail for plenty reasons, many mechanisms. Most merchandise have actually masses of methods they are able to fail. It’s virtually a race among mechanisms to purpose the failure.

Eventually, the whole thing will fail.

One of the primary steps in finding out the unique purpose is figuring out while it failed. How antique turned into the product while it failed.

Early existence (simply sold and installed) screw ups have a tendency to purpose extra purchaser soreness than a product that has supplied an extended existence of beneficial service. In general, we frequently speak approximately 3 styles of screw ups.

Early existence screw ups

Random screw ups (regular failure charge)

Wear-out screw ups

Each kind additionally shows a hard and fast of viable causes. While now no longer continually correct it’s a terrific beginning area while searching out the foundation purpose.

Early existence screw ups

These screw ups are typically because of latent defects inside a product or harm that happens to a product.

A few examples encompass: defective components defective assembly transportation harm set up harm

Early existence (toddler mortality) screw ups have a tendency to show off a reducing failure charge over time. This can be because of best a subset of merchandise having the defective batch of components, for example.

Random screw ups

Generally, those are occasions that arise to a fabricated from thing from an out of doors agent or event. These have a tendency to arise in unpredictable and with random frequency. A few examples encompass:

Lightning strike severe overloading Drop or impact Accidental operation

The opportunity of those screw ups may be monitored, envisioned and predicted.

The failure charge is regular that means every hour (unit of time) has the equal risk of failure as every other hour. Most failure mechanisms have both a growing and reducing failure charge, but a few have a completely small alternate over a time period of interest, therefore successfully regular.

Wear-out screw ups

Think ‘2d regulation of thermodynamics. Most fabric changes (degrades) over time. Water, oxygen, and bodily put on and lots of different elements have a tendency to erode a product’s capacity to function.

Wear-out screw ups encompass:

Steel fatigue (crack formation) corrosion (chemical alternate) abrasive put on (brake pads) polymer lack of elasticity, crazing (chain scissoring) There are many methods product put on out.

The charge of use, the working temperature, and lots of different neighborhood operations and environmental elements make a contribution to the charge of wear and tear out. Becoming privy to a product failure and beginning to decide why it failed is an exploratory manner.

The clues of while the failure happens can also additionally assist body the preliminary investigation. By figuring out the failure mechanisms and root purpose, you and the crew can decide the great route of movement to mitigate or save you different screw ups.

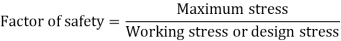

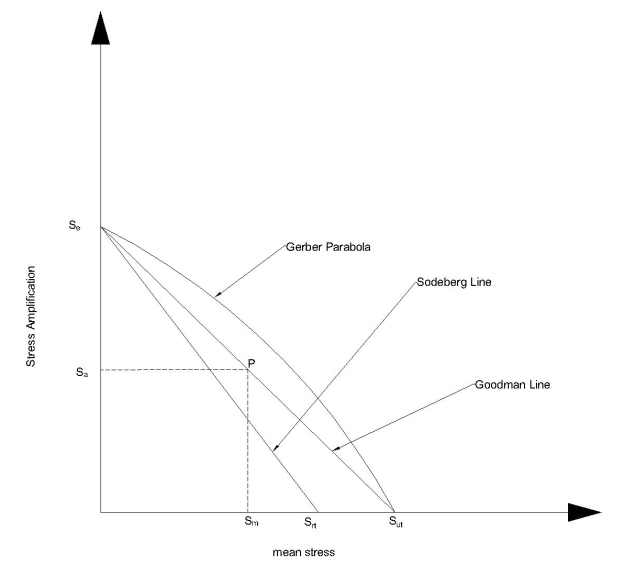

Factor of safety concepts:

“Factor of Safety” generally refers to one in all things:

1) The real load-bearing ability of a shape or factor, or

2) The desired margin of protection for a shape or factor in keeping with code, law, or layout requirements.

A very simple equation to calculate FoS is to divide the ultimate (or maximum) pressure via way of means of the typical (or working) pressure.

A FoS of one method that a shape or factor will fail precisely whilst it reaches the layout load, and can't aid any extra load.

Structures or additives with FoS< 1 aren't viable; basically, 1 is the minimum. With the equation above, an FoS of two method that a factor will fail at two times the layout load, and so on.

Different industries have one-of-a-kind thoughts on what a required margin of protection need to be; one of the problems related to the use of a FoS or SF is a few degree of ambiguity.

But there are a few preferred guidelines of thumb throughout more than one verticals.

Obviously, if the results of failure are significant, which includes lack of life, private harm, or belongings loss, a better FoS could be required via way of means of layout or via way of means of law.

Another attention is value: how a lot more does it value according to element to acquire a sure FoS

Factor Of Safety Formulas:

Factor of protection = Maximum stress / Working or layout stress

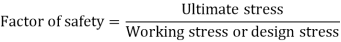

In the case of ductile substances e.g. Slight steel, wherein the yield factor is truly described, the issue of protection is primarily based totally upon the yield factor stress, In such cases,

Factor of protection = Yield factor stress / Working or layout stress

In the case of brittle substances e.g. Solid iron, the yield factor isn't nicely described as for ductile substances. Therefore, the issue of protection for brittle substances is primarily based totally at the final stress.

Factor of protection = Ultimate stress / Working or layout stress

This relation will also be used for ductile substances.

Mathematically,

For Brittle: It is the ratio of the Ultimate stress to the working or design stress

For Ductile: It is the ratio of the yield stress to the working stress

Theories of Failure:

Theories of failure assist us to decide the secure dimensions of the gadget additives while they're subjected to bi-axial or tri-axial nation of stresses.

Anything is failed if the triggered pressure exceeds the elastic restrict and everlasting deformation of the thing takes region. The failure within side the substances is of kind i.e. brittle failure and ductile failure. In brittle failure the direct separation takes region with none form of considerable elongation while in ductile failure we will see considerable inelastic elongation earlier than the failure.

Both sorts of failure depend upon the kind of fabric through which gadget thing is made.

All the mechanical additives failed while elastic restrict is reached to a positive fee and yielding starts. Different theories had been proposed for exclusive substances and failures. These theories are used to attain the connection among stresses triggered below bi-axial and tri-axial nation of pressure situations and the fabric houses which might be received through the anxiety take a look at or compression take a look at.

These houses are Sut (final energy in anxiety), Syt (yield energy in anxiety) and so on. The yielding with inside the fabric relies upon the numerous pressure additives.

The failure of any mechanical element relies upon different factors like houses of fabric, kind of loading and temperature etc. for instance a strength screw subjected to torsional second in addition to axial force, an overhang crank is subjected to blended bending and torsional second, identical with inside the case of bolts of the bracket which might be subjected to forces that reasons tensile pressure and shear pressure, in which as crank shafts and connecting rods are examples of the ones additives which might be subjected to complicated

Before designing of any gadget element numerous experiments are achieved on them to attain secure running pressure below blended loading situations. These experiments assist us to decide the exclusive houses of the substances below comparable loading situations.

But every so often it isn't always feasible to carry out those exams for exclusive feasible combos of load to attain mechanical houses. Generally maximum of the mechanical houses of anything are received through anxiety take a look at that is achieved on UTM (Universal Testing Machine).

These houses are yield energy, final tensile energy and percent of elongation. Theories of failure provide a courting among the energy of gadget thing which might be subjected to complicated nation of stresses with the mechanical houses which might be received all through the anxiety take a look at.

Following are the important thing factors which might be beneficial in higher expertise of theories of failure:

σ1, σ2 and σ3 are the precept stresses triggered at a factor at the gadget element in 3 mutual perpendicular instructions because of the exclusive loading situations. We use exclusive theories to attain the connection among σ1, σ2 and σ3 with the fabric houses like Syt (yield shear energy in anxiety), Sut (final energy in anxiety), Sys (yield energy in shear) and issue of protection FOS (N).

Under uniaxial nation of pressure circumstance i.e. best σ1 is appearing at the gadget thing then the energy criterion and all theories of failure will provide the identical end result so we haven't any requirement of idea of failure in case of uniaxial nation of pressure circumstance. In case of bi-axial and tri-axial nation of pressure situations all of the theories of failure will offer exclusive results.

So for the secure layout of anything below bi-axial and tri-axial nation of pressure circumstance suitable idea of failure must be selected. Under bi-axial and tri-axial nation of pressure situations all of the theories of failure offer nearly identical end result while σ1 may be very big in comparison to the σ2 and σ3.

Concept and mitigation of stress concentration, Fatigue failure and curve:

Stress attention is the buildup of strain in a frame because of unexpected alternate in its geometry.

When there may be an unexpected alternate within side the geometry of the frame because of cracks, sharp corners, holes and reduce within side the pass phase area, then there may be an boom with inside the localized strain close to those cracks, sharp corners, holes, and reduced pass phase area.

The frame has a tendency to fail from those locations in which the strain attention is extra. So to save you a frame from getting failed, the attention of strain need to be prevented or reduced. It is likewise known as strain raisers or strain risers.

Effect

- When a frame has strain attention in it, the possibilities of its failure increases.

- The frame has a tendency to fail from the vicinity in which it has extra attention of strain.

- A frame has much less existence that has extra irregularities inside it.

- In order to boom the existence of the frame, the depth of strain need to be reduced.

It is defined as the ratio of highest stress in the body to the reference stress. It is denoted by Kt.

Mathematically,

Where

σmax = Highest stress or maximum stress

σref = Reference stress

Fatigue failure and curve:

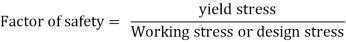

Fatigue homes of substances are regularly defined the use of the fatigue restrict or the S-N curve (fatigue curve, Wohler curve). The S-N curve describes the relation among cyclic strain amplitude and quantity of cycles to failure.

The discern beneath suggests a standard S-N curve. On the horizontal axis the quantity of cycles to failure is given on logarithmic scale.

On the vertical axis (both linear and logarithmic) the strain amplitude (once in a while the most strain) of the cycle is given. S-N curves are derived from fatigue tests. Tests are executed via way of means of making use of a cyclic strain with steady amplitude (CA) on specimens till failure of the specimen.

In a few instances the check is stopped after a totally big quantity of cycles (N>10^6). The consequences is then interpreted as countless life. Fatigue curves are regularly given for Kt=1 (unmatched specimens). Those curves describe the fatigue homes of a material.

Actual systems are higher defined with S-N curves for Kt>1 (notched specimens).

Endurance limit and factors affecting it, Notch sensitivity, Goodman, Gerber and Soderberg criteria:

The persistence restriction we've got determined experimentally cannot be used as such in layout even for the same formed additives as that of specimen.

Experiments screen that although a real mechanical thing examined for persistence restriction, each values of persistence limits for real member and check specimen might be absolutely one of a kind.

This is due to the precautions and situations which we've got observed even as experimentation.

For experimentation reason check specimen become relatively polished and very last polish become carried out in axial course which gets rid of opportunity of the circumferential scratch which in any other case might also additionally motive the pressure awareness and fatigue crack.

On different hand self-aligned bearing are used to assist the specimen to make certain the radial loading.

So, the standardization specimen become subjected to the natural bending second beneath proper reversal of stresses. In realistic state of affairs those experimental circumstance cannot be feasible and this is why the persistence restriction have been determined one of a kind for mechanical thing and the check specimen of equal fabric.

So, we will say that the persistence restriction isn't always a real fabric belongings as its miles determined that persistence restriction is tormented by many elements inclusive of floor finish, reliability, temperature, length etc.

The cost received experimentally (Se) is consequently changed on the premise of the triumphing situations in real exercise wherein the thing is employed.

Se=ka kb kc kd ke kf′ Se′

Eq 1

Se endurance limit of the component, N/mm2

Se′ Endurance limit for rotating beam specimen, N/mm2

ka surface finish factor

kb size factor

kc reliability factor

kd temperature factor

ke load factor

Kf′=kf//1

Where kf fatigue stress concentration factor, and

Se=(ka kb kc kd kd/kf) Se′

1. Surface Finish (ka)

The fatigue check specimen has rather polished floor end and that can be taken into consideration as scratch free. The different floor finishes can also additionally have micro-cracks and whilst such additives are subjected to fluctuating loading, those micro-cracks can also additionally propagate ensuing right into a fatigue fracture.

The polished floor assumes team spirit cost for floor end element and it reduces because the floor end deteriorates.

Number of experiments had been carried out for maximum usually used engineering fabric (metal) with special floor end and located the remaining electricity of the metal additionally have an effect on the fatigue fracture for identical floor end

2. Size Factor (kb)

As the dimensions receives large, the persistence restrict is reduced because of the expanded probability of getting defects with inside the large volume. The length of fashionable check specimen is ready eight mm and consequently the element is taken as team spirit as much as this diameter.

3. Notch Sensitivity

We have mentioned approximately the pressure awareness in element for the elements subjected to static load and we realize that: The pressure close to the discontinuity will increase via way of means of an element ktkit is theoretical cost kt want now no longer be carried out for ductile and forged brittle fabric It might be a totally negative layout exercise if a brittle fabric is used for any member subjected to dynamic loading.

The element kt offers us the theoretical cost of pressure awareness element and is impartial of the fabric. But, on the identical time, it isn't for use for ductile fabric. The nature of fatigue fracture shows that even ductile fabric fails as though they have been brittle whilst problem to dynamic loading. Therefore, the impact of pressure awareness have to be taken into consideration for ductile fabric subjected to dynamic loading.

The complete cost of kt is used for brittle fabric and kt for ductile fabric ought to be decreased and changed. This changed element is referred to as fatigue pressure awareness element.

Goodman, Gerber and Soderberg criteria:

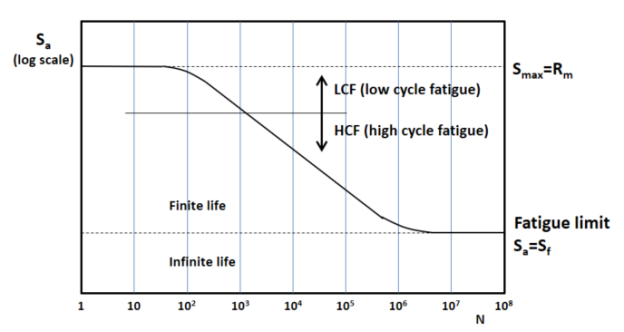

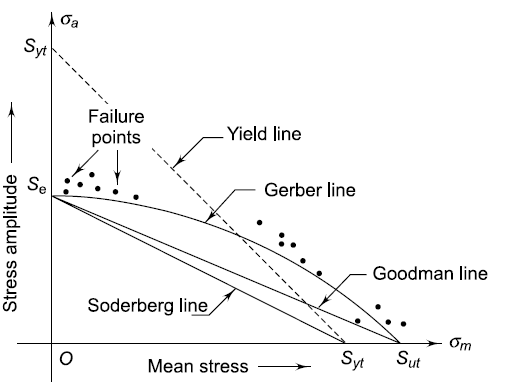

- Mean strain in addition to strain amplitude exist whilst an element is subjected to fluctuating stresses.

- It has been discovered that the suggest strain element has an impact on fatigue failure whilst it's far found in mixture with an alternating element.

- The fatigue diagram for this trendy case is proven in Fig. Below.

- In this diagram, the suggest strain is plotted at the abscissa and strain amplitude on ordinate.

- The magnitudes of suggest strain and strain amplitude rely upon the magnitudes of most and minimal pressure appearing at the element.

- These limits are plotted at the abscissa.

- When the suggest strain is zero, the strain is absolutely reversing and the criterion of failure is the patience restriction Se this is plotted at the ordinate.

- When the element is subjected to each additives of strain, the real failure happens at special scattered factors proven with inside the figure.

- They include Gerber line, Soderberg line and Goodman line.

- There exists a border, which divides secure place from dangerous place for numerous combos of suggest strain and strain amplitude.

- Different criterion are proposed to assemble the borderline dividing secure region and failure region.

- They encompass Gerber line, Soderberg line and Goodman line.

- Gerber Line: A parabolic curve becoming a member of Se at the ordinate to Sut at the abscissa is referred to as the Gerber line.

- Soderberg Line A immediately line becoming a member of Se at the ordinate to Syt at the abscissa is referred to as the Soderberg line.

- Goodman Line A immediately line becoming a member of Se at the ordinate to Sut at the abscissa is referred to as the Goodman line.

Within the department of substances technology called cloth failure theory, the Goodman relation (additionally known as a Goodman diagram, a Goodman-Haigh diagram, a Haigh diagram or a Haigh-Soderberg diagram) is an equation used to quantify the interplay of suggest and alternating stresses at the fatigue lifestyles of a fabric

The equation is commonly provided as a linear curve of suggest pressure vs. Alternating pressure that gives the most range of alternating pressure cycles a fabric will resist earlier than failing from fatigue.

A scatterplot of experimental statistics proven on an amplitude as opposed to suggest pressure plot can frequently be approximated through a parabola called the Gerber line, that can in flip be (conservatively) approximated through a instantly line known as the Goodman line.

- A straight line joining 'Se' on the stress amplitude axis and 'Syt' on the mean stress axis is called soderberg line.

- According to the soderberg criteria, the triangular region below this line is considered to be safe. Hence, any point laying in this triangular region will ensure the safety of the component for infinite line. The equation for the soderberg line is,

Sm Syt + Sa Se = 1 ......(1)

OR

σm Sut + σo Se = 1NF1NF

Where, Syt = yield strength of the material,

- The equation (1) and (2) represent the soderberg line.

- Soderberg diagram gives the most conservative/safe design.

- Soderberg diagram is used for ductile materials.

Key Takeaways:

- These theories are used to attain the connection among stresses triggered below bi-axial and tri-axial nation of pressure situations and the fabric houses which might be received through the anxiety take a look at or compression take a look at.

- Theories of failure provide a courting among the energy of gadget thing which might be subjected to complicated nation of stresses with the mechanical houses which might be received all through the anxiety take a look at.

- The frame has a tendency to fail from those locations in which the strain attention is extra. So to save you a frame from getting failed, the attention of strain need to be prevented or reduced. It is likewise known as strain raisers or strain risers.

References:

1. Design of Machine Elements, V.B. Bhandari, Tata McGraw Hill

2. Mechanical Engineering Design, J.E.Shigley, C.R.Mischke, R.G.Budynas and K.J.Nisbett, TMH

3. Machine Design, Pandya and Shah, Charotar Book Stall

4. Fundamentals of Machine Component Design by R.C.Juvinall and K.M.Marshek, John Wiley & Sons.

5. Machine Drawing by N.Sidheswar, McGraw-Hill