Unit-1

Fresh water

Fresh water (or freshwater) is any naturally occurring water except seawater and brackish water. Fresh water is generally characterized by having low concentrations of dissolved salts and other total dissolved solids. Though the term specifically excludes seawater and brackish water, it does include mineral-rich waters such as chalybeate springs. Fresh water may include water in ice sheets, ice caps, glaciers, icebergs, bogs, ponds, lakes, rivers, streams, and even underground water called groundwater.

Water is critical to the survival of all living organisms. Some organisms can thrive on salt water, but the great majority of higher plants and most mammals need fresh water to live.

Fresh water is not always potable water, that is, water safe to drink. Much of the earth's fresh water (on the surface and groundwater) is to a substantial degree unsuitable for human consumption without some treatment. Fresh water can easily become polluted by human activities or due to naturally occurring processes, such as erosion.

Fresh water habitats are classified as either lentic systems, which are the still waters including ponds, lakes, swamps and mires; lotic which are running-water systems; or ground waters which flow in rocks and aquifers. There is, in addition, a zone which bridges between groundwater and lotic systems, which are the hyporheic zone, which underlies many larger rivers and can contain substantially more water than is seen in the open channel. It may also be in direct contact with the underlying underground water.

The source of almost all fresh water is precipitation from the atmosphere, in the form of mist, rain and snow. Fresh water falling as mist, rain or snow contains materials dissolved from the atmosphere and material from the sea and land over which the rain bearing clouds have traveled. In industrialized areas rain is typically acidic because of dissolved oxides of sulfur and nitrogen formed from burning of fossil fuels in cars, factories, trains and aircraft and from the atmospheric emissions of industry. In some cases this acid rain results in pollution of lakes and rivers.

In coastal areas fresh water may contain significant concentrations of salts derived from the sea if windy conditions have lifted drops of seawater into the rain-bearing clouds. This can give rise to elevated concentrations of sodium, chloride, magnesium and sulfate as well as many other compounds in smaller concentrations.

Key Takeaways:

To design a water supply scheme, the first study to consider the demand and then the secondary requirement is to find sources to fulfill that demand.

1.2.1 Various types of water demands

Why planning water supply scheme, it is necessary to find the total yearly water demand, required average rates of flow (draft) and the variation in these rates. The following quantities are generally recorded

1.2.2 Types of water demands

1. Domestic Water demand - Water required in residential building for drinking cooking bathing gardening and sanitary purposes etc. Amount varies from maximum 135 l/h/d to 225 l/h/d as per living conditions accounts for 50-60 % of total water consumption.

2. Industrial water demand- Existing or likely to start in future industry demand. Industrial city per capita water requirement is 450 l/p/d. Normal industrial requirement is 50 LPD.

3. Institutional and commercial demand - Institutions like hospitals hotels restaurant schools and colleges have per capita demand 20 l/h/d.

4. Demand for public uses - Watering of parks gardening washing and sprinkling on roads public fountains etc. 5% of total collection is 10 l/h/d approx.

5. Fire demand - For thickly populated and industrial areas. Fire hydrants must be 100-150 m apart. 1 l/h/d for cities having population greater than 50000 the fire demand in kilo litres is

a) Kuichling’s formula

Q = 3182

Where, Q = Amount of water on l/min

P = Population in thousand

b) Freeman formula

Q = 1136

c) National board of fire under writers formulas

When population is less than or equal to 2 lakh.

Q = 4637  (1 – 0.01

(1 – 0.01 )

)

When population is greater than 2 lakh, 54600 litres per minute + extra provision of 9100 to 36400 litres per minute for second fire.

ii. For residential city

Small floor buildings = 2200 l/min

Larger or higher buildings = 4500 l/min

High value residences, apartments = 4650 – 13500 l/min

Three storage buildings = up to 27000 l/min

d) Buston formula

Q = 5663

e) Jabalpur formula

Q =

Where, R = Recurrence interval of fire minimum 1year.

t = Duration of fire in minimum 30 minute.

6. Water required compensating losses in theft and wastes - Losses due to leakage bad plumbing damage meter, unauthorized connections 15% of total consumption.

1.2.3 Total requirement of water for a town or a city

1.2.3.1 Per capita demand (q) - The annual average daily draught a letter per day required by a town can be worked out by multiplying the probable number of the persons who are going to use the facilities and the annual average daily consumption of each person is called per capita demand.

1.2.3.2 Design period - The future period for which of provision is made in the water supply scheme is known as a design period. mm design period should neither be so long as to throw unnecessary extra financial burden on the present generation no it should be so short as to make the design insufficient for future needs.

1.2.3.3 Per capita demand - Includes domestic use, industrial and commercial use, public use, wastes, theft etc.

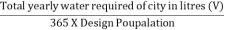

=

1.2.3.4 Factor affecting per capita demand

The annual average demand for water ranges between 100-350 LCD and depends on following factors

a) Size of the city.

b) Climatic conditions.

c) Types of gently and habits of people.

d) Industrial and commercial activities.

e) Quality of water supplies.

f) Pressure in the distribution system.

g) Development of sewage facilities.

h) System of supply. (Continuous and intermittent).

i) Cost of water.

j) Policy of metering and method of charging.

1.2.3.5 Factors affecting losses and wastes

a) Water tight joints.

b) Pressure in the distribution system.

c) System of supply.

d) Metering.

e) Unauthorized connections.

Key Takeaways:

(365 x Population).

This normal variation in demand should generally be assessed and known in order to design supply pipes, service reservoirs, distributaries pipes etc.

1.3.1 Assessment of Normal variations

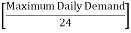

Maximum Daily Demand = 1.8 X Average Daily Demand

= 1.8q

2. Maximum hourly consumption is generally taken as one 150% of its average hourly consumption.

Peak Demand = 1.5 X Average Hourly consumption of the maximum day

= 1.5 X

= 1.5 X  = 2.7 X q/24

= 2.7 X q/24

= 2.7 X Annual Average Hourly Demand

Goodrich formula for finding ratio of steel demand rates to their corresponding means:

P = 180 X t0.10

where, P = % of annual average draft for the time ‘t’ in days.

t = time in days from 1/24 to 365.

When, t = 1 day for daily variations

P = 180 X (1)0.10 = 180

Maximum daily demand = 180%

1.3.2 Effects of variation in demand on the design capacities of different components of water supply system

Key Takeaways:

1.4.1 Population data – The census counts every 10 years (decanal census).

1.4.2 Population growth

Three main factors responsible for changes in populations.

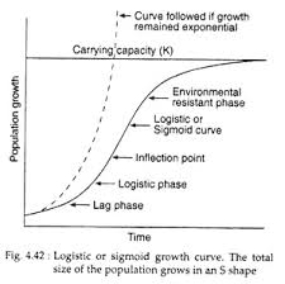

1.4.2.1 Ideal population growth curve - When all these varying influences do not produce extra ordinary changes, space or with limited economic opportunity. The curve is S-shaped and is known as logistic curve.

Fig.1: Ideal population growth curve

The curve represents early growth AB at an increasing rate and late growth DE at a decreasing rate as a saturation value Ps is approached. The transitional middle curve BD follows an automatic increase what the future holds for a given population depends upon, as to where the point lays on the growth curve at a given time.

1.4.3 Population forecasting methods

Some of the method is used when the design period is a small and some are used when the design period is large. The following methods are used for population forecasting which are based on the laws of probability, that only approx population estimation can be made

This method is based on the assumption that the population increases at a constant rate.

Pn = (Po + n )

)

Where,

Pn = Prospective or forecasted Population after ‘n’ decades from the present.

Po = Population at present.

n = Number of decades between now and future.

R = Assumed growth

= Average of population increases in the known decades.

= Average of population increases in the known decades.

2. Geometric increase method

Per decade percentage increase or percentage growth rate (r) is assumed to be constant and the increase is compounded over the existing population every decade. It is also called uniform increase method.

Pn = Po  n

n

r = t - 1

- 1

Where,

Pn = Prospective or forecasted Population after ‘n’ decades from the present.

Po = Population at present.

n = Number of decades between now and future.

r = Assumed growth rate.

P1 = Initial known population.

P2 = Final known population.

t = Number of decades between P1 & P2.

3. Incremental increase method or method of varying increment

In this method the product growth rate is assumed to be progressively increasing or decreasing.

Pn = Po + n +

+  X

X

Where,

Pn = Prospective or forecasted Population after ‘n’ decades from the present.

= Average of population increases in the known decades.

= Average of population increases in the known decades.

= Average incremental increase of known decades.

= Average incremental increase of known decades.

4. Decreasing rate of growth method

In this method, the average decrease in the percentage increase is word out and the subtracted from the latest percentage increase for each successive decade.

5. Simple graphical method

Graph is plotted between time and population and then smoothly extended to the desired year. Approx results.

6. Comparative graphical method

The cities having similar conditions and characteristics similar to .be estimated are selected and then it is assumed that the cities under consideration will develop as the selected similar cities have developed in the past.

7. Master plan or zoning method

Divide cities into various zones and separate residence, commercial and industry.

Population densities are fixed. Say 5 person 10,000 plots

Population = 5 X 10,000 = 50,000

8. The ratio method of apportionment method

The cities census population record is expressed as the percentage of the population of the whole country.

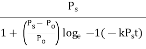

9. Logistic curve method

In normal conditions, the population of a city shall grow as per the logistic curve.

Loge ( ) - Loge (

) - Loge ( ) = -kPst

) = -kPst

Where,

Po = Population at start of curve A

Ps = Saturation population

P = Population at any time‘t’ from origin A

K = Constant

Loge (( ) X (

) X ( )) = -kPst

)) = -kPst

( ) X (

) X ( ) = Loge-1 (-kPst)

) = Loge-1 (-kPst)

( -1) = (

-1) = ( ) Loge-1 (-kPst)

) Loge-1 (-kPst)

P =

Substituting, ( ) = m (a constant)

) = m (a constant)

-K Ps =n (Constant)

P =

Key Takeaways:

It is not appropriate to use Residential Gallons Per Capita Day (R-GPCD) water use data for comparisons across water suppliers, unless all relevant factors are accounted for. Factors that can affect per capita water include:

Rainfall, temperature and evaporation rates – Precipitation and temperature varies widely across the state. Areas with high temperature and low rainfall need to use more water to maintain outdoor landscaping. Even within the same hydrologic region or the same water supply district these factors can vary considerably, having a significant effect on the amount of water needed to maintain landscapes.

Population growth – As communities grow, new residential dwellings are constructed with more efficient plumbing fixtures, which causes interior water use to decline per person as compared to water use in older communities. Population growth also increases overall demand.

Population density – highly urbanized areas with high population densities use less water per person than do more rural or suburban areas since high density dwellings tend to have shared outdoor spaces and there is less landscaped area per person that needs to be irrigated.

Socio-economic measures such as lot size and income – Areas with higher incomes generally use more water than areas with low incomes. Larger landscaped residential lots that require more water are often associated with more affluent communities. Additionally, higher income households may be less sensitive to the cost of water, since it represents a smaller portion of household income.

Water prices – Water prices can influence demand by providing a monetary incentive for customers to conserve water. Rate structures have been established in many districts to incentivize water conservation, but the effectiveness of these rate structures to deter excessive use and customer’s sensitivity to water prices vary.

Key Takeaways:

Water Consumption: - The amount of water that is taken (or withdrawn) from the source is called the water intake, and the amount that is returned is called the water discharge. The difference between the water intake and the water discharge is the amount consumed.

Water intake – Water discharge = Consumption

The future period or the number of years for which a provision is made in designing the capacities of the various components of the water supply scheme is known as design period 30 years.

1.6.1 Factor governing the design period

a) Useful life of component structure and the chances of their becoming old and obsolete.

b) Is and difficulty in expansion, if undertaken at future dates. Difficult extension then high design period.

c) Amount and availability of additional investment likely to be incurred for additional provisions.

d) Rate of interest on borrowings and the additional money invested. Less interest rate than high design period.

e) Anticipated rate of population growth including possible shifts in communities, industries and commercial establishments.

1.6.2 Design period for different components of water supply scheme

S.No. | Item | Design period in years |

1 | Storage by dams | 50 |

2 | Intake | 30 |

3 | Pumping a) Pump House b) Electric motors and pumps |

30 15 |

4 | Water treatment units | 15 |

5 | Pipe connections to treatment units and other small appurtenances | 30 |

6 | Raw water & clear water conveying units | 30 |

7 | Clear waters reservoirs at the head works, balancing etc. | 15 |

8 | Distribution system | 30 |

Key Takeaways:

There are two stages in the transportation of water:

1. Conveyance of water from the source to the treatment plant.

2. Conveyance of treated water from treatment plant to the distribution system.

In the first stage water is transported by gravity or by pumping or by the combined action of both, depending upon the relative elevations of the treatment plant and the source of supply. In the second stage water transmission may be either by pumping into an overhead tank and then supplying by gravity or by pumping directly into the water-main for distribution.

1.7.1 Free Flow System

In this system, the surface of water in the conveying section flows freely due to gravity. In such a conduit the hydraulic gradient line coincide with the water surface and is parallel to the bed of the conduit. It is often necessary to construct very long conveying sections, to suit the slope of the existing ground. The sections used for free-flow are: Canals, flumes, grade aqueducts and grade tunnels.

1.7.2 Pressure System

In pressure conduits, which are closed conduits, the water flows under pressure above the atmospheric pressure. The bed or invert of the conduit in pressure flows is thus independent of the grade of the hydraulic gradient line and can, therefore, follow the natural available ground surface thus requiring lesser length of conduit. The pressure aqueducts may be in the form of closed pipes or closed aqueducts and tunnels called pressure aqueducts or pressure tunnels designed for the pressure likely to come on them. Due to their circular shapes, every pressure conduit is generally termed as a pressure pipe. When a pressure pipe drops beneath a valley, stream, or some other depression, it is called a depressed pipe or an inverted siphon. Depending upon the construction material, the pressure pipes are of following types: Cast iron, steel, R.C.C, hume steel, vitrified clay, asbestos cement, wrought iron, copper, brass and lead, plastic, and glass reinforced plastic pipes.

1.7.3 Hydraulic Design

The design of water supply conduits depends on the resistance to flow, available pressure or head, and allowable velocities of flow. Generally, Hazen-William's formula for pressure conduits and Manning's formula for free flow conduits are used.

a) Hazen-William's formula

U=0.85 C rH 0.63 S0.54

b) Manning's formula

U=1 /n rH 2/3 S01/2

Where,

U = velocity, m/s

RH = hydraulic radius, m

S = slope,

C = Hazen-William's coefficient, and

n = Manning's coefficient.

c) Darcy-Weisbach formula

hL = ( fLU2 )/(2gd)

The available raw waters must be treated and purified before they can be supplied to the public for their domestic, industrial or any other uses. The extent of treatment required to be given to the particular water depends upon the characteristics and quality of the available water, and also upon the quality requirements for the intended use.

Key Takeaways:

1.8.1 Conduit

Depending upon the condition and characteristics of flow, the conduits are divided into

a) Gravity Conduits

b) Pressure Conduits

1.8.2 Gravity Conduit

In such conduits water flows under the action of gravity.

The Hydraulic gradient line (HGL) will coincide with the surface of water and will be parallel to the bed of conduit because the water is all along at atmospheric pressure.

These are of three types (canals, flumes, and aqueducts).

a) Canals: - These are open channels which are constructed by cutting high grounds and constructing banks on low grounds, maybe line or unlined. Generally it is constructed in balanced cut and fill and are cheap to build in suitable soils.

b) Flumes: - Open channels supported above the ground are called flumes. They are used to convey water across valleys and minor depressions. May be masonry, RCC, metal or wood and are circular or rectangular in cross-section.

c) Aqueducts: - These are closed rectangular or circular horse shoe sections, built of masonry or RCC. Although they are covered, or closed yet water does not flow under pressure as they are not allowed to run full (1/2 or 3/4th). They wind their way through landscape, with gradual slopes like roads, highways etc.

Note: - From hydraulic point of view, a circular section provides the maximum hydraulic mean depth and is therefore more efficient. But they cannot be supported on ground level and used less. A rectangular section is hydraulically inefficient but is more stable to support on ground. Horseshoe shape is a compressive between the two shapes.

1.8.3 Pressure Conduits

They are closed conduits, no air can enter into them and the water flows under pressure above the atmospheric pressure. The H.G.L can be obtained by joining in the surface elevations in the piezometers installed in the conduits at various places.

Generally kept circulars and are economical as they can generally follow shorter routes.

The pressure pipes universally used for water supplies whereas gravity conduits are generally adopted for carrying sewage and drainage.

Flow velocity Is generally between 0.9 m/sec to 1.5 m/sec.

Key Takeaways:

The rising main should be as far as possible be laid with an even gradient with a minimum of sharp bends and curves. It should be laid in a trench with a minimum of 0.6m of earth cover, and if brought above ground for any reason should be held firmly by clamps to concrete blocks. It may be necessary, where pressures are high to anchor the pipe at bends’ even if under the ground, and again this is usually done by means of concrete blocks.

In the trench the pipe should be supported along its barrel and not on its joints. This means deeper excavation at every joint, sufficient only to have the bottom of the joint not resting on the trench bottom. In rocky trench it is advisable to lay the pipe on prepared bed of sand.

A wash-out valve is inserted in the rising main immediately outside the pump house with a stop valve or non-return valve immediately downstream of it, to prevent the wash water flowing back to the pump. A non-return valve or reflux valve is better than a stop valve as it cannot be inadvertently left closed when the pump starts up again. Unless the rising main is a long one, it will seldom be necessary to incorporate an air-valve and only in exceptional conditions should this be done for a short rising main.

It is also bad practice to take off connections direct from the rising main, and generally the rising main should convey the water direct from the pump to the high-level storage tank without being tapped or having water drawn off in any way. It may be necessary in certain circumstances e.g. where the rising main passes close to an isolated house which is a long distance from the storage tank and which would require a very expensive gravity pipe back from the tank to supply it. In these cases care should be taken that the connection feeds a storage tank with a ball valve and doesn’t discharge freely at the end.

The diameter of the rising main should be such as to keep the velocity of the water fairly low, and consequently the head lost in friction. A speed of up to 1.5 m/sec. should not be exceeded, and if it is, a thought should be given to installing a larger diameter pipe, balancing this against lower friction head and small pumping units.

In addition to the head lost due to pipe friction (HL), there are minor losses caused by the abrupt changes in the flow geometry as a result of changes in pipe sizes, bends, valves and fittings but these minor losses are neglected.

The head loss due to pipe friction can be found by:

HL = f’lV2/2gd

Where, HL = Head loss in meters

L = Length of pipe ‘m’

d = Diameter of pipe ‘m’, V = Mean velocity of flow in pipe (m/sec)

g = Acceleration due to gravity

f’ = Friction factor (0.02 for new pipes)

(0.075 for old rough pipes)

And depends upon Reynolds number (Ro = Vd/V) and relative roughness

2. Manning’s Formula: -

HL = V2 nl/R4/3

R = A/P = d/4 = m ----for circular pipe

n = Manning’s rugosity coefficient

L = Length of pipe (m)

V = Flow velocity through pipe (m/sec)

R = Hydraulic mean depth of pipe.

3. Hazen-William’s Formula: -

V = 0.85 CH R0.63S0.54

Where, CH = Coefficient of hydraulic capacity of given material

R = Hydraulic mean depth of pipe (m)

S = Slope of energy line

V = Flow velocity through pipe (m/sec)

4. Modified Hazen-William’s Formula: -

V = 143.534 CR R0.6575S0.5525

HL =

Where, R = Hydraulic radius or mean depth

S = Friction slope = HL/L

CR = Dimensionless coefficient of roughness (1.30 concrete & CI)

d = Internal diameter of pipe in ‘m’

Q = Flow in pipe

Key Takeaways:

1.10.1 Laying of water pipes

Pipes are used for conveying water from source to city and also its distribution among consumers. One or two lines of same size are laid for conveying water from source but for distribution, varying sizes having many connections and branches are used.

In supply from source steel or RCC pipes are used.

In distribution cast iron pipes (with bituminous coatings) are used.

Pipes for source to city are laid on ground.

Distributing mains are laid either directly over the compacted soil or laid over small masonry or cement concrete supports at 6-12 m apart. This facilitates inspection, maintenance and repair.

Pipes underground are laid in trenches and top of pipe is 1 m below road surface so as to minimize the impact and traffic loads. Width of trench is 30-50 cm more than outside diameter of pipe.

1.10.2 Testing of pipe lines

The pipeline is tested for soundness in constructing by performing pressure test as below:

Key Takeaways:

1.11.1 Pipe materials

Pipes convey raw water from the source to the treatment plants in the distribution system. Water is under pressure always and hence the pipe material and the fixture should withstand stresses due to the internal pressure, vaccum pressure, when the pipes are empty, water hammer when the values are closed and temperature stresses.

1.11.1.1 Requirements of pipe material

1. It should be capable of withstanding internal and external pressures.

2. It should have facility of easy joints.

3. It should be available in all sizes, transport and erection should be easy.

4. It should be durable.

5. It should not react with water to alter its quality.

6. Cost of pipes should be less.

7. Frictional head loss should be minimum.

8. The damaged units should be replaced easily.

1.11.1.2 Different types of pipes

The following are the different types of pipes

1. Mild Steel Pipes

2. Galvanized Iron (GI) Pipes

3. Poly Vinyl Chloride (PVC unplasticised) Pipes.

4. HDPE

5. Ductile Iron Pipes

1.11.2 Appurtenances

The structures, which are constructed at suitable intervals along the sewerage system to help its efficient operation and maintenance, are called as sewer appurtenances. These include:

(1) Manholes: - The manhole is masonry or R.C.C. chamber constructed at suitable intervals along the sewer lines, for providing access into them. Thus, the manhole helps in inspection, cleaning and maintenance of sewer. These are provided at every bend, junction, change of gradient or change of diameter of the sewer. The sewer line between the two manholes is laid straight with even gradient.

(2) Drop manholes: - The depth of these manholes is more than 1.5 m. The section of such manhole is not uniform throughout (Figure 8.3). The size in upper portion is reduced by providing an offset. Steps are provided in such manholes for descending into the manhole. These are provided with heavy cover at its top to support the traffic load.

(4) Clean-outs: - It is a pipe which is connected to the underground sewer. The other end of the clean-out pipe is brought up to ground level and a cover is placed at ground level. A clean-out is generally provided at the upper end of lateral sewers in place of manholes. During blockage of pipe, the cover is taken out and water is forced through the clean-out pipe to lateral sewers to remove obstacles in the sewer line.

(5) Street inlets called Gullies: - Storm water inlets are provided to admit the surface runoff to the sewers. These are classified in three major groups viz. curb inlets, gutter inlets, and combined inlets. They are provided either depressed or flush with respect to the elevation of the pavement surface.

(6) Catch basins: - Catch basins are provided to stop the entry of heavy debris present in the storm water into the sewers. However, their use is discouraged because of the nuisance due to mosquito breeding apart from posing substantial maintenance problems. At the bottom of the basin space is provided for the accumulation of impurities. Perforated cover is provided at the top of the basin to admit rain water into the basin.

(7) Lamp Holes: - It is an opening or hole constructed in a sewer for purpose of lowering a lamp inside it. It consists of stoneware or concrete pipe, which is connected to sewer line through a T-junction as shown in the Figure 8.12. The pipe is covered with concrete to make it stable. Manhole cover of sufficient strength is provided at ground level to take the load of traffic. An electric lamp is inserted in the lamp hole and the light of lamp is observed from manholes. If the sewer length is unobstructed, the light of lamp will be seen.

1.11.3 Valves

In water works practice, to control the flow of water, to regulate pressure, to release or to admit air, prevent flow of water in opposite direction valves are required.

The following are the various types of valves named to suit their function

1. Sluice valves: - These are also known as gate-valves or stop valves. These valve control the flow of water through pipes. These valves are cheaper, offers less resistance to the flow of water than other valves. The entire distribution system is decided into blocks by providing these valves at appropriate places. They are provided in straight pipeline at 150-200m intervals. When two pipes lines interest, valves are fixed in both sides of intersection. When sluice valve is closed, it shuts off water in a pipeline to enable to undertake repairs in that particular block. The flow of water can be controlled by raising or lowering the handle or wheel.

2. Check valves or reflex valves: - These valves are also known as non-return valves. A reflux valve is an automatic device which allows water to go in one direction only. The swing type of reflux valve as shown in fig is widely used in practice. When the water moves in the direction of arrow, the valve swings or rotates around the pivot and it is kept in open position due to the pressure of water. When the flow of water in this direction ceases, the water tries to flow in a backward direction. But this valve prevents passage of water in the reverse direction. Reflux valve is invariably placed in water pipe, which obtain water directly from pump. When pump fails or stops, the water will not run back to the pump and thus pumping equipments will be saved from damage

3. Air valves: - These are automatic valves and are of two types namely

1. Air inlet valves: - Air inlet valves These valves open automatically and allow air to enter into the pipeline so that the development of negative pressure can be avoided in the pipelines. The vacuum pressure created in the down streamside in pipelines due to sudden closure of sluice valves. This situation can be avoided by using the air inlet valves

2. Air relief valves: - Air relief valves Sometimes air is accumulated at the summit of pipelines and blocks the flow of water due to air lock. In such cases the accumulated air has to be removed from the pipe lines. This is done automatically by means of air relief valves. This valve consists of a chamber in which one or two floats are placed and is connected to the pipe line. When there is flow under pressure in the pipeline water occupies the float chamber and makes the float to close the outlet. But where there is accumulation of air in the pipeline, air enters the chamber, makes the float to come down, thus opening the outlet. The accumulated air is driven out through the outlet.

4. Drain valves or Blow off valves: - A valve used to drain off material that has separated from a fluid or gas stream, or one used to empty a process line, vessel, or storage tank.

5. Scour valve: - These are similar to blow off valves. They are ordinary valves operated by hand. They are located at the depressions and dead ends to remove the accumulated silt and sand. After the complete removal of silt; the value is to be closed.

Key Takeaways:

1.12.1 Introduction

A water distribution system should supply necessary amount of potable water at demand points, for domestic, commercial, industrial, and fire fighting purposes; the system should be capable of meeting the demands almost any time at required pressures. However, sometimes considerable water leakages from the system may cause problems related to the pressures at the consumers tap and significant water losses. Leakages might occur from the main feeder, distribution pipes, service pipes, or storage tank; the sizes of the leakages might change from small cracks to large breaks.

Excessive water losses can limit forming of further extensions of a water distribution network unless new sources are found and new transmission lines are constructed. Most important form of water losses is leakage. Leakage rates may change from very small values of 5-10% to values higher than 50%. In Turkey, leakage values are reported by the water utilities, in the big cities around 35%. The reasons of leaks are related to various factors such as the age of the network, the quality of the maintenance work, pipe material used, soil type, types of hydraulic operations, and high pressures.

1.12.2 Reduction of Water Leakages

There are various methods to reduce leakages in water distribution networks to a feasible rate (Smith et al., 2000); they are classified roughly in two groups: (1) direct methods, (2) indirect methods. Direct methods include all techniques which locate the leakage for an immediate repair. On the other hand, indirect methods comprise all the efforts to form a constant and homogeneous pressure field over the related pressure zone; indirect methods do not permit pressures above required pressures by adjusting pressure regulating valves and/or isolation valves of the network. Avoiding of excessive pressures will not allow formation of extreme leakages.

This study deals with direct methods. Application of direct methods especially in metropolitan areas is difficult because the determination of the weakest portions of the system in order to start to work is a tedious job. Most of the time, this kind of studies is conducted in areas where there is no excessive leakage. However, there are mainly two alternatives as a remedy. First possibility is to compare the supplied water and consumed water in the system. SCADA measurements and/or field measurements taken during night will indicate jerry-built networks. Second possibility is to compare the supplied water and the billings of the water utility.

If there are leaks from the system, the engineer should start his work from the weakest part. Basically, there are two kinds of leak detection methods: (i) Water Audit, (ii) Hydrostatic Testing.

1.12.3 Leakage test

After pressure test, this leakage test is done, at a pressure to be specified by the authority for duration of 2 hours. Leakage is the quantity f water that is required to be supplied for maintaining the specified leakage test pressure after the pipe has been filed with water and the air is expelled.

The allowable leakage during the maintenance stages of pipes should not exceed the value given by:

qL =

Where, qL = Allowable leakages in cm3/hr

N = Number of joints in the length of pipe

D = Diameter of pipe in mm

P = the average test pressure during the leakage test in kg/cm2

Key Takeaways:

References:

1. Manual on Water Supply and Treatment, C. P. H. E. E. O., Ministry of Urban Development, Government of India, New Delhi

2. Manual on Sewerage and Sewage Treatment, C. P. H. E. E. O., Ministry of Urban Development, Government of India, New Delhi

3. Steel and McGhee: Water Supply and Sewerage

4. Fair and Geyer: Water Supply and Wastewater Disposal

5. Hammer and Hammer Jr.: Water and Wastewater Technology

6. Raju: Water Supply and Wastewater Engineering

7. Rao: Textbook of Environmental Engineering

8. Davis and Cornwell: Introduction to Environmental Engineering

9. Kshirsagar: Water Supply and Treatment and Sewage Treatment Vol. I and II

10. Punmia: Water Supply and Wastewater Engineering Vol. I and II

11. Birdie: Water Supply and Sanitary Engineering

12. Ramalho: Introduction to Wastewater Treatment Processes

13. Davis Mackenzie L., Cornwell, David A., “Introduction to Environmental Engineering” McGraw Hill Education (India) Pvt. Ltd., New Delhi.

14. Birdie: Water Supply and Sanitary Engineering

15. Ramalho: Introduction to Wastewater Treatment Processes

16. Parker: Wastewater Systems Engineering

17. A.K. Jain, Environmental Engineering, Khanna Publishing House