Unit-3

Design of shallow foundation

To perform satisfactorily:

Design considerations

FOUNDATION TYPES

SHALLOW

DEEP

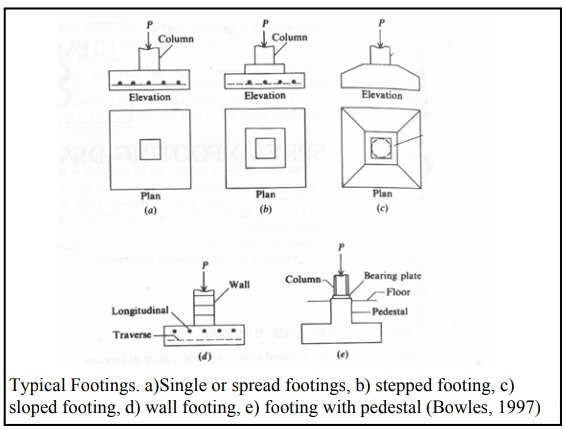

Fig no. 1 Types of shallow footing

SINGLE FOOTING

Types

A strip footing (continuous footing) supports a load wall or cluster of columns.

Combined Footing supports a variety of columns.

SHALLOW FOUNDATION DESIGN

BEARING CAPACITY

TERZAGHIS BEARING CAPACITY THEORY FOR SHALLOW FOUNDATION

For a strip footing:

q u l t = 1/2  BN

BN + c N c +

+ c N c +  Df N q

Df N q

Where

Qu: final bearing capability

N: Bearing capability issue because of the weight of soil with zero surcharge

N c: Bearing capability issue because of cohesion of soil, presumptuous soil to be weightless and surcharge as zero

N q: Bearing capability issue because of surcharge pressure, q o=  D associate horizontal plane at foundation base level, presumptuous soil below foundation as weightless

D associate horizontal plane at foundation base level, presumptuous soil below foundation as weightless

For a square footing with aspect B

q u l t = 0.4  BN

BN  + 1.3 c N c +

+ 1.3 c N c + Df N q

Df N q

For a circular footing with diameter D:

q u l t = 0.3  D N

D N + 1.3 c N c +

+ 1.3 c N c +  Df N q

Df N q

Note: For an oblong footing (L*B) use linear interpolation between strip footing (B/L=0) and sq. footing (B/L=1.0)

N c rect = N c strip [1 + 0.2 (B/L)]

N  rect = N

rect = N strip [1 - 0.2 (B/L)]

strip [1 - 0.2 (B/L)]

N q rect = N q strip

*For identical soil conditions, for various foundation shapes, q u l tvalues square measure differently.

Key takeaways

Shallow foundation

Deep foundation

Masonry, steel, plain concrete like

Settlement failure

Bearing capability failure

The main objectives of foundation style are to make sure that the structural masses are transmitted to the subsoil(s) safely, economically, and with none unacceptable movement throughout the development amount and the anticipated lifetime of the building or structure

Basic style Procedure

This can be thought-about as a series of steps or stages

Isolated footing

Fig no 2 Isolated footing

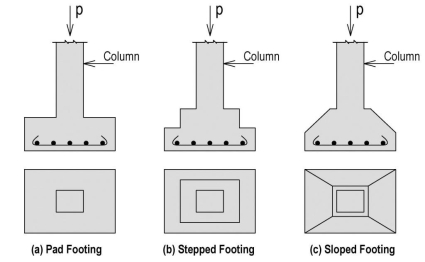

Strip footing

Fig no. 3 Strip footing

2 ways may be accustomed to analyzing the strip footings.

Rigid Analysis

Footing space = (Total Column Load) / (Allowable Bearing Pressure)

Flexible Analysis

Subgrade Reaction = (SF)x 40 x (Allowable Bearing Capacity)

Key takeaways

Isolated foundation

Strip footing – 2 ways may analyze the strip footing

Rigid analysis technique

Flexible analysis technique

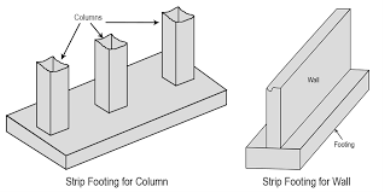

Introduction

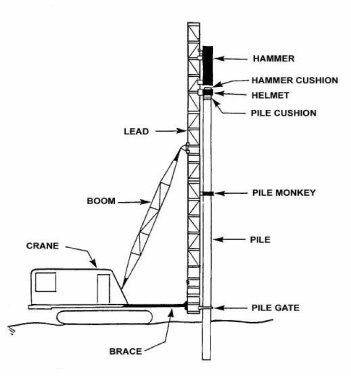

Fig no. 4 Deep foundation

Methods of pile forming

1. Pile driving

2 Pile driving hammers

3. Jetting of piles

4. Pile driving by vibration

Pile Driving

Fig no. 5 Pile driving

Pile Driving Hammers

![CG_6028] Single And Double Action Diagram Free Diagram](https://glossaread-contain.s3.ap-south-1.amazonaws.com/epub/1642793424_7268367.png)

Fig no. 6 Pile driving hammers

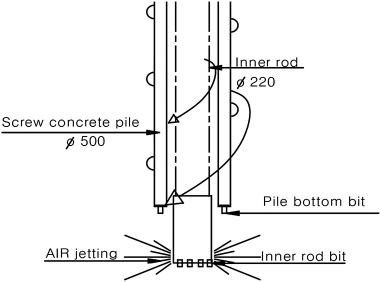

JETTING OF PILES

Fig no. 7 Jetting piles

Pile Driving by Vibration

Key takeaways

Method of pile forming

Following effects are ascertained

1. It causes compaction of loose sandy soils to a radial distance of two to three times pile diameter, D closes the pile and concerning a pair of times, the diameter below the tip takes place. Subsidence happens as a result of compaction. Soil compaction will increase pile capability.

2. Re mould of sensitive clays leads to a loss of strength within the close soil upto a radial distance of D (upto ninetieth of strength is regained by impact in around thirty ten fifty days) A zone of thickness D on the far side re mould zone gets consolidated.

3. Shocks throughout driving might cause a physical change of saturated fine sands and silts.

4. Surface heaving takes place in dense sandy soils thanks to the loosening impact of vibration and because of the plastic flow of soils.

5. Squirting will have a prejudicial scouring effect on non-cohesive soils below existing neighboring structures and might cause the fast sand condition.

6. Concretion of soils behind holding walls increases the lateral pressure.

7. Displacement piles behind holding walls might cause lateral soil movement and develop passive pressure.

8. Piles additionally get broken because of the following

(a) Overdriving or improper driving

(b) Deviation from alignment

(c) Use of defective piles

(d) Obstruction of boulders.

9. The piles should be protected at high and tip by soft pile cap and dolly at high and shoe at the tip.

<1, whereas for sands it is > one

Fig no. 8 Efficiency of piles drive

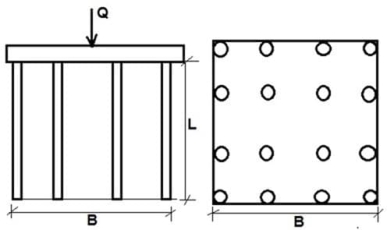

= Q g/N Q p

= Q g/N Q p

Where Q g = group capability

N = No. of piles

Q p = single pile load

For friction piles, cluster potency n is often as high as a hundred% for the spacing of piles > 5D and low as fifty-five you take care of spacing <2.5 D. whereas spacing > 4.5 D is uneconomical.

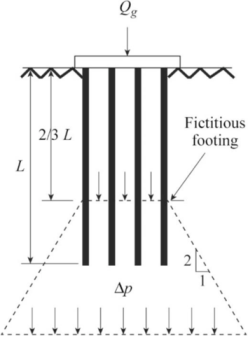

There is no precise methodology for estimating the settlement of pile teams. Therefore, Associate in approximate methodology is mentioned

Pile groups in Cohesive Soil

Fig no. 9 Settlement of piles group for cohesive soil

(a) Immediate settlement

S I =  q n B/E (1-

q n B/E (1-  2) I p

2) I p

Where q n, = net pressure on the equivalent raft at depth2Df/3,

B = breadth of the equivalent raft at depth 2 D f/3

= Poisson's quantitative relation of soil below the depth equivalent raft

= Poisson's quantitative relation of soil below the depth equivalent raft

E = coefficient of elasticity of the soils below the equivalent raft

= (500 - 1000) C u

I p = influence constant, f(L/B), and

= depth correction factor f (Df /B, L/B)

= depth correction factor f (Df /B, L/B)

(b) Consolidation settlement

The consolidation settlement of the pile group is obtained from the quality equation,

S c = [ (C c/1 +e o) H log (P o +

(C c/1 +e o) H log (P o + P/Po)]

P/Po)]

S c = (∑ m v p H)

p H)

Where, C c/ (1 + e o) and m, square measure severally the compressibility index and therefore the constant of volume decrease for the suitable stress level of the relevant strata.

H is that the thickness of strata,

P o and  p square measure the unmoved vertical effective stress and therefore the increase of stress within the various strata, and

p square measure the unmoved vertical effective stress and therefore the increase of stress within the various strata, and

AND

AND square measure severally the depth and pore-pressurecorrection factors.

square measure severally the depth and pore-pressurecorrection factors.

to know the effective depth of soil below the cluster, the simplest methodology is to see the strain increment quantitative relation  p/p, at completely different depths and think about the depth of soil that

p/p, at completely different depths and think about the depth of soil that  p/p> zero.1.

p/p> zero.1.

H = s q u / [N 0.81 (1 +0.4 D f/B)]

H = s q u / [N 0.81 (1 +0.4 D f/B)]

Where  H = settlement

H = settlement

s= settlement constant,

q u = average pressure on the equivalent raft,

N = average SPT worth over a depth 2B below the muse level or D s if the depth of cohesionless soil is a smaller amount than 2B.

Df = depth of equivalent raft, and

B = breadth of equivalent raft.

The settlement constant, s vanes with Df/ B

Key takeaways

Settlement of piles –

Piles group in cohesive soil

Piles group in cohesionless soil.

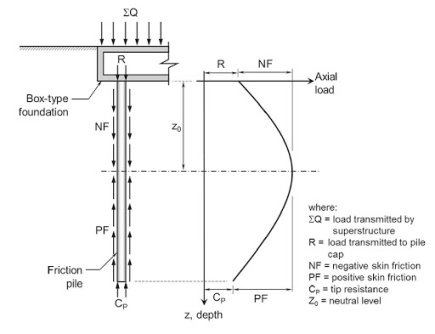

Fig no. 10 Negative skin friction

Determination

The magnitude of F n is determined as

Fn =Q s (kin resistance) = A s f s

Where p = Pile perimeter π D

D p or Lp = Length of the pile at intervals compressible layer

Fs = S u =Un drained shear strength of compressible soil

2. For granular soil

F n = ½ L p2 p  k tan

k tan  <= tan

<= tan

K = coefficient of lateral pressure

= unit weight of soil

= unit weight of soil

3. For pile group

(Fn) g= N (F n) 1

(Fn) g= c L p p +  L p A

L p A

(Fn) g= c L p +p  L p A = L p [c p +

L p A = L p [c p +  A]

A]

Where A = area enclosed in perimeter p of a group of piles

Measure to minimize F n

Prevention:

Key takeaways

(F n) g= N (F n) 1

(F n) g= c L p p +  L p A

L p A

(F n) g= c L p +p  L p A = L p [c p +

L p A = L p [c p +  A]

A]

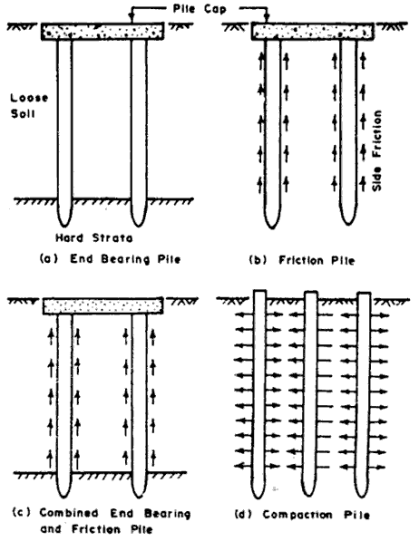

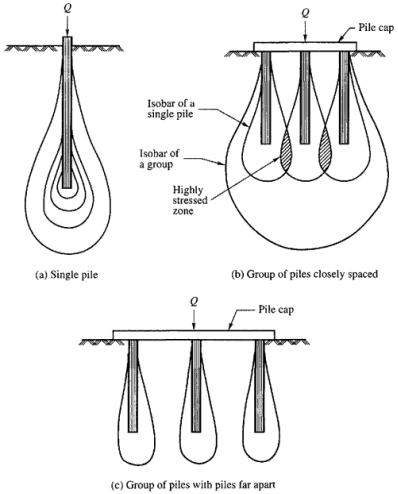

Double piles

End bearing piles

Friction piles

Fig no. 11 end bearing and friction piles with pressure bulbs

Classification

The foundation piles are principally classified supported following criteria

(a) Material of construction Timber, steel, concrete, composite, etc.

(b) Cross-section Circular, hexagonal, square, I section, H section, pipe, etc.

(c) Form: cylindrical, tapered, beneath reamed, etc.

(d) Mode of load transfer Bearing, friction, tension, etc.

(e) Technique of forming per cast, Pre stressed, solid in place government agency.

(f) Methods of installation: Driven (Hammer, squirting or vibration), Bored (cased or uncased), Inserted (jacked, pushed, or pre excavated)

Few different types of piles are discussed here

(g) Function or purpose

Classification of piles

1. Timber piles

2. Metal piles

3. Precast console and

4.Driven and cal-in place-concrete piles

5. Bored and cast-in-place concrete

1 Timber Piles

2. Metal Piles

Precast concrete piles

Key takeaways

Classification of piles

References