Unit 1

Scope of Study of Building Materials

- Building substances ought to serve their meant feature now no longer most effective whilst newly established however additionally for a few perfect durations of time.

- These carrier lifestyles may also remain for the lifestyles of the constructing or, as with paints, for just a few years earlier than renewal.

- It is not unusual place to talk of the sturdiness of a cloth as though it had been a fundamental property, measured because the duration of time it's going to serve satisfactorily.

- The beneficial lifestyles of a cloth in place, however, is constantly associated with the specific aggregate of environmental elements to which it's far subjected, in order that sturdiness, or carrier lifestyles, ought to constantly be associated with the specific situations concerned.

- Experience with conventional substances over a few years allows prediction of the overall performance of the identical cloth below comparable situations.

- Such trial with the aid of using use has supplied a solution to how however now no longer regularly to why substances react as they do.

- When new substances are to be evolved or taken into consideration or whilst conventional substances are for use in untried situations, the capacity to expect overall performance can be significantly constrained until the "why" of beyond revel in, and therefore the essential elements concerned, are understood.

- This is fundamental to the exercising of judgment in design, an aggregate of revel in and analysis.

- Such a technique is likewise vital with inside the improvement and interpretation of any extended take a look at approach designed to enhance prediction of overall performance.

- Most constructing substances are complicated of their chemical and bodily nature, as are the tactics concerned of their reaction to environmental elements.

- Some generalizations can be made in those respects, however, a good way to enhance information of overall performance and offer a foundation for predicting behavior.

Performance and Testing:

- Exact prediction of overall performance calls for whole information of cloth properties, the tactics concerned with inside the interplay of the cloth with its environment, and the environmental elements to which it will likely be subjected. The most effective whole takes a look at of overall performance is trial with the aid of using use.

- Prediction will constantly be constrained with the aid of using loss of whole understanding; trial with the aid of using use could be constrained with the aid of using time and incapability to extrapolate to new situations.

- Test strategies may be used to complement understanding and revel in in predicting overall performance.

- Some take a look at strategies rely upon empirically derived family members among located behavior and a few without problems measured bodily property; others difficulty the cloth to environmental situations simulating the ones to be anticipated in exercise.

- The improvement of higher take a look at strategies and their right utility in exercise can most effective come approximately thru higher information of substances and their overall performance. Such information is likewise prerequisite to the right and vital assessment of beyond revel in.

KEY TAKEAWAYS:

- Building materials carrier lifestyles may also remain for the lifestyles of the constructing or, as with paints, for just a few years earlier than renewal.

- Test strategies may be used to complement understanding and revel in in predicting overall performance.

- Many clearly happening substances, which include clay, rocks, sand, and wood, even twigs and leaves, had been used to assemble buildings. Apart from clearly happening substances, much man-made merchandise is in use, a few greater and a few much less synthetic.

- The production of constructing substances is a longtime enterprise in many nations and the usage of those substances is usually segmented into precise strong point trades, which includes carpentry, insulation, plumbing, and roofing work. They offer the makeup of habitats and systems which include homes.

- Initial financial value of constructing substances is the acquisition price. This is frequently what governs selection making approximately what substances to use. Sometimes humans think about the electricity financial savings or sturdiness of the substances and spot the fee of paying a better preliminary value in go back for a decrease lifetime value.

- For example, an asphalt shingle roof expenses much less than a steel roof to install, however the steel roof will be remaining longer so the lifetime value is much less in step with year. Some substances may also require greater care than others, keeping expenses precise to a few substances may additionally have an impact on the very last selection.

- Risks whilst thinking about lifetime value of a cloth is that if the constructing is broken which includes with the aid of using hearth place or wind, or if the fabric isn't as long lasting as advertised. The value of substances needs to be considered to endure the chance to shop for combustive substances to increase the lifetime. It is stated that, "if it ought to be performed, it ought to be performed well".

1.3.1 Requirement of Good Building Stone

The following are the first-class necessities of right constructing stones:

Fig. 1: Different types of stone

1. STRENGTH

- Generally maximum of the constructing stones have excessive power to face up to the burden approaching it.

- Therefore, it isn't of top problem while it comes to test the high-satisfactory of stones. But while the stones are for use in huge structures, it will become vital to test the compressive power of stones.

- Compressive power of constructing stones usually falls in the variety of 60 to 200N/mm2.

2. DURABILITY

- Building stones have to be successful to face up to the detrimental outcomes of herbal forces like wind, rain and heat. It ought to be long lasting and have to now no longer go to pot because of the detrimental outcomes of the above herbal forces.

3. HARDNESS

- When stones are utilized in floors, pavements or aprons of bridges, they grow to be subjected to carrying and abrasive forces as a result of motion of guys or device over them. So, it's far required to check hardness of stone.

- Hardness of stone is decided via way of means of Mosh scale.

4. TOUGHNESS

- Toughness of stones method it capacity to face up to effect forces.

- Building stones have to be difficult sufficient to maintain stresses advanced because of vibrations.

- The vibrations can be because of the equipment established over them or because of the hundreds shifting over them.

- The stone aggregates utilized in the street buildings have to be difficult.

5. SPECIFIC GRAVITY

- The greater the particular gravity of stone, the greater heavier and more potent the stone is. Therefore, stones having better particular gravity values have to be used for the development of dams, maintaining walls, docks and harbors.

- The particular gravity of suitable constructing stone is among 2.four and 2.8.

6. POROSITY AND ABSORPTION

- Porosity of constructing stones rely upon the mineral constituent and structural formation of the determine rock.

- If stones utilized in constructing creation are porous then rain water can without difficulty input into the pore areas and purpose harm to the stones.

- Therefore, constructing stone have to now no longer be porous. Water absorption of stone is without delay proportional to the porosity of rock.

- If a stone is greater porous then it's going to soak up greater water and purpose greater harm to stone.

- In better altitudes, the freezing of water in pores takes location and it outcomes into the disintegration of the stone.

- Permissible limits of water absorption for a few the normally used constructing stones are as follow.

Types of Stones | Maximum limit of water absorption (%) |

Sandstone | 10 |

Limestone | 10 |

Granite | 1 |

Shale | 10 |

Slate | 1 |

Quartzite | 3 |

7. DRESSING

- Giving required form to the stone is known as dressing.

- It has to be smooth to get dressed in order that the price of dressing is reduced.

- However, the care has to be taken in order that, this isn't being on the price of the desired power and the durability.

8. APPEARANCE

- In case of the stones for use for face works, in which look is a number one requirement, its coloration and capacity to get hold of polish is an essential factor.

- Light cultured stones are greater favored than darkish cultured stones because the coloration are probably to vanish out with time.

9. SEASONING

- Good stones have to be loose from the quarry sap.

- Lateritic stones have to now no longer be used for six to 365 days after quarrying.

- They are allowed to put off quarry sap with the aid of using the motion of nature.

- This procedure of putting off quarry sap is known as seasoning.

10. WORKABILITY

- Stone have to be plausible. Stone is stated to be plausible while the paintings worried in stone working (consisting of cutting, dressing & shaping) is low in cost and smooth to conduct.

11. COST

- Cost is an essential attention in deciding on a constructing material.

- Proximity of the quarry to constructing web website online brings down the price of transportation and consequently the price of stones comes down.

12. FIRE RESISTANCE

- Stones have to be loose from calcium carbonate, oxides of iron, and minerals having exceptional coefficient

KEY TAKEAWAYS:

- Compressive power of constructing stones usually falls in the variety of 60 to 200N/mm2.

- In case of the stones for use for face works, in which look is a number one requirement, its coloration and capacity to get hold of polish is an essential factor.

1.3.2 Characteristics of Building Stones and their Testing

A top constructing stone have to have the subsequent qualities:

Appearance:

- Building Stones used for the face paintings of the constructing have to have best, compact texture.

- Light cultured stone is commonly favored as darkish colorations are susceptible to fade out with time.

- They have to be loose from clay holes, bands or spots of color.

Structure:

- A stone while broken have to now no longer be stupid in look and have to display uniformity of texture.

- It has to be loose from cavities, cracks, and patches of free or smooth material.

- Stratifications that are commonly located in sedimentary rocks have to now no longer be seen to bare eye.

Strength:

- Stones utilized in production have to be sturdy and sturdy to face up to the disintegrating motion of weather.

- Stones with compact best crystalline texture are stronger.

- Compressive power of constructing stones in practice, variety among 60 to 2 hundred N/mm2.

Specific Gravity:

- The precise gravity of Building stone is at once proportional to its weight and power.

- Hence the stones having better precise gravity have to now no longer are used for dams, maintaining walls, docks and harbors.

- Specific gravity of a great constructing stone lies among 2.4 to 2.8.

Hardness:

- When stones are applied for floors, pavements, aprons of bridges and weirs of rivers, the stones are subjected to abrasive forces that are resulting from the wear and tear and friction.

- Hence the stones that are for use in such locations have to be examined for hardness.

Fig. 2: Hardness of Stone

Toughness:

- It is the degree of effect that a stone can withstand.

- When the stones are imagined to go through vibrations of equipment and transferring loads, they ought to be tough.

Porosity and Absorption:

- The porous constructing stones aren’t appropriate in creation particularly for uncovered surfaces of structures.

- The rain water which comes down conveys a few acidic gases forming mild acids which receive soaked at the surface.

- Acids react with the elements of stones inflicting them to crumble.

- In bloodless areas water freezes with inside the pores of stones.

- This water reasons the disintegration of stones due to its boom in quantity on freezing.

Fig. 3: Porosity of stone

The types of some of the stones and their maximum limit of water absorption (%) are as follows:

- Sandstone: 10

- Limestone: 10

- Granite: 1

- Trap: 6

- Shale: 10

- Gneiss: 1

- Slate: 1

- Quartzite: 3

Seasoning:

- All freshly quarried stones incorporate a positive quantity of moisture referred to as quarry sap, which makes them tender and simpler to paintings upon. Good stones must be loose from quarry sap. They are allowed to eliminate quarry sap with the aid of using the movement of nature. This procedure of disposing of quarry sap is referred to as seasoning. A length of 6-one year is normally sufficient for correct seasoning.

Weathering:

- It is the quantity to which the face of a stone resists the movement of weather. Stones with properly weathering residences most effective must be used with inside the production of essential buildings.

Fig. 4: Weathering of Stone

Workability:

- Stones are stated to be plausible if the wok that is worried of their cutting, dressing and shaping is taken into consideration as low-budget and smooth to conduct. Know the Current House creation fee

Fire Resistance:

- Building Stones ought to be loose from calcium carbonate, oxides of iron, and minerals having one of a kind coefficients of thermal expansion. Igneous rock go through fundamental disintegration due to quartz which disintegrates into small debris at a temperature of approximately 575 co. Limestone, however, can face up to a touch better temperature; i.e. as much as 800°C and then they disintegrate.

KEY TAKEAWAYS:

- Specific gravity of a great constructing stone lies among 2.4 to 2.8.

- Stones are stated to be plausible if the wok that is worried of their cutting, dressing and shaping is taken into consideration as low-budget and smooth to conduct. Know the Current House creation fee.

Tests on Stones

To decide the desired residences of stones, the subsequent exams could be conducted:

- Crushing Strength Test of Stone

- Water Absorption Test of Stone

- Abrasion Test of Stone

- Los Angeles Abrasion Test

- Deval Abrasion Test

- Dorry’s Abrasion Test.

- Impact Test of Stone

- Acid Test of Stone

Crushing Strength Test of Stone:

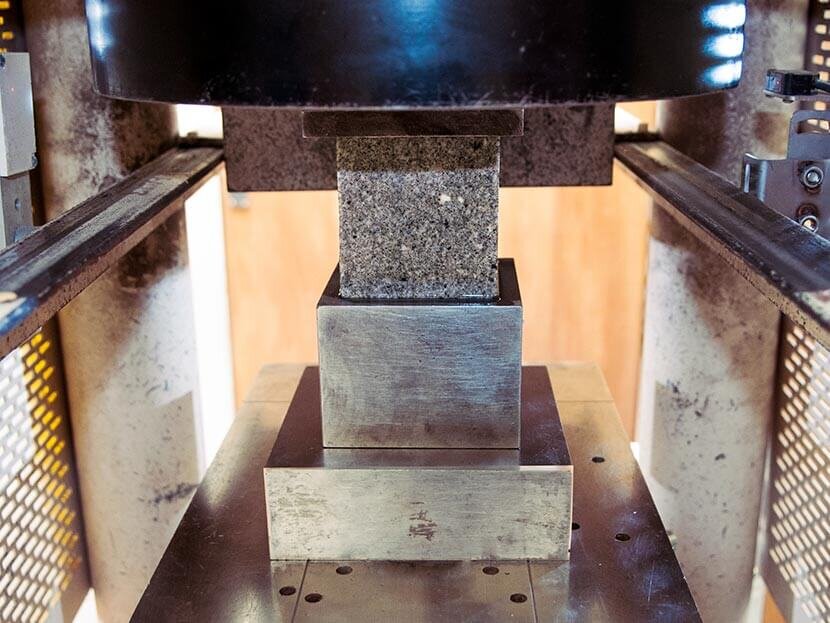

Fig. 5: Compression testing machine

- For accomplishing this check, a specimen of length 40× 40 × 40 mm is ready from determine stone.

- Afterward, the edges are finely dressed and located in water for 3 days.

- The saturated specimen is supplied with a layer of plaster of paris on its pinnacle additionally backside surfaces to get even floor in order that load implemented is shipped uniformly.

- Uniform load distribution might be received satisfactorily with the aid of using presenting a couple of five mm thick plywood in place of the usage of plaster of paris layer additionally.

- The specimen so located withinside the compression trying out system is loaded withinside the fee of 14 N/mm2 in line with minute.

- The crushing load is noted.

- Then crushing energy is identical to this crushing load divided with the aid of using the vicinity wherein the burden is implemented.

- At least 3 specimens ought to be tested, and the common should be taken as crushing energy.

Water Absorption Test of Stone

With this check dice specimen weighing approximately 50 grams are Ready, and the check is executed at the stairs given below:

- Note the load of dry specimens as W1.

- Place the specimen in water for twenty-four hours.

- Take out the specimen, wipe out the floor with a chunk of cloth, and weigh the specimen. Let its weight be W2.

- Suspend the specimen freely in weight and water it. Let its weight be W3.

- Place the specimen in boiling water for five hours. Then take it out, wipe the floor with a cloth, and weigh it. Let this weight be W4. Then,

Percentage absorption with the aid of using weight = (W2 – W1) / W1 x 100 …(1)

Percentage absorption with the aid of using volume = (W2 – W1) / (W2 – W3) x 100…(2)

Percentage porosity with the aid of using volume = (W4 – W1) / (W2 – W3) x 100 …(3)

Density = W1 / (W2 – W1) x 100 ……….(4)

Specific Gravity = W1 / (W2 – W3) x 100 ……….(5)

Saturation Coefficient = Water Absorption / Total Porosity = (W2 – W1) / (W4 – W1)

Abrasion Test of Stone:

- This check is executed on stones which are used as aggregates for street construction.

- The check end result shows the suitability of stones in opposition to the grinding motion beneathneath traffic. Anyone of the subsequent exams might be carried out to discover the suitability of aggregates:

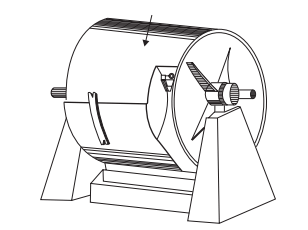

(1) Los Angeles Abrasion Test

(2) Deval Abrasion Test

(3) Dorry’s Abrasion Test.

- However, the Los Angeles abrasion check is favored on account that those check consequences have an excellent correlation with the overall performance of the pavements.

- The Los Angeles apparatus [Below Figure] includes a hole cylinder 0.7 m inner diameter and 0.5 m lengthy with each end closed.

- It is installed onto a body in order that it may be circled approximately a horizontal axis.

- IS code has standardized the check method for specific gradations of specimens. T

- Together with the required weight of the specimen, a certain wide variety of forged iron balls of forty 8 mm diameter are located withinside the cylinder.

Fig. 6: Los Angeles Testing Machine

- Then the cylinder is turned around at a velocity of 30 to 33 rpm for a designated quantity of times (500 to 1000). Then the combination is eliminated in conjunction with sieved on 1.7 mm. IS sieve. The weight of combination passing is determined.

- Then Los Angeles price is determined as = (Weight of combination passing via sieve / Original weight) x 100

- The following values are encouraged for street works:

For bituminous mixes :30

For base course:50%

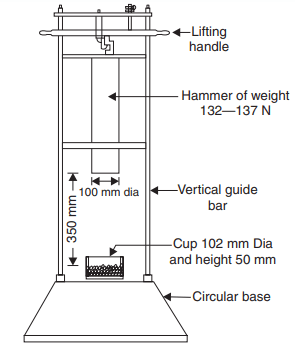

Impact Test of Stone:

- The resistance of stones to effect is determined through carrying out assessments in impacting the trying out machine [Below Figure].

- It includes a body with publications in which a steel hammer weighing 13.5 to 15kg can freely fall from a peak of 380 mm.

Fig. 7: Impact Testing Machine

- Aggregates of length 10 mm to 12.5 mm are stuffed in a cylinder in three identical layers, each layer being tamped 25 times.

- The identical is then transferred into the cup and once more tamped 25 times.

- The hammer is then allowed to fall freely onto the specimen 15 times.

- The specimen is then sieved thru a 2.36 mm sieve.

- Then, Impact value = W2 / W1 where, W2 = Weight of Fines. W1 = Original Weight.

- The advocated effect values for diverse works are:

(a) for carrying course ≯ 30%

(b) for bituminous macadam ≯ 35

(c) for water-certain macadam ≯ 40%

Acid Test of Stone:

Fig. 8: Testing of Stone

- This check is generally performed on sandstones to test the presence of calcium carbonate, which weakens the climate resisting quality.

- In this check, a pattern of stone weighing approximately 50 to 100 gm is taken and saved in an answer of 1 percentage hydrochloric acid for seven days.

- The answer is agitated at intervals. A suitable constructing stone keeps its sharp edges and maintains its floor intact.

- If edges are broken, and powder is fashioned at the floor, it shows the presence of calcium carbonate.

- Such stones can have negative climate resistance.

KEY TAKEAWAYS:

- 3 specimens ought to be tested, and the common should be taken as crushing energy

- The resistance of stones to effect is determined through carrying out assessments in impacting the trying out machine

1.3.3 Common Building Stones

1.Granite:

Composition:

- It is igneous rock.

- Its important constituent minerals are Quartz, (tough and least stricken by carbon dioxide and water) Felspar (crystalline, lustrous, without problems attacked via way of means of atmospheric agencies) and Mica (darkish gray, black or brown in color, soft, without problems stricken by chemical compounds and atmospheric agencies).

Characteristics:

- Its precise gravity is 2.64 and absorption much less than 1%.

- It has mottled appearance.

- Significantly robust and durable.

- Finely grained granite takes a quality polish.

- Crushing energy varies from a hundred and ten to 140MN/m^2

- It has least hearth place resistance because it cracks below a robust hearth place.

- Its color relies upon upon that of feldspar.

Uses:

- Fine grained granite is appropriate for decorative columns, plinth, etc. because it takes a polish.

- Owing to the hardness, weight and sturdiness of granite it’s far taken into consideration maximum appropriate for the development of sea partitions, mild houses, bridge piers etc.

2.Basalt or Trap:

Composition:

- It is an igneous rock (silicious range).

- The Main elements are silica, alumina and feldspar

Characteristics:

- Very tough and difficult.

- Heavier than granite.

- Has greenish gray to darkish gray color.

- Crushing energy varies from 70 to eighty MN/m2.

- Specific gravity = 2.96.

Uses:

- Suitable for paving units and as a avenue metal.

- Used for the manufacture of synthetic stone.

- Used as mixture in concrete.

Occurrence:

- Madhya Pradesh and Deccan traps (alongside western coast) and Rajmahal trap (Bihar).

3. Slate:

Composition:

- It is a metamorphic rock (Argillaceous range).

- It consists of alumina combined with sand or carbonate of lime.

Characteristics:

- Its precise gravity is 2.8.

- A suitable slate is tough, difficult and quality grained.

- It has gray or darkish blue color.

- It may be cut up into skinny sheets.

- Its crushing energy varies from 60 to 70 MN/m2.

- It is non-absorbent.

- When struck with a mild hammer, it produces a pointy metal ring.

- Its sturdiness is suitable.

Uses:

- Used for making electric transfer boards.

- Because of its non-absorbent property, it’s far appropriate to be used in cisterns, urinals partitions, etc.

Occurrence:

- Gurgoan (Haryana), Gurdaspur (Punjab), Cuddadh (Andhra), Chanda (Maharashtra), Chindwara (M.P), Bijapur (Mysore), Alwar (Rajasthan), Chamba, Simla, Kangra (Himachal Pradesh), Baroda (Gujarat).

4. Gneiss:

Composition:

- It is a metamorphic rock.

- It is likewise from time to time referred to as stratified granite because it happens in really parallel layers.

- Its elements are similar to granite, i.e., quartz and eveled.

Characteristics:

- It may be without problems cut up into slabs.

- It is greater effortlessly labored than granite.

- As it’s far to be had in one-of-a-kind colorings, it’s far used for decorative and ornamental purposes.

- It is fairly suitable cloth for road paving.

Occurrence:

- It is essentially located in Madras State, Mysore and Bihar.

5. Sandstone:

Composition:

- It is a sedimentary rock of silicious range.

- It carries sand or quartz cemented via way of means of lime, mica, magnesium, aluminium, oxide of iron or via way of means of a combination of those substances.

- Sometimes fragments of limestone, mica or eveled also are gift.

Characteristics:

- Its shape suggests sandy grains.

- Its typical colorings are white, gray, brown, purple etc.

- Its precise gravity is 2.25.

- Crushing energy varies from 35 to forty MN//m2.

- Fine grained stones are robust and durable.

- The sandstone of skinny-bedded range is referred to as flag stone.

- It splits effortlessly into big slabs alongside the bedding.

- The rock composed of angular sharp-edged sand grains is referred to as grit; it is satisfactorily robust and heavy and is utilized in heavy engineering works.

- The sandstone that may be reduce effortlessly with mallet and hammer into blocks for constructing is referred as loose stone.

- Its sturdiness relies upon upon the character of a cloth.

- The amount of sandstone is negative if it’s far porous or carries lime.

Uses:

- The quality grained and compact range is appropriate for ashlar work, mouldings, carvings etc.

- The tough and coarse-grained stone is hired for rubble work.

Occurrence:

- The pleasant range stones that may effortlessly be quarried in big wonderful blocks are to be had in Mirzapur; Chunar; Fatehpur Sikri; Gwalior (M.P.); Hemanagar close to Ahmedabad (Gujarat); Nagpur (Maharashtra); Kangra and Dharamsala (H.P.), Shahpur and Kasauli Rajpur, and Jabalpur; Dehri; Mandhum and Ranchi (Bihar); Cuttack and Mysore.

6. Limestone:

Composition:

- It is a sedimentary rock of calcareous range.

- When in natural kingdom it carries CaCO3, however regularly is blended with MgCO3 and small quantity of silica and alumina.

- When each MgCO3 and CaCO3 are gift almost in identical percentage it’s far called Dolomite.

Characteristics:

- Its precise gravity is 2.6.

- It is to be had in brown, yellow and darkish gray colorings.

- Crushing energy = 52MN/m2.

Uses:

- It is utilized in big portions in blast furnaces, bleaching, tanning and different industries.

- If compact and quality grained it could be used as stone masonry for partitions and paving set in floor.

- It is used as avenue metal (while higher substances like trap, basalt or granite aren’t to be had).

Occurrence:

- It is located in Alwar (Rajasthan), Hoshiarpur (Punjab), Simla (H.P.), Mirzapur, Ranchi (Bihar) and Mysore etc.

KEY TAKEAWAYS:

- Owing to the hardness, weight, and sturdiness of granite it’s far taken into consideration maximum appropriate for the development of sea partitions, mild houses, bridge piers etc.

- Sandstone carries sand or quartz cemented via way of means of lime, mica, magnesium, aluminium, oxide of iron or via way of means of a combination of those substances.

1.4.1 Manufacturing Process of Clay Bricks

In the method of producing bricks, the subsequent 4 wonderful operations are involved:

- Preparation of clay

- Moulding

- Drying

- Burning

Preparation of clay:

The clay for bricks is ready withinside the following order:

- Unsoiling

- Digging

- Cleaning

- Weathering

- Blending

- Tempering

- Un-Soiling: The pinnacle layer of soil, approximately two hundred mm in depth, is taken out and thrown away. The clay in pinnacle soil is complete of impurities and subsequently it’s miles to be rejected for the motive of making ready bricks.

- Digging: The clay is then dug out from the ground. It is unfolded at the eveled ground, only a little deeper than the overall degree of ground. The peak of thousands of clays is ready six hundred mm to 1200 mm.

- Cleaning: The clay, as received withinside the method of digging, ought to be wiped clean of stones, pebbles, vegetable matter, etc. If those debris are in excess, the clay is to be washed and screened. Such a method clearly will show to be tough and expensive. The lumps of clay ought to be transformed into powder shape withinside the earth crushing roller.

- Weathering: The clay is then uncovered to environment for softening or mellowing. The length of publicity varies from few weeks to complete season. For a massive project, the clay is dug out simply earlier than the monsoon and its miles allowed to climate during the monsoon.

- Blending: The clay is made unfastened and any aspect to be introduced to its miles unfold out at its pinnacle. The mixing suggests intimate or harmonious mixing. It is executed with the aid of using taking small part of clay whenever and with the aid of using turning it up and down in vertical direction. The mixing makes clay suit for the subsequent degree of tempering.

- Tempering: In the method of tempering, the clay is added to a right diploma of hardness and it’s miles made suit for the subsequent operation of moulding. The water in required amount is introduced to clay and the entire mass is kneaded or pressed beneathneath the toes of guys or cattle. The tempering ought to be achieved exhaustively to achieve homogeneous mass of clay of uniform character.

Moulding:

The clay which is ready as above is then despatched for the subsequent operation of moulding.

Following are the 2 approaches of moulding:

- Hand moulding

- Machine moulding.

Hand Moulding:

- In hand moulding, the bricks are moulded via way of means of hand i.e., manually.

- It is followed wherein manpower is reasonably-priced and is effortlessly to be had for the producing technique of bricks on a small scale.

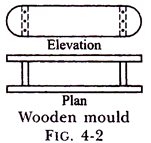

- The moulds are square packing containers which might be open at pinnacle and backside. They can be of timber or metallic.

- A regular timber mold is proven in fig.

- It needs to be organized from well-pro timber.

- The longer aspects are saved barely projecting to function handles.

- The strips of brass or metallic are once in a while constant on the rims of timber moulds to cause them to greater durable.

Fig. 9:Wooden mold

- Hence the moulds are to be made large than the dimensions of Steel mold absolutely burnt bricks. The moulds are consequently made longer via way of means of approximately eight to twelve in line with cent in all directions. The specific percent of boom in dimensions of mold is decided via way of means of real test on clay for use for making ready bricks.

- The bricks organized via way of means of hand moulding are of types:

(a) Ground-moulded bricks

(b) Table-moulded bricks.

Machine Moulding:

- The moulding will also be performed via way of means of machines It proves to be good value while bricks in big amount are to be synthetic on the identical spot in a brief time. It is likewise beneficial for moulding difficult and robust clay.

- These machines are extensively categorized in categories:

(a) Plastic clay machines

(b) Dry clay machines.

(a) Plastic Clay Machines:

- Such machines incorporate a square starting of length same to period and width of a brick. The pugged clay is positioned withinside the system and because it comes out via the starting, its miles reduce into strips via way of means of wires constant in frames.

- The association is made in any such manner that strips of thickness same to that of the brick are obtained. As the bricks are reduce via way of means of twine, they may be additionally referred to as the twine reduce bricks.

(b) Dry Clay Machines:

- In those machines, the robust clay is first transformed into powder shape. A small amount of water is then delivered to shape a stiff plastic paste. Such paste is positioned in mold and pressed via way of means of system to shape difficult and well-formed bricks. These bricks are referred to as the pressed bricks and that they do now no longer nearly require drying. They may be despatched immediately for the method of burning.

- The twine reduces and pressed bricks have everyday shape, sharp edges and corners. They have cleaned outside surfaces. They are heavier and more potent than regular hand-moulded bricks. They bring awesome frogs and show off uniform dense texture.

Drying:

The damp bricks, if burnt, are possibly to be cracked and distorted. Hence the moulded bricks are dried earlier than they may be taken for the following operation of burning. For drying, the bricks are laid longitudinally in stacks of width same to 2 bricks. A stack includes 8 or ten tiers.

The bricks are laid alongside and throughout the inventory in exchange layers. All bricks are positioned on edge. The bricks ought to be allowed to dry until they grow to be leather-based difficult or bone-dry with moisture content material of approximately 2 in line with cent or so.

The vital records to be remembered in reference to the drying of bricks are as follows:

Artificial Drying:

- The bricks are usually dried through herbal technique. But while bricks are to be hastily dried on a big scale, the synthetic drying can be followed. In this kind of case, the moulded bricks are allowed to byskip thru unique dryers which might be withinside the shape of tunnels or warm channels or floors. Such dryers are heated with the assist of unique furnaces or through warm flue gases. The tunnel dryers are greater most cost-efficient than warm ground dryers and they'll be both periodic or continuous.

- In the previous case, the bricks are filled, dried and emptied in rotation. In the latter case, the loading of bricks is finished at one stop and they're taken out at the opposite stop. The temperature is generally much less than 120°C and the technique of drying of bricks takes approximately 1 to three days relying upon the temperature maintained withinside the dryer, fine of clay product, etc.

Circulation of Air:

- The bricks in stacks have to be organized in this kind of manner that enough air area is left among them without cost move of air.

Drying Yard:

- For the drying purpose, unique drying yards have to be prepared. It have to be barely on a better stage and it's far suited to cowl it with sand. Such an association could save you the buildup of rain water.

Period for Drying:

- The time required through moulded bricks to dry relies upon on winning climate conditions. Usually it takes approximately three to ten days for bricks to turn out to be dry.

Screens:

- It is to be visible that bricks aren't without delay uncovered to the wind or solar for drying. Suitable screens, if important, can be furnished to keep away from such situations.

Burning:

- This is a totally vital operation withinside the manufacture of bricks. It imparts hardness and energy to the bricks and makes them dense and durable. The bricks have to be burnt properly. If bricks are over-burnt, they'll be brittle and as a result ruin easily. If they're below-burnt, they'll be gentle and as a result can't deliver loads.

- When the temperature of stupid crimson heat, approximately 650°C, is attaired, the natural rely contained withinside the brick is oxidized and additionally the water of crystallization is pushed away.

- But heating of bricks is finished past this restriction for the subsequent purposes:

- If bricks are cooled after accomplishing the temperature of approximately 650°C, the bricks shaped will soak up moisture from the air and get rehydrated.

- The reactions among the mineral materials of clay are accomplished at better temperature and those reactions are important to offer new homes consisting of energy, hardness, much less moisture absorption, etc. to the bricks.

- When the temperature of approximately 1100°C is reached, the debris of vital materials of brick clay, namely, alumina and sand, bind themselves collectively ensuing withinside the growth of energy and density of bricks. Further heating isn't always suited and if the temperature is raised past 1100°C, a extraordinary quantity of fusible glassy mass is shaped and the bricks are stated to be vitrified. The bricks start to unfastened their form past a positive restriction of vitrification.

- The burning of bricks is finished both in clamps or in kilns. The clamps are transient systems and they're followed to fabricate bricks on a small scale to serve a nearby call for or a particular purpose. The kilns are everlasting systems and they're followed to fabricate bricks on a big scale.

1.4.2 Classification of Clay Bricks

(1) Classification of Bricks Based on Quality:

On the premise of fine, Bricks are of the subsequent types

First Class Brick:

- The length is standard.

- The colour of those bricks is uniform yellow or crimson.

- It is properly burnt, ordinary texture, uniform form.

- The absorption capability is much less than 10%, crushing energy is, 280kg/cm2 (mean) wherein it's far 245 kg/cm2 (minimal).

- It doesn’t have efflorescence.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is unfastened from pebbles, gravels or natural matters.

Second Class Brick:

- The length is standard, colour is uniform yellow or crimson.

- It is properly burnt, barely over burnt is acceptable.

- It has a ordinary form; efflorescence isn't always appreciable.

- The absorption capability is greater than 10% however much less than 15%.

- Crushing energy is 175kg/cm2(mean) wherein the minimal is 154 kg/cm2.

- It emits a metal sound while struck through any other comparable brick or struck through a hammer.

- It is tough sufficient to face up to any fingernail expression at the brick floor if one attempts to do with a thumbnail.

- It is used for the development of one-storied buildings, transient shed while meant sturdiness isn't always greater than 15 years.

Third Class Brick:

- The form and length aren't ordinary.

- The colour is gentle and mild crimson colored.

- It is below burnt, barely over burnt is acceptable.

- It has massive efflorescence.

- The texture is non-uniform.

- The absorption capability is greater than 15% however much less than 20%.

- The crushing energy is 140kg/cm2(mean) wherein the minimal crushing energy is 105kg/cm2.

- It emits a stupid or blunt sound while struck through any other comparable brick or struck through a hammer.

- It leaves fingernail expression while one attempts to do with the thumbnail.

(2) Classification of Bricks Based on Raw Materials:

On the premise of uncooked substances bricks are of the subsequent kinds:

Burnt Clay Brick:

- It is received via way of means of urgent the clay in molds and fried and dried in kilns.

- It is the maximum used bricks. It calls for plastering while utilized in production works.

Fly ash clay Brick:

- It is synthetic while fly ash and clay are molded in one thousand diploma Celsius.

- It includes a excessive extent of calcium oxide in fly ash.

- That is why commonly defined as self-cementing.

- It commonly expands while getting into touch with moisture.

- It is much less porous than clay bricks. It proved a clean floor so it doesn’t want plastering.

Concrete Brick:

- It is product of concrete.

- It is the least used bricks.

- It has low compression energy and is of low pleasant.

- These bricks are used above and under the damp evidence course.

- These bricks are used may be used for facades, fences and inner brickworks due to their sound discounts and warmth resistance qualities.

- It is likewise referred to as mortar brick.

- It may be of various colorings if the pigment is brought in the course of manufacturing.

- It ought to now no longer be used under ground.

Sand-lime Brick:

- Sand, fly ash and lime are combined and molded below pressure.

- During moist mixing, a chemical response takes region to bond the mixtures.

- Then they're positioned withinside the molds.

- The shadeation is greyish because it gives some thing of a classy view.

- It gives a smoother end and uniform look than the clay bricks.

- As a result, it additionally doesn’t require plastering.

- It is used as a load bearing participant as it's far immensely strong.

Firebrick:

- It is likewise referred to as refractory bricks.

- It is made of a in particular designed earth.

- After burning, it may face up to very excessive temperature with out affecting its shape, length, and energy.

- It is used for the liner of chimney and furnaces wherein the same old temperature is predicted to be very excessive.

1.4.3 Properties of Clay Bricks

- All residences of brick are stricken by composition of the uncooked substances and the producing processes.

- It is because of this that maximum producer’s combination clays to lessen the opportunity of impurities from one clay supply affecting the general pleasant of the completed product.

- The residences that maximum problem the customers of brick are:

1) durability,

2) Colour,

3) texture,

4) length version

5) Compressive Strength

6) Absorption

1.4.4 Testing Methods for Clay Bricks

The following are the assessments that wishes to be accomplished at the brick:

Site assessments on bricks

- Hardness Test

- Dimensional Tolerance Test

- Soundness Test

- Impact Test

- Colour Test

Laboratory Tests on bricks

- Water Absorption Test

- Compressive Strength Test

- Efflorescence Test

- Warpage Test

Site Tests for Evaluating Quality of Bricks

The following assessments may be accomplished at webweb page with none device required. These assessments will supply an concept approximately the pleasant of bricks.

Hardness Test

- Hardness take a look at is accomplished to test hardness of brick. This is an oblique take a look at to recognise its compressive energy and to recognise how properly the brick is kilned. This is examined via way of means of the use of a pointy gear or finger nail and scratching in opposition to the brick floor. If there may be no affect of the scratch at the brick floor, the brick is satisfactorily tough and healthy to be used

Dimensional Tolerance Test

- Dimensional Tolerance take a look at is used to test the shape & length brick. In this take a look at 20 bricks are organized them alongside its length, breadth, and height. The dimensions are in comparison to every different and in comparison, with the usual dimensions.

Sound (Ringing) Test

- Sound take a look at of a brick is subject take a look at to apprehend the pleasant of bricks received. In this take a look at, two bricks are struck with every different. Good pleasant bricks commonly don’t damage and ought to produce a steel sound (bell ring) sound while struck with every different.

Impact Test

- In this check the bricks are allowed to fall from a peak of one meter on ground (now no longer tough floor). Good high-satisfactory brick shouldn’t break. Incase it breaks, it’s higher now no longer to apply for production.

Color Test

- Well kilned (burnt) clay brick is of uniform in color in the course of its segment and sun sunglasses of red. Black bricks are over burnt, now no longer of accurate high-satisfactory.

Laboratory Tests to Determine the Quality of Bricks

Water Absorption Test

- Absorption check is carried out to decide the quantity of moisture content material that the brick absorbs. If the bricks soak up extra than 20% of the burden of dry brick, then the brick need to now no longer be used for production as they soak up water from the cement mortar decreasing the general brickwork electricity. In this check five bricks are taken from the pattern and dry weight of every brick is taken. Weights are once more recorded after completely immersing the bricks in water for 25. Water absorption is calculated primarily based totally on each those weights. Detailed Procedure for Water Absorption of a Brick

Compressive Strength Test

- Compressive Strength of a brick is decided through setting a brick withinside the compressive trying out device and loading the pinnacle face (frog face) until failure. The brick frog face if packed with mortar and cured for a duration of four days earlier than. A minimal compressive electricity of 3.five N/mm2 need to be received as in keeping with IS codes. If the compressive electricity of the brick is much less than 3.five N/mm2, the ones bricks need to now no longer be used for production purposes. Detailed Procedure for Calculating Compressive Strength of a Brick

Efflorescence Test

- Efflorescence is a fine, white, powdery deposit of water-soluble salts left at the floor of masonry because the water evaporates. A accurate brick shouldn’t comprise soluble salts in it. In this check bricks are immersed in water for twenty-four hrs after which allowed to dry completely. If any white or gray patches seem at the brick floor, then the brick consists of soluble salts.

Warpage Test

- Wrapage check is to decide how flat the brick floor is. If the bricks are heated and cooled correctly, Wrapage need to be beneathneath permissible limits. A convex wrapage and a concave wrapage check is.

1.4.5 Problems of Efflorescence & Lime Bursting in Bricks & Tiles

What Is Efflorescence:

Efflorescence is a whitish crystalline deposit on floor of the bricks. Usually magnesium sulphate, calcium sulphate and carbonate of sodium and potassium are determined in efflorescence. The motion of groundwater into the rules of homes and through capillary movement into brickwork could be very regularly the motive of efflorescence.

Remedies of Efflorescence:

- Well fired bricks need to use for production. Sand trying out need to accomplished earlier than beginning production work.

- Proper DPC need to offer in building.

- Efflorescence need to be put off through dry brushing and washing repeatedly.

- This efflorescence can also additionally reappear in dry season however are in much less intensity.

Fig.10: Efflorescence in Bricks

1.4.6 Different Types of Bricks

- There are more than one kinds of brick to apply for masonry, and every has its very own benefits and capacity drawbacks.

- It is beneficial to emerge as acquainted with the numerous kinds of brick which can be to be had to decide which sort high-satisfactory fits your needs.

- Having an knowledge of the kinds of brick additionally enables decide how regularly brick recuperation is essential to make certain lengthy-time period reliability.

- Whether you've got got production plans or are interested by studying the sort of brick used to your home, you could find out about every of the maximum not unusualplace kinds below.

- The following is an in-intensity review of burnt clay bricks, concrete bricks, engineering bricks, fly ash bricks, sand-lime bricks and solar-dried bricks.

- Clay bricks may be damaged into categories — burnt clay bricks and unburnt clay bricks. However, burnt bricks are extra normally used for production functions.

- There are 4 distinct training of burnt clay bricks, which dictate the general first-rate of the power, look and form of the brick. The 4 training are:

- First-elegance bricks

- Second-elegance bricks

- Third-elegance bricks

- Fourth-elegance bricks

- First-elegance bricks are the high-satisfactory first-rate.

- They have a clean floor and properly-described edges, and that they paintings properly for everlasting constructions.

- Second-elegance bricks additionally have right power and durability, however they're now no longer as clean and do now no longer have first-rate edges the identical manner fine bricks do.

- Third-elegance bricks are plenty rougher, and that they do now no longer preserve up as properly whilst uncovered to water and terrible climate lengthy-time period.

- They are normally used for brief systems.

- Fourth-elegance bricks are most usually recycled and infrequently used for production functions.

Concrete Bricks

- Concrete bricks are a famous opportunity to burnt clay bricks. Concrete bricks are made the use of cement, sand, coarse aggregates and water. Many production crews discover them less complicated to fabricate as they could accomplish that at the development site.

- Concrete bricks may be pigmented all through manufacturing to attain the right colour. This offers them an great colour in addition to advanced power this is supplied through the concrete. They additionally block warmness and noise and face up to water properly. The best downside is that the colour can also additionally fade earlier than it'd with clay bricks.

Engineering Bricks

- More than one ground constructing with distinct sort of bricksEngineering bricks are made the use of enormously excessive temperatures. Subsequently, they have got a excessive density, are long lasting and are warmness and water-resistant. Engineering bricks are normally used for basement production as they're proof against moisture and water damage.

- They also are normally utilized in civil engineering projects, which includes sewers and manholes. They aren't the maximum aesthetically beautiful sort of brick, so they're now no longer used as regularly as clay bricks or concrete bricks for outdoors partitions on residential homes.

Fly Ash Bricks

- Fly ash bricks are one of the maximum underrated kinds of brick. Fly ash bricks are made the use of fly ash and water, and are the maximum much like concrete bricks. They are enormously proof against climate, and that they provide advanced frost prevention, hearthplace insulation and resistance to water penetration.

- In addition, fly ash bricks have a clean floor. For regions that can be liable to water pressure, bloodless temperatures or threat of hearthplace, fly ash bricks are a long lasting and secure solution.

Sand Lime Bricks

- Bricks of various sun sunglasses of buildingsSand lime bricks, regularly called calcium silicate bricks, are used for production functions and masonry works.

- They include sand, lime and fly ash bonded thru an in depth chemical process. This creates brick this is very strong, long lasting and that may undergo quite a few weight with out cracking or turning into damaged.

- Sand lime bricks aren't the maximum attractive, however they're very dependable. They also can correctly face up to water, wind and warmth over lengthy intervals of time.

Sun-Dried Bricks

- Sun-dried bricks, which might be regularly referred to as unburnt clay bricks, are precisely what they sound like — they're clay bricks which can be dried through solar exposure.

- They aren't usually used for everlasting production as they do now no longer have dependable power lengthy-time period.

- However, they're a much less luxurious and handy opportunity for systems that best want to face temporarily.

- Since they're softer and now no longer as resistant, additionally they aren't as long lasting whilst uncovered to terrible climate.

KEY TAKEAWAYS:

- First-elegance bricks are the high-satisfactory first-rate.

- Well fired bricks need to use for production. Sand trying out need to accomplished earlier than beginning production work.

1.5.1 Properties of Gypsum Plaster

- It is lightweight and as a result its utilization for plastering does now no longer boom the structural load at the building.

- Gypsum plaster does now no longer reduce in the course of drying and hardening approaches in contrast to cement plaster.

- It is much less at risk of cracks.

- Gypsum is non-flamable and incorporates excessive content material of crystal water.

- In the occasion of fire, it acts like a barrier and protects the block work, concrete and steel.

- Gypsum plaster prevents rusting of metallic fittings like pipes and will increase their durability.

- Gypsum plaster has low thermal conductivity and guarantees power and electricity saving.

- Gypsum plaster offers excessive tensile and flexural strength. According to ‘SP 62: S & T 1997’, (Handbook on Building Construction Practices Excluding Electrical Work), after the plaster is well set and the plaster backing and backgrounds are dry, it's miles feasible to color gypsum plaster with any sort of paint besides cement paint.

1.5.2 Building Products made of Gypsum and their Uses

- Gypsum Plasters Obtained via way of means of Incomplete Calcination (CaSO4.½H2O)

- Plaster of Paris : is shaped via way of means of incomplete calcination at 100- 190°C. No admixtures are located.

- Hard Wall Plaster Plaster of Paris + Admixtures (Glue, Sand...) Obtained via way of means of Complete Calcination (CaSO4) Flooring Plaster (CaSO4 and not using a impurities) Hard Finish Plaster (CaSO4 + Al2(SO4)3) (CaSO4 + Na2)

- To produce gypsum board, calcined gypsum is blended with water and components to shape a slurry that's fed among non-stop layers of paper on a board machine.

- As the board movements down a conveyer line, the calcium sulfate recrystallizes or rehydrates, reverting to its unique rock state.

- The paper turns into chemically and robotically bonded to the core.

- The board is then reduce to duration and conveyed thru dryers to put off any unfastened moisture.

- Gypsum producers additionally depend an increasing number of on “synthetic” gypsum as an powerful opportunity to herbal gypsum ore.

- Plasterboard is used for walls and the liner of partitions, ceilings, roofs and floors.

- Gypsum is a crucial component in cutting-edge plasterboard.

- Gypsum fibreboard is used for walls and the liner of partitions, ceilings, roofs and floors.

- Standard gypsum fibreboard is soundproof, in addition to being top at resisting shocks and humidity.

- Dehydrated plaster powder, blended with water, is used to line brick and block partitions and ceilings, in addition to for complex and exquisite decorations.

- This gypsum plaster is extensively called plaster of Paris and has been utilized by craftsmen for heaps of years to create ornamental mouldings and models.

- Gypsum plaster is extensively used for partitions and ceilings. It is a excessive appearing and smooth to use fabric with a brief putting time, which helps the building’s construction.

- Gypsum blocks are used for indoor walls and gypsum tiles for ceilings.

- Anhydrite is a white mineral which, while blended with water, may be converted to gypsum and used to stage floors.

KEY TAKEAWAYS:

- Plasterboard is used for walls and the liner of partitions, ceilings, roofs and floors.

- Gypsum plaster has low thermal conductivity and guarantees power and electricity saving

1.6.1 Raw Materials Used

- The Indian mining enterprise performs an crucial position in offering the uncooked substances utilized in cement enterprise.

- The maximum crucial uncooked fabric used withinside the cement production technique is the Limestone this is located withinside the sedimentary rock.

- Limestone rocks are modified via way of means of dynamic metamorphism to show into marbles.

- Other styles of Limestone are marl, lime shell, algal limestone, coral limestone, pisolite limestone, crinoidal limestone, travertine, onyx, hydraulic limestone, lithographic limestone, etc.

- The lime shell and marl are thick calcareous dust comprise a variable quantity of clay and slits.

- Limestone mining extracts 203,224 million tonnes of limestone this is majorly utilized in cement production industries.

- States like Andhra Pradesh, Karnataka, Madhya Pradesh, Rajasthan, Gujrat, Meghalaya, Telangana have a first-rate reservoir of limestone.

- Another crucial cement uncooked fabric is coal that acts as an power supply withinside the cement production technique.

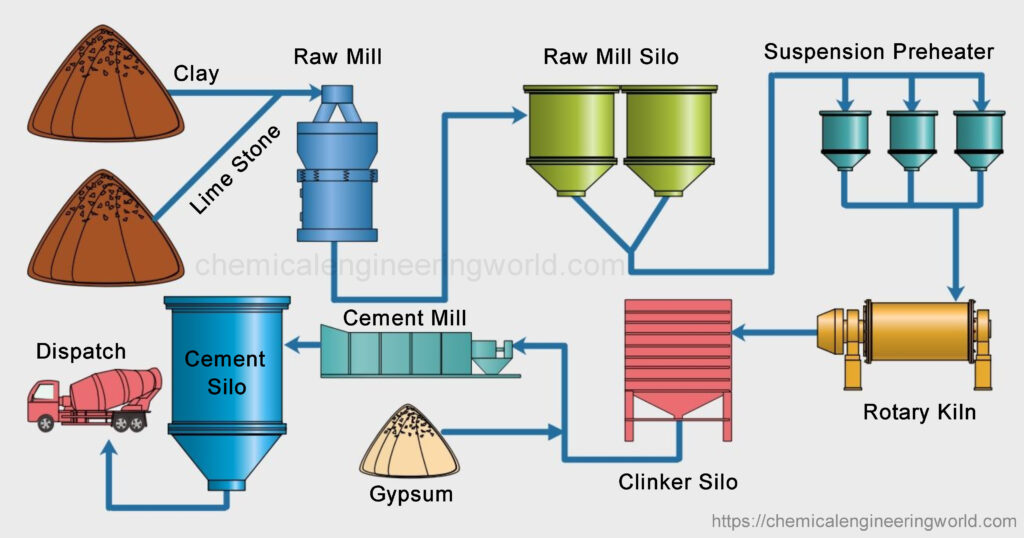

1.6.2 Process of Manufacturing

- The cement production technique begins offevolved with the mining of limestone this is excavated from open forged mines.

- Then this limestone is overwhelmed to -eighty mm length and is loaded in longitudinal stockpiles.

- Limestone is taken out diagonally from those stockpiles for grinding in uncooked mill hoppers.

- As stated in advance coal is used as a gas to warmth the uncooked substances withinside the cement production technique.

- After receiving cement uncooked substances from the Indian mining enterprise, limestone is transferred in uncooked mill for grinding right into a excellent powder.

- This excellent powder of limestone is then heated at a completely excessive temperature of 1450 ranges centigrade for clinkerisation.

- To warmth, this excellent powder at such excessive-temperature coal is utilized in clinkerisation section.

- This clinkerised uncooked fabric is then fed into electrostatic precipitator to keep it withinside the shape of the concrete silo.

- This is referred to as as kiln feed. Kiln feed is fed into preheater for pyro processing.

- The pyro processing of kiln feed produces cement clinkers.

- The warm clinkers are then cooled down and bucketed to keep in clinker stockpiles.

- After this stage, the clinker and gypsum are blended collectively and despatched to the mill inlet for the similarly grinding technique to shape a excellent gray powder.

- This excellent gray powder is cement that's then packed and dispatched withinside the marketplace for sale.

- The cement production technique begins offevolved with the mining of limestone this is excavated from open forged mines.

- Then this limestone is overwhelmed to -eighty mm length and is loaded in longitudinal stockpiles.

- Limestone is taken out diagonally from those stockpiles for grinding in uncooked mill hoppers.

- As stated in advance coal is used as a gas to warmth the uncooked substances withinside the cement production technique.

- After receiving cement uncooked materialsfrom the Indian Mining Industry, limestone is transferred in uncooked mill for grinding right into a excellent powder.

- This great powder of limestone is then heated at a totally excessive temperature of 1450 stages centigrade for clinkerisation.

- To heat, this great powder at such excessive-temperature coal is utilized in clinkerisation section.

- This clinkerised uncooked fabric is then fed into electrostatic precipitator to keep it withinside the shape of the concrete silo.

- This is referred to as as kiln feed. Kiln feed is fed into preheater for pyro processing.

- The pyro processing of kiln feed produces cement clinkers.

- The warm clinkers are then cooled down and bucketed to keep in clinker stockpiles.

- After this stage, the clinker and gypsum are combined collectively and despatched to the mill inlet for the similarly grinding system to shape a great gray powder.

- This great gray powder is cement that is then packed and dispatched withinside the marketplace for sale.

Fig. 11: Manufacturing process of Cement

1.6.3 Chemical Composition

- The maximum crucial hydraulic parts are the calcium silicates, C2S and C3S.Upon blending with water, the calcium silicates react with water molecules to shape calcium silicate hydrate (3CaO · 2SiO2 · 3H2O) and calcium hydroxide (Ca[OH]2).

- These compounds are given the shorthand notations C–S–H (represented through the common components C3S2H3) and CH, and the hydration response may be crudely represented through the subsequent reactions:

- 2C3S + 6H = C3S2H3 + 3CH

- 2C2S + 4H = C3S2H3 + CH

- During the preliminary degree of hydration, the determine compounds dissolve, and the dissolution in their chemical bonds generates a substantial quantity of warmness.

- Then, for motives that aren't completely understood, hydration involves a stop.

- This quiescent, or dormant, length is extraordinarily crucial withinside the placement of concrete.

- Without a dormant length there could be no cement trucks; pouring could should be performed right now upon blending.

- Following the dormant length (that may remaining numerous hours), the cement starts to harden, as CH and C–S–H are produced.

- This is the cementitious cloth that binds cement and urban together.

- As hydration proceeds, water and cement are constantly consumed.

- Fortunately, the C–S–H and CH merchandise occupy nearly the equal extent because the authentic cement and water; extent is about conserved, and shrinkage is manageable.

1.6.4 Compounds formed and their effect on Strength

- The composition of portland cements is what distinguishes one type of cement from another.

- ASTM C 150 and AASHTO M 85 present the standard chemical requirements for each type.

- The phase compositions in portland cement are denoted by ASTM as tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF).

- However, it should be noted that these compositions would occur at a phase equilibrium of all components in the mix and do not reflect the effects of burn temperatures, quenching, oxygen availability, and other real-world kiln conditions.

- The actual components are often complex chemical crystalline and amorphous structures, denoted by cement chemists as “elite” (C3S), “belite” (C2S), and various forms of aluminates.

- The behavior of each type of cement depends on the content of these components.

1.6.5 Types of Cement

- Ordinary Portland Cement (OPC)

- Ordinary Portland Cement additionally called OPC is a form of cement this is synthetic and used worldwide.

- It is extensively used for all functions including: Cement businesses in Malaysia provide OPC in 3 unique grades, specifically grades 33, 43, and 53.

- Besides the aforementioned functions, Ordinary Portland cement is likewise used to fabricate grout,wall putty,stable concrete blocks,AAC blocks and unique forms of cement

2. Portland Pozzolana Cement (PPC)

- To organized PPC or Portland Pozzolana cement, you want to grind pozzolanic clinker with Portland cement.

- PPC has a excessive resistance to unique chemical attacks on concrete.

- It is extensively utilized in production such as:Marine systems,Sewage works,Bridges,Piers,Dams,Mass concrete works

3. Rapid Hardening Cement

- Cement providers in Malaysia additionally provide fast Hardening cement.

- Rapid Hardening Cement is made while finely grounded C3S is displayed in OPC with better concrete.

- It is generally utilized in fast buildings just like the production pavement.

4. Extra Rapid Hardening Cement

- As the call suggests, Extra fast hardening cement profits power faster and it's far acquired through including calcium chloride to fast hardening cement.

- Extra fast hardening cement is extensively utilized in bloodless climate concreting, to set the cement fast.

- It is set faster than that of fast hardening cement through one or days.

5. Low Heat Cement

- Cement producers in Malaysia gives low warmness cement that is ready through maintaining the proportion of tricalcium aluminate under 6% and through growing the share of C2S.

- This low warmness cement is utilized in mass concrete production like gravity dams.

- It is crucial to understand that it's far much less reactive and the preliminary putting time is more than OPC.

6. Sulfates Resisting Cement

- This form of cement is synthetic to withstand sulfate assault in concrete.

- It has a decrease percent of Tricalcium aluminate.

- Sulfates resisting cement is used for buildings in touch with soil or groundwater having greater than 0.2% or 0.3% g/l sulfate salts respectively.

- It also can be utilized in concrete surfaces subjected to change wetting and drying like bridge piers.

7. Quick Setting Cement

- Cement providers in Malaysia additionally provide short putting cement which units quicker than OPC however the power stays the equal.

- In this components, the share of gypsum is reduced.

- Quick putting cement is used for buildings that want a short putting, like underwater systems and in bloodless and wet climate conditions.

8. Blast Furnace Slag Cement

- This form of cement is synthetic through grinding the clinker with approximately 60% slag and it's far just like Portland cement.

- It is used for buildings wherein monetary concerns are crucial.

9. High Alumina Cement

- High alumina cement is acquired through blending calcining bauxite and lime with clinker all through the producing technique of OPC.

- To be taken into consideration excessive alumina cement, the full quantity of alumina content material need to be as a minimum 32%, and the ratio of the load of alumina to lime need to be saved among 0.85 to 1.30.

- The maximum not unusualplace makes use of are in buildings which might be concern to excessive temperatures like a workshop, refractory, and foundries.

10. White Cement

- This form of cement is synthetic through the use of uncooked substances which might be unfastened from iron and oxide.

- White cement wishes to have lime and clay in a better proportion.

- It is just like OPC however it's far greater expensive.

1.6.6 Testing of Cement Properties

The following assessments are performed on cement withinside the laboratory are as follows:

- Fineness Test

- Consistency Test

- Setting Time Test

- Strength Test

- Soundness Test

- Heat of Hydration Test

- Tensile Strength Test

- Chemical Composition Test

Fineness test

- The fineness of cement is responsible for the rate of hydration, rate of evolution of warmth and the rate of benefit of energy.

- Finer the grains greater is the floor location and quicker the improvement of energy.

- The fineness of cement may be decided via way of means of Sieve Test or Air Permeability check.

Sieve Test

- Air-set lumps are broken, and the cement is sieved constantly in a round and vertical movement for a duration of 15 mins.

- The residue left at the sieve is weighed, and it have to now no longer exceed 10% for normal cement.

- This check is hardly ever used for fineness.

Consistency test on cement

- This check is performed to locate the putting instances of cement the use of a general consistency check equipment, Vicat's equipment.

- Standard consistency of cement paste is described as that water content material with a view to allow a Vicat plunger of 10 mm diameter and 50 mm period to penetrate depths of 33-35 mm inside three-five mins of blending.

- The check has to go through 3 instances, on every occasion the cement is blended with water various from 24 to 27% of the load of cement.

- This check have to be performed at a consistent temperature of 25°C or 29°C and at a consistent humidity of 20%.

Setting Time of cement

- Vicat's equipment is used to locate the putting instances of cement i.e., preliminary putting time and very last putting time.

- Initial Setting Time: For this check, a needle of one mm rectangular length is used. The needle is permitted to penetrate into the paste (a combination of water and cement as in keeping with the consistency check). The time taken to penetrate 33-35 mm intensity is recorded because the preliminary putting time.

- Final Setting Time: After the paste has attained hardness, the needle does now no longer penetrate the paste greater than 0.five mm. The time at which the needle does now no longer penetrate greater than 0.five mm is taken because the very last putting time.

Strength test of cement

- The energy of cement can not be described without delay at the cement.

- Instead the energy of cement is not directly described on cement-mortar of one:three.

- The compressive energy of this mortar is the energy of cement at a selected duration.

Soundness test of cement

- This check is performed in Le Chatelier's equipment to hit upon the presence of uncombined lime and magnesia in cement.

Heat of Hydration Test

- During the hydration of cement, warmness is produced because of chemical reactions.

- This warmness might also additionally increase the temperature of concrete to a excessive temperature of 50°C.

- To keep away from these, in huge scale buildings low-warmness cement needs to be used.

- This check is finished the use of a calorimeter adopting the precept of figuring out warmness benefit.

- It is concluded that Low-warmness cement have to now no longer generate sixty five energy in keeping with gram of cement in 7 days and seventy five energy in keeping with gram of cement in 28 days.

Tensile Strength of Cement

- This check is finished the use of a cement-mortar briquette in a tensile checking out machine.

- A 1:three cement-sand mortar with the water content material of 8% is blended and moulded right into a briquette withinside the mould.

- This combination is cured for twenty-four hours at a temperature of 25°C or 29°C and in an surroundings at 90% relative humidity.

- The common energy for 6 briquettes examined after three and seven days is recorded.

Chemical Composition Test

- Different assessments are performed to decide the quantity of numerous elements of cement.

- The necessities are primarily based totally on IS: 269-1998, is as follows: The ratio of the share of alumina to that of iron oxide have to now no longer be much less than 0.sixty six.

- Lime Saturation Factor (LSF), i.e., the ratio of the share to that of alumina, iron oxide and silica have to now no longer be much less than 0.sixty six and now no longer be extra than 1.02.

- Total loss on ignition have to now no longer be extra than 4%. Total sulphur content material have to now no longer be extra than 2.seventy five%.

- Weight of insoluble residue have to now no longer be extra than 1.50%.

- Weight of magnesia have to now no longer be extra than five%.

Field Tests of Cement

The following assessments have to go through earlier than blending the cement at creation sites:

Colour Test of Cement

- The color of the cement have to now no longer be uneven.

- It have to be a uniform gray color with a mild greenish shade.

Presence of Lumps

- The cement have to now no longer include any difficult lumps.

- These lumps are fashioned via way of means of the absorption of moisture content material from the surroundings.

- The cement luggage with lumps have to be averted in creation.

Cement Adulteration Test

- The cement have to be easy in case you rubbed it among fingers.

- If now no longer, then it's miles due to adulteration with sand.

Float Test

- The debris of cement have to go with the drift freely in water for someday earlier than it sinks.

Properties of Cement

1) Fineness of Cement

- The length of the debris of the cement is its fineness.

- The required fineness of exact cement is done thru grinding the clinker withinside the remaining step of cement manufacturing process.

- As hydration fee of cement is without delay associated with the cement particle length, fineness of cement may be very important.

2) Soundness of Cement

- Soundness refers back to the cappotential of cement to now no longer cut back upon hardening.

- Good exceptional cement keeps its extent after putting with out not on time expansion, that is as a result of immoderate loose lime and magnesia.

3) Consistency of Cement

- The cappotential of cement paste to go with the drift is consistency.

- It is measured via way of means of Vicat Test.

- In Vicat Test Cement paste of regular consistency is taken withinside the Vicat Apparatus.

- The plunger of the equipment is added down to the touch the pinnacle floor of the cement.

- The plunger will penetrate the cement as much as a sure intensity relying at the consistency.

- A cement is stated to have a ordinary consistency while the plunger penetrates 10¡À1 mm.

4) Strength of Cement

- Three varieties of energy of cement are measured compressive, tensile and flexural.

- Various elements have an effect on the energy which include water-cement ratio, cement-great combination ratio, curing situations, length and form of a specimen, the way of molding and mixing, loading situations and age.

- Compressive Strength: It is the maximum not unusualplace energy check. A check specimen (50mm) is taken and subjected to a compressive load till failure. The loading series ought to be inside 20 seconds and eighty seconds.

- Tensile energy: Though this check was not unusualplace all through the early years of cement production, now it does now no longer provide any beneficial data approximately the residences of cement.

- Flexural energy: This is sincerely a degree of tensile energy in bending. The check is carried out in a forty x40 x a hundred and sixty mm cement mortar beam, that's loaded at its middle factor till failure.

5) Setting Time of Cement

- Cement units and hardens while water is introduced.

- This placing time can range relying on more than one elements, which include fineness of cement, cement-water ratio, chemical content, and admixtures. Cement utilized in production must have an preliminary placing time that isn't too low and a very last placing time now no longer too high. Hence, placing instances are measured.

- Initial set: When the paste starts to stiffen noticeably (commonly happens inside 30-forty five minutes)

- Final set: When the cement hardens, being capable of preserve a few load (happens under 10 hours).

1.6.7 Uses of Cement

- It is utilized in mortar for plastering, masonry work, pointing, etc. It is used for making joints for drains and pipes.

- It is used for water tightness of structure.

- It is utilized in concrete for laying floors, roofs and building lintels, beams, stairs, pillars etc.

- It is used in which a difficult floor is needed for the safety of uncovered surfaces of systems in opposition to the adverse dealers of the climate and positive natural or inorganic chemicals.

- It is used for precast pipes manufacturing, piles, fencing posts etc.

- It is used withinside the production of essential engineering systems which include bridges, culverts, dams, tunnels, lighthouses etc.

- It is used withinside the guidance of foundations, watertight floors, footpaths etc.

- It is hired for the development of wells, water tanks, tennis courts, lamp posts, phone cabins, roads etc.

KEY TAKEAWAYS:

- Three varieties of energy of cement are measured compressive, tensile and flexural.

- During the hydration of cement, warmness is produced because of chemical reactions

1.7.1 Constituent Materials and their Properties

- Concrete is a composite fabric including a binder, that is usually cement, tough and satisfactory aggregates, that are generally stone and sand, and water.

- These contain the constituent substances of concrete. But due to the numerous variables of the uncooked substances and the way they're processed and combined, there are numerous possibilities for issues to seem in concrete.

- Having a essential know-how of the exclusive substances and production tactics may also assist individuals who look into concrete to understand what issues to search for, wherein to search for them, and a way to understand them.

- In easy terms:

- Cement + water = cement paste;

- Cement paste + sand = mortar; and

- Mortar + stone = concrete.

- Admixtures can be covered withinside the blend to manipulate placing properties.

Properties of Cement concrete:

- It has a excessive compressive power.

- It is loose from corrosion and there's no considerable impact of atmospheric marketers on it.

- It hardens with age and the system of hardening keeps for a long term after the concrete has attained enough power.

- It is that this belongings of cement concrete which offers it a wonderful area a number of the constructing substances.

- It is proved to be greater within your budget than metallic.

- This is because of the reality that sand and pebbles or beaten rock, forming the majority of cement concrete, to the volume of approximately eighty to 90%, are generally to be had at slight cost.

- The formwork, that is of metallic or timber, may be used again and again once more or for different functions after it's miles removed.

- It binds unexpectedly with metallic and as it's miles susceptible in tension, the metallic reinforcement is located in cement concrete at appropriate locations to absorb the tensile stresses.

- This is named because the Reinforced Cement Concrete or surely R.C.C. It has a bent to be porous.

- This is because of the presence of voids that are fashioned at some point of and after its placing.

- It ought to be remembered that aside from different substances, the concrete involves the web website online withinside the shape of uncooked substances only.

- Its very last power and first-class rely totally on nearby situations and folks coping with it.

- However the substances of which concrete consists can be subjected to inflexible specifications.

1.7.2 Grades of Concrete

Concrete Grade | Mix Ratio (Cement:Sand:Aggregate) | Compressive Strength | |

MPa(N/mm^2) | Psi | ||

M5 | 1:5:10 | 5 | 725 |

M7.5 | 1:4:8 | 7.5 | 1087 |

M10 | 1:3:6 | 10 | 1450 |

M15 | 1:2:4 | 15 | 2175 |

M20 | 1:1.5:3 | 20 | 2900 |

Standard grade of concrete | |||

M25 | 1:1:2 | 25 | 3625 |

M30 | Design mix | 30 | 4350 |

M35 | Design mix | 35 | 5075 |

M40 | Design mix | 40 | 5800 |

M45 | Design mix | 45 | 6525 |

High strength concrete grades | |||

M50 | Design mix | 50 | 7250 |

M55 | Design mix | 55 | 7975 |

M60 | Design mix | 60 | 8700 |

M65 | Design mix | 65 | 9425 |

M70 | Design mix | 70 | 10150 |

1.7.3 Factors ffecting Strength