Unit 3

Building Construction

- Building production is the procedure of including shape to actual belongings.

- The massive majority of constructing production initiatives are small renovations, which includes addition of a room, or protection of a bathroom.

- Often, the proprietor of the belongings acts as laborer, paymaster, and layout crew for the whole challenge.

- However, all constructing production initiatives consist of a few factors in common - layout, financial, and felony considerations.

- Many initiatives of various sizes attain unwanted quit results, which includes shape collapse, fee overruns, and/or litigation.

- For this reason, people with enjoy withinside the subject make particular plans and hold cautious oversight throughout the challenge to make certain a effective outcome.

- Building production is procured privately or publicly utilising diverse transport methodologies, consisting of tough bid, negotiated price, traditional, control contracting, production control-at-risk, layout & construct and layout-construct bridging.

- Residential production practices, technology, and assets should agree to neighborhood constructing authority guidelines and codes of practice.

- Materials comfortably to be had withinside the location commonly dictate the development substances used (e.g. Brick as opposed to stone, as opposed to timber).

- Cost of production on a in keeping with rectangular meter (or in keeping with rectangular foot) foundation for homes can range dramatically primarily based totally on web website online conditions, neighborhood guidelines, economies of scale (customized houses are constantly greater high-priced to construct) and the supply of professional tradespeople.

- As residential (in addition to all different kinds of production and synthetic houses) can generate quite a few waste, cautious making plans once more is wanted here.

- The maximum famous approach of residential production withinside the United States is timber framed production.

- As performance codes have come into impact in latest years, new production technology and techniques have emerged.

- University Construction Management departments are at the reducing fringe of the most up-to-date techniques of production meant to enhance performance, overall performance and decrease production waste.

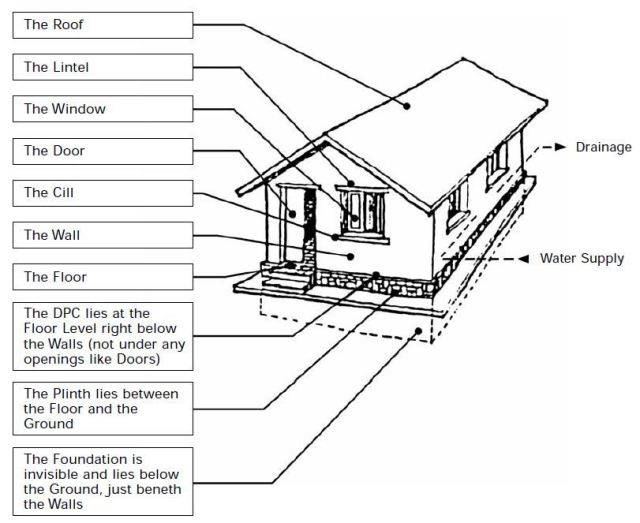

A constructing includes following fundamental components:

Fig. 1: Showing components of building area

1. FOUNDATION

- A basis is essential to calmly distribute the whole constructing load at the soil in this kind of way that no unfavourable settlements take place. Hence, the rules want to be built on good/stable floor.

2. PLINTH

- A plinth is usually built simply above the floor degree and straight away after the basis. It increases the ground above the floor degree and herewith prevents floor water from getting into the constructing.

3. DAMP PROOF COURSE (DPC)

- Damp evidence route is a layer of water proofing cloth which includes asphalt or water-proof cement. Walls are built above the damp evidence route.

- Damp evidence route prevents floor water from growing into the partitions.

- Dampness reduces the power of the partitions and creates bad residing conditions. Also, it influences the paint and plaster and growing the price of maintenance.

- Damp proofing layer isn’t always required in which a plinth beam is built, due to the fact the plinth beam already plays like a DPC.

4. PLINTH BEAM

- A plinth beam is built relying upon the form of the shape of the constructing and nature of the soil. It affords extra balance in regard to settlements of the constructing and earthquake damages.

5. FLOOR

- This is the floor on which we do maximum of our activities. Floorings is laid over the filling of the plinth and on next flooring.

- Flooring may be achieved with distinctive substances; however, care should be for the reason that the floor underneath the ground is nicely compacted.

- Flooring is achieved to save you dampness from growing to the pinnacle and to have a organization platform that may be saved hygienic and clean.

6. WALLS

- Walls are the vertical factors on which the roof ultimately rests. They may be made of various substances like bricks, stones, mud, concrete blocks, lateritic blocks etc. If the partitions are very long, columns may be furnished to hold the roof.

- Walls offer privateness and enclosure. Walls additionally offer safety and safety in opposition to herbal factors which includes wind, rain and sunshine.

- Openings are to be furnished in wall for get entry to and ventilation.

7. OPENINGS

- Openings are usually furnished withinside the partitions as door, home windows and ventilators.

- Doors offer get entry to; home windows and ventilators offer mild and ventilation.

- Lintels are built simply above the openings. It is usually a stone slab or a concrete slab.

- Sill is a part of the wall this is simply underneath the window.

- Lintels are built to preserve up the partitions above the openings. In earthquake susceptible regions a non-stop lintel beam is furnished everywhere in the partitions.

8. STAIRS

- A stair is a chain of steps and its miles furnished to come up with the money for the way of ascent and descent among the flooring and landings.

- The condominium or room of a constructing wherein stair is placed is known as staircase. The area or beginning occupied through the stair is known as a stairway.

- There are distinctive type of stairs are utilized in buildings, like RCC stair, wood stair, metallic stair, brick stair etc.

9. ROOF

- The roof affords safety for the constructing and the human beings residing in it. The roof rests at the partitions and calls for right anchoring in order that wind and different mechanical effect can’t spoil it. A roof will have distinctive shapes however it’s miles usually both flat or sloping.

- Roof is normally product of RCC, stone slab, tiles etc.

10. SURFACES / FINISHES

- External finishes are the outer maximum layer of safety, which shield the shape from weathering. Internal finishes are the layers given on inner faces. They provide sturdiness and desirable look to the inside.

KEY TAKEAWAYS

- Walls offer privateness and enclosure. Walls additionally offer safety and safety in opposition to herbal factors which includes wind, rain and sunshine.

- Residential production practices, technology, and assets should agree to neighborhood constructing authority guidelines and codes of practice.

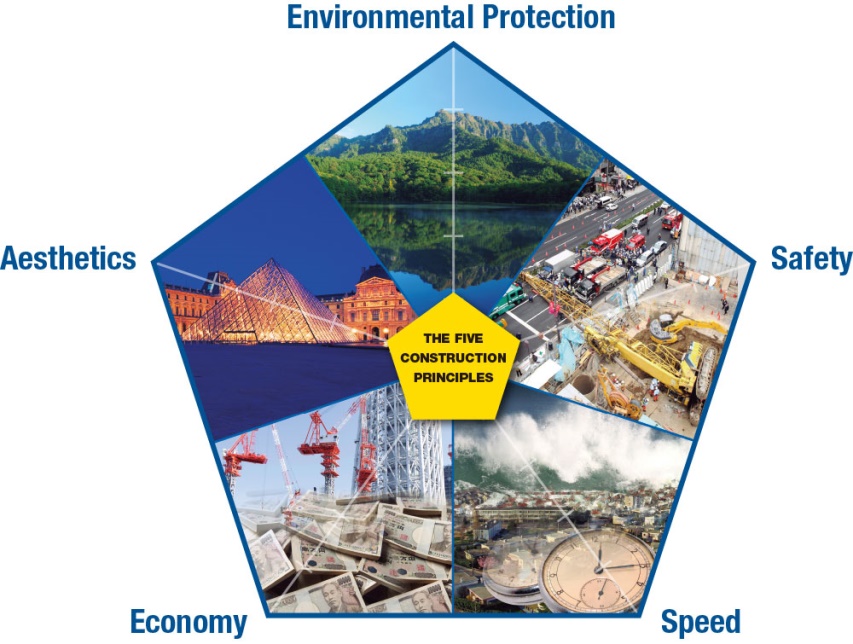

- Giken promotes the Construction Revolution to set up new requirements of transport which surpass the modern traditional method.

- Through regular adherence to the “Five Construction Principles”, which incorporates attention of environmental safety, safety, speed, economic system and aesthetics withinside the shape of a balanced equilateral pentagon, Giken works diligently to supply a balanced method to projects.

- The stability is executed through giving identical weight to the 5 ideas at every degree of a task from idea via planning, layout and production phases.

Fig. 2: Construction Principle

1.Environmental Protection

- Construction paintings must be environmentally pleasant and pollutants free.

2.Safety

- Construction paintings must be accomplished in protection and comfort, with a way that implements the very best protection criteria.

3.Speed

- Construction paintings must be finished withinside the shortest viable duration of time.

4.Economy

- Construction paintings need to be accomplished rationally with an imaginative thought to triumph over all constraints at the bottom cost.

5.Aesthetics

- Construction paintings need to continue easily and the completed product must paint cultural and inventive rgani.

Methods for Building Layout

- For an easy constructing format, which includes a rectangle, the define of the constructing is marked through a line tied to nook posts – a nail withinside the pinnacle of the publish may be used to connect the road to.

- A theodolite, web page rectangular or builder’s rectangular is used to show off 90-diploma angles for the closing corners. Ranging rods can be required to set up an immediately line among nook posts.

- Corner posts are typically 50 x 50mm wood posts pushed firmly into the floor, with a nail withinside the publish’s centre. The define can be marked at the floor with dry lime or comparable powder.

- Timber profile forums may be used on the corners. Profile forums are normally among 0.6-1m in top and incorporate 50 x 50mm posts pushed at the least 600mm into the floor, with a 150 x 38mm cross board.

- Where the define of a constructing is extra complicated than a easy rectangle, it is able to be important to set up various factors withinside the equal manner as for laying out a easy rectangle.

- However, first rate care is required, as small mistakes are much more likely to be brought as extra factors are positioned. Often the very best manner of laying out an abnormal constructing form is to first lay out a massive rectangle that allows you to enclose the whole constructing or the extra a part of it. Once that is accomplished, deductions and changes may be made to acquire the ideal format required.

Trenches

- The format of trenches establishes the excavation size, form and direction, in addition to the width and function of partitions. Trenches are excavated as soon as the constructing define has been set out. The width is frequently marked with a line of dots of dry lime powder for correct excavation through hand, while the centre line is marked for correct system excavation.

- Outline profile forums are frequently used to manipulate trench positioning, width and intensity. In order that they do now no longer hinder the excavation paintings, profile forums must be installation at the least 2m clean of the ditch positions.

- The degree of the profile cross board must be associated with the web page datum and stuck at a handy top above floor degree, frequently with cords strung among profiles at both quit of the ditch. Bands may be painted at the cross board for identity purposes. Pegs are frequently pushed into the lowest of the ditch to mark the pinnacle of the concrete strip this is eventually poured.

- The corners of partitions are transferred from intersecting twine traces to mortar spots at the concrete foundations, the usage of a spirit degree for accuracy.

- The slicing of trenches wishes to be undertaken with first rate care, in particular if they may be to be left open for a prolonged duration as there may be the opportunity of the edges caving in.

Reduced degree excavations

- The normal define of a discounted degree place may be set out running from a baseline. Corner posts are constant to the define of the excavation place and the define marked with dry sand or comparable material. To manage the intensity of the excavation, sight rails are installation at a handy top and at positions that allows you to permit a visitor to be used.

- A visitor is a profile board with a set top, used for controlling excavated ranges among profile forums. By putting the visitor withinside the sightline among degree forums, it’s miles viable to look whether or not or now no longer the excavation has been accomplished to accurate ranges. The top of the visitor is the favored degree of the sight rail minus the formation degree of the excavated place.

- Framed constructing Framed homes are typically associated with a grid, frequently set out from a baseline. The intersections of the grid traces mark the centre factors for remoted or pad foundations.

- The format of the grid is mounted the usage of a theodolite and the grid intersections marked the usage of pegs. Once the grid has been set out, offset pegs or profiles may be constant clean of any next excavation paintings. Control of excavation intensity may be via a visitor sighted among sight rails or through degree and team of workers associated with a domain datum.

KEY TAKEAWAYS

- Timber profile forums may be used on the corners. Profile forums are normally among 0.6-1m in top and incorporate 50 x 50mm posts pushed at the least 600mm into the floor, with a 150 x 38mm cross board.

- Giken promotes the Construction Revolution to set up new requirements of transport which surpass the modern traditional method.

- Damp proofing or a Damp-Proof in creation is a sort of moisture manage carried out to constructing partitions and flooring to save you moisture from passing into the indoors spaces.

- Dampness issues are the various maximum common issues encountered in residences.

- Damp proofing is described through the American Society for Testing and Materials (ASTM) as a cloth that resists the passage of water without a hydrostatic pressure.

- Waterproof is described through the ASTM as a remedy that resists the passage of water beneath pressure.

- Generally, damp proofing continues moisture out of a constructing, in which vapor obstacles maintain indoors moisture from stepping into partitions.

- Moisture resistance isn’t always always absolute; it is also described through a particular check method, limits, and engineering tolerances.

Methods:

- Damp proofing is executed numerous methods including:

- A damp-evidence course (DPC) is a barrier thru the shape designed to save you moisture growing through capillary motion which includes thru a phenomenon referred to as growing damp. Rising damp is the impact of water growing from the floor into property. The Damp evidence path can be horizontal or vertical. A DPC layer is generally laid underneath all masonry partitions, regardless if the wall is a load bearing wall or a partition wall.

- A damp-evidence membrane (DPM) is a membrane cloth carried out to save you moisture transmission. A not unusual place instance is polyethylene sheeting laid beneath a concrete slab to save you the concrete from gaining moisture via capillary action. A DPM can be used for the DPC.

- Integral damp proofing in concrete includes including substances to the concrete blend to make the concrete itself impermeable.

- Surface suppressant coating with skinny water evidence substances together with epoxy resin for resistance to non-pressurized moisture together with rain water or a coating of cement sprayed on together with shotcrete that could face up to water beneath pressure.

- Cavity wall production, together with rainscreen production, is in which the indoors partitions are separated from the outdoors partitions via way of means of a cavity.

- Pressure grouting cracks and joints in masonry substances.

Materials:

Materials extensively used for damp proofing include:

- Flexible substances like butyl rubber, warm bitumen (asphalt), plastic sheets, bituminous felts, sheets of lead, copper, etc.

- Semi-inflexible substances like mastic asphalt.

- Rigid substances, like impervious brick, stone, slate, cement mortar, or cement concrete painted with bitumen, etc.

- Stones.

- Mortar with waterproofing compounds.

- Coarse sand layers beneath flooring.

- Continuous plastic sheets beneath flooring.

- Termites harm family articles like furniture, plywood, clothing, stationery, etc. via way of means of feeding on timber and different natural cloth having cellulose base

- Subterranean termites make nest in soil and people look for timber via way of means of burrowing via the floor and making tunnels of dust

- They tour via masonry paintings, brick partitions and conduits of the constructing to the supply of meals and motive harm to the assets and property

- What is the answer to the problem? Treating the soil below the constructing and round foundations whilst it’s far nonetheless withinside the procedure of production is a superb manner to save you termite infestation.

- Pre-production anti-termite remedy is attracting interest in the course of the world.

- The soil in instantaneously touch with the muse and ground shape of a constructing is dealt with an insecticide which kills or repels termites as a result forming a poisonous barrier that’s deadly to termite entry.

- Pre-production anti-termite remedy is performed withinside the early tiers of production to be able to save you termite infestation withinside the built constructing.

- The steps concerned in Pre-production anti termite remedy:

- Inspection

- Site Preparation

- Rightful utility

- Important Points

- The pre-production anti-termite remedy is powerful best in opposition to subterranean termites and does now no longer deliver any safety for dry-timber termites or different pests of timber.

- After final touch of pre-production anti-termite remedy, if there’s any production/ masonry paintings withinside the dealt with place, the chemical barrier might also additionally get disturbed.

- In this type of scenario, the worried authority of the constructing has to tell your Professional Pest Management organization in order that instantaneously measures are taken to repair the chemical barrier and make sure prevention of termite entry.

- If the purchaser sees any proof of termites after the remedy, they have to file this to the worried government or PMP.

Advantages & Disadvantages:

- Each a part of the place dealt with have to acquire the prescribed dose charge of pesticide for the remedy to be powerful.

- Barrier have to be whole and non-stop beneath the complete of the shape to be blanketed.

- All foundations have to be absolutely surrounded via way of means of and in near touch with the barrier or dealt with soil.

- Do now no longer permit employees to go into the plots in which the remedy is in development.

- Do now no longer keep insecticides in empty packing containers.

3.6.1 Vertical Circulation

Vertical circulate is the method via way of means of which constructing occupants get entry to precise regions of a constructing, including:

- Inner stairs

- Inner ramps

- Elevators

- Staircases

KEY TAKEAWAYS

- Barrier have to be whole and non-stop beneath the complete of the shape to be blanketed.

- Dampness issues are the various maximum common issues encountered in residences

3.6.2 Staircases and their Types

1. Straight

- This one is straightforward (literally). Straight stairs characteristic a unmarried linear flight without an alternate in direction.

Fig. 3: Straight Staircase

2. L-shaped (a.k.a. Quarter-turn)

- The classic straight style, zhuzhed up a little. In this design, the stairs make a 90-degree turn at some point, going left or right after a landing.

Fig. 4: L-shaped Staircase

3. Winder

- The slightly more complicated sister to the L-shaped staircase. A set of winders—treads that are wider on one side than the other—takes the place of the landing to save space.

Fig. 5: Winder Staircase

4. U-shaped (a.k.a. Half-turn)

- If you’ve ever promised yourself, you’d take the stairs every day at your office, you’ve seen this back-to-basics style. The bend is taken even further to form a full U shape, and similar to the L-shaped staircase, a landing separates the two parallel flights.

Fig. 6: U-shaped Staircase

5. Spiral

- A compact design centered around a single pole, so that if you looked at it from above, it would form a perfect circle.

- Something to consider: A spiral staircase’s narrow wedge-shaped treads aren’t the easiest to traverse. (Avoid them if you’re clumsy.)

Fig. 7: Spiral Staircase

6. Curved

- Unlike winder or L-shaped staircases, a curved style has no landings. Instead, the stairs are continuous, following the bend of the banister to make a striking architectural statement.

Fig. 8: Curved Staircase

7. Bifurcated

- The grandest of them all—this is the style of the iconic Titanic staircase—bifurcated stairs include one sweeping set of steps that splits off into two smaller flights going in opposite directions.

Fig. 9: Bifurcated Staircase

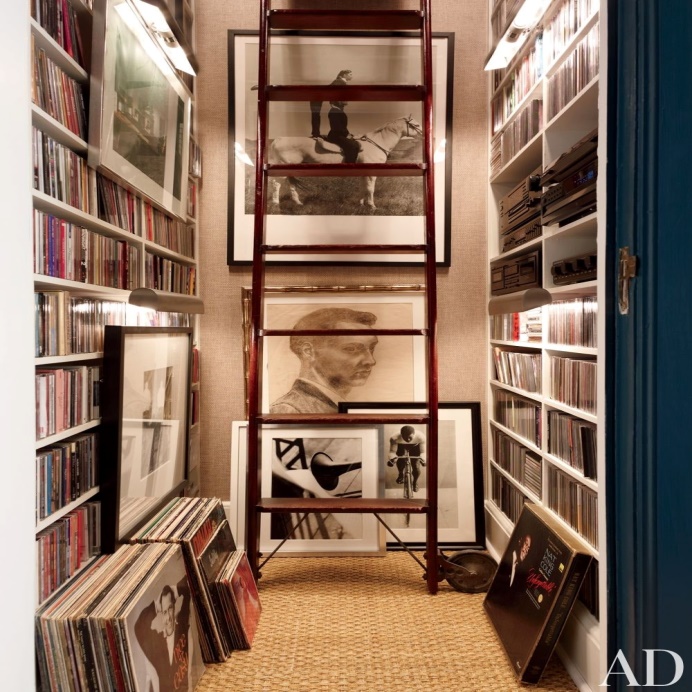

8. Ladder

- No explanation needed here. Small-home owners desperate for even the tiniest extra sliver of square footage could go this route.

Fig. 10: Ladder Staircase

3.6.3 Planning

- Staircases are fundamental to any house that has more than one story.

- They come in all heights, widths, and configurations, from basic and utilitarian to grand and sweeping.

- The form a staircase takes is determined by the home’s design, the builder’s skill, the amount of space available, and the budget.

- A staircase that runs straight from one floor to the next is easiest to build but can be somewhat formidable to climb.

- Stairs that stop at a landing and turn 90 or 180 degrees take up less space and can be safer and easier to traverse.

- A spiral staircase takes up the least amount of space and is economical to install, but it is not easy to climb, is particularly impractical when you need to carry large objects from one floor to the next, and is not safe for use by children or the elderly.

Timber:

Fig. 11: Timber floor

- Given that every piece is different, the specific aesthetic of wood is one of the primary appeals for its use as floors. It also can be very long lasting even though it could scratch and is liable to movement. As wood is hygroscopic (sponge-like), it could incorrect to be used in rooms that can be uncovered to humidity or moisture, even though remedy of the wood could make it immune to moisture.

- There are numerous alternatives for completing wood, which includes wax, oil or lacquer. The primary kinds of wood floors are:

- Solid: Each board is crafted from a unmarried piece of wood, commonly 18-20mm thick, commonly equipped the use of tongue-and-groove.

- Engineered: Each board includes 3 or 4 layers of laminated wood, held collectively at proper angles via way of means of glue to create a plank commonly of round 14mm thickness.

Laminate:

- Laminate floors is a compressed fiberboard plank included with an photograph of a cloth which includes wood, stone, tiles and so forth this is then given a protecting coating.

- Laminates may be appropriate for rooms that want to enjoy the aesthetics of a ‘natural’ ground however at a decrease cost, with less difficult installation, and without the hazard of being broken via way of means of scratching.

- Good pleasant laminates are long lasting and might have a 20-yr warranty. They require minimum preservation and can be hooked up with under-ground heating.

Fig. 12: Laminate Floor

Vinyl:

- Vinyl flooring can be supplied in rolls or tiles and is generally fixed by gluing.

- It can be manufactured in a very wide range of colours and profiles (for example studded) and as with laminate flooring can simulate the appearance of other materials.

Fig. 13: Vinyl floor

The benefits of the usage of vinyl floors include:

- It is long lasting.

- It is simple to preserve and hold clean.

- It is install of having moist without buckling, making it appropriate to be used in bathrooms, kitchens, and so on.

- It is simple to install.

- It may be noticeably inexpensive.

- For extra information, see Vinyl floors.

Bamboo:

- Rather than being wood, that is grass that has been compressed right into a ground cloth, and is nailed down or glued collectively.

- It has the gain of being a renewable useful resource and water resistant.

Cork:

- Cork is a water-resistant, renewable cloth this is appropriate for more than a few spaces, which includes basement and toilet installations.

- Cork may be clicked collectively withinside the equal manner as laminates or may be glued.

- Cork flooring are heat and bendy even though they may be broken without difficulty through sharp objects.

Tile (porcelain or ceramic):

- There are many alternatives in phrases of color, texture, form and finishes of tiles.

- Because in their hardness they’re tough to scratch or dent, and also are appropriate to moist environments.

- However, they’re tough to nstall and might spoil if there’s a loss of help under the tiles.

- Tile (herbal stone) These are typically extra highly-priced than porcelain or ceramic alternatives, however may be extra aesthetically pleasing.

- They want to be nicely sealed while installed, a procedure as a way to want repeating on occasion to hold the tiles protected.

Carpet:

- Carpet is fabricated from a top layer of pile connected to a backing.

- The pile is normally wool or fibers which includes nylon, polyester or polypropylene which might be warmth-handled after having been twisted collectively into tufts or woven.

- There are many types of texture, fashion and color to be had and typically carpet is each long lasting and smooth to preserve.

- Carpet additionally has insulating residences in phrases of each warmth and sound.

- However, carpets can stain pretty without difficulty and may be broken through water and damp.

Rubber:

- Rubber floors is crafted from herbal or artificial materials, which includes recycled rubber tyres. It is classified as a form of resilient floors, because it famous traits of elasticity or ‘bounce’.

- This additionally makes it appropriate for dance flooring, eating places or different excessive visitors’ regions wherein foot fatigue and slippage can occur.

- Rubber floors is likewise turning into a famous choice for home installations.

- It’s getting used for children’s playrooms, bathe and tub rooms, garages, domestic gymnasiums and different programs that have a tendency to require moisture and stain resistance, sound absorption, sturdiness, elasticity and temperature stability.

- Poured flooring (mastic asphalt and polymeric) Mastic asphalt and polymeric flooring are poured as drinks and unfold out throughout surfaces to harden and cure. This creates an end without seams.

- While asphalt and polymer floors alternatives aren’t specifically common, they do have benefits in each commercial (specifically industrial) and home programs wherein water safety and sturdiness are excessive priorities.

KEY TAKEAWAYS

- Rubber floors is crafted from herbal or artificial materials, which includes recycled rubber tyres. It is classified as a form of resilient floors, because it famous traits of elasticity or ‘bounce’.

- Vinyl flooring can be supplied in rolls or tiles and is generally fixed by gluing.

3.8.1 Brick Masonry Construction

Fig. 14: Brick Masonry Construction

- An excellent masonry needs to make use of bricks which can be sound hard, properly burnt, and difficult with uniform color, shape, and size.

- The bricks need to be compact, homogeneous, unfastened from holes, cracks, flaws, air-bubbles, and stone lumps. These bricks need to be nicely soaked in water for at the least hours earlier than use.

- In the brickwork, the bricks need to be laid on their beds with the frogs pointing upwards.

- The bricks guides need to be laid certainly horizontal and need to have certainly vertical joints.

- As a way as feasible the usage of bricks-bats needs to be discouraged.

- As a way as feasible the brick partitions need to be raised uniformly with right bond. Generally, the peak of brick masonry creation in an afternoon need to be much less than 1.5 m. The most distinction withinside the growing of the partitions among the distinctive quantities need to now no longer be multiple meters.

- When the mortar is green, the aspect joints need to rake to a intensity of 12 to 19 mm that allows you to have a right key for plastering or pointing. The mortar joints need to caught end if no plastering or pointing is to do. In order to make sure a non-stop bond among the vintage and the new, the partitions need to be stopped with a toothed end.

- Finished brickwork in lime mortar need to therapy for a length of two to a few weeks. This length can lessen to at least one to two weeks withinside the case of brickwork with cement mortar.

- In order to perform the brickwork at a better level, an unmarried scaffolding is used.

3.8.2 Stone Masonry Construction

Fig. 15: Stone Masonry Construction

- The headers withinside the coronary heart of the wall is the identical length as withinside the face and enlarge as a minimum 12 into the middle of backing.

- Headers in “Walls of feet (600mm) or much less in thickness” enlarge totally thru the wall. The headers shall occupy as a minimum 20% of the face of the wall.

- Lay the guides with leaning beds parallel to the herbal mattress of the material.

- Regularly lessen the thicknesses of the guides, if varied, from the lowest of the pinnacle of the wall, hold a surplus deliver of stones on the web website online in pick out from.

- Before laying the stone withinside the wall, form and get dressed it in an effort to now no longer loosen after it’s far the vicinity. No dressing of hammering with a purpose to loosen the stone may be recognized after it’s far located.

- Clean every stone and saturated it with water earlier than placing it. Clean and moisten the mattress so one can get hold of it.

- Bed the stones in a freshly made mortar with complete joints. Carefully settle that stones in vicinity earlier than the mortar sets. The joints and beds have a mean thickness of now no longer greater than 1 inch. (25 mm).

- The entire method of running stones masonry construction:

- The vertical joints in every direction brack with the adjacent direction as a minimum 6 inches. (one hundred fifty mm). If a stone is greater or if the joints are breaking after the mortar has set, take the stone up and punctiliously easy the mortar from the mattress and joints. Reset the stone in sparkling mortar.

- Whenever possible, nicely factor the face joints earlier than the mortar sets. If joints cannot be the factor, rake them out to a intensity of one inch (25mm) earlier than the mortar sets.

- Do not smear the stone face surfaces with the mortar pressured out of the joints of the mortar utilized in pointed. Drive the mortar into the joints and end with a recognized pointing tool.

- Keep the wall moist even as pointing. In warm or dry weather, defend the factor masonry from the solar and hold it moist for as a minimum 3 days after the pointing is end.

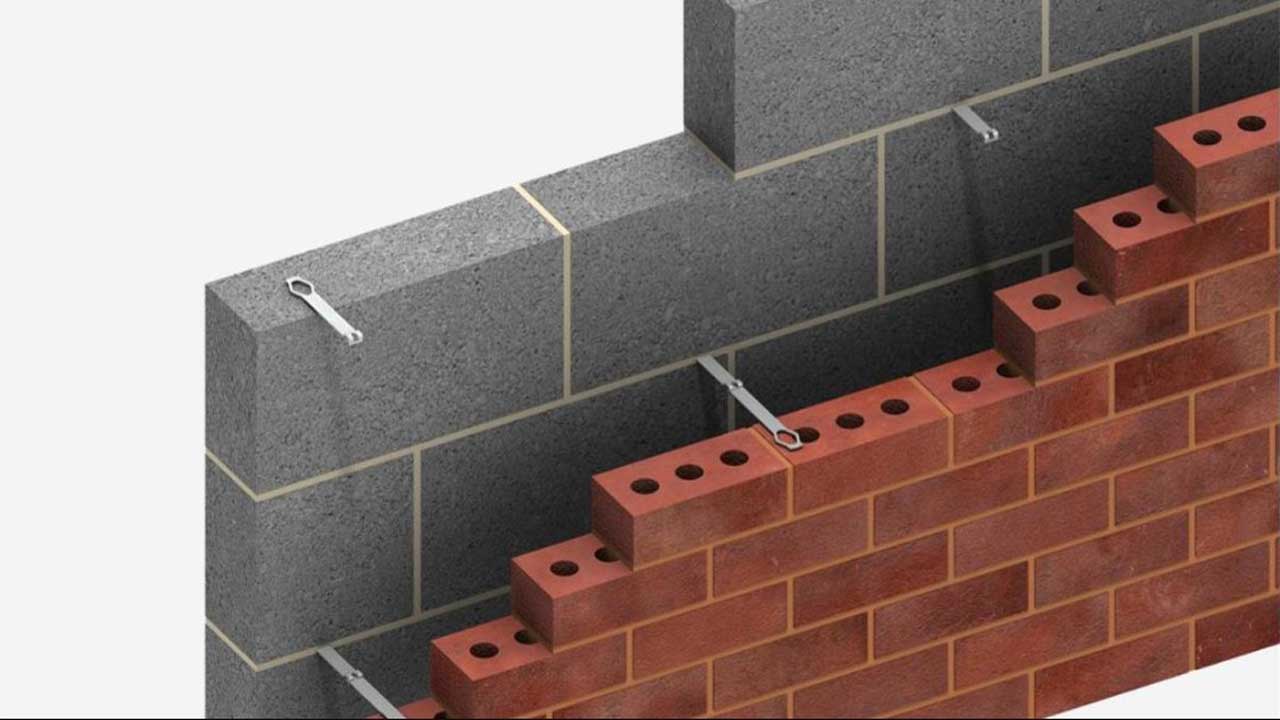

3.9.1 Cavity Wall Construction

- The use of hollow space partitions is not unusual place in bloodless countries. However, one has to recognize how they’re constructed, and why.

- The regular 275 mm (eleven inches) hollow space wall that’s appropriate for homes now no longer exceeding memories in height, includes ½ of brick (four – half inch partitions with 2 inches hollow space).

- Cavity Walls are beneficial in ways. Firstly, the hollow space prevents the dampness from the outer leaf percolating into the internal leaf.

- Secondly, they offer amazing insulation from warmth and sound.

- However, whilst utilized in tropical countries, enough precautions should be taken to peer that they do now no longer grow to be breeding locations for lizards and insects.

- The internal leaf is observed to take a extra part of the imposed load transmitted via way of means of ground and roof. Hence, the 2 leaves of the wall are bonded collectively with ties (wall ties) generally located 900 mm aside vertically and 450 mm horizontally in each sixth direction staggered.

- This offers greater than ties according to rectangular meter. These wall ties are crafted from moderate metallic wires of three to four mm diameter or MS bars and fabricated to shapes as proven withinside the underneath Figure.

Fig. 16: Cavity Wall Construction

- They are dipped in warm tar and sanded or crafted from galvanized metallic to save you rusting.

- In very vital works, copper can be used.

- Wire ties are located with their twisted cease right all the way down to permit water, that could seep inside, to drip down withinside the hollow space.

- The bond for use for each the leaves, whilst the thickness is ½ of brick, is the stretcher bond.

- Where the internal leaves are made thicker for sporting heavy loads. English bond may be used for that part.

- Cavity partitions require enormous care in layout and supervision. Otherwise, their performance as insulators towards riding rain, warmth and bloodless may be severely impaired.

- Particular care is needed on the pinnacle and backside of the partitions and round openings withinside the hollow space wall construction.

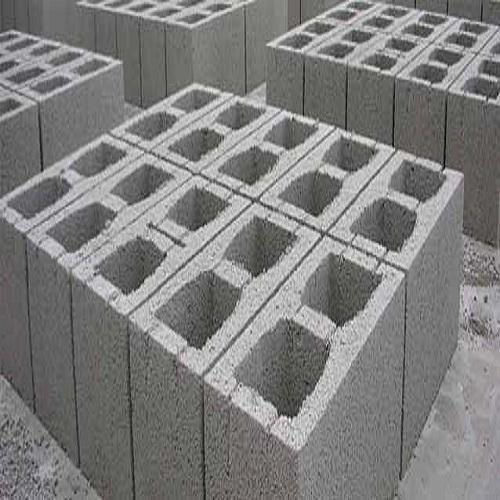

3.9.2 Hollow Block Construction

- Hollow concrete blocks are substitutes for traditional bricks and stones in constructing construction.

- They are lighter than bricks, less difficult to location and additionally confer economics in basis price and intake of cement.

Fig. 17: Hollow Block Construction

Advantage:

- It can face up to warmness for that reason giving hearthplace safety to the residence or buildings.

- It has higher sound overall performance in which it capable of block the sound from out of doors.

- It additionally gives decrease application cost. Energy green houses its inherent mass characteristics assist preserve a domestic cooler withinside the summer time season and hotter withinside the winter.

- It reduces the nation’s power wishes and bring a cleaner environment

- It gives extensive variety of non-fade colors.

- It does now no longer require portray for safety from being destroyed like woods.

- It is a load bearing cloth that's it additionally assists to assist the building.

- It is simply maintenance-free. It in no way wishes portray, caulking or staining.

- It might not burn or rot like different end substances.

Disadvantage:

- During excessive weather, it is able to purpose degradation of the floor because of frost harm.

- It provides a number of weights to the inspiration. Therefore, it will increase the pressure of the inspiration which more potent basis had to assist these bricks.

- When the brick displays a few harms, it's far not able to restore that element most effective however to put off the complete wall segment which very costly. Plus, cloth used are in large part related.

- Poorly made bricks inclusive of clinkers and older recycled bricks is probably pitted, irregularly shaped, worn or at risk of chipping.

- In humid climates, porous brick invitations mould. It suffers harm as water and ice increase and settlement in its pores.

- Brick isn't cost-powerful for lots domestic builders. It may be broken through vines.

- The drawback of block isn't insulated for northern climates due to the fact the body wall isn’t being insulated. Therefore, the bloodless air from the out of doors will switch into the residence. Besides, block isn't at risk of hearthplace, mould and termites.

KEY TAKEAWAYS

- Hollow concrete blocks are substitutes for traditional bricks and stones in constructing construction

- The headers withinside the coronary heart of the wall is the identical length as withinside the face and enlarge as a minimum 12 into the middle of backing.

References

- SK Duggal, “Building Materials” New Age Internationals.

- BC Punmia, “Building Construction” Laxmi Publications.

- “Building Construction”, Techmax Publication.

- PC Varghese, “Building Materials” PHI.