Unit IV

Metal Joining (Welding)

Welding which is the process of joining two metallic components for the desired purpose can be defined as the process of joining two similar or dissimilar metallic components with the application of heat, with or without the application of pressure, and with or without the use of filler metal. Heat may be obtained by chemical reaction, electric arc, electrical resistance, frictional heat, sound, and light energy. If no filter metal is used during welding then it is termed as ‘Autogenously Welding Process’. During ‘Bronze Age’ parts were joined by forge welding to produce tools, weapons, and ornaments, etc, however, present-day welding processes have been developed within about a century.

The first application of welding with carbon electrode was developed in 1885 while metal arc welding with a bare electrode was patented in 1890. However, these developments were more of experimental value, and applicable only for repair welding but proved to be the important base for present-day manual metal arc (MMAW) welding, and other arc welding processes.

In the meantime resistance, butt welding was invented in the USA in the year 1886. Other resistance welding processes such as spot and flash welding with manual application of load were developed around 1905. With the production of cheap oxygen in 1902, oxy – acetylene welding became feasible in Europe in 1903. When the coated electrodes were developed in 1907, the manual metal arc welding processes become viable for the production/fabrication of components, and assemblies in industries on large scale.

Subsequently, other developments are as follows:

• Thermit Welding (1903)

• Cellulosic Electrodes (1918)

• Arc Stud Welding (1918)

• Seam Welding of Tubes (1922)

• Mechanical Flash Welder for Joining Rails (1924)

• Extruded Coating for MMAW Electrodes (1926)

• Submerged Arc Welding (1935)

• Air Arc Gouging (1939)

• Inert Gas Tungsten Arc (TIG) Welding (1941)

• Iron Powder Electrodes with High Recovery (1944)

• Inert Gas Metal Arc (MIG) Welding (1948)

• Electro Slag Welding (1951)

• Flux Cored Wire with CO 2 Shielding (1954)

• Electron Beam Welding (1954)

• Constricted Arc (Plasma) for Cutting (1955)

• Friction Welding (1956)

• Plasma Arc Welding (1957)

• Electro Gas Welding (1957)

• Short Circuit Transfer for Low Current, Low Voltage Welding with CO 2

Shielding (1957)

• Vacuum Diffusion Welding (1959)

• Explosive Welding (1960)

• Laser Beam Welding (1961)

• High Power CO 2 Laser Beam Welding (1964)

All welded ‘ Liberty ‘ ship’s failure in 1942, gave a big jolt to the application of welding. However, it had drawn attention to the fracture problem in welded structures.

Applications:

Although most of the welding processes at the time of their developments could not get their place in the production except for repair welding, however, at the later stage these found a proper place in manufacturing/production. Presently welding is widely being used in the fabrication of pressure vessels, bridges, building structures, aircraft, and space crafts, railway coaches, and general applications. It is also being used in shipbuilding, automobile, electrical, electronic, and defense

industries, laying of pipelines, and railway tracks, and nuclear installations, etc.

General Applications:

Welding is vastly being used for the construction of transport tankers for transporting oil, water, milk, and fabrication of welded tubes, and pipes, chains, LPG cylinders, and other items. Steel furniture, gates, doors, and door frames, body, and other parts of white goods items such as refrigerators, washing machines, microwave ovens, and many other items of general applications are fabricated by welding.

Pressure Vessels:

One of the first major use of welding was in the fabrication of pressure vessels. Welding made considerable increases in the operating temperatures, and pressures possible as compared to riveted pressure vessels.

Bridges:

Early use of welding in bridge construction took place in Australia. This was due to problems in transporting complete riveted spans or heavy riveting machines necessary for fabrication on-site to remote areas. The first all-welded bridge was erected in the UK in 1934. Since then all welded bridges are erected very commonly, and successfully.

Ship Building :

Ships were produced earlier by riveting. Over ten million rivets were used in the ‘Queen Mary’ ship which required skills, and massive organization for riveting but welding would have allowed the semiskilled/ unskilled labor and the principle of pre-fabrication. Welding found its place in shipbuilding around 1920, and presently all-welded ships are widely used. Similarly, submarines are also produced by welding.

Building Structures:

Arc welding is used for the construction of steel building leading to considerable savings in steel, and money. In addition to the building, huge structures such as steel towers, etc also require welding for fabrication.

Aircraft, and Spacecraft:

Similar to ships, aircraft were produced by riveting in the early days but with the introduction of jet engines welding is widely used for aircraft structure and the joining of skin sheets to the body. Space vehicles that have to encounter frictional heat, as well as low temperatures, require outer skin, and other parts of special materials. These materials are welded with full success achieving safety, and reliability.

Railways:

Railways use welding extensively for the fabrication of coaches, and wagons, wheel tyres laying of new railway tracks by mobile flash butt welding machines, and repair of cracked/damaged tracks by thermit welding.

Automobiles:

Production of automobile components like chassis, body, and its structure, fuel tanks, and joining of door hinges require welding.

Electrical Industry:

Starting from generation to distribution, and utilization of electrical energy, welding plays an important role. Components of both hydro, and steam power generation systems, such as penstocks, water control gates, condensers, electrical transmission towers, and distribution system equipment are fabricated by welding. Turbine blades and cooling fins are also joined by welding.

Electronic Industry:

The electronic industry uses welding to a limited extent such as for joining leads of special transistors but other joining processes such as brazing, and soldering are widely being used. Soldering is used for joining electronic components to printed circuit boards. Robotic soldering is very common for joining of parts to printed circuit boards of computers, television, communication equipment, and other control equipment, etc.

Nuclear Installations:

Spheres for a nuclear reactor, pipeline bends joining two pipes carrying heavy water, and other components require welding for safe, and reliable operations.

Defense Industry:

The defense industry requires welding for the joining of many components of war equipment. Tank body fabrication, joining of turret mounting to the main body of tanks are typical examples of applications of welding.

Micro-Joining:

It employs the processes such as micro-plasma, ultrasonic, laser, and electron beam welding, for joining of thin wire to wire, foil to foil, and foil to wire, such as producing junctions of thermocouples, strain gauges to wire leads, etc. Apart from the above applications welding is also used for the joining of pipes, during the laying of crude oil, and gas pipelines, construction of tankers for their storage, and transportation. Offshore structures, dockyards, loading, and unloading cranes are also produced by welding The joining of materials by a solid joint or the cutting of materials without the use of Mechanical cutting tools, usually by means of heat, comprise the following processes: Welding, brazing, thermal spraying, and thermal cutting.

Soldering and brazing involve melting a lower-melting-point material between the Workpiece to form a bond between them, without melting the workpiece. In this process, the melting point of solder should be at a temperature of at least 50oC lower than the melting point of the base material to be joined. Thermal spraying is a process in which molten metal is sprayed onto a surface. The Equipment and power sources used in the process are similar to those used for welding. A thermal cutting (oxy-fuel gas cutting) is a process used for the cutting of materials by means of heat. No cutting tools are used in the process. It is an allied process to Welding, although its purpose is just the opposite, because the same or similar power Sources, and working equipment are used.

An allied process to welding may be adhesive bonding because it also involves the Joining of materials by a solid joint. However, adhesive bonding is distinctly different from welding in terms of operating conditions, and equipment.

Key points:

1) Welding is vastly being used for the construction of transport tankers for transporting oil, water, milk, and fabrication of welded tubes, and pipes, chains, LPG cylinders, and other items. Steel furniture, gates, doors, and door frames, body, and other parts of white goods items such as refrigerators, washing machines, microwave ovens, and many other items of general applications are fabricated by welding.

2) Railways use welding extensively for the fabrication of coaches, and wagons, wheel tyres laying of new railway tracks by mobile flash butt welding machines, and repair of cracked/damaged tracks by thermit welding.

Gas welding is also named oxy-fuel gas welding (OFW). Gas welding derives heat from the combustion of fuel gas such as acetylene in combination with oxygen. The process is a fusion welding process where the joint is completely melted to obtain the fusion. Necessary considerations for gas welding.

Fuel Gases

Fuel gas for Gas welding used is acetylene due to its high temperature in the flame. Thereby the gas welding may be known as oxy-acetylene welding (OAW).

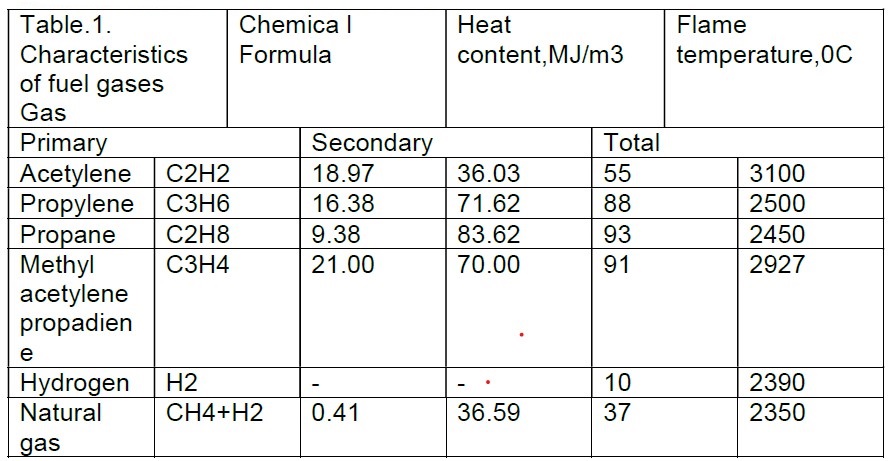

The following table shows the useful fuel gases for gas welding with their calorific values, and temperatures.

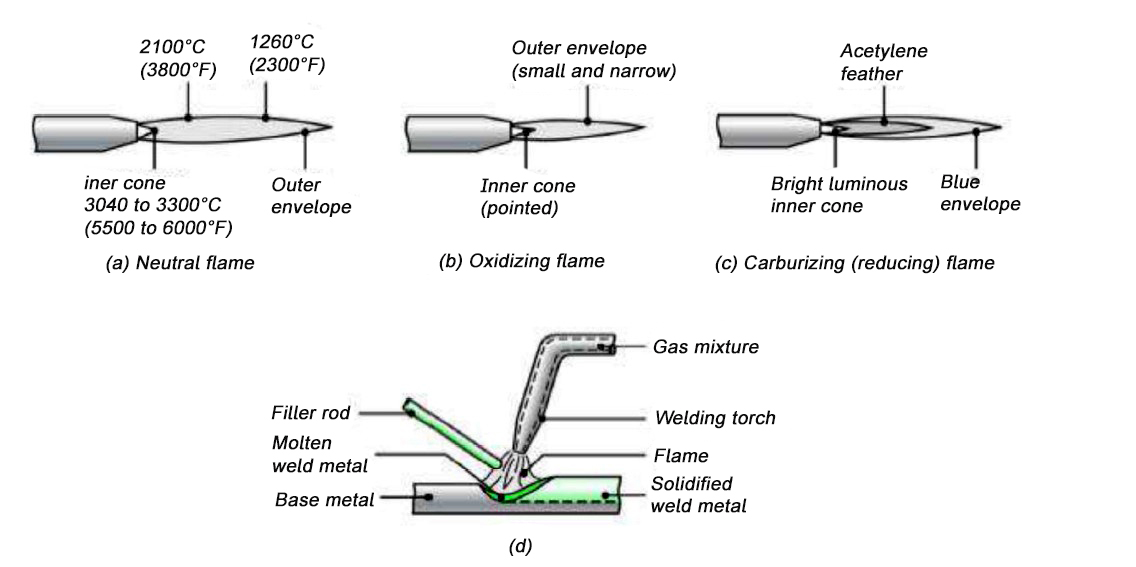

Three basic types of oxyacetylene flames are used in oxyfuel gas welding, and cutting operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing, flame.

The gas mixture in (a) is equal volumes of oxygen and acetylene.

(d) The principle of the oxyfuel gas welding process.

Fig 1

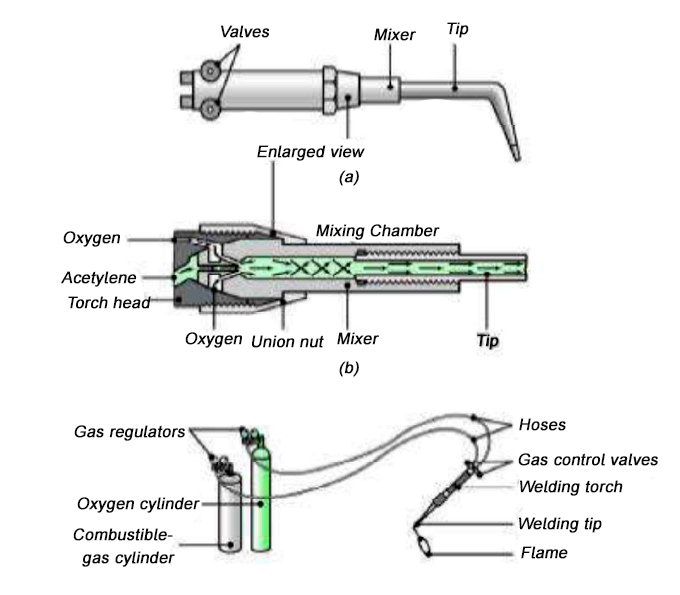

(a) General view of, and (b) cross-section of, a torch used in oxyacetylene welding. The acetylene valve is opened first. The gas is lit with a spark lighter or a pilot light. Then the oxygen valve is opened, and the flame adjusted. (c) Basic equipment used in oxyfuel gas welding. To ensure correct connections, all threads on acetylene fittings are left-handed, whereas those for oxygen are right-handed. Oxygen regulators usually are painted green, and acetylene regulators red.

Fig 2

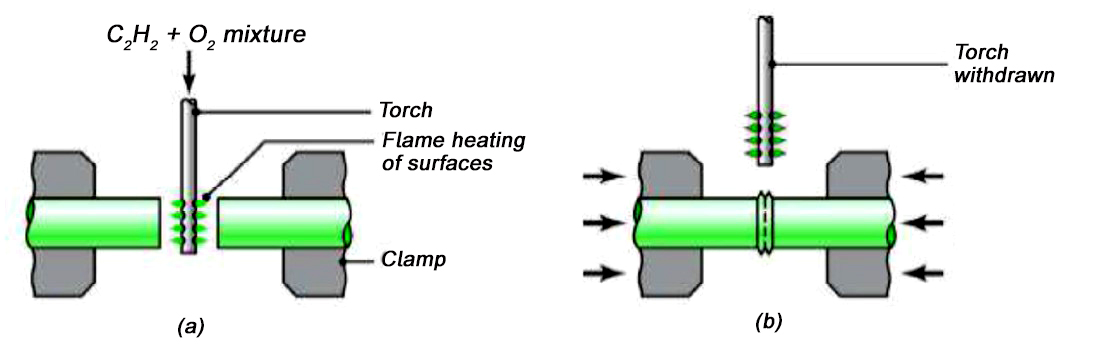

Schematic illustration of the pressure-gas welding process: (a) before, and

(b) after. Note the formation of a flash at the joint; later the flash can be trimmed off.

Fig 3

The acetylene valve on the torch is opened slightly with the help of a friction spark lighter. The acetylene valve is opened to get the required flow of acetylene. The oxygen valve is slowly opened till the intermediate flame feather of the reducing flame.

Key points:

1) Gas welding is also named oxy-fuel gas welding (OFW).

2) Gas welding derives heat from the combustion of fuel gas such as acetylene in combination with oxygen

Arc welding processes uses the heat generated by an electric arc to melt the faying surfaces of the base metal to develop a weld joint.

Manual metal arc welding

In this process, the heat is generated by an electric arc between the base metal, and a consumable electrode. As the electrode movement is manually controlled hence it is termed manual metal arc welding. This process is extensively used for depositing weld metal because it is easy to deposit the molten weld metal at the right place where it is required, and it doesn’t need separate shielding. This process is commonly used for welding metals, which are comparatively less sensitive to atmospheric gases. This process can use both AC and DC. The constant current DC power source is invariably used with all types of the electrode (basic, rutile, and cellulosic) irrespective of base metal (ferrous, and non-ferrous). However, AC can be unsuitable for certain types of electrodes, and base materials. Therefore, AC should be used in light of manufacturer recommendations for electrode application. In the case of DC welding, the heat liberated at the anode is generally greater than the arc column, and cathode side. The amount of heat generated at the anode and cathode may differ appreciably depending upon the flux composition of the coating, base metal, polarity, and the nature of arc plasma. In the case of DC welding, polarity determines the distribution of the heat generated at the cathode, and anode, and accordingly the melting rate of the electrode, and penetration into the base metal are affected.

4. 4. 1 TIG process

Tungsten Inert-Gas Welding (TIG)

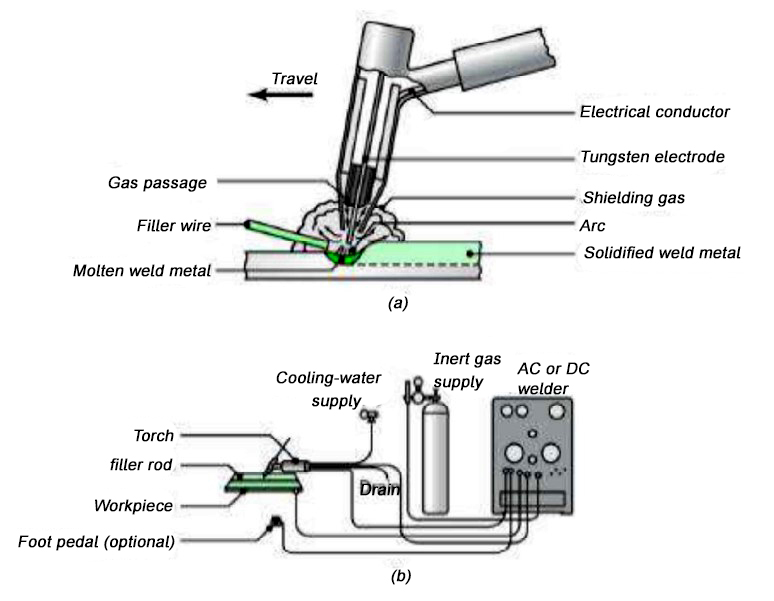

Tungsten inert gas (TIG) welding or gas tungsten arc is an inert gas shielded arc welding using a non-consumable electrode. This electric arc is produced by the passage of current through a conductive ionized inert gas that provides shielding of the electrode, molten weld pool, and solidifying weld metal from contamination by the atmosphere. The process may be used with or without the addition of filler metal using metal rods. (a) The gas tungsten arc welding process, formerly known as TIG (for tungsten g inert-gas) welding. (b) Equipment for gas tungsten-arc welding operations.

Fig 4

Electrode: In TIG welding, tungsten refers to the element used on the electrode. The function of the electrode is to serve as one of the electric terminals which supply the heat required to the weld. Care must be taken so that the tungsten electrode does not come in contact with the weld pool in any way to avoid its contamination resulting in the faulty weld. Pure tungsten is less expensive and will carry less current. Some other elements may be added to the tungsten, like cerium, lanthanum, thorium, and zirconium creating electrode alloys to improve arc stability, emissivity, and bring higher melting points. The electrode may contain 1 to 2% thoria (thorium oxide) mixed along with the core tungsten or tungsten with 0. 15 to 0. 40% zirconia (zirconium oxide). The thoriated tungsten electrodes carry a high current, and more desirable as they can strike, and maintain a stable arc. The zirconia added with tungsten is better than pure tungsten but inferior to the thoriated tungsten electrode.

Tungsten inert gas welding set up: It consists of a welding torch at the center of which is the tungsten electrode. The inert gas supplied to the welding zone through the annular path surrounding the tungsten electrode to effectively displace the atmosphere around the weld puddle.

4. 4. 2 MIG process

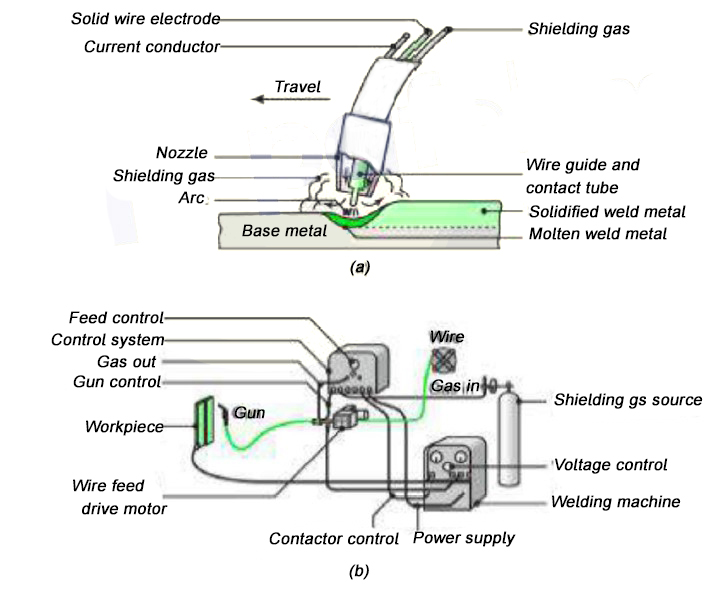

This is also known as Metal inert-gas arc welding (MIG) because it utilizes a consumable electrode. Other gas-shielded arc-welding processes are utilizing consumable electrodes such as flux-cored arc welding, all of which coming under MIG. It’s quite stable for thicker sheets because filler metal requirement in the welding process makes gas-tungsten arc welding (GTAW or TIG) difficult to use, which is more suitable for thin sheets. (a) Schematic illustration of the gas metal-arc welding process, formerly known as MIG (for metal inert-gas) welding. (b) Basic equipment used in gas metal-arc welding operations.

Fig 5

The consumable electrode is in the form of a wire reel fed at a constant rate through the feed rollers. The welding torch is connected to the gas supply cylinder, which provides the necessary inert gas. The electrode and the workpiece are connected to the welding power supply. The power supply is always of the constant voltage type. The current from the welding machine is changed by the rate of feeding of the electrode wire. Normally, DC arc-welding machines are used for GMAW with electrode positive (DCEP). The DCEP increases the metal- deposition rate, and also provides a stable arc and smooth electrode metal transfer. With DCEN the arc becomes highly unstable, and also results in spatter. But special electrodes having calcium, and titanium oxide mixtures as coatings are found to be good for steel with DCEN.

Metal Transfer

The short-circuiting metal transfer occurs with relatively low current settings of the order of 75 to 175 A for an electrode diameter of 0. 9 mm. The number of times that the pinching takes place depends on the inductance of the welding machine used, and the parameters set. The rate at which the short-circuiting current increases is controlled by the inductance of the welding machines. Too low an inductance gives rise to a very high short-circuiting current, and consequently a high pinching rate. With high inductance, the short-circuiting becomes low and results in a somewhat lower pinching force. The effect of inductance is measured in terms of response rate (raising rate of current due to short-circuiting, kA/s). It can be observed that the optimum response rate depends on the electrode wire size. Hence, he is welding machines to be used for short-circuiting transfer make use of a variable choke system which can be tuned for different wire sizes. The frequency of metal transfer may be of the order of 50 to 200per second. This rate also depends on the open-circuit voltage, and wire-feed rate employed.

Shielding gases

Argon, helium, nitrogen, oxygen, carbon dioxide, and a mixture of the above gases in various proportions are used in GMAW as shielding gases. Argon is the most widely used of all the shielding gases, because it reduces the spatter, and concentrates the arc, which in turn gives deep penetration welds. Besides, argon ionizes easily requiring smaller arc voltages, and also has lower thermal conductivity, and hence conducts heat very slowly from the arc to the weld zone. Thus, it is good for welding thin sheets. Because of the lower voltages employed, it is suitable for out-of-position welding. For spray transfer of metal, a large percentage of argon is required. Helium is the most expensive of all the shielding gases. Due to its better thermal conductivity, it is suitable for thicker sheets as well as for metals having higher thermal conductivity such as copper, and aluminium. The filler metal-deposition rate by helium is much higher compared to argon because of the higher current-carrying capacity. The arc in carbon dioxide shielding gas is unstable, and therefore a short arc is to be used to reduce the metal spatter. It is the least expensive of all the shielding gases. Since about 7. 5% of the carbon dioxide decomposes into carbon monoxide, and oxygen in the arc, deoxidizers such as aluminium, and silicon are to be used while using carbon dioxide. It is a heavy gas, and therefore it covers the weld zone very well. The metal transfer is globular only with the carbon dioxide shielding gas. Sometimes the mixtures of gases such as argon-helium, argon-carbon dioxide, argon-oxygen are used for special applications. Shielding gases should always flow in a laminar manner without causing any turbulence because turbulence causes weld contamination. The gas flow rates to be used depend upon the thickness of the sheet being welded, the position of the weld as well as the base material.

Electrodes

The electrode wire comes generally in the form of coils, and normal sizes may be of the order of 0. 5 to 3. 2 mm. Depending upon the base material, various wire compositions are available. For steels, electrodes wire having deoxidizers are used because the deoxidizers help in the reduction of oxidation of the weld metal as well as the porosity. The electrode wire is produced by wire drawing, and uniform diameter throughout otherwise the arc may saunter.

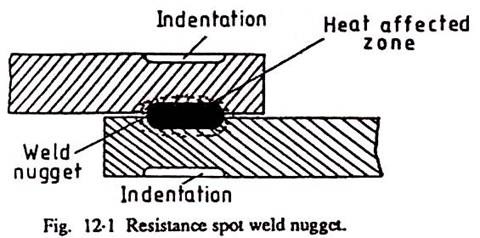

Resistance welding processes differ from other welding processes in that no fluxes are employed, the filler metal is rarely used, and the joints are often of the lap type. The amount of heat generated in the workpiece depends on the magnitude of the current, the resistance of the current-conducting path, and the time for which the current is made to flow.

This is expressed in terms of joule heating. By the simple application of Ohm’s law, the voltage (V) required for a current flow (I) is given by the relationship

V = IR,

where R is the resistance offered by the workpiece to the flow of current.

The heat generated is, thus, expressed by the formula:

H = IVt

= I (IR) t

= I2 Rt

where, H = heat generated, joules

I = current, rms amperes

R = resistance, ohms

t = time of current flow, seconds.

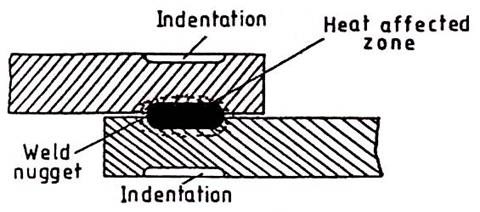

The heat generated is, thus, directly proportional to the resistance offered by any point in the circuit. As the interface of the two surfaces forming the lap joint is the point of greatest resistance, it is also the point of greatest heat. In simple resistance welding processes, a low voltage high amperage current flows from one adjoining plate to the other until the metal at the interface is heated to a high enough temperature to cause localized fusion which under the applied pressure squeezes the molten metal from the two parts to a homogenous mass called the weld nugget, as shown in Fig. 12. 1.

Fig 6

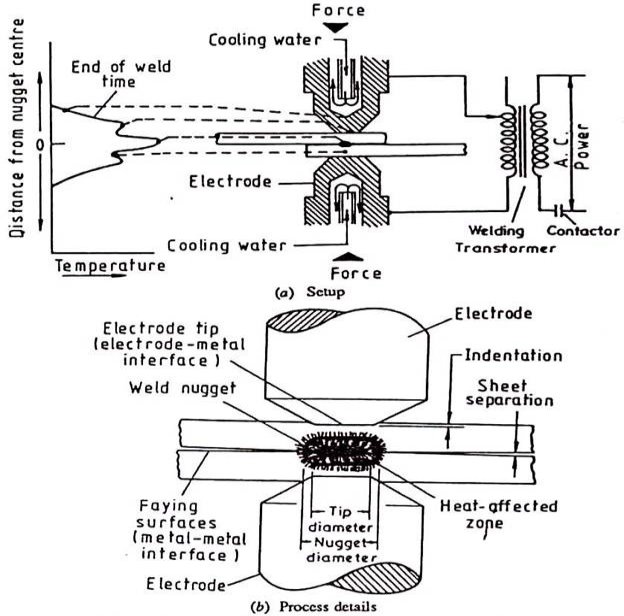

Resistance Spot Welding:

In this process, overlapping sheets are joined by local fusion, at the interface, by the concentration of current flowing between two electrodes. It is characterized by low cost, high speed, and dependability making it, at present the most widely used resistance welding process. Fig.7 shows the essential features of the process, and the basic circuit components are shown in Fig.8.

Fig 7

Fig 8

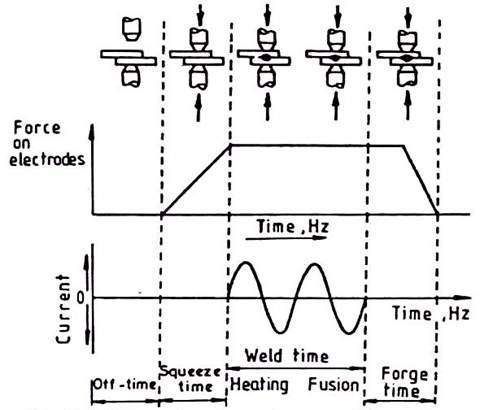

Spot Welding Sequence:

All resistance welding operations are automatic, and therefore all process variables are pre-set, and maintained constant. Once a welding operation has been initiated there is no way in which its progress can be controlled, and, thus, the weld cycle is completed as per the pre-set times.

Welding Cycle:

The welding cycle for spot, seam, and projection welding consists basically of four elements viz. , squeeze time, weld time, hold time, and off time. These timings are pre-set for a particular metal, and a thickness range and the shop operator normally cannot change them on his own. Each one of these four-time phases has its role to play in achieving a sound weld of the required size.

Squeeze Time:

The time interval between the application of electrode pressure to the work, and switching on the welding current is called the squeeze time. This time interval is provided to assure the contact between the electrode, and the work, and to initiate the application of force on it.

Weld Time:

It is the time for which the welding current flows to melt the metal at the interface.

Hold Time:

It is the time for which the electrodes are kept in position, after the welding current is switched off, to assure the application of pressure to consolidate the molten metal into a nugget which is then cooled by the dissipation of heat to the surrounding work material. If the applied force is excessive it may result in the expulsion of molten metal from in-between the sheets.

Off Time:

The time allowed to shift the work to the next location before the cycle is repeated is referred to as the off-time. The electrodes are kept off the work during this time interval.

All these phases of a weld cycle are shown in fig. 12. 4:

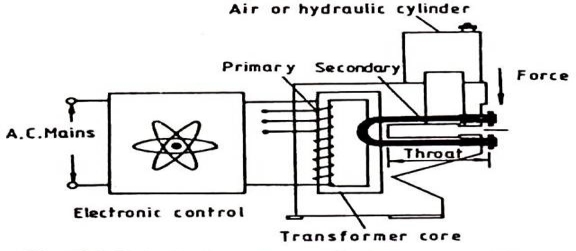

Fig 9

Machine Rating:The actual welding is done in the secondary circuit of the resistance welding machine but the voltage is not known, and the current flowing, for a fraction of a second for each weld cycle, is very heavy. It is, therefore, not easy or economical to measure these electrical parameters in the secondary circuit. The machine rating is, thus, based upon the current drawn by the system at the mains supply, and is given in the KVA unit. Some part of this power is lost in the system which goes to heat up the windings, and stampings.

This leads to a rise in temperature of the transformer which necessitates water cooling of the system otherwise the insulation may get damaged. To give a higher margin of safety the KVA ratings of these machines are quoted based upon the power that can be drawn for thirty seconds in each minute, this accounts for the cooling requirements of the system. The KVA rating of the resistance welding machines for spot, seam, and projection welding, normally varies between 5 to 500 KVA.

Spot Welding Electrodes:Electrodes are an important part of a resistance spot welding unit. They serve four important functions viz. , conduct the welding current to the work, transmit the desired force to the workpieces, dissipate a part of the heat from the work, and provide jigging action to it.

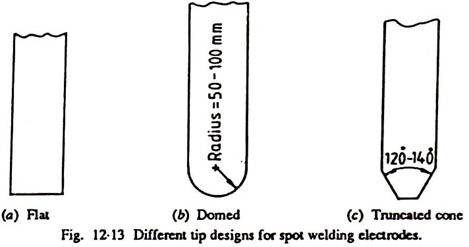

To achieve the desired current density it is important to have a proper electrode shape for which three main types of electrodes are used; these are pointed, domed, and flat electrodes.

Pointed tips are most widely used particularly for ferrous materials; with continued wear, they mushroom uniformly. The pointed electrodes are basically truncated cone electrodes with an angle of 120° – 140°. Compared with other types, the contact area can be controlled more accurately with a truncated cone or pointed electrodes, and any wear in service can be easily seen. However, the pointed tip electrodes make more obvious surface marking on the workpiece, and require more accurate alignment.

Domed electrodes are characterized by their ability to withstand heavier pressure and severe heating without mushrooming which makes them particularly useful for welding non-ferrous metals. The radius of the dome varies but a 50 to 100 mm radius is most commonly used. Filing of electrodes while on the machine should not be permitted as it is not possible to reproduce their original shape by that method.

When inconspicuous or invisible welds are desired or where the weld indentation is to be minimum, a flat lip electrode is used. A combination of one flat and one domed electrode is usually used in such cases. All three types of electrodes are shown in Fig.10

Fig 10

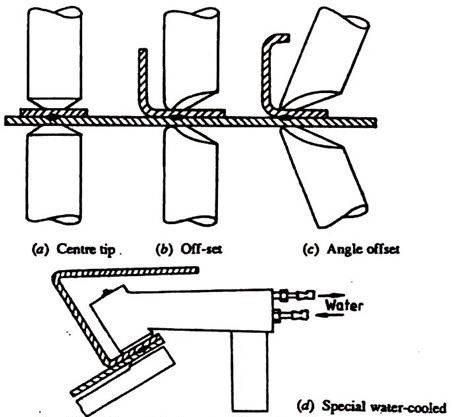

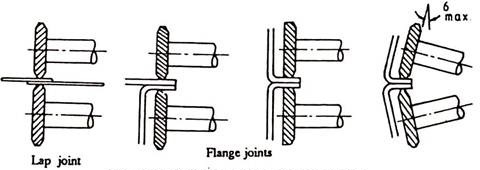

Offest electrodes can be used to make spot welds in places that are inaccessible to weld by conventional type electrodes e. g. , for making comer welds, and for welding parts with overhanging flanges as shown in Fig. 11. If there is excessive off-set undue tip deflection, skidding, and surface deformation may result. If the size of the electrode is restricted to accommodate the joint, overheating may result.

Fig 11

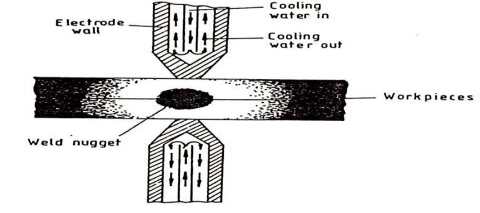

Spot welding electrodes are made of materials with higher electrical, and thermal resistivities, and with sufficient strength to withstand high pressure at elevated temperatures, for example, copper-base alloys such as copper beryllium, and copper tungsten are often chosen for the purpose.

For extra heavy-duty work, the electrodes are made of a harder material. As a rule harder the alloy, the lower its thermal, and electrical conductivities. This results in excessive heating and mushrooming of electrode tips. To overcome this difficulty the electrodes are kept cool by water circulation through the drilled holes in the electrodes as shown in Fig. 12. 15. This reduces the wear, and tear, and delays the tendency to mushrooming.

Fig 12

Proper selection of electrode material is imperative for the success of the spot welding operation. For example, electrodes for aluminium welding are required to have high electrical conductivity though rather lower compressive strength to minimize electrode sticking to work. However, electrodes for welding stainless steels are required to have high compressive strength with rather lower thermal conductivity.

The electrode tips should be kept clean because dirty or scaly points often cause embedding, burning, or splitting. The electrode tips on a spot welder should be approximate of the same size and should meet in proper alignment to obtain good quality welds.

Electrode Size:

The size of the tip of the electrode depends upon the size of the spot weld or the required nugget diameter. The spot weld diameter is decided by the sheet thickness to be welded. Quite often the diameter of the nugget is selected as equal to the diameter of the corresponding rivet used for jointing the same thickness sheet Using Unwin’s formula nugget size is given by dn = 6√t where t is the single sheet thickness in mm. Whereas for rivetting a hole is made to fit in a rivet, a spot weld is an intrinsic part of the workpiece therefore it is considered that the efficiency of a spot weld will be higher than that of a riveted joint designed with the same design formula.

The electrode tip size is considered nearly equal to the nugget size, and is often taken as dc = 5√t- Though this is an empirical relationship it gives satisfactory results. Another empirical formula used for designing electrode tip size is d (mm) = 2. 5 + 2t, where t is single sheet thickness in mm. It gives nearly the same result as the first formula except for very thick or very thin workpieces.

The tip size is decided by the above relationships but if the full length of the electrode is made of that same size it will be too weak to withstand the. the pressure to be exerted through it, and also cause too high an electrical resistance to the flow of current resulting in its overheating.

The practical electrodes, made usually from copper alloys, are of substantial diameter machined to a truncated cone with an angle of 120° – 140°. When domed electrodes are used then the radius of the dome is used to control the area of contact. In domed electrodes, the electrode pressure, and the sheet hardness are the other factors to decide the area of contact.

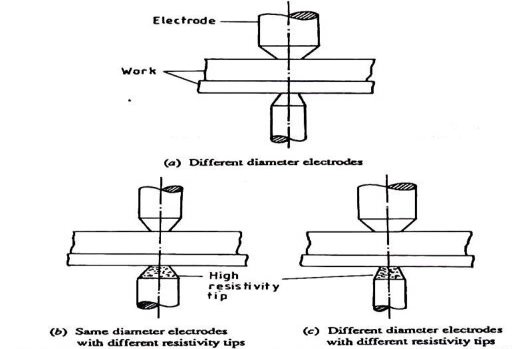

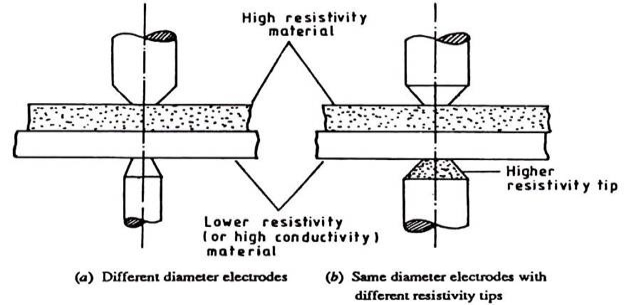

Heat Balance:Quite often sheets of different thicknesses or dissimilar materials are required to be spot welded. Such situations result in heat dissipation or generation of different amounts from the two sheets (or workpieces) which may cause the nugget to develop with its centreline away from the interface resulting in a weak weld. To achieve symmetrical growth of nugget on both sides of the interface it is essential to control the pattern of heat generation (or dissipation).

This is done by using electrodes of different diameters or by using high resistivity inserts, such as that of tungsten, in one of the electrodes. The weld nugget will then develop closer to the electrode with a smaller diameter due to the higher current density or electrode with high resistivity tip due to reduced thermal conductivity hence lower heat dissipation.

Four cases may arise for spot welding two sheets:

(i) Sheets of the same material but different thicknesses,

(ii) Sheets of different materials but the same thickness,

(iii) Thinner sheet of higher electrical resistivity (or lower electrical conductivity),

(iv) Thinner sheet of lower electrical resistivity (or higher electrical conductivity).

In the light of the above discussion the solution for these cases will be as follows:

(i) Thicker sheet has higher resistance (R = ρ 1/a, more thickness means longer 1, therefore higher R, as resistivity (ρ) of the material is constant at a given temperature) or lower conductivity (α), (α =√ρ)/and the nugget tends to penetrate deeper into it.

Therefore use a bigger diameter electrode on the side of the thicker sheet. Heat balance can thus be achieved by decreasing the current density in the thicker sheet or by decreasing the heat loss for the thinner sheet by using high resistivity (or low conductivity )tip or maybe by a combination of both the methods as shown in Fig. 13.

Fig 13

(ii) For sheets of different materials but the same thickness, resistance will depend directly on resistivity. Thus, more heat will be generated in a material with higher resistivity (or lower conductivity).

Therefore, use an electrode with a larger diameter on high resistivity (or lower conductivity) material. Alternatively, use an electrode with a high resistivity tip on the lower resistivity material as shown in Fig. 14.

Fig 14

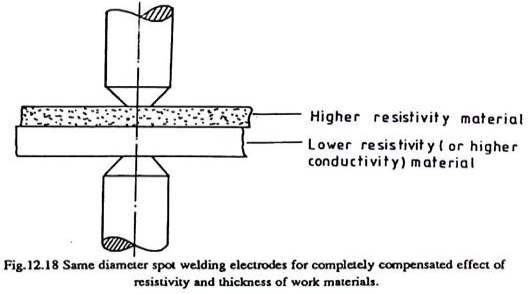

(iii) With a thinner sheet of higher electrical resistivity, the case may be self-compensating. Therefore, depending upon the cumulative effects of resistivity, and thickness the electrodes can be chosen as per the net effect which if completely compensated for may result in the use of same the diameter electrodes, as shown in Fig. 15.

Fig 15

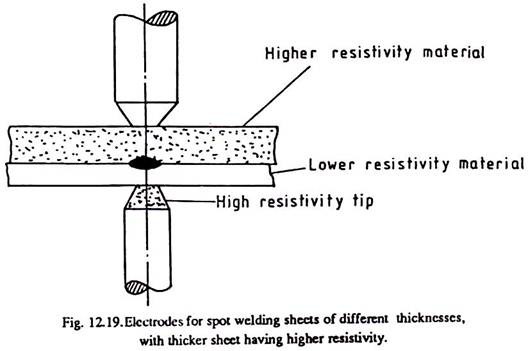

(iv) With a thicker sheet of higher resistivity the differential effect of thickness and resistivity will be accentuating hence the use of a large diameter electrode on the side of the thicker sheet, and at the same time use of an electrode with a smaller diameter, and higher resistivity tip on the side of the thinner sheet may be required to get a completely symmetrically placed nugget as shown in Fig. 12. 19.

Fig 16

Fig. 16. Electrodes for spot welding sheets of different thicknesses, with a thicker sheet having higher resistivity.

Weldability:Most of the industrial metals can be welded by one or the other resistance welding process. However, thicker sections are more difficult to weld, and some of the metals may need post-weld heat treatment (PWHT) to attain the desired properties.

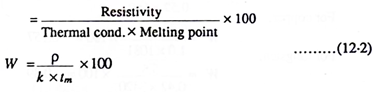

Weldability for resistance welding processes is dependant on three factors viz. , electrical resistivity, thermal conductivity, and the melting point of the metal. Metals with high resistivity, low thermal conductivity, and low melting point can thus be easily welded; ferrous metals generally fall in this category. Metals with low resistivity, and high thermal conductivity like aluminium, and magnesium alloys are difficult to weld due to excessively high thermal conductivity. Refractory metals like tungsten and tantalum are very difficult to weld due to their very high mailing points.

Weldability for resistance welding in general, and spot welding in particular can be expressed by the following relationship:

Percentage Weldability

where W = percentage weldability,

ρ = electrical resistivity of work material, micro-ohm per cm (µΩ/cm),

k = relative thermal conductivity with copper equal to 1. 00,

tm = melting point, °C.

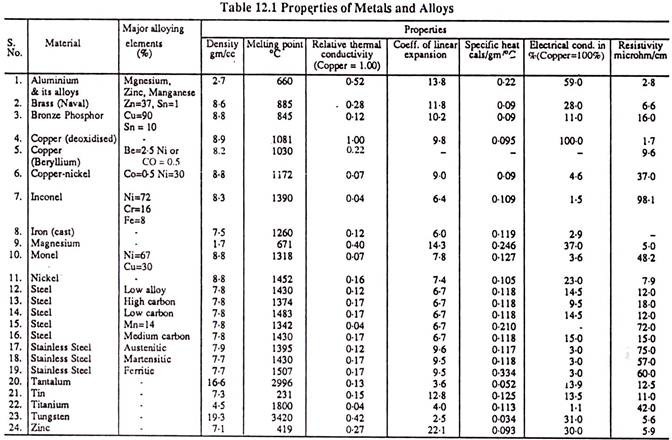

According to the above relationship weldability above 2. 0 is excellent, between 0. 75, and 2. 0 it is good, and below 0. 25 it is poor. Weldability rating for some mild steels is above 10 while for aluminium alloys it lies between 1 to 2. Copper and its alloys like brass have poor weldability and are known to be difficult to weld. Physical properties for the more commonly used industrial metals are given in table 12. 1.

Applications:

High speed of operation, ease of mechanization, self-jigging of lap joints, absence of edge preparation, and filler metal are some of the attractive features of resistance spot welding. The process finds extensive use in welding of mild steel, stainless steels, heat-resisting alloys, aluminium, high nickel alloys, copper alloys, and reactive metals like titanium. Dissimilar metal combinations can also be welded.

Automobile and washing machine bodies, refrigerator shells, furniture, and similar other products are extensively welded by spot welding. Normally this process is used for work thickness of up to 3mm but steel plates up to 6 mm thick are occasionally welded, and in the rare application, the process is reported to have been used for plate thickness up to 22 mm.

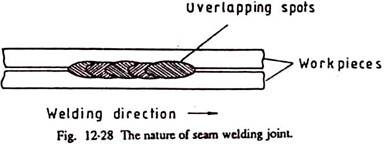

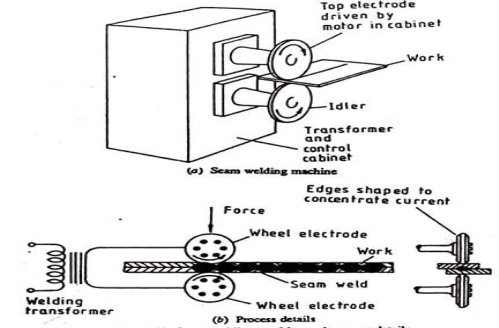

Seam Welding:Seam welding replaces spot welding for producing continuous leak-proof joints for use in sheet metal containers like petrol tanks for automobiles. In practice it is a continuous type of spot welding wherein spot welds overlap each other to the desired extent, as shown in Fig. 17. In seam welding the electrodes used are in the form of copper wheels or rollers, as shown in Fig. 18. One or both electrode wheels are powered.

Fig 17

Fig 18

The wheels may be aligned either in-line with the throat or transverse to it; when they are in line it is generally called a longitudinal seam welding machine. Welding current is supplied through the bearings of the wheel electrodes. The pressure is applied in the same way as in press type spot welding machines.

For producing a gas-tight seam the welds should overlap 15 to 20% of the nugget diameter while for maximum strength the overlap should be to the extent of 40 to 50 %. The size of the nugget will depend upon the weld time for a given welding speed, and current while the amount of overlap depends upon the off-time.

As the electrodes rotate, the work is moved between them, and the current is supplied in pulses during the weld time. The weld lime is adjusted to be long enough to produce a spot weld in the metal of given thickness with the desired overlap. Continuous rotation of electrodes may not be possible for difficult-to-weld metals like Nimonic alloys used in aero-engines. In such applications, the wheel electrodes are moved through a certain angle, and then stopped to effect a weld, and the process is repeated to make subsequent welds. This allows independent controls of weld time, and speed of electrode wheels.

In seam welding severe shunting of current takes place after the first weld is made; thus the welding current must be increased to maintain the size of the weld. With this limitation welds of the desired quality can be produced by this process.

Seam Welding Electrodes:

Seam welding electrodes are in wheel form, the diameter of the wheel is decided by the shape of the workpiece, and width by its thickness, and geometry.

Wheel electrodes of width 10 to 20 mm, and diameter 50 to 600 mm are generally used though diameter range of 175 to 300 mm is more common.

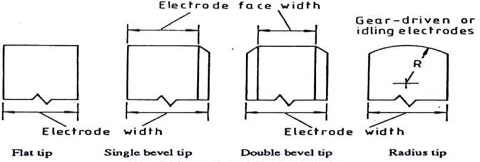

Desired wheel contours may be used to achieve the required seam weld but the standard ones are flat, single bevel, double-bevel, and radius faced as shown in Fig 12. 30. The contour selection is usually based on the welding current, pressure distribution required in the weld zone, and the drive mechanism employed.

Fig 19

Double-bevel type wheel electrodes are most popular as they can be easily restored to shape after use but the best weld appearance is obtained by radius-faced electrodes. Flat-faced electrodes are more difficult to set up as they require the workpieces to be completely parallel otherwise the contact will not be uniform.

Wheel electrodes are more difficult to cool internally than the rod type spot welding electrodes. These are, therefore, more often cooled externally. Flood, immersion, and mist cooling may be used, though the last one is quite messy. If external cooling is not adopted it may lead to excessive electrode wear and warpage of the work.

For low carbon steels, the coolant used is a solution of 5 % borax, while for welding stainless steels, and non-ferrous metals ordinary tap water is found satisfactory. When internal cooling is used it is affected by the use of refrigerants.

Joint Design:

Seam weld size depends upon the contact area between the wheel electrode, and the workpiece hence on the diameter of the electrode wheel, and the track width. Usually, the track width is 5Vt where t is the single sheet thickness in mm. When narrower welds are required, a track width of 2√t to 3 √t may be used which leads to higher welding speed and lower power requirements. Wheel wears quite fast, and that may result in the deformed track. It is, therefore, necessary to incorporate a device in the welding setup to correct the shape of the wheel edge continuously.

Seam weld joints are often similar to those for resistance spot weld joint Some of the more common seam weld joint designs are shown in Fig. 12,31.

Fig 20

Applications:

Seam welding is used for producing leak-proof joints in tanks, and boxes generally required for the automobile industry. This process is, however, restricted to welding thin materials ranging from 2. 5 to 5. 0 mm. Also, it is used mainly for welding metals with low hardenability rating, for example, hot-rolled grades of low alloy steels. The process is commonly used for making flange welds for use in watertight tanks.

Projection Welding:Projection welding is a resistance welding process of joining two sheets or a sheet, and a thick component, or a small component like a nut to a big body like automotive chassis, by making raised portions or projections on one of the components, where weld nugget is required to be made.

Thus projection welding is not confined to welding sheets, instead, any two surfaces which can be brought together, to give point or line contact, can be projection welded. The raised portions or projections act to localize the heat of the welding circuit.

The electrodes used are flat platens of hard material to cover the entire area of the work over which the projection welds are to be made in one go, as shown in Fig. 12. 36. Usually, two or three projections are welded at a time though in specially designed heavy machines 4 to 5 projections have been successfully welded at one time.

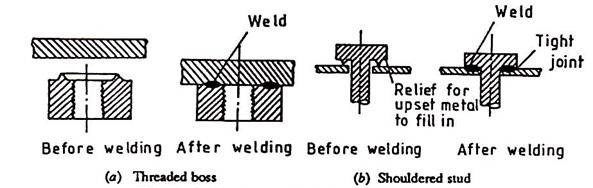

The projections are usually made by forging, embossing, or by intersection, and maybe a button or dome type, ring type, shoulder projection, cross wire welding, and radius projection.

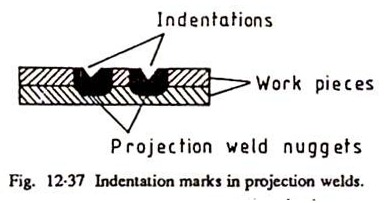

The weld cycle time for projection welding is the same as the spot weld time. The finished weld is similar to spot weld except that a small indentation is left by the projection as is shown in Fig. 12. 37. Projection welding reduces the amount of current, and pressure needed to weld two workpieces with consequential reduced shrinkage, and distortion around the weld nugget.

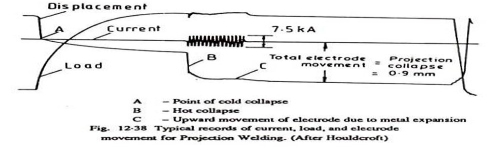

Fig 21

Major welding variables in projection welding include current, time, force, electrical resistivity, thermal conductivity, interfacial resistance, projection diameter, height, and shape, as well as strength at different temperatures of the metal being welded. Records of current, load, and electrode movement in projection welding of two 1. 6 mm thick mild steel sheets are shown in Fig. 12. 38.

Heat Balance:

Due to the collapse of projection during the welding operation, there is a tendency for the part containing projections to get hotter than the other part. That is why in projection welding dissimilar materials projections are made on material with higher thermal conductivity. As in spot welding, the nugget is formed closer to the electrode with low thermal conductivity. Thus heat balance can be achieved when required by manipulation of these factors.

Applications:

One of the attractive features of projection welding is that it gives longer electrode life, as the electrodes can be made of harder material with less wear, and maintenance. The outer surface of the work can be produced without any electrode marks thus eliminating subsequent processing before painting or polishing.

The process is not used for seams longer than 250 mm. It finds wide use in joining small attachments to sheet structures. It is used in the production of automobile bodies, domestic equipment, office furniture, and machine parts.

The maximum thickness ratio of the workpieces which can be welded by this process is 6 to 1. The process is generally used for section thickness ranging from 0. 5 to 4 mm.

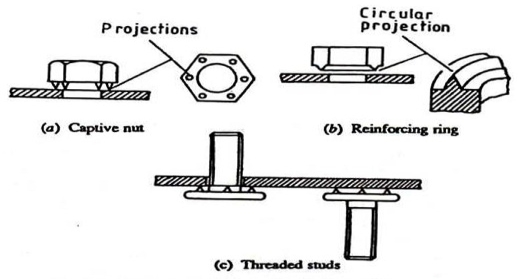

Fig 22

Specific applications include welding of captive nuts to chassis panels of automobiles, as shown in Fig.22. Reinforcing rings are often projection welded around holes in sheet metal tanks. Threaded studs can be welded to the backing bar or plate by this process, as is shown in Fig. 23.

Fig 23

Cross-wire welding is another important application of projection welding. Cross-wire products include such items as refrigerator racks, grills of all kinds, lampshade frames, wire baskets, fencing, grating, and concrete reinforcing mesh.

Projection welding can, however, be used for a small group of metals, and alloys. These include low carbon steels, high carbon, and low alloy steels, stainless, and high alloy steels, zinc die castings and titanium.

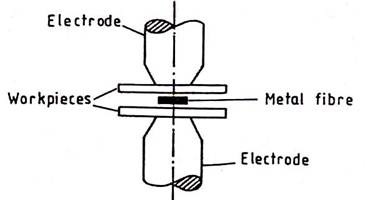

A variant of Projection Welding:

Metal fibre welding is a variant of the Projection Welding process in which use is made of metal fibre instead of projection points, as is shown in Fig. 24. This metal fibre may be composed of different metals, for example, brazing material. The metal fibre is generally a felt material that is produced from a small piece of filler material by pressing. It is then placed between the two workpieces to be projection welded in the usual manner.

Fig 24 metal fibre welding

The metal-fibre facilitates the joining of dissimilar metals by projection welding. For example, copper to stainless steel, stainless steel to other steels, and copper to brass can be easily welded by this process. However, metal fibre welding is more expensive than projection welding.

Key points

1) Resistance welding processes differ from other welding processes in that no fluxes are employed, the filler metal is rarely used, and the joints are often of the lap type.

2) The amount of heat generated in the workpiece depends on the magnitude of the current, the resistance of the current-conducting path, and the time for which the current is made to flow.

3) The heat generated is, thus, expressed by the formula:

H = IVt

= I (IR) t

= I2 Rt

where, H = heat generated, joules

I = current, rms amperes

R = resistance, ohms

t = time of current flow, seconds.

4. 6. 1 Atomic hydrogen welding

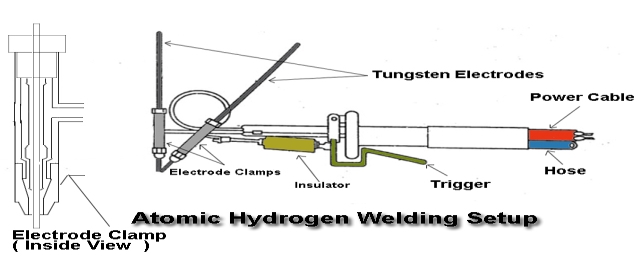

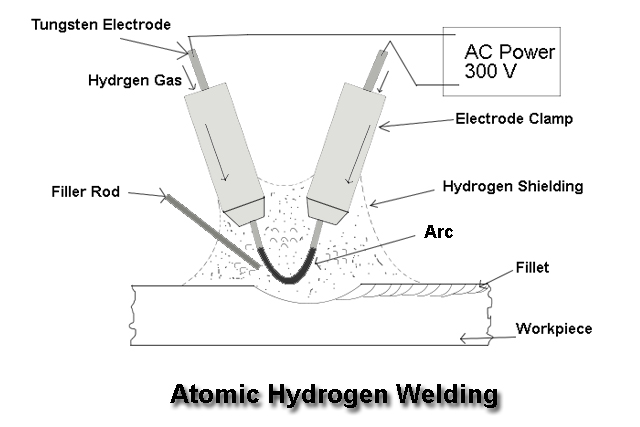

Atomic Hydrogen Welding (AHW ) thermo-chemical is a welding process in which welding is done using the arc produced between two tungsten electrodes, and hydrogen gas provided by a hydrogen gas cylinder. It is named atomic hydrogen welding because the arc disassociates the hydrogen into atomic form. This process is also known as atomic arc welding.

This welding process was invented by Irving Langmuir, an American Chemist, and Physicist at the beginning of the 20th century. A filler rod is optional in this welding process; it may or may not be used. In this welding process, a high temperature of 3400 to 4000°C is obtained by using an electric arc, and hydrogen gas. Tungsten and most of the refractory metal can be weld using the high temperature of this welding process. Hydrogen gas has two functions in this welding process, the first one is to provide a heating effect.

Also, the molten metal produced while welding is surrounded by a shield produced by hydrogen gas, and in this way, hydrogen gas acts as a shielding gas for the molten metal. Hydrogen gas has a very vital role in this welding process.

The main difference between the atomic hydrogen process welding, and welding processes like MMA welding, and TIG welding is that in the MMA, and TIG welding process the arc is formed between the electrode, and base metal while in the AHW the arc is formed between two electrodes.

Fig 25

Main parts of the tungsten electrode:

1) Tungsten Electrode:

In this welding process, the welding torch has two tungsten electrodes which are inclined, and adjusted to produce, and maintain a stable arc.

2) Electrode Holder:

Electrode Holders are used to holding the tungsten electrodes.

3) Nozzles:

Annular nozzles are present around the tungsten electrodes through which the hydrogen gas comes out supplied from the hydrogen gas cylinder.

4) Hydrogen Gas Cylinder:

A cylinder filled with hydrogen gas is used in this process to supply hydrogen gas at the required place in this welding process.

5) AC Power Supply:

A 300 V AC power supply machine with a controller is required in this process. This power supply will be used to create an arc between the tungsten electrodes.

AC is preferred over DC because equal heat is needed at both the electrodes.

7) Transformer:

A transformer is required to produce arc, and maintain it. The transformer should have an open-circuit voltage of 300 volts.

8) Filler Rod:

The filler rod is optional. It is used if it is needed otherwise this process can be done without a filler rod.

9) Pressure Regulator Valve:

A pressure regulator valve is present over the hydrogen gas cylinder. It is used to measure the pressure in the cylinder and display it. It is also connected to the electrode handle so that hydrogen gas reaches the required place.

10) Workpiece Plates:

The welding joint is created over these workpiece plates, and they are joined together.

Dirt, oxides, and other impurities are removed from the workpiece to obtain a good quality weld.

Fig 26

Working:

At first, when the AC power supply is powered, and the two electrodes are brought near to each other, an arc will be created between these two electrodes, and these electrodes are instantaneously separated by a small distance of nearly 1. 5 mm. The electrodes are separated slightly to maintain a stable arc between the electrodes. The heat produced by the arc can be controlled by varying the distance between the electrodes.

Also, the hydrogen gas will be supplied by the hydrogen gas cylinder to the electrodes. This hydrogen gas will provide shielding which will surround the arc produced by the electrodes. Hydrogen will be supplied from the cylinder and will come out from the nozzle present around the electrodes. This hydrogen gas will act as a shielding gas which means it will protect the welding joint from the atmospheric gases and will ensure the quality of the welding joint to be good.

If atmospheric gas like oxygen comes near the welding process it combines with hydrogen to form water, and quickly evaporates due to the heat of the welding process, and prevents the formation of metal oxide. Hydrogen shielding will also protect the welding joint from contamination by atmospheric gases like carbon, nitrogen, or oxygen.

Also, when the arc will come in contact with the jet of hydrogen gas, the hydrogen gas which is in the diatomic form will deionize into H+ single ions, and absorbs heat from the arc. Hydrogen gas gets deionized when it is placed at more than 6000o C near the arc. The amount of heat absorbed by the hydrogen atoms will be equal to the bond energy between the two hydrogen atoms when in diatomic form. The reaction shown below takes place when hydrogen deionizes.

H2 = H + H – 422 KJ (Endothermic Reaction )

When these deionized H+ ions will come near the workpiece and hit the surface of the base metal, they will cool down and will combine with other H+ ions. But when two H+ ions combine, suddenly a large amount of heat will be liberated which is denoted by the following reaction:

H + H = H2 + 422 KJ (Exothermic Reaction)

The heat liberated during the recombination of hydrogen atoms will be absorbed by the workpiece plates. Hence, metal will fuse due to which fusion joint is created between the metal plates or workpieces. Hence, a molten pool will be created between the workpieces. In this process, heat can be produced ranging from 3500oC to 4000oC.

The workpiece in this welding process is not completely part of the electrical circuit. The workpiece becomes part of the electrical circuit only when the portion of the arc comes in contact with the workpiece, and hence voltage is created between the workpiece, and each electrode.

Advantages of Atomic Hydrogen Welding:

1) Welding is faster in this welding process.

2) Since hydrogen itself act as shielding gas, separate shielding gas is not required.

3) There is very little distortion of the flame as the intense flame is obtained which can be concentrated at the joints.

4) The electrodes remain cool as the hydrogen gas flow by the electrodes in the holder which also increases the electrode's life.

5) The flow of hydrogen gas, and the arc can be easily controlled by the operator, and hence the heat produced can also be controlled. So, heat can be adjusted for welding different materials using this welding process.

6) Alloys can be melted without fluxes, and without surface oxidation due to the powerful reducing action of the atomic hydrogen.

Disadvantages of Atomic Hydrogen Welding:

1) This process is more costly as compared to other welding processes.

2) A skilled operator is required to operate this welding process.

3) Large quantities of metal cannot be deposited using this welding process.

4) This welding can be done in flat positions only.

5) This welding process is riskier as hydrogen is a highly inflammable gas.

Applications of Atomic Hydrogen Welding:

1) It is mainly used where rapid welding is required like in the case of stainless steel, and other special alloys.

2) It can be used for welding most of the ferrous, and non-ferrous metals.

3) It is also used for welding thin sheets of metal, and small diameter alloys.

4) This process is also used in repairing dies, and tools, hard surfacing, and joining parts.

5) It can also be used for very precision welding like correcting machining errors.

4. 6. 2 Submerged arc welding

It is used for faster welding jobs. It is possible to use larger welding electrodes (12 mm) as well as very high currents (4000 A) so that very high metal deposition rates of the order of 20 kg/h or more can be achieved with this process. Also, very high welding speeds (5 m/min) are possible in a saw. Some submerged arc welding machines can weld plates of thicknesses as high as 75 mm in butt joint in a single pass. Though it can weld very small thickness, of the order of 1 mm, it is very economical for larger welds only. Schematic illustration of the submerged-arc welding process, and equipment. The un-fused flux is recovered and reused.

Fig 27

The arc is produced in the same manner as in GMAW. The welding zone is completely covered by means of a large amount of granulated flux, which is delivered ahead of the welding electrode by means of a flux-feed tube. The arc between the electrode and the workpiece is completely submerged under the flux and is not visible from the outside. A part of the flux melts and forms the slag, which covers the weld metal. The unused flux can be recycled. The power source used with submerged arc welding can either be AC or DC. Both constant voltage and constant current type machines can effectively use though, for larger electrodes a constant-current type of power supply is used. The current ratings of the SAW machines are, in general, two to three times higher than those of the GMAW machines. Arc blow is not encountered with AC supply with a single wire SAW. But sometimes two wires may be used to deposit larger amounts of metal. These two electrodes being connected to two separate power sources, the arc blow is likely to occur because of the interference of the two magnetic fields surrounding the two electrodes, if the two currents are in phase. To avoid the setting of opposite magnetic fields, the two power supplies are adjusted in such a way that, one of the supply is in a peak, and the other is set to zero current. One of the electrodes is called leading, and the other is called trailing. In this way, the aforementioned problem is reduced. There is no spatter of the molten metal since the arc is completely submerged in the flux. Because of the usage of loose granulated flux to cover the joint, it is difficult to carry out in any position other than the flat or down-hand position. Also, because of the large metal pool generation in the SAW process, the out-of-position welds are difficult to carry out. The electrode wires normally used are of sizes 1. 6, 2, 2. 5, 3. 15, 4, 5, 6. 3, and 8mm. The wires should be smooth with no surface imperfections or contaminants. It is difficult to manually feed the wire into the joint because of the very high wire-feed rate. As the SAW process produces a large amount of molten weld metal, it takes sometimes for solidification. Hence, it is imperative in SAW to provide some way of containing this molten metal. Weld metal backing is normally used. The backing slaves can be with or without grooves, but in general, copper plates are used, which can easily be cooked with internal running water, when necessary. For thin plates, plain copper backing plates without any cooling water would be enough. Pure copper removes heat quickly from the molten weld pool because of its high thermal conductivity.

4. 6. 3 Electroslag

In electro slag welding weld metal is melted by electrical resistance heating, and then it is allowed to cool very slowly for solidification similar to that of casting.

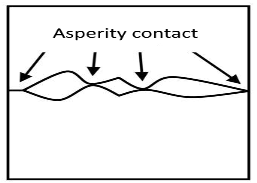

4. 6. 4 Friction welding

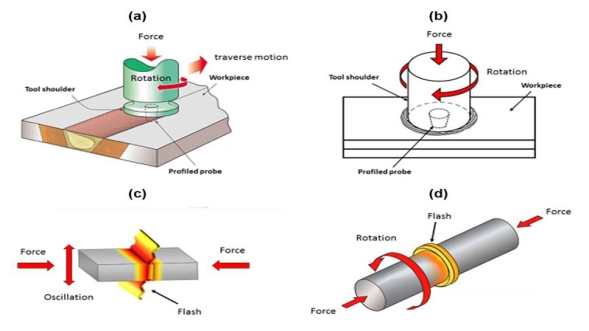

Friction welding is a solid-state joining technique that welds workpieces by generating heat through mechanical friction. In reality, a smooth surface consists of many microscopic projections, called asperities. When one surface moves relative to another these asperities interact, see Figure 1, generating friction – the force resisting motion between two or more interacting surfaces. Interaction of these asperities through elastic and plastic yielding generates heat. Friction welding utilizes this phenomenon for joining applications. The induced mechanical motion of friction welding generates heat, causing the materials to be joined to soften and become viscous. While in the softened state, the mechanical motion of the process mixes the materials to create a bond. The way by which the frictional heat and material mixing occur is very dependent on the friction welding process utilized, of which there are four primary processes: Friction stir welding (FSW), friction stir spot welding (FSSW), linear friction welding (LFW), and rotary friction welding (RFW).

Figure 28 – Asperity interaction

FSW and FSSW utilize a dedicated tool to generate the frictional heat and mechanical mixing. FSW works by using a non-consumable tool, which is rotated, and plunged into the interface of two workpieces. The tool is then moved through the interface, and the frictional heat causes the material to heat, and soften. The rotating tool then mechanically mixes the softened material to produce a bond; see Figure 29(a). FSSW is a variant of FSW and works by rotating, plunging, and retracting a non-consumable tool into two workpieces in a lap-joint configuration to make a “spot” weld. During FSSW there is no traversing of the tool through the workpieces; see Figure 29(b).

LFW and RFW do not require a non-consumable tool, i. e. the individual workpieces to be joined are used to generate the frictional heat and mechanical mixing. LFW works by linearly oscillating one workpiece relative to another while under a compressive force. The friction between the oscillating surfaces produces heat, causing the interface material to soften, and mechanically mix; see Figure 29(c). RFW is similar to LFW except that the workpieces are often round, and are rotated relative to each other; see Figure 29(d). During LFW, and RFW the workpieces typically shorten (“burn-off”) in the direction of the compressive force, forming the flash. During the burn-off interface contaminants, such as oxides, and foreign particles, are expelled into the flash. Once free from contaminants, pure metal to metal mixing occurs, resulting in an integral bond. Although the generated temperatures during friction welding are very hot, the material remains in a solid-state condition (i. e. no melting occurs).

Figure 29 – A process schematic of: (a) FSW, (b) FSSW, (c) LFW, and (d) RFW

Friction welding offers many advantages to the manufacturing sector, including:

4.7 Soldering & Brazing

4. 7. 1 Soldering

Soldering is a process of joining two metals by using another low-temperature metal alloy. The metal used for the joining purpose is called solder. Solders are of two types:

Hard solder is an alloy of copper, and zinc whereas soft solder is an alloy of tin, and lead.

Process

The surfaces to be joined are cleaned, and are placed on each other. A flux is employed to prevent oxidation. Zinc chloride is commonly used for this purpose. The soldering iron is heated either electrically or by some external heat. Then the heart, and is dipped into the flux, and solder is pressed against the surfaces to be joined. A joint is formed by melting the solder.

Applications

Soldering is widely used for sheet metal work, and in radio, and television work for joining wires.

Advantages

Disadvantages

Difference between soldering, and brazing

SR. No. | Brazing | Soldering |

1 | Filler metal has the melting point above 400°c | Filler metal has the melting point below 400°c |

2 | More stable joints can be made | Less stable joints can be made |

3 | High pressure, and temperature do not affect the joint | Joints are affected by high temperature, and pressure |

4 | Equipment cost is more | Equipment cost is very low. |

4. 7. 2 Brazing

The process of joining two metal surfaces by heating, and adding a non-ferrous alloy with a melting point above 400-degree Celsius is known as brazing.

Process

The surfaces to be joined are cleaned from all oil, dirt oxides. Then both the surfaces are placed in the joining position. Flux is sprinkled or placed on it. The heat is given to the surface and the filler metal. The molten filler metal flows to the surfaces to be joined. On cooling, a brazing joint is formed. The filler metals used are copper, copper alloy, silver alloy, and Aluminium alloys. In brazing, the filler metal melts but the surfaces to be joined remain unmelted. The various methods used to melt the filler metal, and flux are:

Applications

Brazing is used for electrical items, radiators, heat exchangers comma pipes, and pipe fittings, and tooltips.

Advantages

Disadvantages

Key points

1) Soldering is a process of joining two metals by using another low-temperature metal alloy. The metal used for the joining purpose is called solder.

2) The process of joining two metal surfaces by heating, and adding a non-ferrous alloy with a melting point above 400-degree Celsius is known as brazing

Adhesive Bonding is the process of joining two surfaces together, usually with the creation of a smooth bond. This may involve the use of glue, epoxy, or one of a wide range of plastic agents that bond either through the evaporation of a solvent or through curing via heat, time, or pressure. Glues have tended to create relatively weak joins but with the use of new self-curing adhesives, these bonds are now close to the strength of the materials themselves. As a result, gluing is now the preferred method of joining for many applications, particularly when the bond is not exposed to prolonged heat or weathering. Many modern types of glue are carbon-based petrochemical derivatives, which can be used for a variety of joining applications including bonding metal, and dissimilar materials. This type of adhesive uses either direct contact or a third surface, such as an adhesive tape, to create the bond. Among the composite applications that are commonly bonded using adhesives are fiberglass, and fiber-epoxies like boron-epoxy, and carbon-epoxy. Due to their shear strength, and toughness, modern adhesives can also serve to join structural materials, of which plywood is a common, and well-known example.

What are the Advantages of Adhesive Bonding?

One of the main advantages of adhesive bonding is that it allows for the even distribution of stress loads, thereby reducing the stress on the joint. Since they are applied inside the joint, adhesives are also invisible within the assembly. The properties of glues mean that they can form both an adhesive, and sealant at the same time, while also resisting vibration and flexing stresses. The ability to act as a seal allows adhesives to help protect a joint from corrosion.

While adhesive bonding can be applied to metal-to-metal, plastic, glass, rubber, ceramic, and many other material combinations, the process can be used to join irregularly shaped surfaces while offering virtually no change in the dimensions or geometry of the parts. Adhesives also add very little by way of weight to the materials being joined and can be used to quickly bond dissimilar substrates, and heat-sensitive materials.

One of the greatest advantages of adhesive bonding is the versatility it affords, allowing for the joining of a wide range of items as well as being easy to automate.

What are the Disadvantages of Adhesive Bonding?

There are, however, several limitations to using adhesives. Firstly, they are prone to failure when exposed to high heat or weathering. Adhesives can also take time to fully fix, and acquire full strength. They also often require surface preparation treatments including cleaning the surface of the materials to be joined. Other surface treatments associated with adhesives include abrasion to create a stronger bond. Adhesives can also cause problems related to disassembly when compared to other, less permanent joining techniques.

Where is Adhesive Bonding Used?

Adhesive bonding is used across many industries including automotive, aerospace, medical, and even textiles. Due to the versatility of this process for a range of material types the only real limitations arise with use, such as for outdoor applications that need to withstand weathering.

Adhesive Bonding Services

TWI has been at the forefront of adhesives, and sealants technology for decades, and is now respected internationally as a world leader in both areas.

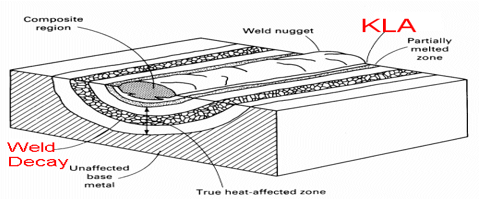

Weld decay is a form of intergranular corrosion, usually of stainless steels or certain nickel-base alloys that occurs as the result of sensitization in the heat-affected zone during the welding operation.

The corrosive attack is restricted to the heat-affected zone (HAZ). Identification of this type of corrosion usually requires microstructure examination under microscopy although sometimes it is possible to visually recognize weld decay if parallel lines are already formed in the heat-affected zone along the weld (see photo below).

Fig 30 Mechanisms of Weld Decay

What causes weld decay? As in the case of intergranular corrosion, grain boundary precipitation, notably chromium carbides in stainless steels, is a well-recognized, and accepted mechanism of weld decay. In this case, the precipitation of chromium carbides is induced by the welding operation when the heat-affected zone (HAZ) experiences a particular temperature range (550oC~850oC). The precipitation of chromium carbides consumed the alloying element - chromium from a narrow band along the grain boundary, and this makes the zone anodic to the unaffected grains. The chromium depleted zone becomes the preferential path for corrosion attack or cracks propagation if under tensile stress

Prevention of Weld Decay

Weld decay can be prevented through:

References:

1. Kalpakjian and Schmid, Manufacturing processes for engineering materials (5th Edition)-Pearson India, 2014.

2. Mikell P. Groover, Fundamentals of Modern Manufacturing: Materials, Processes, and Systems.

3. Manufacturing Technology by P.N. Rao., MCGRAW HILL INDIA.

4. Materials and Manufacturing by Paul Degarmo.

5. Manufacturing Processes by Kaushish, PHI.

6. Principles of Foundry Technology, Jain, MCGRAW HILL INDIA

7. Production Technology by RK Jain.

8. Degarmo, Black &Kohser, Materials and Processes in Manufacturing.