Unit – 5

Refrigeration System Equipment

Air compressors are machines with very low overall efficiency; only 10-30% of the energy supplied to the compressors reaches the point of end use.

The remaining power is converted to unusable heat energy, and to a smaller extent, is lost in friction, misuse, and noise. These factors need to be identified and minimized for optimum performance.

Air compressors are used in a variety of industries for the following purposes:

- Operating machinery like hammers, presses.

- Supplying process requirements.

- Supplying air at high pressure for chemical action

- Heat exchangers are used to transfer heat. Some process like heating, cooling, condensation, boiling or evaporation.

- Different heat exchangers are named according to their application.

- For example, heat exchanger used for boiling purposes are called boilers, heat exchanger being used to condense are known as condensers.

- The condenser is a heat exchanger that usually rejects all the heat from the system.

- The condenser accepts all the hot, high-pressure refrigerant usually a super-heated gas, from the compressor.

- The condenser is usually air cooled by natural or forced convection to increase the cooling effect of the condenser.

Function:

- The purpose of the condenser in the refrigeration system is to remove heat from the refrigerant vapor leaving the compressor (or generator in case of absorption system) so that the refrigerant will condense to its liquid state.

- This liquid refrigerant will then be able to achieve the refrigerating effect in the evaporator.

Working of a Condenser:

In a typical refrigerant condenser, the refrigerant enters the condenser in a superheated state. It is first de- superheated and then condensed by rejecting heat to an external medium. The refrigerant may leave the condenser as a saturated or a sub- cooled liquid, depending upon the temperature of the external medium and design of the condenser.

Key Takeaways:

- The remaining power is converted to unusable heat energy, and to a smaller extent, is lost in friction, misuse, and noise.

- Different heat exchangers are named according to their application.

- The condenser accepts all the hot, high-pressure refrigerant usually a super-heated gas, from the compressor.

- It is first de- superheated and then condensed by rejecting heat to an external medium.

Evaporator:

- An evaporator is a device in a process used to turn the liquid form of a chemical substance such as water into its gaseous-form/vapor. The liquid is evaporated, or vaporized, into a gas form of the targeted substance in that process.

Function of evaporator:

- The evaporator works the opposite of the condenser, here refrigerant liquid is converted to gas, absorbing heat from the air in the compartment. When the liquid refrigerant reaches the evaporator, its pressure has been reduced, dissipating its heat content and making it much cooler than the fan air flowing around it.

Expansion device:

An expansion device in a refrigeration system normally serves two purposes:

1. The thermodynamic faction of expanding the liquid refrigerant from condenser pressure to evaporator pressure.

2. The control functions which may involve the supply of liquid to the evaporator at the rate at which it is evaporated. This determines the efficiency with which evaporator surface is utilized.

An expansion device is essentially a restriction offering resistance to flow so that pressure drops, resulting in throttling process.

Types of Expansion Devices:

I. Variable flow type

- Automatic expansion valve

- Thermostatic expansion valve

II. Constant flow types

- Capillary tubes

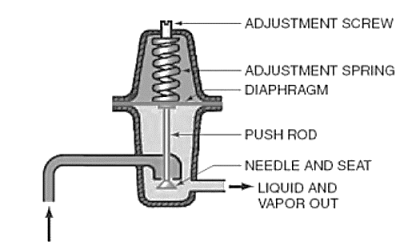

Automatic Expansion Valve (AEV): -

- The automatic expansion valve modulates the flow of the refrigerant into the evaporator to keep the evaporator pressure constant.

- Unlike the capillary tube, which cannot adjust the flow of refrigerant, the automatic expansion valve opens and closes to either increase or decrease the amount of refrigerant feeding into the evaporator in response to the pressure of the refrigerant in the evaporator.

- The valve operates on a “needled and seat” mechanism that changes the amount of refrigerant that is able to pass through the valve.

- The position of the needle is determined by the difference between two pressures:

I. The spring pressures

II. The evaporator pressure.

- The spring pressure is the pressure that opens the valve. This pressure is adjustable and is set at the desired evaporator pressure.

- The higher the spring pressure, the higher the evaporator pressure will need to be for refrigerant to flow.

Key Takeaways:

- The liquid is evaporated, or vaporized, into a gas form of the targeted substance in that process.

- An expansion device is essentially a restriction offering resistance to flow so that pressure drops, resulting in throttling process.

- The automatic expansion valve modulates the flow of the refrigerant into the evaporator to keep the evaporator pressure constant.

- The higher the spring pressure, the higher the evaporator pressure will need to be for refrigerant to flow.

The Propeller Fan:

- The propeller fan is used in exhaust-fan and condenser- fan applications.

- It will handle large volumes of air at low pressure differentials.

- The propeller fan can be cast iron, aluminum or stamped steel and is set into a housing called a venturi to encourage airflow in a straight line from one side of the fan to the other (Figure above).

- The propeller fan makes more noise than the centrifugal fan so it is normally used where noise is not a factor.

The Centrifugal Fan:

- The centrifugal fan has characteristics that make it desirable for duct work.

- It builds more pressure from the inlet to the outlet and moves more air against more pressure.

- This fan has a forward curved blade and a cutoff to shear the air spinning around the fan wheel (Figure above).

- The centrifugal fan is very quiet when properly applied.

Axial Fan:

- The axial-flow fans have blades that force air to move parallel to the shaft about which the blades rotate.

- Axial fans blow air along the axis of the fan, linearly, hence their name.

- This type of fan is used in a wide variety of applications, ranging from small cooling fans for electronics to the giant fans used in wind tunnels

- Axial flow fans are applied for air conditioning and industrial process applications.

- Standard axial flow fans have diameters from 300-400 mm or 1800 to 2000 mm and work under pressures up to 800 Pa.

Key Takeaways:

- The propeller fan makes more noise than the centrifugal fan so it is normally used where noise is not a factor.

- The centrifugal fan is very quiet when properly applied.

- Standard axial flow fans have diameters from 300-400 mm or 1800 to 2000 mm and work under pressures up to 800 Pa.

- Food Preservation is the process of treating and handling food to stop or slow down food spoilage, loss of quality, edibility, or nutritional value and thus allow for longer food storage.

- Preservation usually involves preventing the growth of bacteria, fungi. This means that the food treated that way will go bad (spoil from bacteria) later that if it had not been treated that way. For thousands of years, humans have used methods of preserving food, so that they can store food to eat later.

Advantages:

- Food preservation prevents the food from being spoiled by the action of enzymes and microorganisms.

- Food preservation increases the safe storage period of foodstuffs.

- It increases the availability of out of season foodstuffs.

- It increases the availability of various foodstuffs even at distant and not easily approachable places.

Key Takeaways:

- Preservation usually involves preventing the growth of bacteria, fungi.

- For thousands of years, humans have used methods of preserving food, so that they can store food to eat later.

- Food preservation prevents the food from being spoiled by the action of enzymes and microorganisms.

Transport refrigeration is one of the maximum tough refrigeration packages, and consequently shipping refrigeration structures require additives able to addressing a variety of vital parameters, such as:

Wide ranging and fluctuating temperatures requiring advanced reaction and control

Harsh environments requiring corrosion resistance Constant shocks and vibrations requiring excessive balance and reliability Space constraints requiring compact additives

Fuel performance requiring light-weight aspect materials

Within the Deafness shipping refrigeration parts, you may discover merchandise optimized for an extensive style of shipping packages, inclusive of fridge answers for trucks, trailers, vans, reefer containers, and bus & teach zircon that meet those requirements.

Deafness shipping refrigeration gadget are appropriate to be used with all not unusual place refrigerants and had been tailored to be used with herbal refrigerants.

Transportation refrigeration packages are being released with CO2 as an herbal refrigerant-primarily based totally solution, wherein Deafness as a shipping refrigeration element producer has a complete product imparting available.

Furthermore, we are able to provide answers with low noise degrees whilst allowing low operation and renovation costs.

Features and benefits

- Products appropriate to be used with all not unusual place refrigerants, inclusive of herbal refrigerants

- Superior temperature control

- High strength performance

- Reliable answers, low operation and renovation costs

- Stainless metallic additives for better performance, durability, and reliability Compact, light-weight additives

Transport Refrigeration Units (TRU) are refrigeration structures powered through diesel inner combustion engines designed to refrigerate or warmth perishable merchandise which can be transported in diverse boxes, along with semi-trailers, truck vans, transport boxes and rail cars.

Although TRU engines are pretty small, starting from 9 to 36 HP, sizeable numbers of those engines congregate at distribution centers, truck stops and different facilities, ensuing with inside the capacity for fitness dangers to those who stay and paintings nearby.

Since diesel particulate depend has been diagnosed as a poisonous air contaminant, the California Air Resources Board (CARB) followed an Airborne Toxic Control Measure (ATCM) for TRUs and TRU generator units on Feb. 26, 2004.

More records approximately this rulemaking is at: 2004 TRU ATCM Rulemaking. Key terms: shipping refrigeration unit, TRU genet, reefer, refrigerated truck, refrigerated trailer, refrigerated railcar, refrigerated transport container.

The motive of CARB law is to apply a phased method over approximately 15 years to lessen the diesel particulate depend emissions from in-use TRU engines that perform in California.

Those affected are proprietors and operators of in-use diesel fueled TRUs that perform in California, no matter whether or not they're registered in or out of doors of the state, along with all companies that shipping perishable items the use of diesel-powered refrigeration structures on trucks, semi-trailers, transport boxes and railcars that perform in California.

The primary necessities ought to meet in-use overall performance requirements that had been phased in and commenced Dec. 31, 2008.

Key Takeaways:

- Wide ranging and fluctuating temperatures requiring advanced reaction and control

- Fuel performance requiring light-weight aspect materials

- Deafness shipping refrigeration gadget are appropriate to be used with all not unusual place refrigerants and had been tailored to be used with herbal refrigerants.

- Products appropriate to be used with all not unusual place refrigerants, inclusive of herbal refrigerants

- Key terms: shipping refrigeration unit, TRU genet, reefer, refrigerated truck, refrigerated trailer, refrigerated railcar, refrigerated transport container.

- Cold storage is a typical room with low temperature, we can maintain temperature with refrigeration and air conditioning techniques. The walls and floors of the cold storage room are insulated with low thermal conductivity materials.

- In the absence of cold storage, the people want to sell there as soon after manufacturer it may affect their pricing. By cooling technologies, we may extend the life of products and slower their deterioration, beverages taste good when they are cooled.

- The cold storage system is essential for extending the life of products and helps to maintain product quality. It also helps to reduce the wastage of commodities.

- Control Atmosphere and cold Storage:

- These kinds of cold storage systems used for long-term storage of fruits. Because the fruits need to the proper temperature, a concentration of oxygen, carbon dioxide, ethylene etc. it gets varied based upon the storage products.

- These kinds of cold storage systems are used to store the dry fruits and grains, in this, the temperature is predetermined throughout the room.

Key Takeaways:

- The walls and floors of the cold storage room are insulated with low thermal conductivity materials.

- By cooling technologies, we may extend the life of products and slower their deterioration, beverages taste good when they are cooled.

- A refrigerator (colloquially fridge) is a popular household appliance that consists of a thermally insulated compartment and a heat pump (mechanical, electronic or chemical) that transfers heat from the inside of the fridge to its external environment so that the inside of the fridge is cooled to a temperature below the ambient temperature of the room.

- Refrigeration is an essential food storage technique in developed countries.

- The lower temperature lowers the reproduction rate of bacteria, so the refrigerator reduces the rate of spoilage.

- A refrigerator maintains a temperature a few degrees above the freezing point of water. Optimum temperature range for perishable food storage is 3 to 5 °C (37 to 41 °F).

- A similar device that maintains a temperature below the freezing point of water is called a freezer.

- The refrigerator replaced the icebox, which had been a common household appliance for almost a century and a half. For this reason, a refrigerator is sometimes referred to as an icebox in American usage.

- The Basic Components of a Freezer:

The components of a freezer are as follows:

- A compressor

- A condenser

- An evaporator

- A capillary tube

- A thermostat

- The refrigerant begins the cooling process as a vapor under low pressure. The compressor squeezes the vapor's particles, which heats it up and converts it into a high-pressure state.

- As the vapor travels through the condenser coils, it loses the heat but retains its high pressure.

- Vapor compression isn't the only way to create a super-cold food storage environment.

Key Takeaways:

- Refrigeration is an essential food storage technique in developed countries.

- A similar device that maintains a temperature below the freezing point of water is called a freezer.

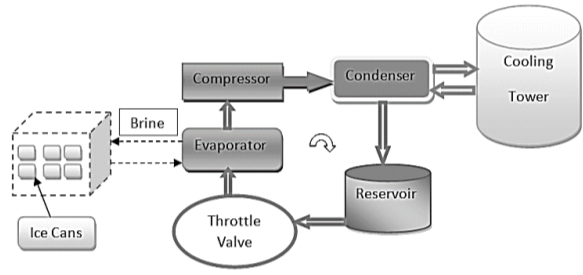

Plant Layout:

- Air Cooled or Water Cooled or with Evaporative Condensers

- Any Environment-compatible Refrigerant (ammonia or halocarbons)

- Standard Ice Cans Square or Rectangular for 25 kg or 50 kg Blocks.

Requirements:

- Suitable Location

- Land

- Structural construction of ice plant

- Utilities

- Machineries

- Management

- Labour

- Clients

Fig. Ice plant

Water cooling system is used for cooling the engine when the temperature of engine is high by using fresh water after boiling of sea water.

Advantages:

1. To cool down the engine.

2. Low-cost maintenance.

Disadvantages:

1. The engine cannot work properly if the engine is too cold.

2. By using seawater, it will leave the deposit and metal corrode easily.

- Comfort air conditioning: - Aim at giving max human comfort to occupants/users of conditioned space.

- Applications of Air-Conditioning to provide Comfort Air-Conditioning: - It is meant for human comfort. It provides comfortable & healthy conditions for the occupants in residences, theaters, hospitals, offices, railway coaches.

- Industrial air conditioning: - The conditioning creates, controls and maintains such an environment inside the conditioned space that it would suit best to the needs of industry.

- Applications of Air-Conditioning to provide Industrial Air-Conditioning: - It is used for improving the quality of the manufactured materials. It increases the working efficiency of the employees in the factories.

Key Takeaways:

- Air Cooled or Water Cooled or with Evaporative Condensers

- Water cooling system is used for cooling the engine when the temperature of engine is high by using fresh water after boiling of sea water.

- It provides comfortable & healthy conditions for the occupants in residences, theaters, hospitals, offices, railway coaches.

- Such strategies are primarily based totally solidly in engineering thermodynamics and depend basically on a mixture of approaches which make up a cycle. A cycle includes a closed circuit in which the running fluid, for instance helium, is compressed, expanded, and warmth exchanged in such a manner as to attain cooling.

- However, actual refrigeration and liquefaction structures are made up of comparable approaches which might be normally as compared of their overall performance to that of the suitable Carnot cycle.

- In all fuelling refrigeration structures, the cooling is accomplished with the aid of using a growth method. There are basically styles of growth which might be applied. Isentropic growth is that in which the fluid does paintings and expands preserving its entropy constant (LIS= 0). This is the best approach of growth as it produces the most important temperature extrude over a given strain extrude.

- The different growth method is isenthalpic growth, in which the fluid undergoes a strain extrude without heat transfer (.dQ = 0). This approach is in not unusual place software in practical refrigeration structures for its ease of use. However, it's far of decrease thermodynamic performance due to the fact it's far an irreversible method main to no idealities.

- The thermodynamic obstacles of the liquefaction manner may be verified excellent with the aid of using attention of an excellent system, that is, a refrigeration cycle that plays at Cabot performance and therefore includes reversible isothermal and isentropic processes.

- Consider a Cabot fridge generating cooling in a low-temperature reservoir. Furthermore, not like the dialogue with inside the preceding section, expect that the fridge includes a huge wide variety of cycles working over small temperature differences.

- The best Cabot fridge achieves a positive quantity of cooling at T c with the aid of using appearing a non-stop manner.

- Two of the maximum not unusual place phrases utilized in cryogenics are “fridge” and “liquefier.” These phrases describe comparable and, as can be seen, in a few instances equal components.

- A fridge presents cooling (this is, absorbs warmth) at cryogenic temperatures. Refrigerators generally placed an operating fluid (which include helium) via certainly considered one among a whole lot of thermodynamic cycles (e.g., Collins, Braydon, Claude, Sterling) to offer the cooling.

- There are some of approaches to categorize fridges. Refrigerators may also use regenerative warmth exchangers or recuperative warmth exchangers (see Cold Facts October 2014).

- Lastly, there are specialized fridges which include adiabatic demagnetization fridges (see Cold Facts Spring 2011) that offer cooling without the usage of an operating fluid.

- Despite the form of fridges to be had, one function they've in not unusual place is that they're closed cycle devices: All of the operating fluid is retained with inside the machine.

- Refrigerators may also create liquid cryogens as a part of the process, however the liquid or its related vapor stays with inside the refrigeration machine. Liquefiers use comparable cycles, operating fluids and system as fridges.

- While liquefier cycles are optimized to provide liquid cryogens, the foremost difference is that liquefiers are open cycle devices. They produce a cryogenic liquid this is then eliminated from the machine and used elsewhere.

- Having made the difference among fridges and liquefiers, it’s really well worth stating that big current cryogenic flowers are regularly designed to function as each fridges and liquefiers simultaneously. It is quite greater suitable to speak approximately liquefaction masses and refrigeration masses.

- An instance of that is given with inside the accelerator cropland presently beneath layout for the European Spallation Source (ESS). This plant will offer up to a few kW of refrigeration at 2K and eleven kW of refrigeration at 40K.

- In addition, however, it will also produce as much as nine g/s of liquid helium in order to be used to chill the radio frequency electricity couplers with inside the accelerator.

- The fuelling from this helium returns to the plant at 300K and represents a liquefaction load. Other structures which have each large refrigeration and liquefaction masses encompass the ARIEL e-lilac cropland at TRIUMF, the W7X Stellated fridge and the ESS Test and Instruments cropland.

- These centers are every so often known as croplands in popularity in their blended refrigeration and liquefaction capabilities.

Key Takeaways:

- A cycle includes a closed circuit in which the running fluid, for instance helium, is compressed, expanded, and warmth exchanged in such a manner as to attain cooling.

- This is the best approach of growth as it produces the most important temperature extrude over a given strain extrude.

- Consider a Cabot fridge generating cooling in a low-temperature reservoir.

- Despite the form of fridges to be had, one function they've in not unusual place is that they're closed cycle devices: All of the operating fluid is retained with inside the machine.

Thermoelectric refrigeration is the manner of pumping warmth electricity out of an insulated chamber on the way to lessen the temperature of the chamber under that of the encircling air. Thermoelectric refrigeration makes use of a precept referred to as the "PELTIER" impact to pump warmth electronically. The Peltier impact is known as after a French scientist who determined it in 1834.

Special order heater ONLY variations of our insulated bins are utilized by Meals on Wheels, different senior warm meal packages, college warm meal packages and via way of means of caterers all throughout the country.

Safety: No open flames, propane, or poisonous refrigerants used.

Reliability: Thermoelectric have a forty 12 months confirmed song file in military, aerospace, laboratory, and now customer packages.

Low upkeep: The best upkeep required with any Kolton unit is periodic "dusting" and Vacuuming to make sure precise warmth dissipation.

COOLING TECHNOLOGY COMPARISON THERMOELECTRIC:

Cooling is done electronically the usage of the "Peltier" impact - warmth is pumped with electric electricity.

COMPRESSOR: Cooling is done via way of means of vaporizing a refrigerant (including Freon) in the fridge - warmth is absorbed via way of means of the refrigerant thru the precept of the "latent warmth of vaporization" and launched out of doors the fridge in which the vapor is condensed and compressed right into a liquid again. Uses mechanical electricity.

In 1834 Jean Peltier mentioned that after an electrical present day is implemented throughout the junction of diverse metals, warmth is eliminated from one of the metals and transferred to the different.

This is the premise of thermoelectric refrigeration. Thermoelectric modules are created from a chain of tiny metallic cubes of diverse distinctive metals which can be bodily bonded collectively and linked electrically.

When electric present day passes thru the dice junctions, warmth is transferred from one metallic to the different. Solid-country thermoelectric modules are able to moving massive portions of warmth while linked to a warmth soaking up tool on one aspect and a warmth dissipating tool at the different.

The Kolton’s inner aluminum bloodless plate fins soak up warmth from the contents, (meals and beverages), and the thermoelectric modules switch it to warmth dissipating fins beneath the manage panel.

Here, a small fan enables to disperse the warmth into the air. The gadget is absolutely environmentally pleasant and includes no dangerous gases, nor pipes nor coils and no compressor.

The best shifting element is the small 12-volt fan. Thermoelectric modules are too high-priced for regular home and business packages which run best on ordinary family present day.

They are perfectly suited to leisure packages due to the fact they may be lightweight, compact, and insensitive to movement or tilting, haven't any shifting elements, and may perform without delay from 12-volt batteries.

Applications the usage of thermoelectric coolers

- Commercially to be had TE coolers are utilized in packages in which layout standards of the cooling machine encompass elements which includes excessive reliability, low weight, small size, intrinsic protection for dangerous electric environments and correct temperature control.

- TE coolers are greater suitable for precise packages which includes area missions, scientific and clinical system in which low COP isn't always an obvious disadvantage. TE cooling gadgets are used for cooling small volumes, which includes transportable and home refrigerator, transportable icebox and beverage can cooler in which the cooling necessities aren't too excessive.

- In general, the COP for each home and transportable thermoelectric fridges is normally much less than 0.5, whilst working at an inside/outdoor temperature distinction among 20 and 25°C.

- Electronic gadgets like PC processors produce very massive quantity of warmth for the duration of their operation which upload top notch assignment to the thermal control as dependable operation temperature for those digital gadgets must be maintained.

- TE cooling gadgets have additionally been carried out to clinical and laboratory system cooling for laser diodes and incorporated circuit chips to lessen the thermal noise and the leakage modern of the digital additives in which traditional passive cooling technology can't completely meet the warmth dissipation necessities.

- For example, cooling CdZnTe detectors for X-ray astronomy among 30 and 40°C can lessen the leakage modern of the detectors and lets in the usage of pulsed reset preamplifiers and lengthy pulse shaping times, which extensively improves their electricity resolution. Integrating skinny movie TE coolers with microelectronic circuits has been carried out the usage of micromachining technology.

Key Takeaways:

- Safety: No open flames, propane, or poisonous refrigerants used.

- Low upkeep: The best upkeep required with any Kolton unit is periodic "dusting" and Vacuuming to make sure precise warmth dissipation.

- Uses mechanical electricity.

- The gadget is absolutely environmentally pleasant and includes no dangerous gases, nor pipes nor coils and no compressor.

- Integrating skinny movie TE coolers with microelectronic circuits has been carried out the usage of micromachining technology.

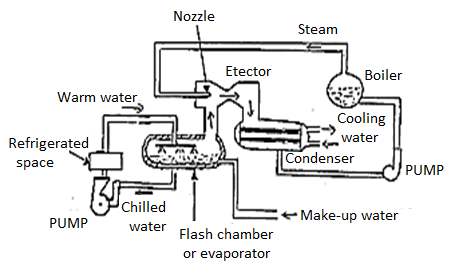

Steam jet or Ejector refrigeration machine makes use of water as refrigerant. It makes use of the simple precept of boiling of liquid at decrease temperature through lowering stress on its surface.

This machine employs a steam ejector or booster in preference to mechanical compressor. The foremost additives as proven in determine are flash chamber or evaporator, steam nozzles, ejector and condenser.

The flash chamber is closely insulated and is outfitted with perforated pipes which spray heat water popping out of refrigerated space. Some of this water is transformed into vapors after soaking up latent warmth from the relaxation of the water, thereby cooling it.

Loss of water via vapors is made up from makeup water line. High stress steam from boiler is surpassed via steam nozzle thereby growing its velocity. This entrains water vapors from flash chamber and outcomes in similarly formation of vapors.

The aggregate of steam and water vapor passes via venture-tube of ejector and receives compressed. This results in upward push in temperature and stress of the aggregate after which it's far fed to the water cooled condenser. The condensate is once more fed to boiler as feed water.

Steam jet refrigeration machine is extensively utilized in paper mills, breweries, meals processing flowers, fuelling flowers etc. Since water is the refrigerant, it cannot be used for programs beneath 0°C.

Advantages of steam jet refrigeration system

- Steam jet refrigeration device used wherein there's no electricity.

- This is basically used wherein steam is especially to be had like. Commercial areas, electricity vegetation etc.

- This is non-inflammable.

- This may be cooled immediately with none excessive cooling systems.

- This has much less maintenance.

- This has no vibrations.

- Construction of this device is easy.

- Cost of jogging is much less.

Disadvantages of steam jet refrigeration system:

- In condenser it required

- Motive steam and ejector vapor to be condensed.

- It required excessive vacuum with inside the evaporator.

- It has low coefficient of pressure.

- If there's beneath four diploma c this device isn't always useful.

- In this air leakage may also arise into the device.

- This cannot be labored below zero ranges c.

Key Takeaways:

- It makes use of the simple precept of boiling of liquid at decrease temperature through lowering stress on its surface.

- Some of this water is transformed into vapors after soaking up latent warmth from the relaxation of the water, thereby cooling it.

- This entrains water vapors from flash chamber and outcomes in similarly formation of vapors.

- Cost of jogging is much less.

- It has low coefficient of pressure.

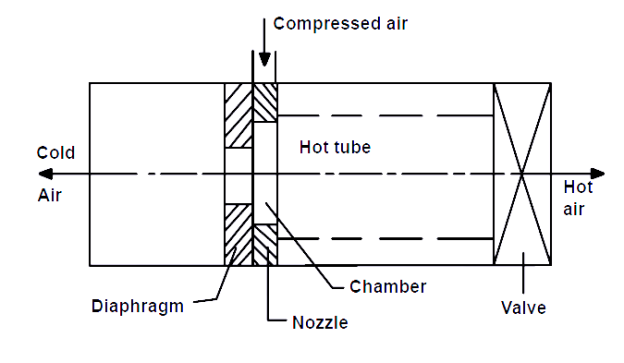

It is one of the non-traditional kind refrigerating structures for the manufacturing of refrigeration. The schematic diagram of vortex tube is proven with inside the Fig. It includes nozzle, diaphragm, valve, warm-air aspect, bloodless-air aspect. The nozzles are of converging or diverging or converging-diverging kind as in line with the layout.

A green nozzle is designed to have better speed, more mass glide and minimal inlet losses. Chamber is a part of nozzle and centers the tangential access of excessive speed air-circulation into warm aspect.

Generally the chambers aren't of round form, however they're steadily transformed into spiral form. Hot aspect is cylindrical in go phase and is of various lengths as in line with layout. Valve obstructs the glide of air via warm aspect and it additionally controls the amount of warm air via vortex tube. Diaphragm is a cylindrical piece of small thickness and having a small hollow of precise diameter on the center.

Air circulation touring via the center of the new aspect is emitted via the diaphragm hollow. Cold aspect is a cylindrical component via which bloodless air is surpassed.

Working:

Compressed air is surpassed via the nozzle as proven in Fig. Here, air expands and acquires excessive speed because of precise form of the nozzle.

A vortex glide is created with inside the chamber and air travels in spiral like movement alongside the outer edge of the new aspect.

This glide is restrained with the aid of using the valve. When the strain of the air close to valve is made extra than outdoor with the aid of using in part final the valve, a reversed axial glide via the center of the new aspect begins off evolved from excessive-strain location to low-strain location.

During this process, warmth switch takes vicinity among reversed circulation and ahead circulation. Therefore, air circulation via the center receives cooled beneath the inlet temperature of the air with inside the vortex tube, whilst air circulation in ahead course receives heated up.

The bloodless circulation is escaped via the diaphragm hollow into the bloodless aspect, whilst warm circulation is surpassed via the outlet of the valve.

By controlling the outlet of the valve, the amount of the bloodless air and its temperature may be varied.

Advantages:

1) It makes use of air as refrigerant, so there may be no leakage problem.

2) Vortex tube is straightforward in layout and it avoids manage structures.

3) There aren't any any shifting elements in vortex tube.

4) It is mild in weight and calls for much less space.

5) Initial fee is low and its running fees also are much less, in which compressed air is easily available.

6) Maintenance is straightforward and no professional labors are required.

Disadvantages:

It’s low COP, constrained ability and handiest small part of the compressed air performing because the bloodless air limits its huge use in practice.

Key Takeaways:

- The nozzles are of converging or diverging or converging-diverging kind as in line with the layout.

- Chamber is a part of nozzle and centers the tangential access of excessive speed air-circulation into warm aspect.

- Cold aspect is a cylindrical component via which bloodless air is surpassed.

- The bloodless circulation is escaped via the diaphragm hollow into the bloodless aspect, whilst warm circulation is surpassed via the outlet of the valve.

Nowadays classical vapor compression refrigeration generation is broadly used, however there are various obstacles in the usage of vapor compression device, due to the fact generation may be very power inefficient.

These refrigerants had been unwanted for environmental reasons. The primary disadvantage of the vapor compression device is that it calls for a compressor to compress a massive quantity of refrigerant vapor, which calls for a massive electricity for its operation.

In addition, it has bad COP compared with the Carnot cycle, environmental dangers restrict to the bottom temperature of the refrigeration cycle.

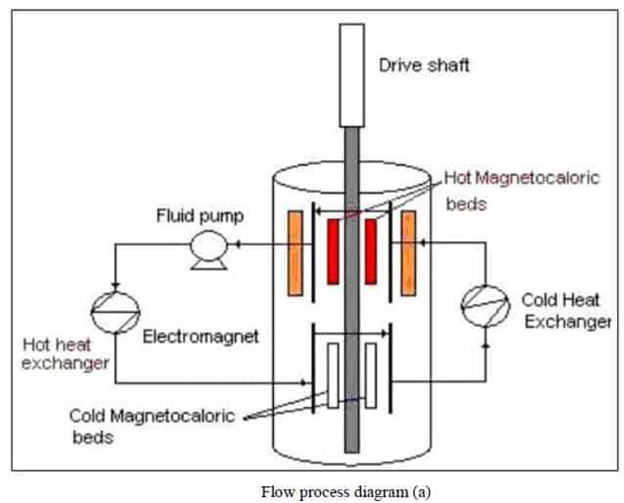

For this reason, researchers and engineers running in refrigeration have commenced to analyze new technologies for refrigeration amongst which the maximum promising is magnetic refrigeration.

Magnetic refrigeration is one in all such techniques, which guarantees to be of sensible importance despite the fact that the idea continues to be into research. The magnetic refrigeration device works with the aid of using making use of a magnetic subject to a magnetic fabric inflicting it to warmth up.

This extra warmth is eliminated from the device with the aid of using water, cooling the fabric back off to its authentic temperature. The take a look at is primarily based totally on a complete and easy evaluation with info of the whole thing one wishes to recognize approximately magnetic refrigeration as an opportunity to the traditional refrigeration device.

In the subsequent sections, the authors will attempt to deliver complete data approximately the traditional refrigeration device and magnetic refrigeration device.

General concept of refrigeration device

There are legal guidelines which are sizable to apprehend the primary refrigeration cycle thermodynamics’ first regulation explains that power is an essential idea of thermodynamics and one of the maximum sizable elements of engineering analysis.

Energy may be saved inside structures in various macroscopic forms: kinetic power, gravitational capability power, and inner power.

Energy can additionally be converted from one shape to every other and transferred among structures. For closed structures, power may be transferred with the aid of using paintings and warmth transfer.

The general quantity of power is conserved in all ameliorations and transfers. Thermodynamics 2nd regulation can assist us higher apprehend how the primary refrigeration cycle works.

One of those legal guidelines states that warmth constantly flows from a fabric at an excessive temperature to a fabric at a low temperature

A best reversible cycle primarily based totally on the 2 temperatures of the device in Figure. May be drawn on a temperature–entropy basis.

The compression and enlargement methods, proven as vertical lines, take region at regular entropy. A regular entropy (isentropic) technique is a reversible or a best technique. Ideal enlargement and compression engines are defined.

The criterion of perfection is composed in the reality that no entropy is generated all through the technique i.e. the amount (s) stays regular.

When the easy vapor compression cycle is proven at the temperature–entropy diagram in Figure 2, the deviations from the reversed Carnot cycle may be diagnosed with the aid of using shaded areas.

The adiabatic compression technique maintains past the factor wherein the condensing temperature is reached.

The shaded triangle represents the greater paintings that might be prevented if the compression technique modified to isothermal (i.e. at regular) temperature at this factor, while it proceeds till the condensing strain is attained.

Working:

The improvement of magnetic refrigeration commenced in 1881 whilst the German physic Emil Warburg determined the magneto caloric impact in iron, which has been till currently constrained to very low temperature.

The use of the magnetic cooling at room temperature become nearly made feasible with the invention of substances which display the magneto caloric impact at room temperature (specifically some uncommon metals and their alloys).

The running precept of magnetic fridges is primarily based totally on magneto caloric impact, perceived as an adiabatic temperature alternate or isothermal entropy alternate.

Let us observe the schematic diagram of the theoretical magnetic refrigeration device in Figure three and its vapor compression counterpart.

The traditional vapor compression device uses a compressor, warmth exchangers – an evaporator and a condenser, a throttling tool.

The refrigerant selections up warmth from the distance to be refrigerated with inside the evaporator wherein it's far transformed into vapor state.

This vapor then passes thru the compressor wherein its strain and temperature is increased.

That use of magnets, both everlasting and superconducting, outcomes a alternate with inside the magnetic subject.

The CFC or HFC refrigerant with inside the traditional device is changed with the aid of using a running substance i.e. a magneto-caloric fabric.

As it become cited before, with inside the bloodless warmth exchanger the running substance selections up warmth from the distance to be refrigerated, then the running substance is delivered right into a sturdy magnetic subject or is magnetized in order that because of magneto-caloric impact its temperature is increased.

Key Takeaways:

- In addition, it has bad COP compared with the Carnot cycle, environmental dangers restrict to the bottom temperature of the refrigeration cycle.

- The magnetic refrigeration device works with the aid of using making use of a magnetic subject to a magnetic fabric inflicting it to warmth up.

- Energy may be saved inside structures in various macroscopic forms: kinetic power, gravitational capability power, and inner power.

- Ideal enlargement and compression engines are defined.

- The adiabatic compression technique maintains past the factor wherein the condensing temperature is reached.

References:

1. Refrigeration and Air conditioning by C.P Arora, McGraw‐Hill

2. Refrigeration and Air conditioning, by Manohar Prasad, New Age International (P) Ltd. Pub.

3. Refrigeration and Air conditioning by R.C. Arora, PHI

4. Principles of Refrigeration by Roy J. Dossat. Pearson Education

5. Refrigeration and Air conditioning by Stoecker& Jones. McGraw‐Hill