Unit - 3

Water Technology

Underground Water: Underground water consists of that water level that is present under the earth which has been absorbed by the surface level of the earth.

Surface Water: Rainwater is one of the purest forms of natural water present on the surface of the earth while seawater is the most impure form of water. Rivers join the sea and throw in the impurities carried by them.

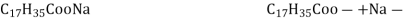

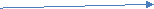

Hardness can be defined as the soap consuming capacity of the water sample. soaps are sodium salts of fatty acids like oleic acid, palmitic acid, and stearic acid. They dissolve readily in water to form lather due to which it has cleansing property.

(calcium stearate)

Hard water is water that contains a required quantity of dissolved minerals (like calcium and magnesium) As rainwater falls, it is naturally soft. However, as water flows through the ground and into waterways, it picks up minerals like chalk, lime, and mostly calcium and magnesium and becomes hard water. Since hard water contains essential minerals, it is essentially used as drinking water. Not only because of the health benefits, but also the flavour. Water that does not produce lather with soap readily is called hard water. Water hardness is usually measured as calcium hardness in milligrams per litre (mg/l) OR parts per million (ppm) OR in grains per gallon (GPG). For e.g.: seawater, river water, spring water, lake water, and well water. |

Key Takeaways:

1) They dissolve readily in water to form lather due to which it has cleansing property.

2) The hardness of water can be calculated from the amount of calcium and magnesium ions present in water along with bicarbonates, sulphates chlorides, and nitrates.

3) Hard water is water that contains a required quantity of dissolved minerals

Types of hardness: -

Mg (Bicarbonates)

II. Permanent hardness:

III. Alkaline or carbonate and non – alkaline or non – carbonate hardness:

4. As the sulphate and chloride are neutral salts, the hardness caused by the presence of calcium and magnesium sulphate, chlorides, and nitrates is termed as non-alkaline hardness or non-carbonate hardness.

IV. Total hardness: The hardness due to all hardness causing salts, known as total hardness. Total hardness = temporary + permanent Estimation of hardness: The hardness of weather can be determined by two methods.

1) Soap solution method:

The difference between the two measurements corresponds to the temporary hardness of the water. Estimation of hardness of water by the complex metric method: Complex metric titration is a form of volumetric analysis in which the formation of a colored complex is used to indicate the endpoint of a titration. Complex metric titrations are particularly useful for the determination of a mixture of different metal ions in solution. An indicator capable of producing an unambiguous color change is used to detect the end-point of the titration. Complexometric titration is those reactions where a simple ion is transformed into a complex ion and the equivalence point is determined by using metal indicators or electrometrically.

Titration with EDTA EDTA (Ethylene Diamine Tetra Acetic Acid), has four carboxyl groups and two amine groups that can act as electron-pair donors. The ability of EDTA to potentially donate its six lone pairs of electrons for the formation of coordinate covalent bonds to metal cations makes EDTA a hexadentate ligand. However, in practice, EDTA is usually only partially ionized and thus forms fewer than six-coordinate covalent bonds with metal cations. Disodium EDTA is commonly used to standardize aqueous solutions of transition metal cations. Disodium EDTA (often written as Na2H2Y) only forms four coordinate covalent bonds to metal cations at pH values ≤ 12. In this pH range, the amine groups remain protonated and thus unable to donate electrons to the formation of coordinate covalent bonds. Note that the shorthand form Na4−xHxY can be used to represent any species of EDTA, with x designating the number of acidic protons bonded to the EDTA molecule. EDTA forms an octahedral complex with most 2+ metal cations, M2+, in an aqueous solution. The main reason that EDTA is used so extensively in the standardization of metal cation solutions is that the formation constant for most metal cation-EDTA complexes is very high, meaning that the equilibrium for the reaction: M2+ + H4Y → MH2Y + 2H+ lies far to the right. Carrying out the reaction in a basic buffer solution removes H+ as it is formed, which also favors the formation of the EDTA-metal cation complex reaction product. For most purposes, it can be considered that the formation of the metal cation-EDTA complex goes to completion, and this is chiefly why EDTA is used in titrations and standardizations of this type. |

Key Takeaways:

1) EDTA stands for Ethylene Di-amine Tetra Acetic Acid.

2) EDTA has four carboxyl groups and two amine groups that can act as electron-pair donors.

3) Disodium EDTA is commonly used to standardize aqueous solutions of transition metal cations.

Thus, 1 mg/l = 1 mg of But 1 L OF Water weighs. = 1 kg = 1000 g = 1000*1000 mg = Therefore, 1mg/l = 1 mg of = 1 part of = 1 part of =1 ppm

3. Clarke’s degree is the number of grains (1/7000lb) of Thus,

4. Degree French (°fr) is the part of Thus, 1°fr = 1 part of

5. Milli equivalent per liter (meq / L ) is the number of milliequivalents of hardness present per liter. Thus, 1meq/L = 1 meq of = = 50 mg of = 50 mg / l of Relation between various units of hardness

|

Disadvantages of using hard water are-

1. Hard water is unfit for washing as it is difficult to form lather with soap.

2. Scum may form in a reaction with soap, wasting the soap.

3. Furring of tea kettles will take place due to the formation of carbonates of calcium and magnesium.

4. Hard blocks hot water pipes. This is due to the formation of layers of carbonates of calcium and magnesium.

Scale & Sludge Formation:

The water evaporates continuously in the boiler and increases dissolved salts in the boiler. On the continuous rise in salt concentration in the boiler respond to the acquiring of a saturation point as after that they are thrown out of water in the form of precipitates on the inner wall of the boiler. If the precipitation takes place in the form of loose and slimy precipitate it is called sludge while if the precipitated matter forms a hard-adhering crust or coating on the inner walls of the boiler, it is called scale.

Sludge | Scale |

Sludge is a loose, soft, and slimy precipitate | Scale forms hard deposits |

Sludge from non-adherent deposits and can be easily removed | Scale sticks firmly to the inner surface of the boiler and is very difficult to remove. |

Sludge is formed by a substance like CaCl2, MgCl2, MgSO4, etc. | The scale is formed by a substance like CaSO4, Mg(OH)2, etc. |

Sludge is formed at comparatively colder portions of the boiler. | The scale is formed at heated portions of the boiler |

They decrease the efficiency of the boiler but are less dangerous | They decrease the efficiency of the boiler and chances of the explosion are also there. |

They can be removed by blowdown operation | They can’t be removed by blowdown operation. |

Key Takeaways:

1) Sludge is a loose, soft, and slimy precipitate.

2) The water evaporates continuously in the boiler and increases dissolved salts in the boiler.

3) They can’t be removed by blow down operation.

Priming and Foaming:

During the duration at which the boiler is producing steam rapidly, some particles of the condensed liquid are carried along with the steam. The process of wet steam formation is called priming. Priming is mainly caused by the presence of large amounts of dissolved solids, high steam velocities, sudden boiling, etc. Whereas the continuous production of foam or bubbles in boilers that do not break easily are called the foaming. This is caused due to the presence of substances like oils in water that reduce the surface tension in water.

Disadvantages:

Priming and Foaming usually occur together. They are objectionable because:

1. The dissolved salts in boiler water are carried by the wet steam to the superheater and turbine blades where they get deposited and reduce the efficiency.

2. The dissolved salts enter the parts of other machinery where steam is used thereby decreasing the life of machinery.

3. The actual height of the water column cannot be judged thereby making the maintenance of boiler pressure becomes difficult.

Key Takeaways:

1) The process of wet steam formation is called priming.

2) Priming is mainly caused by the presence of large amounts of dissolved solids, high steam velocities, sudden boiling, etc.

Caustic Embrittlement: The use of high alkaline water in the boiler cause rust in the boiler which is called Caustic Embrittlement. The presence of sodium carbonate plays a major role during the softening process.

Na2CO3 + H2O → NaOH + CO2

the caustic embrittlement is caused by using sodium phosphate as a softening agent instead of sodium carbonate.

Prevention:

Caustic embrittlement can be avoided:

i) By using Na3PO4 as a softening reagent instead of Na2CO3.

ii) By adding tannin or lignin to boiler water since this blocks the hair cracks thereby preventing infiltration of caustic soda solution in these.

iii) By adding Na2SO4 to the boiler water. Na2SO4 is added to boiler water so that the ratio Na2SO4 concentration

NaOH Concentration

is kept as 1:1:2:1 and 3:1 in boilers working respectively at pressures up to 10, 20, and 30 atmospheres.

Hydroxides Bicarbonates Ca (HCO3)2 Carbonates MgCO3, FeCO3

Hydroxides and carbonates and stronger bases than bicarbonates.

Procedure:- The alkalinities due to the three types of ions can be easily determined by neutralization titration.

Note the burette reading as V 2 ml ( from initial )

Calculations:- P = phenolphthalein alkalinity = = PPM Caco3 equivalent M = methyl orange alkalinity = total alkalinity =

The possible combinations of alkalinities in water are:-

OH- and CO3 – Together

|

Formula:- The hardness of water by EDTA 1) When standard hard water is used Total hardness of water sample = Where, M = mgCaco3 in titrated standard hard water V1 = EDTA volume for titrated standard hard water V2 = EDTA volume for V ml water sample

2) When EDTA of known molarity used Total hardness of water sample =

Where, Y = EDTA volume for V ml of water sample Z = molarity of EDTA solution Chloride ions in a water sample:- cl- quantity = Where, Y = volume of AgNo3 Z = molarity of AgNo3 Alkalinity in a water sample Phenolphthalein alkalinity P = Methyl orange alkalinity M = Where, V1 = volume of acid for V ml water sample in titration with use of phenolphthalein indicator. V2 = volume of acid for V ml water sample in the continued titration using methyl orange indicator. Z = normally of acid in barette. |

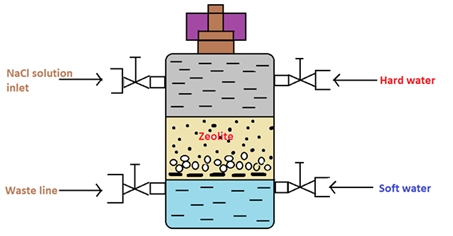

There are two types of zeolite used in this process they include natural and synthetic zeolite. The natural form is found to be porous and the synthetic form is a non-porous zeolite. however synthetic form possesses a high exchange capacity per unit weight than the natural form.

|

Figure 01: Cylinder Containing the Zeolite Bed

In the water softening process, hard water is passed through a bed of zeolite (inside a cylinder) at a specified rate. Then the cations that cause the water-hardening will remain on the zeolite bed because these cations exchange with the sodium cations of zeolite. Therefore, the water coming out of this cylinder contains sodium cations rather than calcium and magnesium cations.

After some time, the zeolite bed gets exhausted, the water flow is stopped, and treat the bed is treated with concentrated brine solution (10%) to regenerate the zeolite. The bed is treated with a brine solution, as it washes away all the calcium and magnesium ions, by exchanging them with sodium ions in a brine solution. hence, this treatment regenerates the zeolite.

Ion Exchange Process

Ion exchange process to soften water, using cations or anions. This is done by exchanging cations or anions with the calcium and magnesium ions in hard water. This process involves a reversible chemical reaction. However, we can use this technique only in dilute solutions. The equipment that we use for this purpose is ion exchangers.

There are two types;

- Cation exchangers – use zeolite, greensand, sulfonated coal, etc. as the exchanging material.

- Anion exchangers – uses metallic oxides, synthetic resins, etc.

The materials used in cation exchangers include either weak acids or strong acids. Strong acid cation exchangers mainly contain sulfate functional groups. Weak acid cation exchangers mainly contain carboxyl groups. The materials that are used in anion exchangers include either weak bases or strong bases. Moreover, there are several categories of ion exchange processes used for water softening, De-alkalization, and demineralization. The ions that are part of the exchange process (the ions that exchange with the calcium and magnesium cations in hard water) include sodium ions, hydrogen cations, chloride anions, and hydroxyl anions.

Key Takeaways:

1) The zeolite process is a process of softening hard water through an ion-exchange technique using a chemical compound zeolite.

2) Zeolite compound can exchange its sodium cations reversibly with calcium and magnesium ions in the water softening process.

3) Ion exchange process to soften water, using cations or ions.

4) The materials that are used in anion exchangers include either weak bases or strong bases.

Electro dialysis:

Electro dialysis (ED) is used to transport salt ions from one solution through ion-exchange membranes to another solution under the influence of an applied electric potential difference. This is done in a configuration called an electro dialysis cell. The cell consists of a feed (dilute) compartment and a concentrate (brine) compartment formed by an anion exchange membrane and a cation exchange membrane placed between two electrodes. In almost all practical electro dialysis processes, multiple electro dialysis cells are arranged into a configuration called an electro dialysis stack, with alternating anion and cation exchange membranes forming the multiple electro dialysis cells. Electro dialysis processes are different from distillation techniques and other membrane-based processes (such as reverse osmosis (RO) in that dissolved species are moved away from the feed stream rather than the reverse. Because the quantity of dissolved species in the feed stream is far less than that of the fluid, electro dialysis offers the practical advantage of much higher feed recovery in many applications.

Treatment processes for the production of freshwater from any kind of water sources such as groundwater and surface water, as well as recycled process and wastewater, are becoming more and more important to cope with rapidly increasing water demand. Increased nitrate concentrations, mainly caused by non-clarified wastewater or excessive application of artificial fertilizer and manure in agriculture, are found quite often in groundwater. Also, many surface waterworks are confronted with the necessity to remove dissolved ionic substances. Common treatment methods used at waterworks are a combination of chemical oxidation, coagulation-flocculation, sand filtration, and disinfection. However, in recent years, membrane technology has become an extraordinarily useful tool for the production of freshwater.

Applications:

- Large scale brackish and seawater desalination and salt production.

- Small and medium scale drinking water production (e.g., towns & villages, construction & military camps, nitrate reduction, hotels & hospitals)

- Water reuse

- Pre-demineralization

- Food processing

- Agricultural water

- Glycol desalting

- Glycerin purification

Reverse osmosis (RO) and Nano filtration (NF)

Reverse osmosis (RO) and Nano filtration (NF) are often used down the line in the boiler feed water treatment system process so most of the harmful impurities that can foul and clog the RO/NF membranes have been removed. Similar processes of separation, they both force pressurized water through semipermeable membranes, trapping contaminants such as bacteria, salts, organics, silica, and hardness, while allowing concentrated, purified water through. Not always required in boiler feedwater treatment, these filtration units are used mostly with high-pressure boilers where the concentration of suspended and dissolved solids needs to be extremely low.

Key Takeaways:

1) Electro-dialysis (ED) is used to transport salt ions from one solution through ion-exchange membranes to another solution under the influence of an applied electric potential difference.

2) Increased nitrate concentrations, mainly caused by non-clarified wastewater.

3) Reverse osmosis (RO) and nano-filtration (NF) are often used down the line in the boiler feed water treatment system process so most of the harmful impurities that can foul and clog the RO/NF membranes have been removed.

Applications of pH meter:

- The measurement of pH reflects the effective concentration and activity of H+ and other ions present in solutions

- For chemical reactors and scrubbers, they provide indications of the solution used being acidic or basic qualitatively

- These meters find major application to correct the hyper chloric concentration for an oxidation-reduction potential measurement.

- Water treatment plants, micro-electronics laboratories, and pharmaceutical laboratories are in constant need of pH level monitoring and control for their very accurate and precise applications.

Applications of conduct meter:

- Conduct meter is used to determine the acids ‘basicity. The basicity is defined as the number of carboxylic acid groups attached to the molecules.

- Use in the determination of the sparingly soluble salts such as barium sulfate and lead sulfate.

- It is used in the determination of the purity of water.

- The determination of the salinity of seawater.

- It is used in the determination of the ionic product of the water.

- Also, use in the quantitative analysis of the compound.

REFERENCE BOOKS:

1) A textbook of engineering chemistry by M.M. Uppal

2) Applied Chemistry by Krishnamurthy P. Vallinayagam and K. Jeysubramanian TMH Publication

3) A textbook of engineering chemistry by Shashi Chawla

4) A textbook on experiment and calculations in engineering chemistry by S.S. Dara, S. Chand Publication

5) Engineering Chemistry by R.V. Gadag and A.N. Shetty

6) Textbook of polymers science by F.W. Billmer, John Wiley and sons

7) University chemistry, Mahan, Pearson education