Unit - 4

Corrosion Science and Lubricants

Corrosion: Corrosion is defined as the phenomenon in which metal get a coated covering over its whole body due to the chemical reaction from its surrounding that results in the conversion of metal into the oxide, salt, or any other compound. In common language, this process is called the rusting of iron. The theories behind the corrosion of the metal are:

1-Direct Corrosion

2-Electro-Chemical Corrosion

3-High-Temperature Oxidation

Direct Corrosion:

Direct Corrosion is the simplest corrosion that occurs directly in the environment temperature. Under this, there is a chemical attack which includes oxidation under which the oxygen present in the environment combines with all the possible parts of the surface of the material.

Fe + O + 2CO2 + H2O → Fe(HCO3) 2 2Fe(HCO3)2 + O → 2Fe(OH)CO3 + 2CO2 + H2O Fe(OH)CO3 + H2O → Fe(OH)3 + CO2 |

Electro-Chemical Corrosion:

The corrosion takes place due to a chemical reaction in combination with electrolysis. It takes place at room temperature when the metal comes in contact with the moisture. In the presence of an electrolyte, the current must be passing through the circuit and the most important circuit must be closed for this type of corrosion.

High-Temperature Oxidation:

The formation of scales and oxides in iron rusting took place for rusting of ferrous alloys at high temperatures while the other form of the corrosion may be noted when liquid metal flows through other metals. The corrosion is caused due to the tendency of the solid to dissolve into the liquid metal within the limit of solubility.

Causes:

1- Corrosion took place due to the presence of salt.

2- Corrosion took place due to the inadequate design procedure.

3- The presence of excess water-cement ratio causes corrosion.

4- The internal structure of the metal.

Prevention:

1- Maintaining a high degree of workmanship.

2- Use of high quality and impermeable concrete.

3- Using the correct cement-water ratio.

Key Takeaways:

1) Corrosion is defined as the phenomenon in which metal get a coated covering over its whole body.

2) The corrosion that occurs in the environment temperature is called as the direct corrosion.

3) The corrosion takes place due to a chemical reaction in combination with electrolysis is electro chemical corrosion.

4) The formation of scales and oxides in iron rusting took place for rusting of ferrous alloys at high temperatures while the other form of the corrosion may be noted when liquid metal flows through other metals.

Chemical Corrosion: The reaction of metal with water vapour or gas at high temperature causes the metal to corrode chemically. This is the redox process in which the electron of the metal is passed directly to the substance in the environment. The metal corrodes generally in the metal which is in higher contact with water.

3Fe + 4H2O Fe3O4 + 4H2

3Fe + 4H2O Fe3O4 + 4H2

3Fe + 2O2 Fe3O4

3Fe + 2O2 Fe3O4

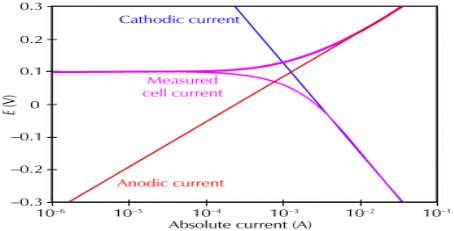

Electrochemical Corrosion: Corrosion occurs due to the electrochemical process of oxidation and reduction process. In the corroding solution, electrons are released by the metal and that is gained by the elements in the corroding solution. The release of an electron from metal is called oxidation while vice-versa that is the gain of an electron by elements is reduction. The regular electron flow in the corrosion reaction can be measured and controlled electronically. This is why controlled electrochemical experimental methods are used to characterize the corrosion properties of the metal.

For example,

(i) a thin film of moisture on a metal surface forms the electrolyte for atmospheric corrosion.

(ii) when wet concrete is the electrolyte for reinforcing rod corrosion in bridges. Although most corrosion takes place in water, corrosion in non-aqueous systems is not unknown.

|

Corrosion process showing the anodic and cathodic component of the current

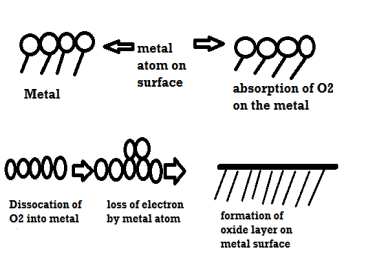

Mechanism of dry corrosion due to O2 gas there are 4 types: -

- Absorption of oxygen molecules on the metal surface

- Dissociation of an oxygen atom into the metal atom

- Loss of e- by a metal atom

- Formation of the oxide layer on the metal surface.

|

Key Takeaways:

1) The reaction of metal with water vapour or gas at high temperature causes the metal to corrode chemically.

2) The regular electron flow in the corrosion reaction can be measured and controlled electronically.

3) The corrosion takes place due to a chemical reaction in combination with electrolysis is electro chemical corrosion.

(i) Nature of the metal

Position of metal in galvanic series.

If the position is higher in galvanic series, then it corrodes faster

While for 2 metals the difference between them shows the corrosion ratio.

(ii) Potential Difference

If the difference at the electrode potential between two metals is high then the rate of corrosion would be also high while vice versa for the lesser difference.

(iii) Purity of metal

Corrosion never took place in pure metals. While if the metal itself has an impurity then galvanic cells are set up easily which intend increases the rate of corrosion.

(iv) Relative areas of cathode and anode parts

The rate of corrosion directly depends on the area of the cathode and inversely depends on the area of the anode. If the area of cathode is larger then there is more demand for electrons while in the smaller anode area the corrosion took place very fast.

(v) Nature of corrosion Product

The metal oxide film is formed on the surface of the metal by corrosion due to oxygen. The formed film would be stable, unstable, volatile.

(vi) Temperature

At high temperatures, the rate of corrosion increases because there is a consistent increase in the ionization and mobility difference rate while in some cases rate of corrosion decreases at high temperatures as the solubility of O2 gas increases.

(vii) Presence of moisture

The rate of corrosion decreases in dry while increases in presence of moisture. Moisture act as the solvent for setting up electrochemical corrosion.

(viii) Effect of pH

The rate of corrosion is high at acidic pH due to the evolution of H2 gas at the cathode.

(ix) Concentration of electrolytes

This is also called the Oxygen concentration cell. The rate of corrosion would directly depend on the supply of oxygen in the air.

(x) Over Voltage

The difference between the actual value and theoretical value of the decomposition potential of the electrode.

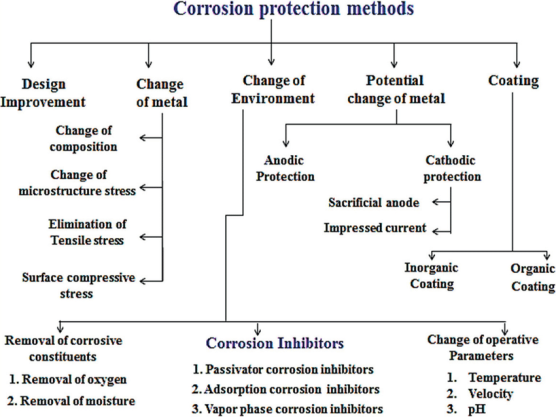

4.4.1 Corrosion Control

|

4.4.2 Anodizing and phosphating

Phosphating:

The conversion of surface metal atoms into their phosphates by chemical or electrochemical reactions is called phosphating.

The phosphating bath contains three essential components:

1) free phosphoric acids

2) a metal phosphoric such as Fe, Mn phosphate

3) An accelerator such as H2O2, nitrites, nitrates

4) Temperature – 35oC

5) pH – 1.8 – 3.2

Phosphating not only improves the corrosion resistance but also imparts good paint adhesion quality to the surface.

4.4.3 Galvanizing and tinning

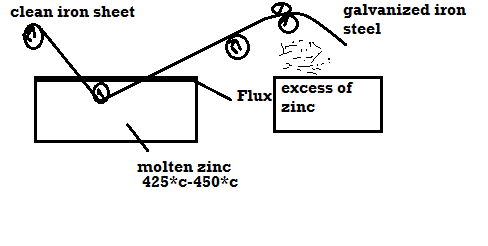

Galvanizing:

Method:

- Coating of Zn on the steel or iron is called galvanizing.

- Steel article is cleaned well with dil H2SO4 then with water and dry it.

- Then the steel article is dipped in molten Zn bath and it is maintained at the temp 425 – 450 c.

- The molten Zn bath is covered with flux.

- Then the article is allowed to pass through to mate uniform coating layer and to remove excesses of Zn.

|

Applications: -

- Various galvanized iron (G.I) articles are used.

- It is useful for the protection of iron.

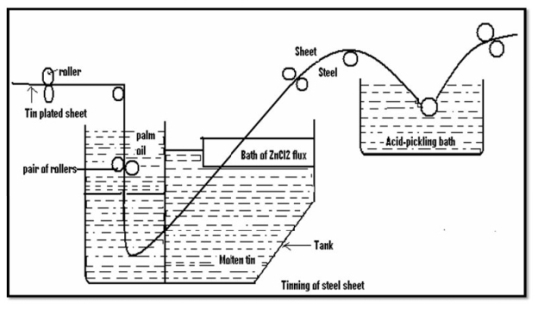

Tinning

Method: -

- Coating of tin on a base metal i.e. steel iron is called tinning.

- The steel article is cleaned well and then passes through a molten tin bath which is maintained at temp 240c.

- Then, the article is allowed to pass through a palm oil bath which protects the hot tin-coated surface against corrosion.

- Then the article is allowed to pass through to make a uniform coating layer to remove the excess of tin.

|

4.4.4 Cathodic and anodic protection

Cathodic Protection:

This is the technique used to control the corrosion on the surface of the metal by the formation of the cathode layer on an electrochemical cell. There are 2 types of cathodic protection:

(i) Sacrificial Anodic Protection

(ii) Impressed Current Cathodic Protection

Sacrificial Anodic Protection:

The metal surface can be protected from corrosion by connecting its wire to a more anodic metal. The sacrifice of this more anodic metal to save the metal from corrosion is called the Sacrificial Anode. The most common metal used for this purpose is Mg, Zn, Al, etc.

Applications:

(i) The underground cable and pipeline protection from soil erosion.

(ii) Ships and boat protection from marine corrosion.

(iii) Prevention of rusty water by inserting Mg sheets or rods into domestic water boiler or tanks.

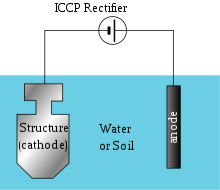

Impressed Current Cathodic Protection:

This is the type of corrosion protection that consists of sacrificial anodes that are connected to an external power source. The external power source is a DC power supply, that provides the sufficient current to drive the electrochemical reaction required for the cathodic protection to occur.

|

Key Takeaways:

1) The conversion of surface metal atoms into their phosphates by chemical or electrochemical reactions is called phosphating.

2) Coating of tin on a base metal i.e steel iron is called tinning.

3) The metal surface can be protected from corrosion by connecting its wire to a more anodic metal.

4) This is the type of corrosion protection that consists of sacrificial anodes that are connected to an external power source.

Lubricants are the fluid, solid, or plastic substance that is helpful in the control of friction by the introduction of the friction-reducing film between moving surfaces in contact. There are many different forms of the substance which is helpful in lubrications. The most common substances that are used are oil and grease. Grease is composed of oil and a thickening agent to obtain its consistency, while the oil is helpful in lubrication. Oil can be a synthetic vegetable or mineral as well as a combination of these.

The application determines which oil, commonly referred to as the base oil and should be used. In extreme conditions, synthetic oils can be beneficial. Where the environment is of concern, vegetable base oils may be utilized. Lubricants containing oil have additives that enhance, add, or suppress properties within the base oil. The amount of additives depends on the type of oil and the application for which it will be used. For instance, engine oil might have a dispersant added. A dispersant keeps insoluble matter conglomerated together to be removed by the filter upon the circulation. In environments that undergo extremes in temperature, from cold to hot, a viscosity index (VI) improver may be added. These additives are long organic molecules that stay bunched together in cold conditions and unravel in hotter environments. This process changes the oil’s viscosity and allows it to flow better in cold conditions while still maintaining its high-temperature properties. The only problem with additives is that they can be depleted, and in order to restore them back to sufficient levels, generally the oil volume must be replaced. The roles of lubricant are -

- Reduce friction

- Prevent wear

- Protect the equipment from corrosion

- Control temperature (dissipate heat)

- Control contamination (carry contaminants to a filter or sump)

- Transmit power (hydraulics)

- Provide a fluid seal

Lubricants are classified based on their physical state:

(i) Lubricating Oil

(ii) Semi-solid Lubricants (grease)

(iii) Solid lubricants

Lubricating Oil:

It plays a major role in the reduction of friction between two moving metallic surfaces. The lubricating oil provides the fluid film in between the metallic surfaces those results in friction reduction. Lubricants also act as the cooling medium, corrosion preventer.

Properties:

(i) They possess low pressure or high boiling point

(ii) Adequate viscosity for particular service condition

(iii) High oxidation resistance

(iv) The non-corrosive properties

They are further classified as-

Vegetable oils:

The petroleum industry's existence took several decades before its existence oil of the vegetable and animal origins were the most commonly used lubricants. They were very good for the use but due to their cost and the property of its to undergo oxidation easily tend to leave its presence. They were used as the blending agent with other lubricating oils to produce the desired effects.

Mineral or petroleum oils: They are obtained by petroleum distillation. The carbon chain varies from 12 to 50 carbon atoms. They possess viscosity according to their chain length the shorter chain possesses lower viscosity while vice versa for the longer chain. This is one of the most widely used lubricants because of its price and its availability. Crude liquid petroleum oils contain a lot of impurities (like wax, asphalt, etc.) and consequently, they have to be thoroughly purified before being put to use.(i) The wax, if not removed, raises the pour-point and renders the lubricating oil unfit for use at low temperatures. (ii) Certain constituents get easily oxidized under working conditions and cause sludge formation. (iii) Some constituents mainly asphalt, undergo decomposition at higher temperatures, causing carbon deposition and sludge formation. A number of processes are used for removing these unwanted impurities by using Dew axing or acid refining or by solvent refining.

Semi-solid Lubricants (grease):

Greases have higher shear or frictional resistance than oils and, therefore, can support much heavier loads at lower speeds. They also do not require as much attention, unlike the lubricating liquids. But greases tend to separate into oils and soaps.

Grease is used:

(i) in situations where oil cannot remain in place, due to high load, low speed, intermittent operation, sudden jerks, etc. e.g. rail axle boxes,

(ii) in bearing and gears that work at high temperatures

(iii) in situations where bearing needs to be sealed against entry of dust, dirt, grit, or moisture because greases are less liable to contamination by these

(iv) in situations where dripping or spurting of oil is undesirable because unlike oils, greases if users do not splash or drip over articles being prepared by the machine. For example, in machines preparing the paper, textiles, edible articles, etc.

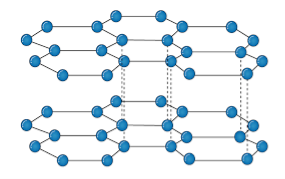

Solid lubricants:

Solid lubricants are used at the place where liquid lubricant or grease cannot secure to be useful. The most usual solid lubricants used are graphite and molybdenum di supplied.

Graphite:

Structure:

|

Conducting Property: As the carbon of Graphite is sp2 hybridized that means the p orbital remains vacant of the carbon atom which tends to the overlapping of the vacant P-orbital. This overlapping of the vacant orbital is responsible for the movement of electrons in parallel on their vacant orbital that is why Graphite shows the conducting property.

Lubricating Property: There is the presence of weak Vander Wall forces between two layers due to these weak forces the two layers are flexible in nature which in result make the Graphite to be used for Lubricating purpose.

Applications:

1-Graphite can be used as the solid lubricant

2-Graphite can be used as a conductor.

3-Graphite can be used as electrodes.

Key Takeaways:

1) Lubricants are the fluid, solid, or plastic substance that is helpful in the control of friction by the introduction of the friction-reducing film between moving surfaces in contact.

2) The amount of additives depends on the type of oil and the application for which it will be used.

3) Greases have higher shear or frictional resistance than oils and, therefore, can support much heavier loads at lower speeds.

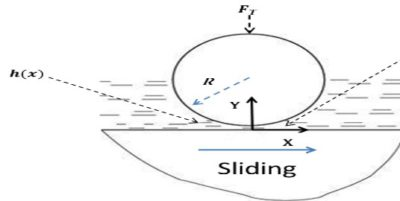

(i) Fluid Film or Hydrodynamic Lubrication:

The shaft rotating in a bearing is supported by a layer or wedge of oil so that the shaft is not in contact with the bearing material. It is carried out with the help of liquid lubricants. In this mechanism, two moving and sliding surfaces are separated by a thick film of lubricant fluid of about 1000A°, applied to prevent direct surface to surface contact and consequently reduce wearing and tearing of metals. Therefore it is known as a thick film or fluid film lubrication or hydrodynamic lubrication. In this case, fluid is formed by mixing hydrocarbon oils and anti-oxidants with a long-chain polymer to maintain viscosity. Fluid film lubrication is useful in delicate and light machines like watches, clocks, guns, scientific equipment.

|

The lubrication film between the two contact surfaces is thick enough and two contact surfaces are separated by the viscous oil film. At this time, the frictional force of two contact surfaces is determined by the viscous resistance of lubricant and it can take a very small value. Under this condition, when shaft also rotates due to the viscosity of the lubricant oil and generates oil pressure at the load area. This phenomenon is called a wedge effect. The oil pressure P generated within the lubricating oil film is affected by the change of temperature and viscosity of lubricating oil, surface roughness, clearance, and rotational speed of the shaft.

|

(ii) Thin Film or Boundary Lubrication:

It is carried out with grease and graphite & molybdenum disulphide lubricants. Boundary lubrication is a condition in which the lubricant film becomes too thin to provide total separation. In this type of lubrication, a thin film of lubricant is adsorbed on the surface by weak Vander Waals forces. Thin-film lubrication is operating at relatively low speed and high pressure. Lubricating oil film between the two contact surfaces is extremely thin and no viscous hydrodynamic oil film exists between the two contact areas, only a film of absorbed oil molecules exists.

|

The absorptive oil film is arranged oil molecules that are adhered onto the solid surfaces and its shear resistance is greater than hydrodynamic oil film. Frictional force in this area is greater compare to hydrodynamic lubrication. In the frictional contact points, the oil film is frequently broken. The lubrication condition that generates a frictional condition such as this is called boundary lubrication; to decrease the friction under this condition selection of self-lubricating bearing may be desirable.

Key Takeaways:

1) It is carried out with the help of liquid lubricants.

2) The oil pressure generated within the lubricating oil film is affected by the change of temperature and viscosity of lubricating oil, surface roughness, clearance, and rotational speed of the shaft.

3) The lubrication condition that generates a frictional condition such as this is called boundary lubrication.

Viscosity is used to measure the internal friction of a fluid. It is one of the most important properties of the fluid. The viscosity of lubricant varies with temperature and pressure. “It is defined as the resistance offered by liquid to flow i.e.; some liquid can flow easily and some can’t. It exhibits most of the property of liquid. This resistance to flow depends on other physical properties such as temperature, pressure, etc.”

Significance:

1. Viscosity of lubricating oil determines its performance under operating conditions.

2. If the viscosity of the liquid is too low, the fluid lubricant film cannot be maintained between the moving surfaces, as a result of which excessive wear may take place.

3. If the viscosity of the lubricating oil is too high, excessive friction may take place.

Key Takeaways:

1) Viscosity is used to measure the internal friction of a fluid.

2) It is defined as the resistance offered by liquid to flow i.e.; some liquid can flow easily and some can’t.

3) It exhibits most of the property of liquid.

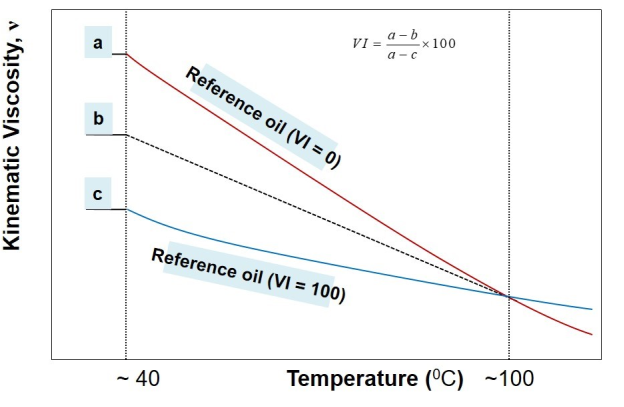

The rate at which viscosity of lubricant changes with temperature is measured by an arbitrary scale is known as viscosity index. The viscosity of the liquid decreases with increasing temperature so that lubricating oil becomes thinner as the operating temperature is raised, and lubricant can be squeezed out from the subbing parts.

|

A stepwise procedure to estimate viscosity index, VI, may be outlined as below:

- Measure kinematic viscosity of the unknown oil at 40o C and 100oC.

- Identify two reference oils whose kinematic viscosity at 100oC coincides with the kinematic viscosity of the unknown oil (from the look-up chart of ASTM standard).

- Pick-up the kinematic viscosity of two identified reference oils at 40oC

- About the illustration above, now a, b, and c are known.

- Use the following formula to calculate the viscosity index

VI=(a-b)/(a-c) *100

Key Takeaways:

1) The rate at which viscosity of lubricant changes with temperature is measured by an arbitrary scale is known as viscosity index.

2) The viscosity of the liquid decreases with increasing temperature so that lubricating oil becomes thinner as the operating temperature is raised, and lubricant can be squeezed out from the subbing parts.

Cloud point is defined as the minimum temperature at which oil becomes hazy. Pour point is defined as the minimum temperature at which oil stops pouring (or ceases to flow). When the oil is cooled, the wax starts crystallizing, and the oil becomes hazy tiny wax crystals agglomerate and form a bigger crystal lattice, at this stage the oil solidifies completely and does not pour out on tilting.

Both cloud and Pour points should be very less than the operating temperature

Cloud and pour points can be reduced by adding depressants.

The flashpoint for any volatile material is defined as the lowest temperature at which vapors of the material will ignite when ignited by a source. Similarly, the fire point is defined as the lowest temperature at which vapors of the material will catch fire and continue burning even after the ignition source is removed. The fire point is higher than the flashpoint because the vapors produced at the flashpoint are not sufficient enough to ignite the fuel. Flash and fire points depend upon the volatility of the biodiesel. Volatility is the tendency of the substance to vaporize, and it is directly related to the vapor pressure of the biodiesel at that particular temperature. The biodiesel exhibiting higher vapor pressure at a given temperature is said to be more volatile than the one exhibiting lower vapor pressure at the same temperature. Hence the lower the NBP (normal boiling point), the higher the volatility, which is in turn inversely proportional to its flash and fire point.

Key Takeaways:

1) The flashpoint for any volatile material is defined as the lowest temperature at which vapors of the material will ignite when ignited by a source.

2) Flash and fire points depend upon the volatility of the biodiesel.

3) The biodiesel exhibiting higher vapor pressure at a given temperature is said to be more volatile than the one exhibiting lower vapor pressure at the same temperature.

4.11.1 Acid Value

The acid value (AV) is a common parameter in the specification of fats and oils. It is defined as the weight of KOH in mg needed to neutralize the organic acids present in 1g of fat and it is a measure of the free fatty acids (FFA) present in the fat or oil. An increment in the amount of FFA in a sample of oil or fat indicates hydrolysis of triglycerides. Such reaction occurs by the action of lipase enzyme and it is an indicator of inadequate processing and storage conditions (i.e., high temperature and relative humidity, tissue damage). The source of the enzyme can be the tissue from which the oil or fat was extracted or it can be a contaminant from other cells including microorganisms. Besides FFA, hydrolysis of triglycerides produces glycerol.

Acid value (mg KOH/g fat) = Titre value x Normality of KOH x 56.1 Weight of sample (g)

It is the measure of the aromatic content of the lubricating oil. The low aniline point has high aromatic content which attacks rubber seals. The higher the aniline point means the lower percentage of hydrocarbons. Thus Aniline point is used as an indication of possible deterioration of rubber sealing.

Determination of Aniline Point:

Aniline + Sample oil Homogenous Solution Cloudiness

Key Takeaways:

1) The acid value (AV) is a common parameter in the specification of fats and oils.

2) An increment in the amount of FFA in a sample of oil or fat indicates hydrolysis of triglycerides.

3) The higher the aniline point means the lower percentage of hydrocarbons.

The best lubricant possesses the following properties:

1) The best lubricant had a high boiling point and low freezing points.

2) They have a high viscosity index

3) They possess thermal stability.

4) They possess hydraulic stability.

5) The best lubricant prevents corrosion

6) They show high resistance towards oxidation.

REFERENCE BOOKS:

1) A textbook of engineering chemistry by M.M. Uppal

2) Applied Chemistry by Krishnamurthy P. Vallinayagam and K. Jeysubramanian TMH Publication

3) A textbook of engineering chemistry by Shashi Chawla

4) A textbook on experiment and calculations in engineering chemistry by S.S. Dara, S. Chand Publication

5) Engineering Chemistry by R.V. Gadag and A.N. Shetty

6) Textbook of polymers science by F.W. Billmer, John Wiley and sons

7) University chemistry, Mahan, Pearson education