Unit – 2

Renewable Power Generation

SOLAR

Solar power is the conversion of sunlight into electricity, either directly using photovoltaic’s (PV), or indirectly using concentrated solar power (CSP).

Concentrated solar power systems use lenses or mirrors and tracking systems to focus a large area of sunlight into a small beam. Photovoltaic’s convert light into an electric current using the photovoltaic effect.

Main Components

1. Solar Panels

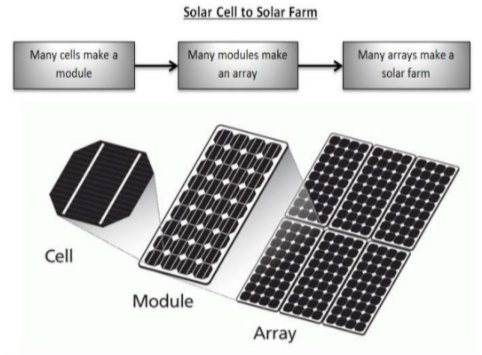

It is the heart of the solar power plant. Solar panels consists a number of solar cells. We have got around 35 solar cells in one panel. The energy produced by each solar cell is very small, but combining the energy of 35 of them we have got enough energy to charge a 12 volt battery.

2. Solar Cells

It is the energy generating unit, made up of p-type and n-type silicon semiconductor. It’s the heart of solar power plant.

3. Battery

Batteries are used to produce the power back or store the excess energy produced during day, to be supplied during night.

4. D.C. To A.C. Converter (Inverter)

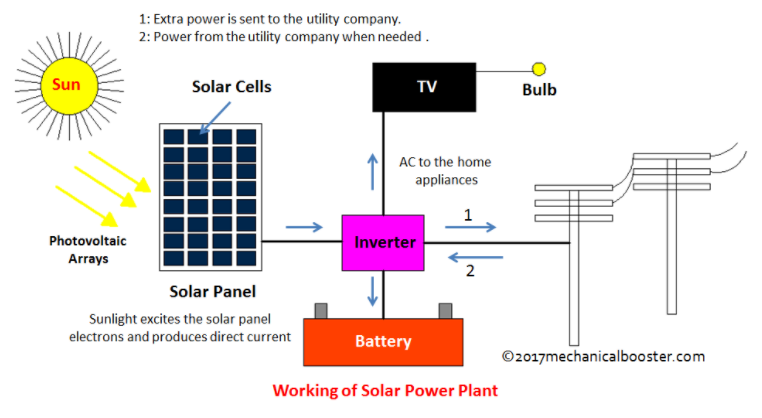

Solar panels produce direct current which is required to be converted into alternating current to be supplied to homes or power grid.

Working of Solar Power Plant

As sunlight falls over a solar cells, a large number of photons strike the p-type region of silicon. Electron and hole pair will get separated after absorbing the energy of photon. The electron travels from p-type region to n-type region due to the action of electric field at p-n junction. Further the diode is reversed biased to increase this electric field. So this current starts flowing in the circuit for individual solar cell. We combine the current of all the solar cells of a solar panel, to get a significant output.

Solar power plant have a large number of solar panels connected to each other to get a large voltage output. The electrical energy coming from the combined effort of solar panels is stored in the Lithium ion batteries to be supplied at night time, when there is no sunlight.

Materials used in solar cells

- The materials which are used for this purpose must have band gap close to 1.5ev.

- Crystalline silicon (c-Si): These cells are entirely based around the concept of a p-n junction. Solar cells made of c-Si are made from wafers between 160 and 240 micrometers thick.

- Monocrystalline silicon (mono-Si): Solar panels using mono-Si cells display a distinctive pattern of small white diamonds.

- Epitaxial silicon : Solar cells made with this technique can have efficiencies approaching those of wafer-cut cells, but at appreciably lower cost.

- Polycrystalline silicon : Polysilicon cells are the most common type used in photovoltaic’s and are less expensive, but also less efficient, than those made from monocrystalline silicon.

- Cadmium telluride : Cadmium telluride is the only thin film material so far to rival crystalline silicon in cost/watt. However cadmium is highly toxic and tellurium supplies are limited. 6.Gallium arsenide thin film : The semiconductor material Gallium arsenide (GaAs) is also used for single-crystalline thin film solar cells.

Advantages

- Most clean and renewable source of energy.

- It is available in abundance and endless.

- It provides electricity at low cost, as fuel is free.

- With new research in this sector we now have a good power storage solution.

- Keeping in mind the pollution and cost of fossil fuel, it’s becoming the most reliable source of clean energy.

Disadvantages

- It requires a lot of land to be captured forever.

- Initial cost of installation is too high.

- The energy storage options are not efficient and moreover costly if efficient.

- Power production is quite low as compared to nuclear or other resources to produce power.

- There is a problem if it is cloudy for few days.

BIOGAS

- Biogas is a combustible gas.

- It is produced through the anaerobic breakdown of waste biomass.

- The biogas plant consists of the following parts:-

- 1) Inlet or charge pit:- for passage of slurry into the digester.

The raw material used is cattle dung, farm refuse, organic waste. - 2) Digester:- cylindrical tank which is airtight, above which is present a floating gas holder of metal with an outlet of gas and pit for removal of sludge.

Here the organic wastes get solubilized into simpler substances called monomers (solubilisation).

Monomers change to organic acid by fermenting microbes (acidogenesis).

Organic acid mostly formed is acetic acid.

Methanogens become active and act on components of microbial digestion and form methane gas (methanogenesis).

- 3) Outlet- consists of sludge which is used as manure.

- The methane gas formed in this process is used for cooking and lighting.

Advantages

Biogas is Eco-Friendly

Biogas Generation Reduces Soil and Water Pollution

Biogas Generation Produces Organic Fertilizer

It’s A Simple and Low-Cost Technology That Encourages A Circular Economy

Healthy Cooking Alternative For Developing Areas

Disadvantages

Few Technological Advancements

Contains Impurities

Effect of Temperature on Biogas Production

Less Suitable For Dense Metropolitan Areas

BIOMASS

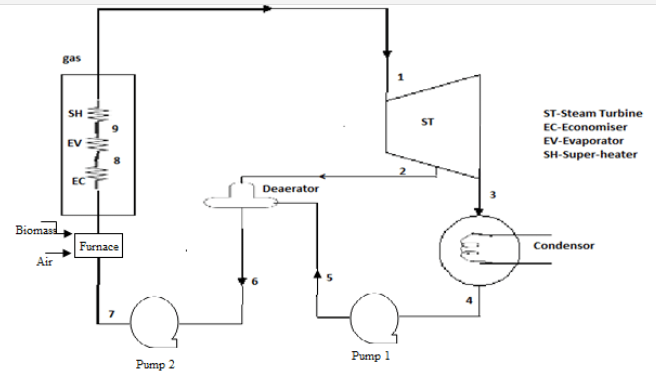

Biomass is biological material derived from living, or recently living organisms. It most often refers to plants or plant-based materials which are specifically called lignocellulosic biomass. As an energy source, biomass can either be used directly via combustion to produce heat, or indirectly after converting it to various forms of biofuel. Conversion of biomass to biofuel can be achieved by different methods which are broadly classified into: thermal, chemical, and biochemical methods.

Biogas is produced as a result of anaerobic fermentation of biomass in the presence of water.

The various forms of biomass are mixed with an equal quantity of water in the mixing tank. This forms the slurry. The slurry is fed into the digester through the inlet chamber. When the digester is partially filled with the slurry, the introduction of slurry is stopped and the plant is left unused for about two months. During these two months, anaerobic bacteria present in the slurry decomposes or ferments the biomass in the presence of water. As a result of anaerobic fermentation, biogas is formed, which starts collecting in the dome of the digester. As more and more biogas starts collecting, the pressure exerted by the biogas forces the spent slurry into the outlet chamber. From the outlet chamber, the spent slurry overflows into the overflow tank. The spent slurry is manually removed from the overflow tank and used as manure for plants. The gas valve connected to a system of pipelines is opened when a supply of biogas is required. To obtain a continuous supply of biogas, a functioning plant can be fed continuously with the prepared slurry.

Advantages

- Biomass is always and widely available as a renewable source of energy

- It is carbon neutral

- It reduces the overreliance of fossil fuels

- Is less expensive than fossil fuels

- Biomass production adds a revenue source for manufacturers

- Less garbage in landfills

Disadvantages

- Biomass energy is not as efficient as fossil fuels

- It is not entirely clean

- Can lead to deforestation

- Biomass plants require a lot of space

OCEAN THERMAL ENERGY CONVERSION (OTEC)

- The oceans and rivers cover about 70% of the earth’s surface which receives, store and dissipates the vast amount of thermal energy. Thus they act as huge reservoirs of thermal energy. The temperature gradient across the depth of sea can be used to generate electrical power. It is known as ocean thermal energy conversion system.

- There are two basic types of ocean thermal energy conversion (OTEC) systems which are as under:

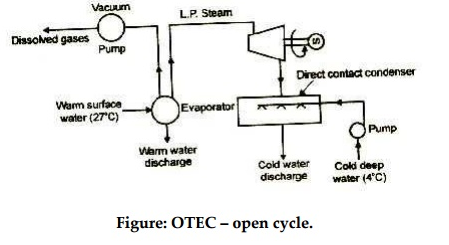

- Open Cycle Ocean Thermal Energy Conversion System

- In this system, the warm water from the ocean surface is fed to the deaerator. It removes the dissolved non-condensable gases from water and fed it to the evaporator.

- The flash evaporator is maintained under high vacuum. As a result, a low-pressure steam is produced due to throttling effect and the residue liquid is released back to the ocean at high depth.

- In the next step, this low-pressure steam is fed to the turbine where it expands and rotates the turbine. The mechanical power so developed is converted into electrical power by the generator.

- The exhaust steam from the turbine is released into a direct contact type heat exchanger where it mixes with the cold water drawn from the ocean depth. It condenses the exhaust steam and the mixture is discharged into the ocean

b. Closed Cycle Ocean Thermal Energy Conversion System

- The warm water from the surface of the sea is circulated through a heat exchanger with help of a pump.

- In the heat exchanger, the heat of seawater is absorbed by Freon and Freon vapors are generated at high pressure.

- This vapor expands in the turbine to drive it and a coupled generator with it.

- The Freon vapor from the turbine condensed in a condenser with the help of cold water.

- The Freon condensate is pumped again into the heat exchanger and the complete cycle is repeated.

Advantages

- It is a clean and pollution free renewable source of energy.

- Power generated by this system is continuous. Only a small variation in output takes place from season to season. In simple words we can say, the system is independent of weather.

- By making only small changes in design, conventional power plants can be used in this system.

- It can produce the desalinated water and nutrients for mariculture at the same time.

Disadvantages:

- The capital cost is very high.

- The overall efficiency of the system is very low.

- The open cycle system needs very large sized turbine due to the low pressure of steam.

- In the closed cycle system, the working fluid is very expensive.

- The cost of power generation per kWH is very high.

TIDAL ENERGY

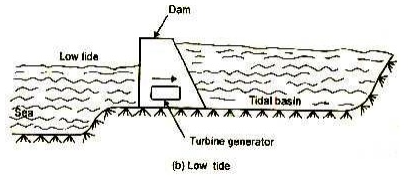

During high tide, when the level of water in the sea is high, sea-water flows into the reservoir of the barrage and turns the turbines. The turbines then turn the generator shaft to produce electricity.

During high tide, when the level of water in the sea is high, sea-water flows into the reservoir of the barrage and turns the turbines. The turbines then turn the generator shaft to produce electricity.

During low tide, the sea-water stored in the barrage reservoir is allowed to flow out into the sea. This flowing water also turns the turbines and generates electricity. Thus, as the sea-water flows in and out of the tidal barrage during high and low tides, the turbines rotate continuously to generate electricity.

Advantages

- It is predictable

- It is renewable

- It serves as coastal protection

- It reduces foreign importation of fuel

- It has a long lifespan

- It is effective at low speeds

- Operational and maintenance costs are low

Disadvantages

- It still has some environmental effects

- High tidal power plant construction costs

- It is still considered a new technology

- It is not cost-effective

- It should be close to land

FUEL CELL

FUEL CELL

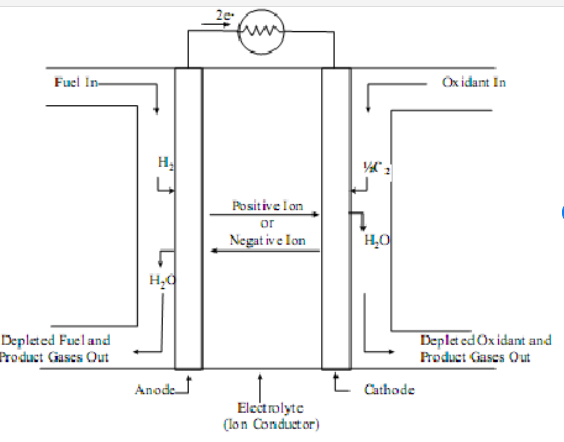

A Fuel cell is an electrochemical device in which the chemical energy of a conventional fuel is converted directly and efficiently into low voltage, direct-current electrical energy. One of the chief advantages of such a device is that because the conversion, atleast in theory, can be carried out isothermally, the Carnot limitation on efficiency does not apply. A fuel cell is often described as primary battery in which the fuel and oxidizer are stores external to the battery and fed to it as needed.

The fuel gas diffuses through the anode and is oxidized, thus releasing electrons to the external circuit; the oxidizer diffuses through the cathode and is reduced by the electrons that have come from the anode by way of the external circuit.

The working of this fuel cell involved the passing of hydrogen and oxygen into a concentrated solution of sodium hydroxide via carbon electrodes. The cell reaction can be written as follows:

Cathode Reaction: O2 + 2H2O + 4e– → 4OH–

Anode Reaction: 2H2 + 4OH– → 4H2O + 4e–

Net Cell Reaction: 2H2 + O2 → 2H2O

The fuel cell is a device that keeps the fuel molecules from mixing with the oxidizer molecules, permitting, however, the transfer of electrons by a metallic path that may contain a load.

Hydrogen has so far given the most promising results, although cells consuming coal, oil or natural gas would be economically much more useful for large scale applications.

Advantages

- High Efficiency- when utilizing co-generation, fuel cells can attain over 80% energy efficiency

- Good reliability- quality of power provided does not degrade over time.

- Noise- offers a much more silent and smooth alternative to conventional energy production.

- Environmentally beneficial- greatly reduces CO2 and harmful pollutant emissions.

- Size reduction- fuel cells are significantly lighter and more compact

Disadvantages

- Expensive to manufacture due the high cost of catalysts (platinum)

- Lack of infrastructure to support the distribution of hydrogen

- A lot of the currently available fuel cell technology is in the prototype stage and not yet validated.

- Hydrogen is expensive to produce and not widely available

MAGNETO HYDRO DYNAMICS (MHD)

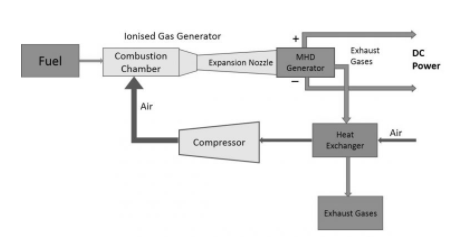

The MHD generator requires a gas source of high temperature, which can be either a coolant of a nuclear reactor or can be high-temperature combustion gases produced from coal.

As the gas and fuel pass through the expansion nozzle, it decreases the pressure of the gas and increases the speed of fluid/plasma through the MHD duct, and increasing the overall efficiency of the power output. The exhaust heat produced from the fluid through the duct is the DC power. It used to run the compressor to boost the fuel combustion rate.

Fuels like coal, oil, natural gas, and other fuels that are capable of producing high temperatures can be utilized in MHD generators. Besides this, MHD generators can use nuclear energy to generate electricity.

MHD generators are of two types – open cycle and closed-cycle systems. In an open cycle system, the working fluid is passed only once through the MHD duct. This produces exhaust gases after generating electrical energy, which is released to the atmosphere via a stack. The working fluid in a closed cycle system is recycled to the heat source for reusing it repeatedly.

The working fluid used in an open cycle system is air, whereas helium or argon is used in a closed cycle system

.

Advantages

- MHD generators convert heat or thermal energy directly into electrical energy

- It has no moving parts, so mechanical losses would be minimal

- Highly efficient Has higher operational efficiency more than conventional generators, therefore, the overall cost of an MHD plant is less compared to conventional steam plants

- Operational and maintenance costs are less

- It works on any type of fuel and has better fuel utilization

Disadvantages

- Aids in the high amount of losses that include fluid friction and heat transfer losses

- Needs large magnets, leading to higher costs in implementing MHD generators

- High operating temperatures in the range of 200°K to 2400°K will corrode the components sooner

Reference Books

- Textbook of Energy and Environmental Engineering by Chuck Lancaster et al

- Environmental Pollution Control Engineering by C S Rao

- Environmental Engineering-1 by H.S Vishwanath et al