Unit 7

Internal Combustion Engines

Content

Internal combustion (IC) engines- the fuel used undergoes combustion inside the engine in the presence of air. The product produced by the combustion becomes the working fluid of the engine.

Internal combustion engines have higher efficiency and are lighter in weight in comparison to the power developed. They have become very much suitable for mobile applications. With all these advantages, IC engines have become universal means of power generation and very much popular.

Classification of Internal Combustion (IC) Engine:

Internal combustion engines may be classified on the basis of:

- Thermodynamic cycle used – Otto cycle, diesel cycle, and dual cycle engine

- Fuel used – Petrol engine, diesel engine, gas engine, and kerosene oil engine

- Number of strokes for completion of cycle – Four-stroke engine and two-stroke engine

- Types of fuel ignition – Spark ignition (SI) and compression ignition (CI)

- Number of cylinders – Single cylinder engine and multi-cylinder engine

- Position of cylinders – Horizontal, vertical, V-engine, and radial engine

- Method of cooling engines – Air-cooled engine and water-cooled engine

Components of Internal Combustion (IC) Engine:

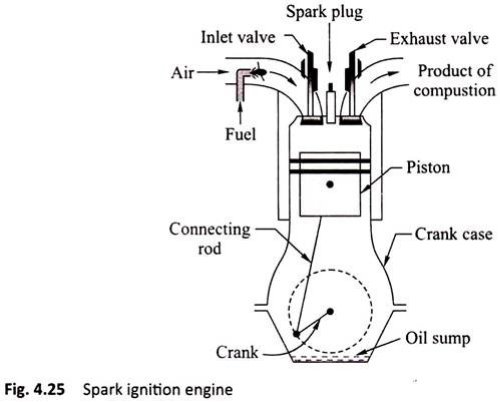

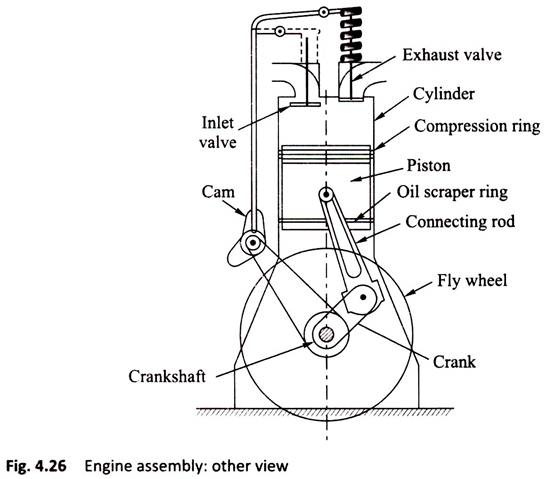

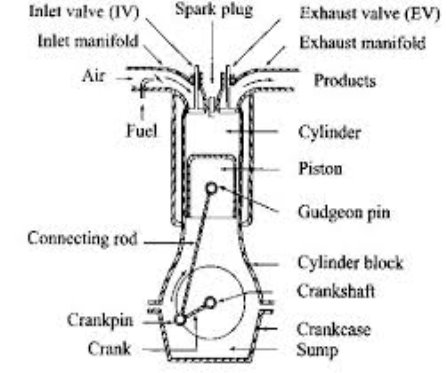

An assembled diagram with various parts of an IC engine is shown in Figure

i. Engine Cylinder:

It is a cylindrical vessel in which the fuel is burnt and the product of combustion gets expanded to develop power. Inside the cylinder, there is a sleeve fitted called the cylinder liner of hard metal. A piston makes reciprocating motion inside the cylinder.

Ii. Cylinder Head:

It is fitted at the top of cylinder to cover the cylinder. The cover provides the accommodation of inlet valve, exhaust valve, and spark plug (in SI engine) or injector (in CI engine).

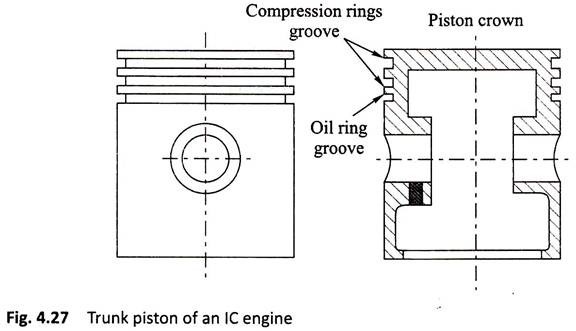

Iii. Piston:

Piston is a tightly fitted block generally known as trunk piston which receives the gas pressure inside the engine cylinder. The gas pressure is transmitted to the crankshaft through the connecting rod (Fig. 4.27).

Piston Rings:

There are two types of rings fitted on the circumferential groove provided on the outer surface of piston (Fig. 4.28):

Compression Ring:

Compression rings maintain a gas tight contact between cylinder and the piston.

Oil Scraper Ring:

Lubrication is required in the cylinder sleeve surface to reduce frictional forces. However, the excess oil needs to be removed. Thus, the ring will have a groove which removes this excess lubricating oil from the sleeve of the cylinder into the crank case.

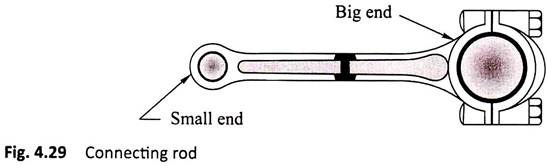

Connecting Rod:

Connecting rod transmits the force from piston to crankshaft. It helps in converting the reciprocating motion to rotary motion. It has two ends—small end and big end. The small end is connected with piston with a gudgeon pin. The big end is connected with crankshaft (Fig. 4.29).

Crank and Crankshaft:

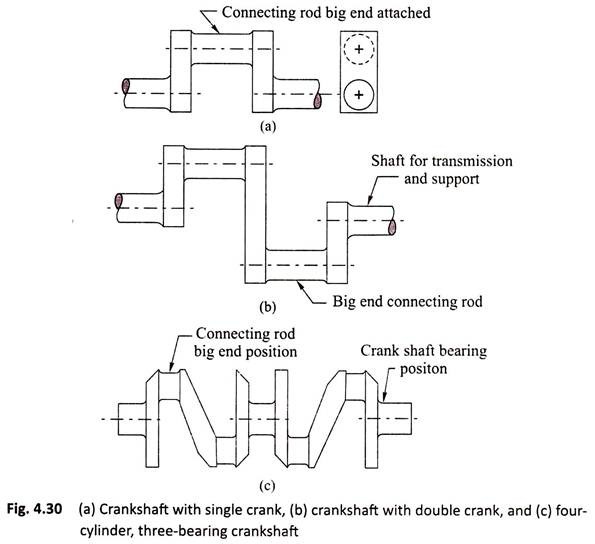

It converts the reciprocating motion of the piston to rotary motion of the shaft. The crankshaft is enclosed inside a crank case [Figs. 4.30(a) – 4.30(c)].

Valves:

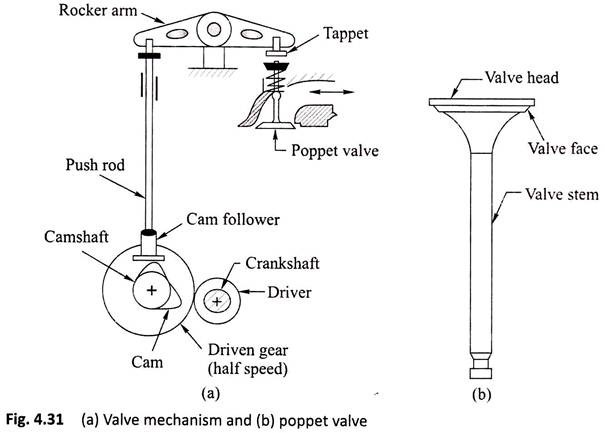

These valves are also called poppet valves.

There are two types of valves:

i. Suction valve and

Ii. Exhaust valve.

i. Suction Valve:

This valve controls the mixture of petrol vapours and air in SI engines and only air in CI engines.

Ii. Exhaust Valve:

It controls the flow of exhaust gas from the cylinder. The product of combustion is to be expelled out by opening this valve for starting fresh cycle.

The valves are operated by cam mechanism with the help of rocker arms in a single cylinder engine and by camshaft in a multi cylinder engine [Figs. 4.31(a) and 4.31(b)]. In four-stroke engines, the rotation of the camshaft is half of rotation of the crankshaft.

Fly Wheel:

Fly wheel is a heavy wheel mounted on engine shaft. It has large moment of inertia and, hence, absorbs energy during operation and supplies back the energy to the engine when required. Thus, this removes the cyclic fluctuation and maintains uniform rotation of the crankshaft. A single cylinder engine will have a large fly wheel, whereas a multi cylinder engine will have a smaller fly wheel.

Crank Case:

It is fitted in the lower part of the engine cylinder to cover crankshaft and also to store the lubricating oil known as oil sump.

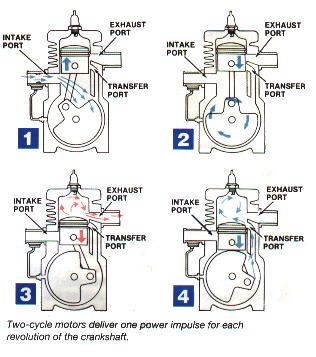

In two stroke engine the working cycle is completed in two stroke of the piston or one revolution of crankshaft. This is achieved by carried out suction and compression in one stroke expansion and exhaust in the second stroke.

A two stroke engine has port instead of valves. Opening and closing of the port are controlled by the piston

Following are the process in two stroke engine

1) Suction stroke: In this stroke piston while moving downward BDC (bottom dead centre) both the transfer port and exhaust port are open. The fresh fuel air mixture flows into the engine cylinder from crankcase.

2) Compression stroke: In this stroke, the piston while moving upwards, first cover the transfer port then exhausts port. After that fuel is compressed as the piston moves upwards. In this stage the inlet port opens and fresh air fuel mixture enters into crankcase.

3) Expansion stroke: During compression stroke the piston reached TDC (top dead centre) the charge is ignited with the help of spark plug .It suddenly increases the pressure and temperature of the product of combustion and volume remain constant. Due to rise in pressure the piston is pushed downwards with greater pressure .During the expansion some of the heat energy is produces and transform into mechanical work.

4) Exhaust stroke: In this stroke piston move downward and exhaust port is opened. The burned gases are exhaust from the engine cylinder through exhaust port into the atmosphere.

The two-stroke engines lighter, simpler and less expensive to manufacture. Two-stroke engines also have the potential to pack about twice the power into the same space because there are twice as many power strokes per revolution. The combination of light weight and twice the power gives two-stroke engines a great power-to-weight ratio compared to many four-stroke engine designs.

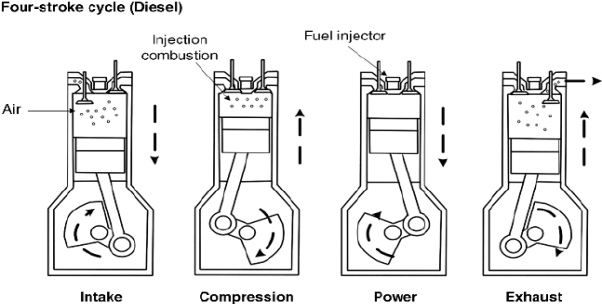

Four stroke engine

In four stroke engine the working cycle is completed in four stroke of the piston or two revolution of crankshaft. This is achieved by carried out suction in one stroke and compression in second stroke, expansion in third stroke and exhaust in the fourth stroke. They have inlet and exhaust valve. Suction and compression in one revolution of crankshaft, expansion and exhaust in second revolution of crankshaft.

Following are the process in four stroke engine;

1) Suction stroke: In this stroke while piston moving downward BDC (bottom dead centre) inlet valve opens and pure air is sucked into the cylinder.

2) Compression stroke: In this stroke, the piston while moving from BDC to TDC, the inlet and outlet valve are closed. The compressed start as piston moves upwards. Which increase pressure and temperature .this complete one revolution of crankshaft

3) Expansion stroke: just before the piston reached the top dead centre fuel oil injected in the form of very fine spray into the cylinder. At this point temperature of the compressed air is sufficiently high to ignite the fuel which suddenly increase the pressure and temperature of combustion products. Due to increase in pressure the piston is pushed down with a great force.

4) Exhaust stroke: In this stroke exhaust valve open as piston move from BDC to TDC .This movement of the piston moves up and pushed out the burned gases to atmosphere from the engine cylinder

SI and CI engine

S.I Engine:

S I Stands for Spark Ignition. This is one kind of IC (Internal Combustion) engine.

There are four processes in engine.

- Intake or suction

- Compression

- Power or combustion

- Exhaust

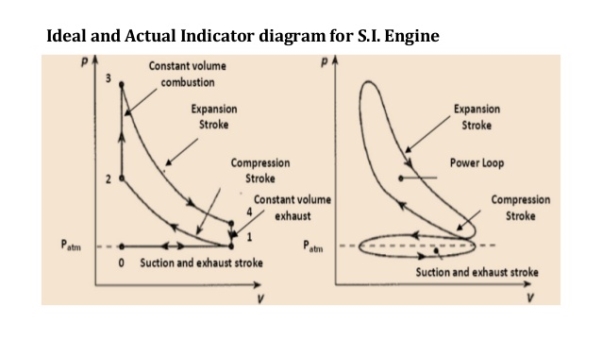

Process 0-1 (Suction stroke)

At the start of cycle, the piston moves from TDC to BDC. The inlet valve (I.V.) is opened automatically by valve operating mechanism at the start of this process. Due to increase in volume inside the cylinder, a slight vacuum is created and, the fresh charge i.e. mixture of air and petrol prepared in Carburettor is sucked inside the cylinder through inlet valve. At the end of stroke, the piston reaches BDC position, total volume of cylinder is filled with fresh charge and inlet valve is closed. Theoretically, the charge is filled at constant pressure P1 and it occupies the total volume of cylinder V1.

Process 1-2 (Compression stroke)

During this stroke, both the valves remain closed and piston is moved from BDC to TDC by the force of crank. As the piston moves up, volume of cylinder shrinks and the fresh charge is compressed to a higher pressure P2 and volume V2 equal to clearance volume. Theoretically, this process is adiabatic compression process. Temperature of fresh charge is also raised in compression from T1 to T2.

Process 2-3 (heat addition or constant volume combustion)

This process is actually a constant volume heat addition process. At point 2, spark plug ignites and starts the combustion of already compressed, high temperature charge. Due to very favourable conditions of combustion, combustion of charge and heat release takes place in no time and pressure & temperature further shoots up to P3 and T3. Theoretically the volume remains constant from 2 to 3. So V2=V3=VC=Clearance Volume.

Process 3-4 (expansion or working stroke)

This is the process or stroke of piston in which positive work is obtained. The burnt gases at high pressure and high temperature at point 3 expand and push the piston again from TDC to BDC, thus doing work on the piston. This work is given to output shaft of engine through connecting rod and crank shaft. A small portion of it is stored in the heavy rotating flywheel mounted on crankshaft, which is used in movement of piston in three other idle stroke i.e. Suction, Compression and Exhaust. When piston reaches BDC, cylindrical total volume is filled with comparatively lower pressure and temperature burnt gases or smoke. At this point 4, the exhaust valve (EV) opens.

Process 4-1 (heat rejection or constant volume exhaust)

In this process, as soon as the exhaust valve is opened at point 4, the burnt gases start escaping to atmosphere and their pressure reduces to atmospheric pressure P1. Theoretically, this process happens in no time and escaping of exhaust gases take away some heat from the engine.

Process 1-0 (exhaust stroke)

This stroke is just opposite to suction stroke. Piston moves from BDC to TDC and pushes away or sweeps the remaining burnt gases out through E.V. As the piston reaches TDC most of burnt gases escape and E.V. Is closed. One cycle of the engine completes here. Simultaneously, the I.V. Opens and next cycle starts.

In this way, piston goes on moving or reciprocating from TDC to BDC and BDC to TDC with a high speed and engine produces power continuously by burning of petrol or gas etc. The power output and RPM of engine can be easily controlled by a throttling valve fitted in the passage of air intake or in the carburettor where fuel and air are mixed together in the right proportion in the exhaust phase, the piston goes upward and the burnt gases go away through the exhaust valve.

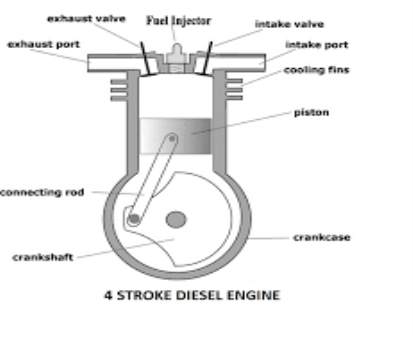

C.I Engine:

A diesel engine is called compression Ignition engine because here the conditions of combustion or ignition are achieved only by compression of air to a very high pressure.

There is no spark plug to initiate the combustion, but in place of that a fuel injector is there, which injects and atomizes the fuel. Diesel at a very high pressure in very hot compressed air after compression stroke in engine Due to high pressure and temperature above the ignition temperature, fuel atomization, evaporation and self-ignition take place.

The rest of the working of Diesel Engine is same as that of Petrol or Gasoline Engine. Here also one complete cycle is comprised of all the processes of Diesel cycle along with suction of fresh air and exhaust of burnt gases. To carry out all these processes, here also normally 4 strokes of piston are required. So, it is called a 4-stroke Diesel Engine or C.I Engine.

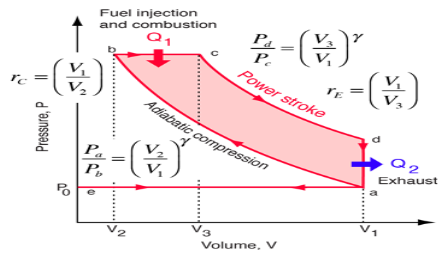

Process e-a (suction stroke)

At the start of cycle, the piston moves from TDC to BDC and inlet valve is opened at the start of process at point e. Due to increase in volume of cylinder by the movement of piston, the fresh air from atmosphere enters the cylinder and occupies all the space inside the cylinder until piston reaches BDC. At the point a, air filled in cylinder is at volume V1 and its pressure & temperature are theoretically same as that of outside atmosphere. Here inlet valve is closed and cylinder becomes a closed thermodynamic system.

Process a-b (compression stroke)

In this stroke, piston moves from BDC to TDC by the force of crank. As both valves are closed, the air sucked in previous stroke is compressed to the clearance volume. Here in Diesel engine the compression ratio rc which is the ratio of total volume V1 to clearance volume V2 is very high as compared to SI Engine. So, naturally the rise in pressure and temperature of air at the end of compression stroke is also more. The range of rc (compression ratio) in Diesel Engine is 15 to 22. Theoretically, the compression process is adiabatic & isentropic Compression.

Process b-c (heat addition or fuel injector)

This process is actually a constant pressure heat addition process or a mix of constant volume and constant pressure process as in case of high speed diesel engine. At the point b the fuel injector injects a fix quantity of fuel in very hot & compressed air compressed to the clearance volume. Due to that fuel spray ignites itself thus releasing of heat in the cylinder. As this heat addition process is slow, piston moves back to some distance from TDC to point c shown in fig and the volume increases which nullifies the effect of increase in pressure due to heat addition. Pressure remains constant theoretically up to point c, where the injector stops injection of fuel and so the addition of heat. Point c is also called cut-off point. A part of piston stroke from b to c takes place along with this process and the burning fuel plus air mixture expand and push the piston producing a positive work.

Process c-d (expansion stroke or power stroke)

Actually, the complete expansion stroke is from point b to point d but a part of it is along the previous heat addition process b-c. After point c heat addition stops and the hot and high pressure burnt gases expand at the cost of their own internal energy and produce positive work by pushing the piston to BDC. This stroke is called working stroke as here piston moves the crankshaft and give mechanical energy. Major part of this energy is given to output shaft and a small portion is stored in heavy flywheel in the form of its rotational kinetic energy and used up during idle strokes of piston i.e. Suction, Compression & Exhaust.

Process d-a (heat rejection)

This process takes place at constant volume and heat is rejected directly by escaping of some of burnt gases due to pressure difference inside and outside the engine as soon as exhaust valve opens at point d i.e. just at the end of expansion or working stroke. Theoretically, piston remains at BDC and gases escape in no time, taking away some heat from the engine. Pressure inside the cylinder reduces to atmospheric pressure.

Process a-e (exhaust stroke)

In this process or stroke, piston is moved by crank from BDC to TDC. As the exhaust valve remains open during this stroke, piston displaces or sweeps out the burnt gases through it and only a small fraction of gases remain in the clearance volume finally. The piston reaches TDC and the cycle completes as the initial conditions are again reached. At this point, exhaust valve closes and inlet valve opens and next cycle starts.

In this way piston moves or reciprocates from TDC to BDC and again from BDC to TDC with a high speed and engine produces power continuously by burning of air and fuel mixture. The power output and RPM of engine here can be controlled by controlling the quantity of fuel injected only. There is no restriction on the quantity of air sucked by engine. There is a mechanical or electric control on the fuel injection depending on fuel injection system used. When more power is required more quantity of fuel is injected and when less power is required accordingly fuel supply is reduced. There is no control on the quantity of air so air sucked remains more or less same. In this way only the quality of combustible mixture changes in different conditions of loading and so Quality Governing is used in CI Engine.

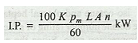

The indicated power of an IC engine (briefly written as I.P.) is the power actually developed by the engine cylinder. Mathematically,

Where

K = Number of cylinders,

pm = Actual mean effective pressure in bar (1 bar = 100 kN/m2),

L = Length of stroke in meters,

A = Area of the piston in m2,

n = Number of working strokes per minute

= Speed of the engine for two stroke cycle engine

= Half the speed of the engine for four stroke cycle engine.

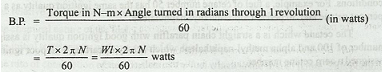

The brake power (briefly written as B.P.) of an IC Engine is the power available at the crankshaft. The brake power of an I.C. Engine is, usually, measured by means of a brake mechanism (prony brake or rope brake).

In case of prony brake, brake power of the engine

Where

W = Brake load in newtons,

l = Length of arm in metres, and

N = Speed of the engine in r.p.m.

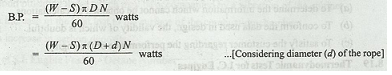

In case of rope brake, brake power of the engine

Where

W = Dead load in newtons,

S = Spring balance reading in newtons,

D = Diameter of the brake drum in metres,

d = Diameter of the rope in metres, and

N = Speed of the engine in r.p.m.

Note : The brake power (B.P.) of an engine is always less than the indicated power (I.P.) of an engine, because some power is lost in overcoming the engine friction (known as frictional power). Mathematically,

Frictional power, F.P. = I.P. — B.P.

The power developed by the engine at the output shaft is called break power. Indicated power produced inside the IC engine cylinder will be transmitted through the piston connecting rodand crank. Therefore, a certain fraction of the indicated power produced inside the cylinder will be lost due to friction of the moving parts of the engine. Therefore, net power available at the crankshaft will be equal to the difference between the Indicated power produced insidethe engine cylinder and the power lost due to friction.

The efficiency of an IC engine (Internal Combustion Engine) is defined as the ratio of work done to the energy supplied to an engine. The following efficiencies of a 1.C. Engine are important:

(a) Mechanical efficiency. It is the ratio of brake power (B.P.) to the indicated power (I.P.).Mathematically, mechanical efficiency,

Since B. P. Is always less than I.P. , therefore mechanical efficiency is always less than unity (i.e. 100%).

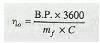

(b) Overall efficiency. It is the ratio of the work obtained at the crankshaft in a given time to the energy supplied by the fuel during the same time. Mathematically, overall efficiency,

Where

B.P. = Brake power in kW,

Mf = Mass of fuel consumed in kg per hour, and

C = Calorific valve of fuel in kJ / kg of fuel.

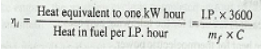

(c) Indicated thermal efficiency. It is the ratio of the heat equivalent to one kW hour to the heat in the fuel per I.P. Hour, indicated thermal efficiency,

The following ratio is Known as specific fuel consumption per I.P. Hour:

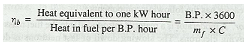

(d) Brake thermal efficiency. It is the ratio of the heat equivalent to one kW hour to the heat in the fuel per B.P. Hour. Mathematically, brake thermal efficiency,

The following ratio is known as specific fuel consumption per B. P. Hour:

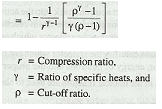

(e) Air standard efficiency. The general expression for the air standard efficiency is given as

(For petrol engines)

(For diesel engines)

(f) Relative efficiency. It is also known as efficiency ratio. The relative efficiency of an I. C. Engine is the ratio of the indicated thermal efficiency to the air standard efficiency.

(g) Volumetric efficiency. It is the ratio of the actual volume of charge admitted during the suction stroke at N.T.P to the swept volume of the piston.