GUJARAT TECHNOLOGICAL UNIVERSITY

Unit – 1

Introduction to Civil Engineering and Civil Engineering Materials

Content

Civil Engineering is that field of engineering concerned with planning, design and construction for environmental Control, development of natural resources, buildings, transportation facilities and other structures required for health, welfare, safety, employment and pleasure of mankind"

The main scope of civil engineering or the task of civil engineering is planning, designing, estimating, supervising construction, managing construction, execution, and maintenance of structures like building, roads, bridges, dams, etc. ' One who designs and maintains works of public utility is known as civil engineer. Civil engineer should have qualities like scientific attitude, imaginative and intuitive approach, He should have good analysis and decision power. He should be able to solve engineering problems, by using mathematical modelling, scientific principles and laboratory techniques using computer and information technology. He should be able to use operation research techniques for solution of management problems.

Branches in civil engineering

Civil engineering is the design, implementation, and maintenance of public works. This involves facilities and structures such as arenas, large scale monuments, government buildings, transportation routes as well as other structures. Engineers will either work for the city or for a private firm that has been hired by the city. Some civil engineers work in the private sector on projects for independent companies. There are several types of civil engineering. A civil engineer can specialize in a number of different civil engineering branches. Those branches are described briefly below:

- Structural Engineering

- Geotechnical Engineering

- Environmental Engineering

- Transportation Engineering

- Water Resource Engineering

- Earthquake Engineering

- Material Engineering

- Construction Engineering

- Surveying

- Municipal Engineering

- Coastal Engineering

- Tunnel Engineering

Scope of Civil Engineering Civil engineering is the oldest branch of engineering which is growing right from the stone age of civilization. American society of civil engineering defines civil engineering as the profession in which a knowledge of the mathematical and physical sciences gained by study, experience and practice is applied with judgment to develop ways to utilize economically the materials and forces of the nature for the progressive well being of man.

Role of Civil Engineers in various construction activities

A civil engineer has to conceive, plan, estimate, get approval, create and maintain all civil engineering activities.

Civil engineer has very important role in the development of the following infrastructure:

- Measure and map the earth’s surface.

- Plan new townships and extension of existing towns

- Build the suitable structures for the rural and urban areas for various utilities

- Build tanks and dams to exploit water resources.

- Build river navigation and flood control projects.

- Provide and maintain communication systems like roads, railways, harbours and airports

- Purify and supply water to the needy areas like houses, schools, offices etc.

- Build canals and distributaries to take water to agricultural fields

- Devise systems for control and efficient flow of traffic

- Provide and maintain solid and waste water disposal system

- Monitor land, water and air pollution and take measures to control them

Fast growing industrialization has put heavy responsibilities on civil engineers to preserve and protect environment.

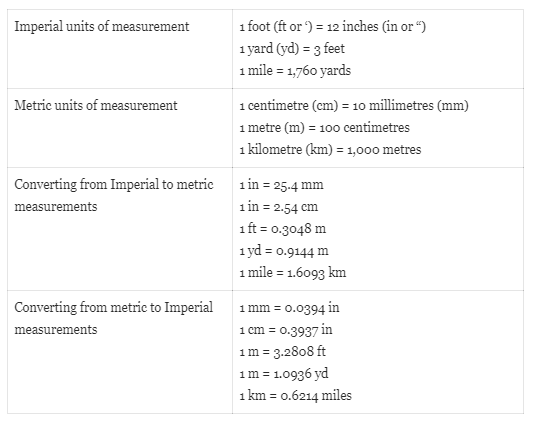

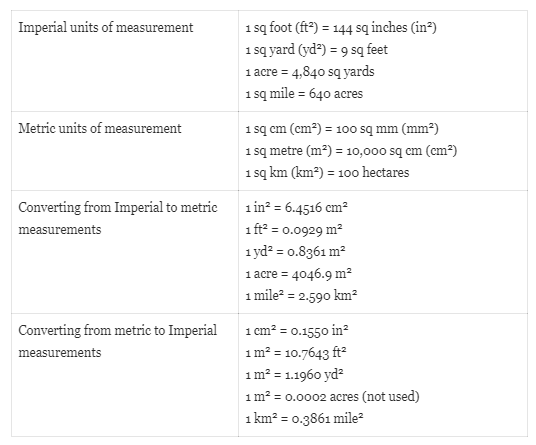

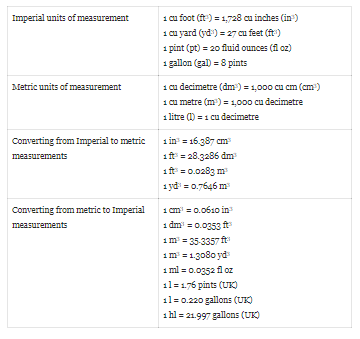

In the fields of civil engineering, unit conversion of various measurements is must have knowledge now-a-days. Therefore, we must know the basic conversion of different units. A unit of measurement is a definite magnitude of a quantity, defined and adopted by convention or by law, that is used as a standard for measurement of the same kind of quantity. Any other quantity of that kind can be expressed as a multiple of the unit of measurement.

Systems of Unit Measurement

There are different standards and unit systems used in the world. Few common systems of measurements used in Engineering fields are:

CGS Unit System

In the CGS unit system, the length is measured in centimetre, mass is measured in gram and time is measured in second.

FPS Unit System

In the FPS system, the length is measured in feet, mass is measured in pound and time is measured in second.

SI Unit System

Different units are used in different countries for the measurement of physical quantities. In the US, pound metrics is used commonly for indicating mass. But in India, the kilogram is used to measure the same physical quantity. To remove these differences, the SI (International System of units) system was standardized in 1960. In the SI unit, 8 physical quantity is assumed to be the Fundamental Unit or Basic Unit.

Unit Conversion

Conversion of Length

Conversion of Length

Conversion of Volume/Capacity

CEMENT

Cement is a binder, a substance that sets and hardens and can bind other materials together. Cements used in construction can be characterized as being either hydraulic or non-hydraulic, depending upon the ability of the cement to be used in the presence of water. Non-hydraulic cement will not set in wet conditions or underwater, rather it sets as it dries and reacts with carbon dioxide in the air. It can be attacked by some aggressive chemicals after setting. Hydraulic cement is made by replacing some of the cement in a mix with activated aluminium silicates, pozzolanas, such as fly ash. The chemical reaction results in hydrates that are not very water-soluble and so are quite durable in water and safe from chemical attack. This allows setting in wet condition or underwater and further protects the hardened material from chemical attack (e.g., Portland cement).

USE OF CEMENT

- Cement mortar for Masonry work, plaster and pointing etc.

- Concrete for laying floors, roofs and constructing lintels, beams, weather shed, stairs, pillars etc.

- Construction for important engineering structures such as bridge, culverts, dams, tunnels, light house, clocks, etc.

- Construction of water, wells, tennis courts, septic tanks, lamp posts, telephone cabins etc.

- Making joint for joints, pipes , etc.

- Manufacturing of precast pipes, garden seats, artistically designed wens, flower posts, etc.

- Preparation of foundation, water tight floors, footpaths, etc.

ENGINEERING PROPERTIES OF CEMENT

Fineness

- This test is carried out to check proper grinding of cement. The fineness of cement particles may be determined either by sieve test or permeability apparatus test.

- In sieve test ,the cement weighing 100 gm is taken and it is continuously passed for 15 minutes through standard BIS sieve no. 9.The residue is then weighed and this weight should not be more than 10% of original weight.

- In permeability apparatus test, specific area of cement particles is calculated. This test is better than sieve test. The specific surface acts as a measure of the frequency of particles of average size.

Compressive strength

- This test is carried out to determine the compressive strength of cement.

- The mortar of cement and sand is prepared in ratio 1:3.

- Water is added to mortar in water cement ratio 0.4.

- The mortar is placed in moulds. The test specimens are in the form of cubes and the moulds are of metals. For 70.6 mm and 76 mm cubes ,the cement required is 185gm and 235 gm respectively.

- Then the mortar is compacted in vibrating machine for 2 minutes and the moulds are placed in a damp cabin for 24 hours.

- The specimens are removed from the moulds and they are submerged in clean water for curing.

- The cubes are then tested in compression testing machine at the end of 3days and 7 days. Thus compressive strength was found out.

Consistency

- The purpose of this test is to determine the percentage of water required for preparing cement pastes for other tests.

- Take 300 gm of cement and add 30 percent by weight or 90 gm of water to it.

- Mix water and cement thoroughly.

- Fill the mould of Vicat apparatus and the gauging time should be 3.75 to 4.25 minutes.

- Vicat apparatus consists of a needle is attached a movable rod with an indicator attached to it.

- There are three attachments: square needle, plunger and needle with annular collar.

- The plunger is attached to the movable rod. The plunger is gently lowered on the paste in the mould.

- The settlement of plunger is noted. If the penetration is between 5 mm to 7 mm from the bottom of mould, the water added is correct. If not process is repeated with different percentages of water till the desired penetration is obtained.

Setting time

- This test is used to detect the deterioration of cement due to storage. The test is performed to find out initial setting time and final setting time.

- Cement mixed with water and cement paste is filled in the Vicat mould.

- Square needle is attached to moving rod of vicat apparatus.

- The needle is quickly released and it is allowed to penetrate the cement paste. In the beginning the needle penetrates completely. The procedure is repeated at regular intervals till the needle does not penetrate completely. (up to 5mm from bottom)

- Initial setting time equal to or less than 30min for ordinary Portland cement and 60 min for low heat cement.

- The cement paste is prepared as above and it is filled in the Vicat mould.

- The needle with annular collar is attached to the moving rod of the Vicat apparatus.

- The needle is gently released. The time at which the needle makes an impression on test block and the collar fails to do so is noted.

- Final setting time is the difference between the time at which water was added to cement and time as recorded in previous step ,and it is equal to or less than 10hours.

Soundness

- The purpose of this test is to detect the presence of un combined lime in the cement.

- The cement paste is prepared.

- The mould is placed and it is filled by cement paste.

- It is covered at top by another glass plate. A small weight is placed at top and the whole assembly is submerged in water for 24 hours.

- The distance between the points of indicator is noted. The mould is again placed in water and heat is applied in such a way that boiling point of water is reached in about 30 minutes. The boiling of water is continued for one hour.

- The mould is removed from water and it is allowed to cool down.

- The distance between the points of indicator is again measured. The difference between the two readings indicates the expansion of cement and it should not exceed 10 mm.

Tensile strength

- This test was formerly used to have an indirect indication of compressive strength of cement.

- The mortar of sand and cement is prepared.

- The water is added to the mortar.

- The mortar is placed in briquette moulds. The mould is filled with mortar and then a small heap of mortar is formed at its top . It is beaten down by a standard spatula till water appears on the surface. Same procedure is repeated for the other face of briquette.

- The briquettes are kept in a damp for 24 hours and carefully removed from the moulds.

- The briquettes are tested in a testing machine at the end of 3 and 7 days and average is found out

BRICKS

Constituents of good brick earth: Bricks are the most commonly used construction material. Bricks are prepared by moulding clay in rectangular blocks of uniform size and then drying and burning these blocks. In order to get a good quality brick, the brick earth should contain the following constituents.

- Silica

- Alumina

- Lime

- Iron oxide

- Magnesia

Brick plays very important role in the field of civil engineering construction. Bricks are used as an alternative of stones in construction purpose.

- Uses of Bricks

- Construction of walls of any size

- Construction of floors

- Construction of arches and cornices

- Construction of brick retaining wall

- Making Khoa (Broken bricks of required size) to use as an aggregate in concrete

- Manufacture of surki (powdered bricks) to be used in lime plaster and lime concrete

Classification of Bricks as per constituent materials

There are various types of bricks used in masonry

- Common Burnt Clay Bricks

- Sand Lime Bricks (Calcium Silicate Bricks)

- Engineering Bricks

- Concrete Bricks

- Fly ash Clay Bricks

Common Burnt Clay Bricks

Common burnt clay bricks are formed by pressing in moulds. Then these bricks are dried and fired in a kiln. Common burnt clay bricks are used in general work with no special attractive appearances. When these bricks are used in walls, they require plastering or rendering.

Sand Lime Bricks

Sand lime bricks are made by mixing sand, fly ash and lime followed by a chemical process during wet mixing. The mix is then moulded under pressure forming the brick. These bricks can offer advantages over clay bricks such as: their colour appearance is grey instead of the regular reddish colour. Their shape is uniform and presents a smoother finish that doesn’t require plastering. These bricks offer excellent strength as a load-bearing member.

Engineering Bricks

Engineering bricks are bricks manufactured at extremely high temperatures, forming a dense and strong brick, allowing the brick to limit strength and water absorption. Engineering bricks offer excellent load bearing capacity damp-proof characteristics and chemical resisting properties. Concrete Bricks Concrete bricks are made from solid concrete. Concrete bricks are usually placed in facades, fences, and provide an excellent aesthetic presence. These bricks can be manufactured to provide different colours as pigmented during its production.

Fly Ash Clay Bricks

Fly ash clay bricks are manufactured with clay and fly ash, at about 1,000 degrees C. Some studies have shown that these bricks tend to fail poor produce pop-outs, when bricks come into contact with moisture and water, causing the bricks to expand.

- ENGINEERING PROPERTIES OF BRICKS

To know the quality of bricks following 7 tests can be performed. In these tests some are performed in laboratory and the rest are on field.

- Compressive strength test

- Water Absorption test

- Efflorescence test

- Hardness test

- Size, Shape and Colour test

- Soundness test

Structure test Compressive strength test

This test is done to know the compressive strength of brick. It is also called crushing strength of brick. Generally 5 specimens of bricks are taken to laboratory for testing and tested one by one. In this test a brick specimen is put on crushing machine and applied pressure till it breaks. The ultimate pressure at which brick is crushed is taken into account. All five brick specimens are tested one by one and average result is taken as brick’s compressive/crushing strength.

Water Absorption test

In this test bricks are weighed in dry condition and let them immersed in fresh water for 24 hours. After 24 hours of immersion those are taken out from water and wipe out with cloth. Then brick is weighed in wet condition. The difference between weights is the water absorbed by brick. The percentage of water absorption is then calculated. The less water absorbed by brick the greater its quality. Good quality brick doesn’t absorb more than 20% water of its own weight.

Efflorescence test

The presence of alkalies in bricks is harmful and they form a grey or white layer on brick surface by absorbing moisture. To find out the presence of alkalis in bricks this test is performed. In this test a brick is immersed in fresh water for 24 hours and then it’s taken out from water and allowed to dry in shade. If the whitish layer is not visible on surface it proofs that absence of alkalis in brick. If the whitish layer visible about 10% of brick surface then the presence of alkalis is inacceptable range. If that is about 50% of surface then it is moderate. If the alkalies’ presence is over 50% then the brick is severely affected by alkalies.

Hardness test

In this test a scratch is made on brick surface with a hard thing. If that doesn’t left any impression on brick then that is good quality brick.

Size, shape and colour test

In this test randomly collected 20 bricks are staked along lengthwise, width wise and height wise and then those are measured to know the variation of sizes as per standard. Bricks are closely viewed to check if its edges are sharp and straight and uniform in shape. A good quality brick should have bright and uniform colour throughout.

Soundness test

In this test two bricks are held by both hands and struck with one another. If the bricks give clear metallic ringing sound and don’t break then those are good quality bricks.

Structure test In this test a brick is broken or a broken brick is collected and closely observed. If there are any flows, cracks or holes present on that broken face then that isn’t good quality brick.

STONES

- USES OF STONES

- Stone masonry is used for the construction of foundations, walls, columns and arches.

- Stones are used for flooring.

- Stone slabs are used as damp proof courses, lintels and even as roofing materials.

- Stones with good appearance are used for the face works of buildings. Polished marbles and granite are commonly used for face works.

- Stones are used for paving of roads, footpaths and open spaces round the buildings.

- Stones are also used in the constructions of piers and abutments of bridges, dams and retaining walls.

- Crushed stones with graved are used to provide base course for roads. When mixed with tar they form finishing coat.

Crushed stones are used in the following works also:

- As a basic inert material in concrete.

- For making artificial stones and building blocks.

- As railway ballast.

- ENGINEERING PROPERTIES OF STONES

1. STRUCTURE

The structure of the stone may be stratified (layered) or unstratified. Structured stones should be easily dressed and suitable for super structure. Unstratified stones are hard and difficult to dress. They are preferred for the foundation works.

2. TEXTURE

Fine grained stones with homogeneous distribution look attractive and hence they are used for carving. Such stones are usually strong and durable.

3. DENSITY

Denser stones are stronger. Light weight stones are weak. Hence stones with specific gravity less than 2.4 are considered unsuitable for buildings.

4. APPEARANCE

A stone with uniform and attractive colour is durable, if grains are compact. Marble and granite get very good appearance, when polished. Hence they are used for face works in buildings.

5. STRENGTH

Strength is an important property to be looked into before selecting stone as building block. Indian standard code recommends, a minimum crushing strength of 3.5 N/mm2 for any building block

6. HARDNESS

It is an important property to be considered when stone is used for flooring and pavement. Coefficient of hardness is to be found by conducting test on standard specimen in Dory’s testing machine. For road works coefficient of hardness should be at least 17. For building works stones with coefficient of hardness less than 14 should not be used.

7. PERCENTAGE WEAR

It is measured by attrition test. It is an important property to be considered in selecting aggregate for road works and railway ballast. A good stone should not show wear of more than 2%.

8. POROSITY AND ABSORPTION

All stones have pores and hence absorb water. The reaction of water with stone causes disintegration. Absorption test is specified as percentage of water absorbed by the stone when it is immersed under water for 24 hours. For a good stone it should be as small as possible and in no case more than 5.

9. WEATHERING

Rain and wind cause loss of good appearance of stones. Hence stones with good weather resistance should be used for face works.

10. TOUGHNESS

The resistance to impact is called toughness. It is determined by impact test. Stones with toughness index more than 19 are preferred for road works. Toughness index 13 to 19 is considered as medium tough and stones with toughness index less than 13 are poor stones.

11. RESISTANCE TO FIRE

Sand stones resist fire better. Argillaceous materials, though poor in strength, are good in resisting fire.

12. EASE IN DRESSING

Cost of dressing contributes to cost of stone masonry to a great extent. Dressing is easy in stones with lesser strength. Hence an engineer should look into sufficient strength rather than high strength while selecting stones for building works.

13. SEASONING

The stones obtained from quarry contain moisture in the pores. The strength of the stone improves if this moisture is removed before using the stone. The process of removing moisture from pores is called seasoning. The best way of seasoning is to allow it to the action of nature for 6 to 12 months. This is very much required in the case of laterite stones.

TIMBER

TIMBER is the oldest material used by humans for construction after stone. Despite its complex chemical nature, wood has excellent properties which lend themselves to human use. It is readily and economically available; easily machinable; amenable to fabrication into an infinite variety of sizes and shapes using simple on-site building techniques;

- Exceptionally strong relative to its weight

- A good heat and electrical insulator

- It is a renewable and biodegradable resource

A tree basically consists of three parts namely, trunk, crown and roots. The function of the trunk is to support the crown and to supply water and nutrients from the roots to the leaves through branches and from the leaves back to the roots .The roots are meant to implant the trees in the soil ,to absorb moisture and the mineral substances it contains and to supply them to the trunk.

ENGINEERING PROPERTIES OF TIMBER

The quality of timber must be ensured before using it for a purpose. The quality can be ensured by investigating the properties of timber. Here we have discussed both physical and mechanical properties of timber which affects timber quality.

Followings are the physical and mechanical properties of Timber

- Colour

- Appearance

- Hardness

- Specific Gravity

- Moisture Content

- Grain

- Shrinkage and Swelling

- Strength

- Density

- Toughness

- Elasticity

- Warping

- Durability

- Defectless

- Workability

- Soundness

- Free of abrasion

Colour

Color is a uniform property by which most trees are characterized as they show variation from tree to tree. Light color indicates weak timber. For example, freshly cut teak, Deodar, and Walnut have a golden yellow, whitish and dark brown shades respectively.

Appearance

Smell is a good property as timbers for few plants as they can be identified by their characteristic aroma. Fresh cut timbers have a good smell. For example resinous smell from pine.

Hardness

For the resistance of any kind of damage, hardness is an obvious property.

Specific Gravity

Variation of timber in specific gravity (0.3-0.9) is found. It depends on pores present inside timber. The specific gravity of this light material is less than that of water (<1). But in case of compact wood where pores are almost absent and become heavier, their specific gravity increases up to 1.5.

Moisture Content

Timbers are hygroscopic and gain water from nature (atmosphere). The absorption of water or dehydration depends on atmospheric humidity. If timbers moisture content is high that means the timber quality is low. Water content is the risk of fungal attack.

Grain

Several types of grain arrangement found. On the grain structure quality of timber varies. Grains remain closely related.

- Straight grain: Arrangement of vascular tissue (xylem and phloem) is important which grow parallel to the length of the timber that is termed as straight grain.

- Coarse grain: vascular tissue and fibre arranged broadly and widely.

- Interlocked grain: Instead of parallel arrangement twisted, a spiral arrangement may be found.

Shrinkage and Swelling

The percentage of shrinkage and swelling varies from plant to plant. Some give higher percentage after drying. Shrinkage starts when cell walls of timber start to release water. In moisture atmosphere timber swells when cell walls absorb water. Good quality timbers swell less. Timbers having thicker wall swell more than a thinner one.

Strength

Best quality timbers have the highest strength. Strength means capable to bear loads. Anisotropic material like timber has different structure at the different portion. So, the strength of timber is different at different points. Grain structure determines the strength of the timber. Some types of strength are

- Compressive strength: 500 kg/cm2 to 700 kg/cm2 load is enough to test timbers strength.

- Tensile strength: When timber is enough strong to the tensile force. If perpendicular force is made then timber is weaker. 500-2000 kg/cm2 is the range of tensile strength load.

- Transverse strength: Enough bending strength indicates good quality timber.

Density

Timber having higher density have a thicker wall. An important property that quality of timber. Moisture content: Presence of defects: There may be some of the natural and artificial defects in timber such as cross-grain, knots, and shakes, etc. All of them cause a decrease in the strength of the timber.

Toughness

Timber has to have the capability to bear shocks, jerk. Anti-bending and ant splitting characteristic is needed. Old timbers have annual rings which indicate their age is a good indicator.

Elasticity

Another property elasticity means timber should attain its own shape after use. Because of this quality, it is used in sports bat.

Warping

Environmental change with season can’t effect good quality timber.

Durability

A good quality timber has the property to resist the attack the infection of fungus or other insects. This resistance quality makes timber better.

Defectless

This property is gained if the timber is from a sound tree. A defectless tree is free from sap, shakes, and dead knots.

Workability

A good timber is always easy to work on it. Easy to drag using saw on good timber. The finishing can be done well.

Soundness

A good quality timber gives good sound.

Texture

The texture of good timber is fine and even.

Free of Abrasion

Timber should not be damaged by the external environment. It has to gain the ability to protect its skin.

USES OF TIMBER

Wood is a plant part having multipurpose uses those are impossible to deny and difficult to note all in our daily life. From the ancient time wood is used by human and this continuation still remains in the modern civilization. A few of many uses of wood are mentioned below:

1. Construction and Fencing

- Home Construction:

During the early periods, use of wood in domestic construction was a common scene and this is still followed in this twenty-first century. In different parts of the world in the making of houses, wood is used commonly like the flooring, frames of doors and windows for its strength and internment quality. e.g. Deodar, walnut wood is used in Pakistan widely, teak in South Asia and all over the world, Chir pine etc. In Bangladesh during construction of buildings woods from mango,bur flower tree are used for casting and piling.

- Fencing and Decorating Gardens:

In modern decoration system woods are also used for building the fencing and simple decoration for artificial gardening inside a home or on roofs.

E.g. Cedar, redwood, Shorea sp, Acacia sp.

2. Household Uses

- Utensils:

Utensils made up of wood instead of plastic and steel are a symbol of elegance which increases the charm and loveliness of the home corners.

e.g. Black walnut wood is used in the west for home utensils.

- Hand Tools:

The handles of most common hand tools made of wood help as heat resistant when they are kitchenware used in an oven and closes the chance to shock while used on electricity.

3. Art Industry

- Artworks:

For artworks such as statues, sculptures, carvings and making decorative objects woods are widely used. The frames of art board, color plate are also made from wood in many cases. E.g. Pine, maple, cherry wood for framing work.

- Musical instrument:

The musical instruments such as Piano, violin, cello, drums, flute, guitar, double bass and a number of other music instruments material requires wood for making a perfect tune. e.g. Mahogany , maple, ash wood for guitars.

4. Sports Equipment

- Wooden Toys:

These are preferred to plastic towards the health conscious people which were supposed as a fashion before. Plastic is nothing but the combination of chemicals which is hazardous to children's health. Cricket, hockey, billiard, table tennis etc. Toys and sports equipment have long made use of wood for handles and main parts. e.g. Willow wood for cricket, tennis bat; Mulberry wood for hockey sticks.

5. Commercial Uses

- Furniture:

At present, the market for wooden furniture is very profitable. No one can deny the demand for wooden furniture as it is a sign of aristocracy since ancient time.

e.g. Teak wood is the best for making furniture. Some other woods from Mahogany , Shimul , Sundari, Jackfruit, Mango trees are used in south Asia for making different types of furniture.

- Ship building

Ships and rural fishing boats were made from wood. For constructing boats and ships wood is one of the most important construction material. Hardwood and softwood were used in the past for ship industry.

e.g. Teak, shal , mango, Arjun were frequently used in the past. Now Cypress ,redwood ,white, oak are water resistant and used for shipbuilding and boat building. Woods like kauri is used for making the frames of ships.

- Fuel

Wood is an age-old source of energy all over the world. Before the exploration of gas, fuel was the main source we can also define as only one source of energy that people used by burning as woods were available in the forest easily. Generally, sticks, pellets, sawdust, and charcoal are used as an energy source from wood. Usually, woods from cheap plants are used in this sector.

- Stationary

Some stationaries like paper pencil are made of wood. Wood pulp is used for making paper. Wood is used for making pencils too.

e.g. In the past Cyper papyrus trees were used to make paper.

SAND

Sand is a mixture of small grains of rock and granular materials which is mainly defined by size, being finer than gravel and coarser than silt. And ranging in size from 0.06 mm to 2 mm. Particles which are larger than 0.0078125 mm but smaller than 0.0625 mm are termed silt.

Sand is made by erosion or broken pebbles and weathering of rocks, which is carried by seas or rivers. And freezing and thawing during the winter break rock up the sand will be made. Sometimes Sand on beaches can also be made by small broken-up pieces of coral, bone, and shell, which are broken up by predators and then battered by the sea, and even tiny pieces of glass from bottles discarded in the sea and other mineral materials or the bones of fishes or other oceanic animals. Sand can be also considered as a textural class of soil or soil type.

USES OF SAND

In the real world, there are a lot of situations where we can find uses of sand. Followings are the common sand uses.

- We can use sand to filter water; it works like an abrasive.

- We can use sand to give a grip to our painting or wall art by combining 2 cups of paint with a ¾ cup of sand.

- People make sandpaper by gluing sand to a paper.

- While bunging metal, we can mix sand with clay binder for frameworks used in the foundries.

- Sand can be used for cleaning up oil leak or any spill by dredging sand on that spill. The material will form clumps by soaking up, and we can quickly clean the mess.

- Sand can be used as a road base which is a protective layer underneath all roads

- Industrial sand is used to make glass, as foundry sand and as abrasive sand.

- One creative usage of sand is serving as a candle holder. We can try putting some sand before pouring tea light or any candle in a glass. It holds the candle still and refrain the candle from rolling by giving it an excellent decoration.

- Adds texture and aesthetic appeal to space.

- Sand is mostly pure to handle, promptly available and economically wise.

- We can make children’s sandpit to keep the play areas safer. It is quite inexpensive as well.

- We use sand in aquariums, fabricating artificial fringing reefs, and in human-made beaches

- Sandy soils are ideal for growing crops, fruits and vegetables like watermelon, peaches, peanuts, etc.

- Sand can light a path by filling mason jars with sand and tea light which is another inexpensive way to make a walkway glow.

- Sand can be used for cleaning narrow neck receptacle by putting a little sand and warm soapy water in the container.

- We can keep an item steady which needs repairing by using sand. Burying the broken pieces under sand grains helps to hold the elements together while gluing.

- Sand helps to improve resistance (and thus traffic safety) in icy or snowy conditions.

- We need sand in the beaches where tides, storms or any form of preconceived changes to the shoreline crumble the first sand.

- Sand containing silica is used for making glass in the automobile and food industry- even household products for the kitchen.

- Sand is a strong strand which is used for plaster, mortar, concrete and asphalt.

- The usual bricks formulated of clay only is way weaker and lesser in weight than blocks made of clay mixed with sand.

ENGINEERING PROPERTIES OF GOOD SAND

Followings are the desirable properties of sand:

- Should be completely inert. (i.e., should not have any chemical activity).

- Grains should be sharp, strong & angular.

- Should not contain any hygroscopic salts (i.e., CaCl2, MgCl2, etc.).

- Should not contain clay & silt; usually 3-4% clay & silt is ordinarily permitted for practical reasons.

- There should be no organic matter.

AGGREGATES

Aggregate is an aggregation of non-metallic minerals obtained in particulate form and can be processed and used for civil and highway engineering construction.

Aggregates are mainly classified into two categories:

- Fine Aggregate

- Coarse Aggregate

ENGINEERING PROPERTIES OF AGGREGATES

Aggregates are used in concrete to provide economy in the cost of concrete. Aggregates act as filler only. These do not react with cement and water. But there are properties or characteristics of aggregate which influence the properties of resulting concrete mix. These are as follow.

- Composition

- Size & Shape

- Surface Texture

- Specific Gravity

- Bulk Density

- Voids

- Porosity & Absorption

- Bulking of Sand

- Fineness Modulus of Aggregate

- Surface Index of Aggregate

- Deleterious Material

- Crushing Value of Aggregate

- Impact Value of Aggregate

- Abrasion Value of Aggregate

1. COMPOSITION

Aggregates consisting of materials that can react with alkalies in cement and cause excessive expansion, cracking and deterioration of concrete mix should never be used. Therefore it is required to test aggregates to know whether there is presence of any such constituents in aggregate or not.

2. SIZE & SHAPE

The size and shape of the aggregate particles greatly influence the quantity of cement required in concrete mix and hence ultimately economy of concrete. For the preparation of economical concrete mix on should use largest coarse aggregates feasible for the structure. IS-456 suggests following recommendation to decide the maximum size of coarse aggregate to be used in P.C.C & R.C.C mix.

Maximum size of aggregate should be less than

- One-fourth of the minimum dimension of the concrete member.

- One-fifth of the minimum dimension of the reinforced concrete member.

- The minimum clear spacing between reinforced bars or 5 mm less than the minimum cover between the reinforced bars and form, whichever is smaller for heavily reinforced concrete members such as the ribs of the main bars.

3. SURFACE TEXTURE

The development of hard bond strength between aggregate particles and cement paste depends upon the surface texture, surface roughness and surface porosity of the aggregate particles. If the surface is rough but porous, maximum bond strength develops. In porous surface aggregates, the bond strength increases due to setting of cement paste in the pores.

4. SPECIFIC GRAVITY

The ratio of weight of oven dried aggregates maintained for 24 hours at a temperature of 100 to 1100C, to the weight of equal volume of water displaced by saturated dry surface aggregate is known as specific gravity of aggregates.

5. BULK DENSITY

It is defined as the weight of the aggregate required to fill a container of unit volume. It is generally expressed in kg/litre.

Bulk density of aggregates depends upon the following 3 factors.

- Degree of compaction

- Grading of aggregates

- Shape of aggregate particles

6. VOIDS

The empty spaces between the aggregate particles are known as voids. The volume of void equals the difference between the gross volume of the aggregate mass and the volume occupied by the particles alone.

7. POROSITY & ABSORPTION

The minute holes formed in rocks during solidification of the molten magma, due to air bubbles, are known as pores. Rocks containing pores are called porous rocks. Water absorption may be defined as the difference between the weight of very dry aggregates and the weight of the saturated aggregates with surface dry conditions.

Depending upon the amount of moisture content in aggregates, it can exist in any of the 4 conditions.

- Very dry aggregate ( having no moisture)

- Dry aggregate (contain some moisture in its pores)

- Saturated surface dry aggregate (pores completely filled with moisture but no moisture on surface)

- Moist or wet aggregates (pores are filled with moisture and also having moisture on surface)

8. BULKING OF SAND

It can be defined as in increase in the bulk volume of the quantity of sand (i.e. fine aggregate) in a moist condition over the volume of the same quantity of dry or completely saturated sand. The ratio of the volume of moist sand due to the volume of sand when dry, is called bulking factor.

9. FINENESS MODULUS

Fineness modulus is an empirical factor obtained by adding the cumulative percentages of aggregate retained on each of the standard sieves ranging from 80 mm to 150 micron and dividing this sum by 100.

Fineness modulus is generally used to get an idea of how coarse or fine the aggregate is. More fineness modulus value indicates that the aggregate is coarser and small value of fineness modulus indicates that the aggregate is finer.

10. SPECIFIC SURFACE OF AGGREGATE

The surface area per unit weight of the material is termed as specific surface. This is an indirect measure of the aggregate grading. Specific surface increases with the reduction in the size of aggregate particle. The specific surface area of the fine aggregate is very much more than that of coarse aggregate.

11. DELETERIOUS MATERIALS

Aggregates should not contain any harmful material in such a quantity so as to affect the strength and durability of the concrete. Such harmful materials are called deleterious materials. Deleterious materials may cause one of the following effects

- To interfere hydration of cement

- To prevent development of proper bond

- To reduce strength and durability

- To modify setting times

12. CRUSHING VALUE

The aggregates crushing value gives a relative measure of resistance of an aggregate to crushing under gradually applied compressive load. The aggregate crushing strength value is a useful factor to know the behavior of aggregates when subjected to compressive loads.

13. IMPACT VALUE

The aggregate impact value gives a relative measure of the resistance of an aggregate to sudden shock or impact. The impact value of an aggregate is sometime used as an alternative to its crushing value.

14. ABRASION VALUE OF AGGREGATES

The abrasion value gives a relative measure of resistance of an aggregate to wear when it is rotated in a cylinder along with some abrasive charge.

MORTAR

Mortar is a bonding agent which is generally produced by mixing cementing or binding material (lime or cement) and fine aggregate (sand, surki, sawdust, etc.) with water. Mortar is used to bind different building blocks like bricks, stones, etc. It can also add a decorative pattern in brick or stone masonry.

Mortar, a bonding agent between building materials, is mainly a mixture of water, fine aggregate (sand, surki, etc) and binding material like cement, lime etc. The applications of mortar in various construction phase have made it a very important civil engineering material.

- USES OF MORTAR

- Mortar is used to bind together the bricks or stones in brick or stone masonry.

- It is used to give a soft even bed between different layers of brick or stone masonry for equal distribution of pressure over the bed.

- It is used to fill up the spaces between bricks or stones for making walls tight.

- It is used in concrete as a matrix.

- It is used in plastering works to hide the joints and to improve appearance.

- It is used for molding and ornamental purpose.

ENGINEERING PROPERTIES OF MORTAR

Cement: It should be fresh and free from adulteration. To know more about the properties of good cement read >> Properties of Good Cement

Lime: Lime must be well slaked.

Sand: Sand should be sharp, angular and porous. It should be free from salts and other impurities. Read>> Function of Sand in Mortar

Surki: Surki should be perfectly pure and free from foreign matter. It should be sufficiently fine to pass through the desired sieve

Mud: Mud should be free from adulteration.

Water: Water should be clean and free from salts and other impurities.

CONCRETE

Concrete is a composite material composed mainly of water, aggregate, and cement. Often, additives and reinforcements are included in the mixture to achieve the desired physical properties of the finished material. When these ingredients are mixed together, they form a fluid mass that is easily molded into shape. Over time, the cement forms a hard matrix which binds the rest of the ingredients together into a durable stone-like material with many uses.

- USES OF CONCRETE

- It’s an important building product. Concrete is chosen over wood as a construction material.

- It is a durable and cost-effective material which is a necessity for underground use.

- Concrete is a sustainable choice for residential and commercial projects.

- The strength of concrete increases over time.

- Concrete can hold up against weather condition and is easy to maintain.

- It is budget friendly to use everywhere. It is easy to repair & energy efficient.

- Concrete is safe for building occupants.

- Concrete is an inert material which doesn’t burn, mildew or feed rot.

- Its superior structural integrity provides added degree of protection from the severe weather as well as an earthquake.

- Concrete walls and floors make a home quite place of rest, relaxation and rejuvenation.

- Concrete is produced from locally available materials and leaves a small environmental footprint while still providing high-level durability.

- It is used as aggregate in roadbeds or as granular materials while making new concrete.

- Concrete is fire resistant. It can resist extreme level of flames and heat which is a good choice of the ceiling in a storage room.

- Concrete can be shaped in various forms when freshly mixed.

- Concrete isn’t sensitive to moisture.

- It doesn’t release any volatile organic compounds into the air which is environment-friendly.

- Concrete gives a longer service life.

- It keeps home safe from insects. It doesn’t attract insect pest and rodents. That’s why small animals cannot burrow through the concrete to make a home.

- Concrete has multiple design possibilities.

- Concrete can be used to achieve optimum environmental performance.

- As it is recyclable, it is possible to use it for addition.

- High-performance concrete is used to build bridges.

- Concrete is able to accommodate steel reinforcements in gates, tunnel lines, electrical controls.

- A concrete floor can be stamped to create an attractive surface. It can admit natural light during the day and transmit artificial light after work.

- Concrete is used in driveways and patios

- ENGINEERING PROPERTIES OF CONCRETE

Strength

Strength of concrete are of the following types:

- Compressive strength

- Tensile strength

- Flexural strength

- Shear strength

a. Compressive Strength

b. Tensile strength

Concrete is very weak in tension. The tensile strength of ordinary concrete ranges from about 7 to 10 percent of the compressive strength.

c. Flexural strength

The flexural strength of plain concrete is almost wholly dependent upon the tensile strength. However, experiments show that the modulus of rupture is considerably greater than the strength in tension.

d. Shear strength

It is the real determining factor in the compressive strength of short columns. The average strength of concrete in direct shear varies from about half of the compressive strength for rich mixtures to about 0.8 of the compressive strength for lean mixtures.

Workability

The strength of concrete of a given mix proportion is very seriously affected by the degree of its compaction. It is therefore vital that the consistency of the mix be such that the concrete can be transported, placed and finished sufficiently easily and without segregation. A concrete satisfying these conditions is said to be workable.

Factors affecting the workability of concrete are:

- Water Content

- Mix Proportions

- Size of Aggregates

- Shape of Aggregates

- Grading of Aggregates

- Surface Texture of Aggregates

- Use of Admixtures

- Use of Supplementary Cementitious Materials

- Time

- Temperature

Elastic Properties

Concrete is not perfectly elastic for any range of loading, an appreciable permanent setting taking place for even low loads. The deformation is not proportional to the stress at any stage of loading. The elastic properties of concrete vary with the richness of the mixture and with the intensity of the stress. They also vary with the age of concrete.

Durability

Durability is the property of concrete to withstand the condition for which it has been designed, without deterioration over a period of years. Lack of durability can be caused by external agents arising from the environment or by internal agents within the concrete.

Impermeability

Penetration of concrete by materials in solution may adversely affect its durability, for instance, when Ca(OH)2 is being leached out or an attack by aggressive liquids (acids) takes place. Permeability has an important bearing on the vulnerability of concrete to water and frost. In the case of reinforced cement concrete, the penetration of moisture and air will result in the corrosion of steel. This leads to an increase in the volume of the steel, resulting in cracking and spalling of the concrete. Permeability of concrete is also of importance for liquid retaining and hydraulic structures

Segregation

The tendency of separation of coarse aggregate grains from the concrete mass is called segregation. It increases when the concrete mixture is lean and too wet. It also increases when rather large and rough-textured aggregate is used. The phenomenon of segregation can be avoided as follows.

- Addition of little air-entraining agents in the mix.

- Restricting the amount of water to the smallest possible amount.

- All the operations like handling, placing and consolidation must be carefully conducted.

- Concrete should not be allowed to fall from large heights.

Bleeding

The tendency of water to rise to the surface of freshly laid concrete is known as bleeding. The water rising to the surface carries with it, particles of sand and cement, which on hardening form a scum layer is popularly known as laitance. Concrete bleeding can be checked by adopting the following measures.

- By adding more cement

- By using more finely ground cement

- By properly designing the mix and using the minimum quantity of water

- By using little air entraining agent

- By increasing the finer part of fine aggregate

Fatigue

Plain concrete when subjected to flexure, exhibits fatigue. The flexure resisting ability of concrete of a given quality is indicated by an endurance limit whose value depends upon the number of repetitions of stress. In concrete pavement design, the allowable flexural working stress is limited to 55% of the modulus of rupture.

STEEL

USES OF STEELS

Some vital utilization of steels are given below:

- Steel is environment-friendly & sustainable. It posses great durability.

- Compared to other materials, steel requires a low amount of energy to produce lightweight steel construction.

- Steel is the world’s most recycled material which can be recycled very easily. Its unique magnetic properties make it an easy material to recover from stream to be recycled.

- Steel can be designed into various forms. It gives better shape and edge than iron which is used to make weapons.

- Engineering steels are used for general engineering and manufacturing sectors.

- Steel is highly used in the automobile industry. Different types of steels are used in a car body, doors, engine, suspension, and interior. The average 50% of a car is made of steel.

- Steel reduces CO2 emissions.

- All types of energy sectors demand steel for infrastructure and resource extraction.

- Stainless steels are used to produce offshore platforms and pipelines.

- Steels are used for packaging and protecting goods from water, air and light exposure.

- Most of the household appliances like fridge, TV, oven, sinks, etc are made of steel.

- Steels are used for producing industrial goodies like farm vehicles and machines.

- Stainless steel is used as a cutlery material.

- Because of its easily welding capability and attractive finishing, steel has become a prominent feature in modern architecture.

- Stainless steel gives a hygienic environment. That’s why it is used for surgical implants.

- Steel has a wider range of temperature which is used to make large sheets.

- Renewable energy resources like solar, hydro and wind power use the stainless steel components.

- Mild steel is used for building construction. It is also a highly favored building frame material.

- ENGINEERING PROPERTIES OF STEEL

- Tensile strength

The stress-strain curve for the steel is generally obtained by conducting tensile test on any standard steel specimen. Tensile strength of the steel can be defined in terms of yield strength and ultimate strength.

b. Hardness

Hardness is regarded as the resistance of any material to identification and scratching. This is generally determined by forcing an indenter on to the surface. The resultant deformation steel is both elastic and plastic. The different methods to find out the hardness of metal which includes Brinell hardness test, Vicker’s hardness test, and Rockwell hardness test.

c. Toughness

There is the possibility of microscopic cracks in a material or the material may develop such cracks as a result of several cycles of loading. These cracks may result in sudden collapse of the structure and it is very dangerous. Therefore to ensure that this should not happen, materials in which the cracks grow slowly are preferred. These types of steel are known as notch-tough steels and the amount of energy it absorb is measure by impacting the notch specimen.

d. Fatigue strength

A component of structure, which is designed to carry a single monotonically static load, may fail if the same load is applied cyclically a large number of times. If the example of a thin rod is considered, it bent back and forth beyond yielding fails after few cycles of such repeated bending. This type of failure is termed as fatigue failure. Examples: bridges, cranes, offshore structure, slender tower, etc.

e. Corrosion resistance

Corrosion is the procedure in which oxidation of a metal in a normal atmospheric condition owing to the excessive presence of moisture and oxygen in the air. Corrosion of the metal is a very natural and rapid phenomenon in the areas of high humidity and places closer to saline water. Therefore the efforts to be made to control the corrosion by using galvanize and epoxy coated reinforcement bars but failed in practical usage due to the risk of disbanding, causing accelerated corrosion. Corrosion resistance elements such as copper, phosphorus and chromium are added in appropriate measure to the metal which results in corrosion resistance steel.

BITUMEN

A black viscous mixture of hydrocarbons obtained naturally or as a residue from petroleum distillation.

- ENGINEERING PROPERTIES OF BITUMEN

- Adhesion

- Resistance to Water

- Hardness

- Viscosity and Flow

- Softening Point

- Ductility

- Specific Gravity

- Durability

- Versatility

- Economical

- Strength

Adhesion

The adhesive property of bitumen binds together all the components without bringing about any positive or negative changes in their properties. Bitumen has the ability to adhere to a solid surface in a fluid state depending on the nature of the surface. The presence of water on the surface will prevent adhesion.

Resistance to Water

Bitumen is insoluble in water and can serve as an effective sealant Bitumen is water resistant. Under some conditions water may be absorbed by minute quantities of inorganic salts in the bitumen or filler in it.

Hardness

To measure the hardness of bitumen, the penetration test is conducted, which measures the depth of penetration in tenths of mm. Of a weighted needle in bitumen after a given time, at a known temperature.

The grades with penetrations greater than 40 are mostly used in road construction and occasionally in industrial applications. The grades with penetrations less than 40 are used exclusively in industrial applications. In hot climate lower grades such as 60/70 is used

Viscosity and Flow

The viscous or flow properties of bitumen are of importance both at high temperature during processing and application and at low temperature to which bitumen is subjected during service. The flow properties of bitumens vary considerably with temperature and stress conditions. Deterioration, or loss of the desirable properties of bitumen, takes the form of hardening. Resultantly, decrease in adhesive and flow properties and an increase in the softening point temperature and coefficient of thermal expansion.

Softening point

This property make us to know whether given bitumen can be used at the particular place i.e. softening point value should be higher than pavement temperature otherwise bitumen present in the layer get soften and come out.

Softening point is the temperature at which a steel ball falls a known distance through the bitumen when the test assembly is heated at a known rate.

Ductility

Ductility test is conducted to determine the amount bitumen will stretch at temperature below its softening point. A briquette having a cross sectional area of 1 in 2 is placed in a tester at 77 °F. Ductility values ranges from 0 to over 150 depending on the type of bitumen. Presence of ductility means the formation of the film and coating would be proper.

Specific Gravity

Specific gravity of a binder does not influence its behaviour . But all the same, its value is needed in mix design. The property is determined at 27º C.

Durability

Bitumen durability refers to the long-term resistance to oxidative hardening of the Material in the field. Although, in-service, all bitumens harden with time through reaction.

With oxygen in the air, excessive rates of hardening (poor durability) can lead to premature binder embrittlement and surfacing failure resulting in cracking and chip loss. Bitumen lives up to twenty years if maintained properly throughout the pavement life.

Versatility

Due to versatility property of Bitumen it is relatively easy to use it in many applications because of its thermoplastic property. It can be spread easily along the underlying pavement layers as it liquefies when heated making the job easier and hardens in a solid mass when cooled.

Economical

It is available in cheaper rates almost all over the world which makes it feasible and affordable in many applications.

Strength

Though the coarse aggregates are the main load bearing component in a pavement, bitumen or asphalt also play a vital role in distributing the traffic loads to the layers beneath.

- USES OF BITUMEN

Damp proofing

For damp proofing, prefabricated mats that are sprayed with blown bitumen are used. They are also used to prevent pollution from spreading in the form of small water-retaining, bituminous walls at refuse disposal sites.

Roofing

Coverings of Roofs (Shingles) and Roofing felts are made of fibres or plastics. These are impregnated with penetration-grade bitumen and coated with blown-grade bitumen.

Tanking of basements

Bitumen is the usual choice for waterproofing of Basements like Asphalt.

Preservation of stones

These materials are used for preservation of stonework from attack by salts and other substances present in the ground and atmosphere.

Pavements

Largely used for the construction of roads, runways, taxiways, etc.

Protection of structures

It is used as a protective coating by impregnation for concrete elements such as slabs, piles, etc. Organic binders of 10-15 mm thickness are also applied over these coatings, to prevent the bitumen from corroding off.

PLASTIC

Plastics are man-made materials. Plastics have taken the place of traditional materials like woods and metals.

Plastics differ from other materials largely because of the size of their molecules. Most materials have molecules made up of less than 300 atoms, plastics contain thousands of atoms. We call them Macromolecules.

Some plastics are derived from natural substances such as animals, insects and plants but most are man-made. These are named Synthetic Plastics.

Most synthetic plastics come from crude oil but coal and natural gas is also used.

When crude oil is refined gasses are given off . The gasses are broken down into Monomers. These are chemical substances consisting of a single molecule. Thousands of these are linked together in a process called Polymerisation to form new compounds called Polymers.

There are two main types of plastics and these are named Thermoplastics and Thermosetting Plastics.

Thermoplastics are made up of lines of molecules with few cross linkages. This allows them to soften when heated and to be bent into a variety of shapes and forms. They become stiff and solid again when cold. This process can be repeated many times.

Thermosetting Plastics are made up of lines of molecules which are heavily cross linked. It creates a rigid molecular structure. They may be heated the first time and shaped but they become permanently stiff and solid. They cannot be reshaped again.

Plastic Memory. Each time a plastic is reheated it will attempt to return to its original flat shape unless it has been over heated or damaged. This is called a plastic memory.

Below is 7 of the most popular and commonly used plastics:

- Acrylic or Polymethyl Methacrylate (PMMA)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PETE or PET)

- Polyvinyl Chloride (PVC)

- Acrylonitrile-Butadiene-Styrene (ABS)

SOIL

Soil is a material composed of five ingredients — minerals, soil organic matter, living organisms, gas, and water. Soil minerals are divided into three size classes — clay, silt, and sand (Figure 1); the percentages of particles in these size classes is called soil texture.

TYPES

Sandy soil

- Sandy Soil is light, warm, dry and tend to be acidic and low in nutrients. Sandy soils are often known as light soils due to their high proportion of sand and little clay (clay weighs more than sand).

- These soils have quick water drainage and are easy to work with. They are quicker to warm up in spring than clay soils but tend to dry out in summer and suffer from low nutrients that are washed away by rain.

- The addition of organic matter can help give plants an additional boost of nutrients by improving the nutrient and water holding capacity of the soil.

Clay Soil

- Clay Soil is a heavy soil type that benefits from high nutrients. Clay soils remain wet and cold in winter and dry out in summer.

- These soils are made of over 25 percent clay, and because of the spaces found between clay particles, clay soils hold a high amount of water.

- Because these soils drain slowly and take longer to warm up in summer, combined with drying out and cracking in summer, they can often test gardeners.

Silt Soil

- Silt Soil is a light and moisture retentive soil type with a high fertility rating.

- As silt soils compromise of medium sized particles they are well drained and hold moisture well.

- As the particles are fine, they can be easily compacted and are prone to washing away with rain.

- By adding organic matter, the silt particles can be bound into more stable clumps.

Peat Soil

- Peat soil is high in organic matter and retains a large amount of moisture.

- This type of soil is very rarely found in a garden and often imported into a garden to provide an optimum soil base for planting.

Chalk Soil

- Chalk soil can be either light or heavy but always highly alkaline due to the calcium carbonate or lime within its structure.

- As these soils are alkaline they will not support the growth of ericaceous plants that require acidic soils to grow.

- If a chalky soil shows signs of visible white lumps then they can’t be acidified and gardeners should be resigned to only choose plants that prefer an alkaline soil.

Loam Soil

- Loam soil is a mixture of sand, silt and clay that are combined to avoid the negative effects of each type.

- These soils are fertile, easy to work with and provide good drainage. Depending on their predominant composition they can be either sandy or clay loam.

- As the soils are a perfect balance of soil particles, they are considered to be a gardeners best friend, but still benefit from topping up with additional organic matter.

PROPERTIES

Colour

The easiest property of soil to spot is its colour. Colour tells us about a soil's nutrients. For the most part, the darker a soil is, the more nutrients it has to support plant growth.

The dark colour comes from decaying organic matter, materials from living things. Think about what happens to a banana as it starts to rot. The yellow peel turns black. This is the same process that happens to the organic matter in soil.

Texture

Have you ever grabbed a handful of sand from a sandbox? You can see individual grains of sand as you hold it in your hand because sand is a type of soil made of large particles. The size of the particles that make up a soil are its texture.

A soil's texture determines how easily water can move through it. The larger the particles making up a soil are, the larger the pores (spaces) between the particles are. Large pores make it easy for air and water to move through soil. If water can move through soil easily, it is not stored for plants to use. This is bad news for most plants that need water around to grow.

Structure

Soil structure describes the way particles in soil are stuck together to form shapes called peds, and the way those peds are arranged.

There are many different soil structures. Some soils have blocky peds shaped like cubes, while others have platy peds shaped like flat sheets of paper.

Just like texture, soil structure affects the way water and air move through soil. Different types of peds fit together in different ways- some soil structures have large spaces for water and air to travel through, while others have small spaces

EPOXY

The resins which have at least two epoxy groups per molecule are known as epoxy resins.

An epoxide is a cyclic ether with a 3 atom ring.

Types

- Bisphenol A epoxy resin

- Bisphenol F epoxy resin

- Novolac epoxy resin

- Aliphatic epoxy resin

- Glycidylamine epoxy resin

PROPERTIES

- High thermo stability

- High abrasion resistance

- Acceptable drying time

- Low shrinkage

- Excellent weather/ chemical resistance

- Excellent adhesive strength

APPLICATIONS

- Paints and coatings

- Adhesives Industrial tooling and composites

- Electrical systems and electronics

- Petroleum & petrochemical

- Consumer and marine applications

- Aerospace applications

- Biology

- Art

FLYASH

It is one of the residues generated in combustion of coal. Comprises of fine particles which rise with the flue gases.

One of the major pollutants which originate from combustion.

Due to recent mandate of using pollution control equipments, these are now collected using electrostatic precipitators and other particle filters.

It is a heterogeneous material containing SiO2, Al2O3 and Fe2O3 as major constituents with CaO occasionally being the minor constituent.

USES

- Waste Treatment

- As a catalyst

- Geo polymers

- Embankments

- Asphalt Concrete

- Fly ash Bricks

- Soil Stabilization

- Admixture for Portland Cement

PROPERTIES

Physical Characteristic of Fly Ash

Fly ash is a fine grained material consisting mostly of spherical, glassy particles. Some ashes also containing irregular or angular particles. Fly ash is the pulverized fuel ash extracted from the fuel gases by any suitable process like cyclone separation or electrostatic precipitation.

Size and Shape of Fly Ash

The size of particles varies depending on the sources. Some ashes may be finer or coarser than Portland cement particles. Fly ash consists of silt sized particles which are generally spherical, typically ranging in size between 10 to 100 micron , Shows the scanning electron microscope (SEM) micrographs of polished sections of sub-bituminous and shows a secondary electron SEM image of bituminous of fly ash particles . Some of these particles appear to be solid, whereas other larger particles appear to be portions of thin, hollow spheres containing many smaller particles.

Colour of Fly Ash

Fly ash can be tan to dark gray, depending on its chemical and mineral constituents. Tan and light colours are typically associated with high lime content. A brownish colour is typically associated with the iron content. A dark gray to black colour is typically attributed to an elevated unburned content. Fly ash colour is usually very consistent for each power plant and coal source.

Fineness of Fly Ash

Dry and wet sieving are commonly used to measure the fineness of fly ashes. ASTM designation C311-77 recommends determining the amount of the sample retained after it is wet sieve done on a 45-m sieve, in accordance with ASTM method C 430, except that a representative sample of the fly ash or natural pozzolana is substituted for hydraulic cement in the determination. Dry sieving on a 45-m sieve can be performed according to a method established at Canada Center for Mineral and Energy Technology(CANMET). High-calcium fly ashes were finer than low-calcium fly ashes.

Specific Gravity of Fly Ash

The specific gravity of different fly ashes varies over a wide range. The specific gravity ranged from a low value of 1.90 for a sub-bituminous ash to a high value of 2.96 for an iron-rich bituminous ash. Some sub-bituminous ash had a comparatively low specific gravity of ≈ 2.0, and this shows that hollow particles, such as ceno spheres or plero spheres, were present in significant proportions in the ashes.

In general, the physical characteristics of fly ashes vary over a significant range, corresponding to their source. Fineness is probably influenced more by factors such as coal combustion and ash collection and classification than by the nature of the coal itself. Similarly, the type of fly ash showed no apparent influence on the specific surface as measured by the Blaine technique. Moreover, except in some cases, there was very little relationship between the specific surface as measured by the Blaine and the fineness as determined by percentage retained on a 45цm sieve.

STEEL SLAG

Steel slag, a by-product of steel making, is produced during the separation of the molten steel from impurities in steel-making furnaces. The slag occurs as a molten liquid melt and is a complex solution of silicates and oxides that solidifies upon cooling.

Virtually all steel is now made in integrated steel plants using a version of the basic oxygen process or in specialty steel plants (mini-mills) using an electric arc furnace process. The open hearth furnace process is no longer used.

In the basic oxygen process, hot liquid blast furnace metal, scrap, and fluxes, which consist of lime (CaO) and dolomitic lime (CaO.MgO or "do lime"), are charged to a converter (furnace). A lance is lowered into the converter and high-pressure oxygen is injected. The oxygen combines with and removes the impurities in the charge. These impurities consist of carbon as gaseous carbon monoxide, and silicon, manganese, phosphorus and some iron as liquid oxides, which combine with lime and do lime to form the steel slag. At the end of the refining operation, the liquid steel is tapped (poured) into a ladle while the steel slag is retained in the vessel and subsequently tapped into a separate slag pot.

There are many grades of steel that can be produced, and the properties of the steel slag can change significantly with each grade. Grades of steel can be classified as high, medium, and low, depending on the carbon content of the steel. High-grade steels have high carbon content. To reduce the amount of carbon in the steel, greater oxygen levels are required in the steel-making process. This also requires the addition of increased levels of lime and dolime (flux) for the removal of impurities from the steel and increased slag formation.

Physical Properties

Steel slag aggregates are highly angular in shape and have rough surface texture. They have high bulk specific gravity and moderate water absorption (less than 3 percent). Table 18-1 lists some typical physical properties of steel slag.

Chemical Properties

The chemical composition of slag is usually expressed in terms of simple oxides calculated from elemental analysis determined by x-ray fluorescence. Table 18-2 lists the range of compounds present in steel slag from a typical base oxygen furnace. Virtually all steel slags fall within these chemical ranges but not all steel slags are suitable as aggregates. Of more importance is the mineralogical form of the slag, which is highly dependent on the rate of slag cooling in the steel-making process.

USES

The use of steel slag as an aggregate is considered a standard practice in many jurisdictions, with applications that include its use in granular base, embankments, engineered fill, highway shoulders, and hot mix asphalt pavement.

Copper slag

Copper slag is a by-product created during the copper smelting and refining process. As refineries draw metal out of copper ore, they produce a large volume of non-metallic dust, soot, and rock. Collectively, these materials make up slag, which can be used for a surprising number of applications in the building and industrial fields.

USES

- Copper slag is mainly used for surface blast-cleaning.

- Copper slag is just one of many different materials that may be used as abrasive grit.

- Copper slag can be used in concrete production as a partial replacement for sand.

- Copper slag is used as a building material, formed into blocks.

- In Sweden, fumed and settled granulated copper slag from the Boliden copper smelter is used as road- construction material.

Physical Properties

The specific gravity and density of copper slag and river sand were determined in accordance with IS 2386 part III. Copper slag has a specific gravity of 4.12 and bulk density of 2.31 g/cc which is higher than that for normal river sand (2.6, 1.53 g/cc) which may result in production of concrete with higher density. Also, the measured water absorption for copper slag was 0.40 % compared with 0.83 % for sand. This suggests that copper slag has less surface porosity and would demand less water than that required by sand in the concrete mix. Therefore due to the free water content in concrete matrix and also due to the higher coarseness of copper slag will increase the workability of the concrete as the copper slag content increases.

Optical Fiber

Optical fiber is the technology associated with data transmission using light pulses travelling along with a long fiber which is usually made of plastic or glass. Metal wires are preferred for transmission in optical fiber communication as signals travel with fewer damages. Optical fibers are also unaffected by electromagnetic interference. The fiber optical cable uses the application of total internal reflection of light. The fibers are designed such that they facilitate the propagation of light along with the optical fiber depending on the requirement of power and distance of transmission. Single-mode fiber is used for long-distance transmission, while multimode fiber is used for shorter distances. The outer cladding of these fibers needs better protection than metal wires.

Types of Optical Fibers

The types of optical fibers depend on the refractive index, materials used, and mode of propagation of light.

- The classification based on the refractive index is as follows:

Step Index Fibers: It consists of a core surrounded by the cladding, which has a single uniform index of refraction.

Graded Index Fibers: The refractive index of the optical fiber decreases as the radial distance from the fiber axis increases.

2. The classification based on the materials used is as follows

Plastic Optical Fibers: The polymethyl methacrylate is used as a core material for the transmission of the light.

Glass Fibers: It consists of extremely fine glass fibers.

3. The classification based on the mode of propagation of light is as follows

Single-Mode Fibers: These fibers are used for long-distance transmission of signals.

Multimode Fibers: These fibers are used for short-distance transmission of signals.

Advantages of Optical Fibre Communication

- Economical and cost-effective

- Thin and non-flammable

- Less power consumption

- Less signal degradation

- Flexible and lightweight

PIPE

A water pipe is any pipe or tube designed to transport treated drinking water/potable water to consumers/building.

They differ according to sizes:-

1) Large diameter main pipes, which supply entire towns

2) Smaller branch lines that supply a street or group of buildings,

3) Small diameter pipes located within individual buildings

DIFFERENT TYPES

- CAST IRON (CI) PIPES

- STEEL PIPES

- GALVANIZED IRON (GI) PIPES

- COPPER PIPES

- PLASTIC OR POLYTHENE OR PVC PIPES

- ASBESTOS CEMENT (AC) PIPES

- CONCRETE PIPES

- POLYPROPYLENE(PPR) PIPES

WIRES AND CABLES

Wires and Cables Wires & Cables are purpose built conductors. The size & type of wire/cable must suit the power rating required for their use. The higher the power the thicker the wire/cable.

Uses of Wires

- Domestic & small industry

- Wiring in appliances

Uses of Cable

- Small & big industries

- Distribution Lines Transmission lines

Various types of wires.

1.VIR wire:

- It is called vulcanized insulation rubber wire. Copper & aluminum conductor and rubber coating are used in it. Now single & double braided wires are mostly in a use. But it has lower tensile strength, chemical reaction & bad insulation so it is not used.

- Suitable for: low & medium voltage supply only

- Old type: not readily available to purchase

2. CTS & TRS wire:

It is called crab tyre sheath wire & tuff rubber sheath wire. Hard & good rubber coating on copper wire is used in this wire. Its used in house wiring & industrial wiring. Available in 250/440V only

3. Weather proof wire: