Unit 4

Water

Hard water: is water that contains an required quantity of dissolved minerals (like calcium and magnesium) As rainwater falls, it is naturally soft. However, as water flows through the ground and into waterways, it picks up minerals like chalk, lime and mostly calcium and magnesium and becomes hard water. Since hard water contains essential minerals, it is essentially used as drinking water. Not only because of the health benefits, but also the flavour. Water that does not produce lather with soap readily is called hard water. Water hardness is usually measured as calcium hardness in milligrams per litre (mg/l) OR parts per million (ppm) OR in grains per gallon (GPG).

For eg: sea water, river water, spring water, lake water and well water.

- Removal of hardness of water by lime soda

Surface water hardly exceed hardness level above 200 mg/1 and softening is not at all required in most of the cases, unless the water is being polluted by some effluent sources. In case of groundwater, hardness level of more than 1000 mg/1 are quite common. Since, soft water is corrosive, therefore public water supply are usually not softened below 30 to 50 mg/1. The most accepted and commonly used water softening methods are cat ion exchange and precipitation method. In order to obtain maximum profit, the factors to be considered are a good choice of a softening process, quality of the raw water, the cost of softening chemicals and the cost of disposing of waste streams.

Precipitation methods

The principle that follows the precipitation method is to bind calcium cations Ca and magnesium cations Mg , with ions of CO3 and OH . The precipitate CaC03 and Mg (OH)2 formed are removed from the water. Slake lime Ca(OH)2, Quick lime CaO , soda ash NaC03 and sodium hydroxide (caustic soda) NaOH, are reagents that are commonly used in water softening. Depending upon the quality of initial water, the following main precipitation methods are determined. a) Lime softening b) Lime - Soda softening c) Sodium Hydroxide softening Lime affects the carbonate hardness (alkalinity) and therefore can be used in order to decrease the carbonate hardness present in the initial water. This method however does not result in deep softening. Magnesium is removed from water if there is excess of OH” present. Water dissolved carbon dioxide is removed, total solids in the treated water diminishes and the total hardness in the lime treated water also reduces. But the pH increases to 10 or beyond. When lime is added to the hard water following reactions occurs, In the above reactions,

Lime Addition:-

Hardness Lime Precipitate

CO2 + Ca(OH)2 -- > CaCO3 + H2O Ca(HCO3)2 + Ca(OH)2 -- > 2CaCO3 + 2H2O Mg(HCO3)2 + Ca(OH)2 -- > CaCO3 + MgCO3 + 2H2O MgCO3 + Ca(OH)2 -- > CaCO3 + Mg(OH)2 CO2 the insoluble products do not contribute to the hardness, but It reacts with the lime, and thereby uses up some lime before the lime can start removing the hardness in water. Lime - Soda softening method is commonly practiced in most of the Public water supply. (Belan1984) The method is universal as water of almost any composition is treated with lime and soda. In this treatment, two reagents are used namely lime and soda ash. Lime as earlier discussed , decreases the carbonate hardness, (Mg2+) and removes C02 from the water.

Soda therefore reduces the non - carbonate hardness, mainly due to Ca2+, that shows after reaction with lime and the reaction occurs after the addition of soda ash is as follows.

Lime and Soda ash

Addition:- Lime Precipitate MgSO4 + Ca(OH)2 -- > Mg(OH)2 + CaSO4 Soda ash Precipitate CaSO4 + Na2CO3 -- > CaCO3 + Na2SO4 2.

- Ion exchange method including Zeolite method

Ion Exchange Process

Ion exchange process to soften water, using cations or anions. This is done by exchanging cations or anions with the calcium and magnesium ions in hard water. This process involves a reversible chemical reaction. However, we can use this technique only in dilute solutions. The equipment that we use for this purpose is ion exchangers.

Types

There are two types;

- Cation exchangers – use zeolite, greensand, sulfonated coal, etc. as the exchanging material.

- Anion exchangers – uses metallic oxides, synthetic resins, etc.

The materials used in cation exchangers include either weak acids or strong acids. Strong acid cation exchangers mainly contain sulphate functional groups. Weak acid cation exchangers mainly contain carboxyl groups. The materials that are used in anion exchangers include either weak bases or strong bases. Moreover, there are several categories of ion exchange process used for water softening, DE alkalization and demineralization. The ions that are part of the exchange process (the ions that exchange with the calcium and magnesium cations in hard water) include sodium ions, hydrogen cations, chloride anions and hydroxyl anions.

- Zeolite process

Zeolite process is a process of softening hard water thru ion exchange technique using a chemical compound zeolite. It possesses a chemical compound that has hydrated sodium aluminosilicate. Thus, the name of the process is called as zeolite process. Zeolite compound can exchange its sodium cations reversibly with calcium and magnesium ions in the water softening process.

There are two types of zeolite used in this process they include natural and synthetic zeolite. The natural form is found to be porous and synthetic form is a non-porous zeolite. However synthetic form possesses a high exchange capacity per unit weight than the natural form.

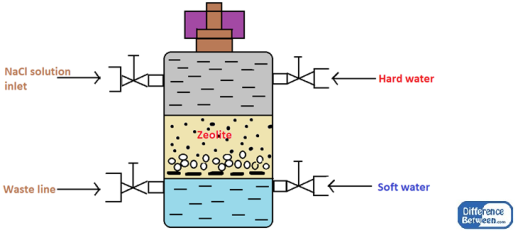

Figure 01: Cylinder Containing the Zeolite Bed

Process

In the water softening process, hard water is passed through a bed of zeolite (inside a cylinder) at a specified rate. Then the cations that cause the water-hardening will remain on the zeolite bed because these cations exchange with the sodium cations of zeolite. Therefore, the water coming out of this cylinder contains sodium cations rather than calcium and magnesium cations.

After some time, the zeolite bed gets exhausted, the water flow is stopped and treat the bed is treated with concentrated brine solution (10%) in order to regenerate the zeolite. The bed is treated with a brine solution, as it washes away all the calcium and magnesium ions, by exchanging them with sodium ions in a brine solution. Hence, this treatment regenerates the zeolite.

Fuels :-

A fuel is the substance which on combustion produces a large amount of heart.

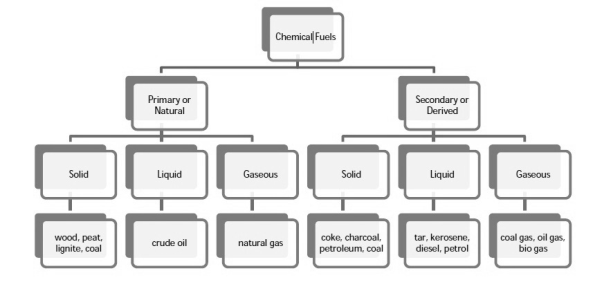

Classification of chemical fuels :-

Chemical fuels are classified on the basis of occurrence into :-

- Primary ( natural )

- Secondary ( derived ) types / manmade .

The secondary fuels are obtained from primary fuel by processing or they are manmade. e.g.:- charcoal is obtained from wood by partial combustion of wood , ethyl alcohol is obtained by fermentation of carbohydrates .

Both the primary and secondary fuels are further classified on the basis of physical state into solid liquid and gaseous fuels.

Extra definitions :-

1] fuels :-

Fuels are defined as materials that create usable energy through chemical nuclear or electrochemical reaction.

2] chemical fuel :-

The fossil fuels , wood vegetal oils etc. . which produce heat on burning are known as chemical fuels.

Coal is mainly composed of C , H , N , S moisture volatile matter.

The purpose for coal analysis is

- To decide price of coal

- To determine quality

- To specify use of coal for a particular purpose

- To calculate theoretical calorific values of coal

- To calculate air requirement for complete combustion of coal and design the furnace fire box suitably.

A sample of coal taken out from coal mine is analyzed in two ways.

- Proximate analysis

- Ultimate analysis

Proximate analysis of coal ( 5 / 6 m )

Proximate analysis is the study or analysis of coal sample in which

- Moisture ( percent )

- Volatile matter ( percent )

- Ash ( percent )

- Fixed carbon ( percent ) are found out

A] moisture ( percent ) :-

- A known weight of powdered and air-dried coal sample is taken in a crucible and it is placed in an oven for 1 hour at 110°C .

- Then the coal it is placed in a dedicator and weighed out.

- If the initial weight of the coal is m gms and final weight m gms . The loss in weight ( m – m1 ) corresponds to moisture in coal.

Moisture percent =  *100

*100

B] volatile matter (V.M) :-

- Moisture free coal left in the crucible in first experiment ( m1 ) is covered with a lid loosely . Then it is heated at 925° c in a muffle furnace for 7 minutes .

- The crucible is taken out and cooled in a desiccator.

- Then it is weighed ( m2 gms ) the loss in weight ( m1 –m2 ) is due to loss of volatile matter in m gms of the coal sample. (volatile matter is the lower molecular weight organic compound in a coal and decomposed coal during burning of coal, that escapes without combustion, in the forms of smoke)

Volatile matter (percent ) :-

=

The volatile matter percent can be also determined by taking the fresh weight of the air dried coal but the loss in weight .at 925°c will be due to loss of moisture and volatile matter if W is the mass of coal left at 925° c heating,

Then ,

Volatile matter percent =  *100

*100

=  – moisture percent

– moisture percent

C] Ash percent :-

- The residual coaling the above experiment is heats and weighed (n m3 gm)

Therefore ,

Ash ( percent ) * 100 =

) * 100 =  *100

*100

D] fixed carbon ( percent ) :-

It is found by calculation

f.c = 100 – ( moisture + v.m + ash )

Significance ( important of proximate analysis )

Moisture :-

- Decrease calorific value of coal largely as it does not burn and take away heat in the form of latent heat.

- It increases ignition point of coal.

- It increases ignition point of coal hence, a coal with lower moisture is better quality.

Volatile matter :-

- It decreases calorific value of coal.

- It elongates flame and decrease flame temp

- It forms smoke and pollutes air

However, the coals containing 15 – 25 percent of X.M on carbonization gives coke oven gas which is the source of various organic aromatic chemicals such coals have good caking property and caking the coals be obtained from the coals.

Overall, regarding burning of coal the coal the coal with lesser V.M is better quality coal.

Ash :-

- Ash reduces C.V of coal as ash is non – burning part in coal.

- Ash disposal is a problem

- Ash fuses to form clinker at high temperature obstructing the air supply to coal burning in.

Principle of ash :-

- Inorganic matter in the coal gets oxidized to form metal oxides coal get oxidized to form metal oxidize and silica which is non – combustible and left as ash.

D ] Fixed carbon :-

- Carbon is the burning part in coal and high the fe higher C.V hence a good quality coal containing high FC (percent )

f.c(percent ) = 100 – ( moisture + V.M + ash )

Numerical:-

- Compute the proximate analysis results 1.9 gms of a coal sample loses 0.285gm weight at 110°c.

- 1.5 gm of the same coal sample loses 0.36gm weight at 925°c.

- 2.15 gms of the coal sample leaves 0.26 gm ash.

Given data :-

M=1.9 gm

( m – m1 )= 0.285 gm ( moisture loss )

Loss in weight due to moisture and VM = 0.36gm

Weight of coal = 2.15 gm

Weight of ash = 0.26gm

- Moisture ( percent ) =

*100

*100

=  = 15 percent

= 15 percent

2. V.M ( percent ) :-

v.m =  *10

*10

=  *100-15 = 24 – 15

*100-15 = 24 – 15

= 9 percent

3. Ash ( percent ) :-

Therefore ,

Ash =

=

= 12 ( percent )

Principle :-

The C in the coal gets converted co2 and hydrogen to h2o vapors burning in the presence of pure o2

Ultimate analysis of coal :-

The analysis of coal in which percentage of C , N , H , S and O elements are found out is known as ultimate analysis .

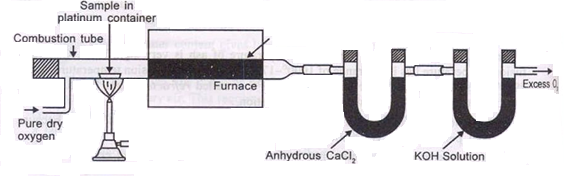

A] C,H in coal :-

- A known weight of powdered and air-dried coal sample is burnt in the presence of pure oxygen in a combustion apparatus C and H are converted to CO2 and H2O vapors respectively

- The gaseous products are allowed through first the pre-weighed u – tube containing any hydrous crack (absorbing H2O vapors and through the KaH solution in a pre-weighed u – tube (absorption of co2 )

- The increase in weight of u – tube containing any hydrous Cacl2 corresponds to weight of water formed and increase in weight of u – tube containing KoH solution corresponds to co2 formed by combusting the coal sample.

C + O2 – CO 2

2H + ½ - H2O

2KoH + CO2 – K2CAO3 + H2O

Cacl2 + 7H2O – Cacl2 – CacL2 .7h20

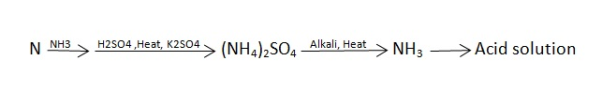

N ( percent ) – n in coal gets converted to anomnous sulphate by action of hot conc . H2SO4 and then on treatment with alkali solution .

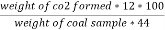

C ( percent ) =

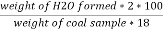

H ( percent ) =

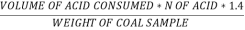

B] nitrogen in coal :-

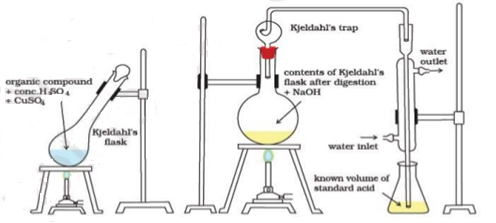

- A known weight of powdered and air-dried coal is heated with concentrated H2SO4 along with K2So4 catalyst in a long necked kjeldahls flask.

- After the contents become clean it is treated with alkali solution in a round bottom flask the ammonia ( basic gas ) liberated is passed in a round bottom flask the ammonia ( basic gas ) liberated is passed in known volume of std. Acid solution.

The unused acid is determined by titration with NaOH solution.

- Mass of coal = M gms

- Volume of X N acid in which NH3 is passed

- Volume of acid unused = V2ml

- Volume of the acid consumed by NH3 = ( V1 – V2 ) ml

N ( percent ) =

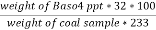

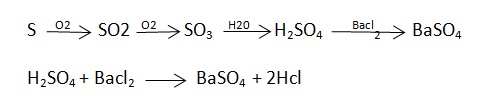

C] Sulphur in coal :-

- Take out 10 ml of distilled water in the bomb pot. Burn the known weight of powdered and air-dried coal sample in the bomb calorie meter experiment.

- The collect the washing of bomb pot in a beaker add Bacl2 solution in it.

- Filter the precipitate of Baso4 from weight of Baso4 precipitate, calculate as below:-

S ( percent ) =

- Ash :- as carried out as under proreimate analysis

- O :- it is obtained by difference

Importance of ultimate analysis:-

Carbon :-

- Greater than percent of carbon in coal better is the coal quality and c.v

Hydrogen :-

- Most the hydrogen in coal is in the form of moisture and volatile matter only a small percentage of hydrogen is combustible hence it decreases c.v of coal . Smaller the H better is the coal quality.

Nitrogen :-

- Nitrogen does not burn during coal combustion and therefore, it has no calorific value hence a good quality coal has negligible N.

Sulphur :-

- Although Sulphur can burn and increase calorific value of coal, but it causes so pollution and cause acidic rain corrosion of metallic equipment hence lower the percent of s in coal better is a coal quality.

Oxygen :-

- Most of the oxygen in coal is in the form of moisture .

- It decreases calorific value of coal ( 1 percent oxygen in coal decrease c.v by 1.7 hence, lower the o percent better is coal quality . )

Numerical :-

- Calculate C , N , H , S from the following observation for a sample of coal.

- 2.05 gms of the coal is burnt in combustion tube. The increase in weight of any hydrous Cacl2 is 0.55 gm and increase in weight of KoH tube is 5.75gm.

- 0.75 of the coal is kjaldahl experiment released NH3 which is passed in 50ml 0.12 N NaoH to neutralize in back titration.

- Washings of the bomb pot when 1.8 gm.

Given data :-

Increase in weight of any hydrous calcl2 = 0.55

Mass of coal = 0.75gms

Volume of 0.12 NHCL consumed by NH3 = 50 – 41

= 9 ml

Mass of coal = 1.8gms

Weight of Baso4 = 0.31 gm

- Weight of CO 2 formed = increase in wt. OfKoH

Therefore ,

C percent ) =  *

* *100 = 76.5 percent .

*100 = 76.5 percent .

Increase in weight of any hydrous Cacl2

= weight of H2O formed

Mass of coal = 2.05gm

H ( percent ) =  *

* *100

*100

= 2.98 ( percent )

2. N ( percent ) =

=

= 2.02 ( percent )

3. S ( percent ) =  *100

*100

=

= 2.36 ( percent )

Theoretical calorific values

A] gouthal formula :-

Theoretically calorific value of coal can be calculated from proximate analysis data by using gouthal formula .

G.C.V Cal / gm = 82fc + a.VM

The values of constant are as under

The gross calorific value of solid fuels and liquid fuels can be determined by bomb calorimeter .( if the liquid is volatile , then it is filled in a polythene capsule of negligible mass then used in experiment.

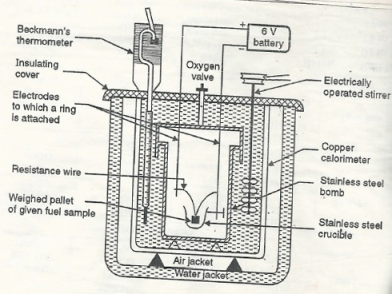

Construction :- a bomb colorimeter consists of

- Bomb pot

- Calorie meter

- Water and air jackets

- Accessories

- Pellet press

- Oxygen cylinder

Bomb pot :-

It is a cylindrical strong stainless-steel pot having a lid. the lid can be fitted air. Tight to bomb pot by screwing.

- There are two type of electrodes fitted through lid and there is an oxygen inlet valve as its center.

- One of these electrodes is provided with a ring to hold the crucible containing fuel. There is thin resistance wire tied to the electrodes in loop form and the loop touches the fuel.

- The weighed fuel is burnt in the bomb pot in the presence of high-pressure oxygen.

Calorimeter :-

- There is a stainless steel or copper calorimeter in which the bomb pot is kept .it contains a known volume of water and the water is kept circulating around the bomb pot with the help of a stirrer.

- A Beckman thermometer or digital thermometer is kept in the water of calorimeter, which can record the rise in temperature of welter due to absorb in a heat generated .

- There are insulator stands between calorimeter and water jacket.

Accessories :-

- There is a pellet press to convert the powder of solid fuel to pellet form. For a liquid fuel a capsule of negligible weight can be used.

- There is an oxygen cylinder with pressure gauge to fill oxygen in the bomb pot at the pressure of nearly 25 kg / cm².

- There is also a D.C battery of a about 6 volts to start combustion of fuel.

Fig: Bomb Caloriemeter

Working :-

- Weigh the pellet of solid fuel or liquid capsule and keep it in the crucible. Keep the crucible in the ring of the electrode. keep the resistance wire touching to the fuel.

- Add about 10 ml of distilled water at the bottom of bomb pot and fix the lid tightly to bomb by screwing.

- Fill the bomb with oxygen at the pressure about 25 kg / cm².

- Place the bomb in calorimeter add known volume of water in the calorimeter so that the bomb gets immersed in the water.

- Place the calorimeter in the water jacket over the plastic studs. Keep the thermometer and stirrer in the water of calorimeter.

- Put the plastic cover on the and make electrical connections from battery to electrodes.

- Operate the stirrer for s minutes and note the initial temperature of water ( t1° c ).

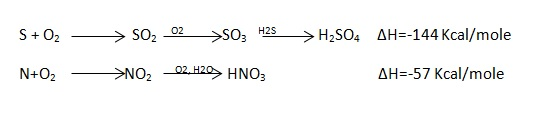

- Pass the current for about 5 – 10 seconds to heat the wire so that the fuel catches fire. If the fuel contains S and N elements, they get converted to SO3 and N2O5 .these gases get dissolved in the distilled water in bomb to form H2SO4 and HNO3 ( along with liberation little heat ).

- Note the maximum temperature reached .after that note the rate of fall of temperature per minute and the time taken for reaching to initial temp. Are noted.

- Open the bomb pot and wash the contents at its bottom into a beaker to find out the amount of H2SO4 and HNO3 formed.

Calculations :-

Gross calorific value of fuel = l calories / gm

Rise in temperature of water = ( t2 – t1 )

Heat liberated by burning fuel = heat absorbed by water and calorimeter

Therefore ,

XL = ( W+W) ( T2 – T1 )

G.CV = L =  cal / gm

cal / gm

Note :-

Water equivalent of calorimeter – set ( w ) is determined by burning fuel of known gross calorific value and using the above equation.

Standard gross calorific values of some pure fuels are,

Naphthalene = 9622 Cal / gm

Benzoic acid = 6325 Cal / gm

Camphor = 9292 Cal / gm

Salicylic acid = 5269 Cal /gm

NCV for the fuel is calculated as below .

If H is percentage of hydrogen in the fuel, then the heat taken by water formed during combustion to convert it into steam is = 0.09h * 587 Cal / gm

And

NCV = GCV – 0.09h * 587 Cal / gm or kcal / kg.

Corrections :-

To get more accurate results , the following corrections should be considered.

- Fuse wire correction ( F )

- Acid correction ( a )

- Cooling correction ( tc )

- Fuse wire correction ( f ) :-

Out of the total obtained little heat is given out by fuse wire when the current is passed for s – 10 sec .to start the combustion. Hence it must be subtracted. Are exothermic and the heat measured includes a small share by these acid formation.

2. Cooling correction ( te ) :-

If the time taken for water in calorimeter to cool from maximum temperature attained to the room. Temperature is t minutes and average cooling rate is dt / min , then the cooling correction to be added to rise in temperature is t.dt .

- The actual rise in temperature would have been ( t23 – t1 ) had the heat liberated been absorbed by water and calorimeter rapidly and there would have no loss of heat from the set by radiation.

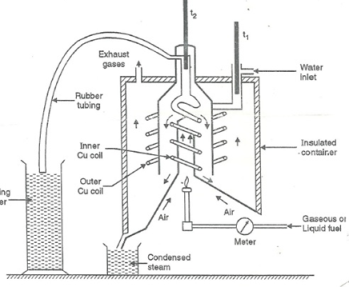

This calorimeter is used to measure calorific value of gaseous fuels and highly volatile fuels.

Principle :-

The gaseous fuel is burnt at a known constant rate in the calorimeter under such conditions that entire amount of heat produced is absorbed by water.

- Gas burner

- Combustion chamber ( chimney )

- Thermometers

- Insulating cover

- Gas burner :-

- There is a gas burner in which a known volume of gas is burnt at a known pressure .the gas is burnt at the rate of 3 – 4 lit. Per minute.

3. Combustion chamber ( chimney ) :-

Around the burner there Is a combustion chamber which has a copper tubing coiled inside as well as outside of it water enters from top of the outer coils , moves to bottom of chimney and then goes up through the inner coil to the exit at top.

4. Thermometer :-

There are two thermometer to measure temperatures of inlet water and outlet water.

5. Insulating cover :-

The assembly is covered with by an insulator to detach combustion chamber from atmosphere .there are three holes for exhaust gas, water inlet and condensed steam.

Working :-

- Start burning the gas at suitable pressure and adjust the rate of water flow such that the temperature of outgoing water remains constant.

- Burn the gas for 5 – 10 minutes to have the steady temperatures in and around the combustion chamber.

- After the steady ( temperature in and around the combustion chamber ) conditions of outgoing.

A) Volume of gas burnt at given temperature and pressure in certain time period.

B) Quantity of water passed through coil during this period.

C) Mass of water condensed from product gas during the period.

D) The steady rise in temperature of water ( t2 – t1 )

Fig: Boy’s gas calorimeter

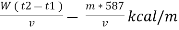

Calculations :-

- First convert the volume of gas burnt to volume of gas at STP .let this STP volume be V

.

. - Let W = mass of cooling water used in the period of observation in Kg

- Let m= mass of water condensate in kg

- L= G.C.V OF THE FUEL

Heat produced by combustion of fuel = heat absorbed by cooling water

( assuming no heat loss in the steady state conditions )

Vl = w ( t2 – t1 )

L =  Kcal /

Kcal /

The mass of condensate water per m of gas will be m/v kg /m .

If this water had left as steam in product gases it would have taken away heat.

=  *587 kcal /

*587 kcal /

Therefore ,

NCV = GCV -  *587

*587

NCV =

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|