UNIT 4

Electrical Installations

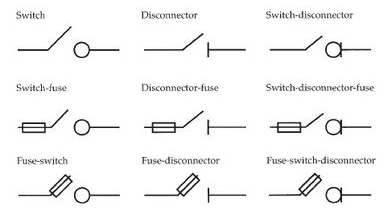

It has one switch unit and one fuse unit. When the breaker is operated the contact to the switch is close and supply passes through the fuse unit to output. In fuse switch unit there is only fuse unit which acts as a switch. During operating the fuse unit closes the input and output of the breaker.

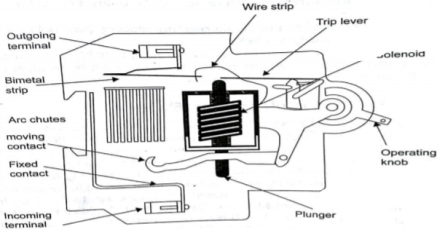

MCB is a switch which automatically turns off when the current flowing through it passes the maximum allowable limit. Generally, MCB is designed to protect against over current and over temperature faults. In MCB there are two contacts one movable and other non-movable. When the current exceeds the predefined limit, a solenoid forces the moveable contact to open and the MCB turns off, thereby stopping the current from flowing in the circuits.

It mainly consists of one bi- metallic strip, one trip coil and one hand operated on-off lever. The current in MCB flows from left side of circuit to bimetallic strip further going into the current coil, moving contact and at last through right side of circuit. When circuit is overloaded the bimetallic strip is overheated.

This deformation of bimetallic strip causes displacement in the latch. This displacement releases the spring through which the MCB is connected to the moving contact. This spring makes moving contact to open MCB.

The current coil or trip coil placed in such a manner that during SC faults, the MMF of that coil causes its plunger to hit the same latch point and force the latch to be displaced. Hence, the MCB will open in the same manner.

They are frequently used in domestic and industrial purposes. The MCB detects faults like switching, overload, short circuit protection and overload protection.

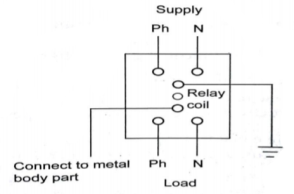

An Earth Leakage Circuits Breakers (ELCB) is a device used to directly detect currents leaking to earth from an installation and cut the power. There are two types of ELCBs:

(i) Voltage Earth Leakage Circuits Breaker (voltage -ELCB)

It consists of a relay coil; one end of that coil is connected to the metal body and other to the ground. When voltage on the equipment body rises to 50V (danger level) the current in the relay loop moves the relay contact by disconnecting the supply current and saves from electric shock.

(ii) Current Earth Leakage Circuits Breaker (Current -ELCB)

It is mostly commonly used ELCB. It consists of transformer having two primary (neutral and line wire) windings and one secondary winding. In balanced condition there is no current in secondary because the neutral wire balances the current through the phase wire.

During fault a small current flow to ground causing imbalance between line and neutral currents. As a result of which current is induced in secondary winding. The sensing circuit connected to the secondary sends signal to the tripping system and the contact is tripped.

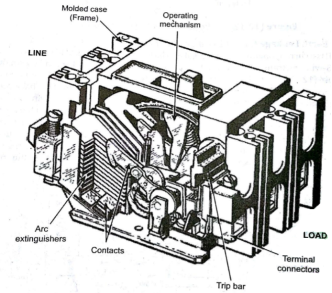

Moulded case circuits breakers are electromechanical devices which protect a circuit from over current and short circuits. They provide over current and short circuits protection for circuits ranging from 63A up to 3000 A. They are used for heavy duty applications as they have high current ratings. They provide electric feeder protection, capacitor bank protection, generator protection, welding applications, low current application that require adjustable trip setting and motor protection.

They are made up of heavy duty insulated plastic. MCCB has a bimetallic contact that expands and contacts when there is change in temperature. When current exceeds the adjustable trip value the contact gets heated and expands. The fault currents in MCCB can be interrupted immediately. Whenever a fault occurs, the extremely high current induces a magnetic field in a solenoid coil located inside the breaker – this magnetic induction trips a contact and current it interrupted

Types of Wiring

The wires used for domestic or industrial wiring are classified into different groups as

(I) According to the conductor material used

(a) Copper conductor cables

(b) Aluminium conductor cable

(ii) According to number of cores

(a) Singles core cable (SCC)

(b) Double core or twin core cables (DCC)

(c) Three core cables

(d) four core cables

(e) Two cores with earth continuity conductor cables

(iii) According to type of insulation

(a) Vulcanized Indian rubber (VIR) insulated wires/cables

(b) Tough rubber sheathed (TRS) or cable tyre sheathed (CTS) cables

(c) Polyvinyl chloride (PVC) cables

(b) Lead sheathed cables

(e) Weather proof cables

(f) Flexible cords and cables

(g) XLPE cables

(IV) According to the voltage at which they are manufactured

(a) Low tension (LT) cables – up to 1000V

(b) High tension (HT) cables – up to 11kV

(c) Super tension (ST) cables – from 22-33kV

(d) Extra high tension (EHT) cables – from 33-66kV

(e) Extra super voltage cables – beyond 132 kV

Earthing

It means connecting electrical equipment to earth with very low resistance wire. This ensures safe discharge of electrical energy due to failure of the insulation line coming in contact with the casing, etc. Earthing brings the potential of the body of the equipment to zero.

The main purpose of Earthing is to protect the operating personnel from shock. Under unbalanced load maintain the line voltage. To avoid risk of fire due to leakage currents. For protecting the equipment.

Methods of Earthing:

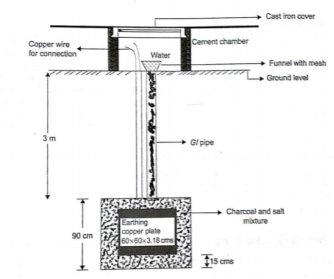

(i) Plate earthing: A copper plate of dimension 60cm x 60cm x 3.18 is used for earthing. The plate is buried in ground and layered with coal and salt. Then water is poured to maintain the earth’s electrode resistance below maximum value. The earth wire is bolted to the earth plate.

(ii) Pipe earthing:

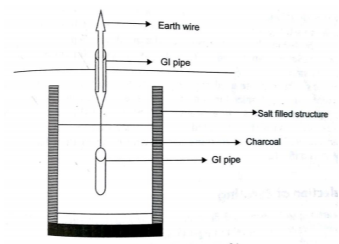

The earth’s electrode made of galvanized iron pipe with holes on surface is placed upright in wet ground. In order to maintain the earth’s resistance, the pipe is filled with mixture of salt and coal.

This system can carry larger leakage currents compared to plate earthing method.

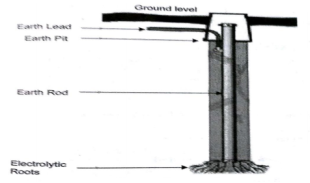

(iii) Rod earthing: It is similar to pipe earthing method. A copper rod is buried upright in the earth manually or with pneumatic hammer. The length of embedded electrodes in soil reduces earth resistance to a desired level.

(iv) Strip or wire earthing: In this the earthing strip electrodes are buried in horizontal trenches of depth 0.5m. The copper plate or round conductors are used. The length of the conductor buried in the ground would give a sufficient earth resistance and this length should not be less than 15m. The electrodes shall be as widely distributed as possible in a single straight or circular trench radiating from a point. This type of earthing is used where the earth bed has a rocky soil and excavation work is difficult.

Application

It converts chemical energy into electric energy. A combination of two or more voltaic cells is called as battery. Due to chemical reaction inside the cell voltage is produced. Electrodes are immersed in an electrolyte, which forces the electric charge to separate in the form of ions and free electrons.

i) Primary Batteries:

These are basically disposable batteries. They can be used only once. They are not rechargeable. EX. AA, AAA.

Types of Primary Batteries:

(a) Carbon- zinc dry cell: These are AA, AAA. They have zinc electrode as negative electrode and carbon as positive electrode. The output voltage of a single cell is about 1.5 V.

(b) Alkaline cell: It is AA type. It lasts long than carbon-zinc cell. It consists of a zinc anode and manganese dioxide cathode in an alkaline electrolyte

(c) Zinc chloride cell: These are heavy duty cells. It is modified zinc-carbon cell.

(d) Mercury cell: It is not used these days. It consists of zinc anode, mercury compound cathode and potassium or sodium hydroxide electrolyte.

(e) Silver oxide cell: This cell consists of a zinc anode, silver oxide cathode, and potassium of sodium hydroxide electrolyte. Normally used in cameras and watches.

(f) Lithium cell: It is light weight. It offers high output voltage. Two forms of 3V output in widespread use: (a) Lithium-sulphur dioxide(LiSO2 ). (b) Lithium- thionyl chloride.

Ii) Secondary Batteries:

These are rechargeable batteries. These are also called as storage batteries. They are rechargeable because the electric current reverses the chemical reaction inside the batteries that occurred during use. EX used in mobile phones, MP3 players.

Types of Secondary Cells:

(a) Lead-acid cell: It is most commonly used cell. It has porous lead anode and lead-oxide cathode. Used in automobile inverters. The output is of 2.1V.

(b) Nickel cadmium (NiCd) cell: It has Nickel hydroxide anode and cadmium hydroxide cathode. It delivers high current. It is used in cadmium hydroxide electrolyte. Used in alarm systems, TV equipment.

(c) Lithium-ion battery: It has graphite anode and lithium manganese dioxide cathode. The electrolyte used is mixture of lithium salts.

(d) Nickel-metal- hydride (NiMH) cell: They are used in power tools. They only have negative electrode, rest all similar to NiCd cells.

(e) Nickel-iron (Edison) cell: They have Nickel hydroxide anode and iron cathode with potassium hydroxide electrolyte. They are not in use now.

(f) Fuel cell: It converts chemical energy into water and produces electricity. They are used as source of DC power in space program. They are very efficient.

(g) Solar cell: They convert sunlight to electric energy. They are arranged in modules to form an array called solar array. An applied voltage higher than the voltage of one cell can be obtained by connecting cells in series. The total voltage available across the battery of cells is equal to the sum of the individual values for each cell. Parallel cells have the same voltage as one current capacity

The basic characteristics are:

i) Chemistry: Some batteries like lead, nickel and lithium need their own charger. So, the chemistry of the battery is important. It will not be properly charged if exact charger is not used.

Ii) Battery Capacity: It is the charge stored by the battery. y. The battery capacity represents the maximum amount of energy that can be extracted from the battery under certain specified conditions. The energy stored in a battery, called the battery capacity, is measured in either watt-hours (Wh), kilowatt-hours (kWh), or ampere-hours (Ahr). The most common measure of battery capacity is Ah, defined as the number of hours for which a battery can provide a current equal to the discharge rate at the nominal voltage of the battery.

Iii) Voltage: Any battery has a nominal voltage. It is important to check the correct nominal voltage before use.

Iv) Cold Cranking Amps(CCA): Every starter battery is marked with cold cranking amps, also abbreviated CCA. The number denotes the number of amps that the battery is able to provide at -180C.

The measurement of electrical energy depends on power. But

Power= Voltage x Current

Energy = Power x Time

Joule is the smallest unit of energy. Watt-hour is the standard unit used for measurement of energy.

Energy in watt hours = Power in watts × Time in hours

Energy in kilowatt hours = Power in kilowatts × Time in hours

This kilowatt hour is board of trade (BOT) unit.

Que) A consumer uses a 10-kW geezer, a 6-kW electric furnace and five 100 W bulbs for 15 hours. How many units (kWh) of electrical energy have been used?

Sol : Given that Load – 1 = 10 kW

Geezer Load – 2 = 6 kW

Electric furnace Load – 3 = 500 watt (five 100-watt bulbs)

Total load = 10kW + 6kW + 0.5kW = 16.5kW

Time taken = 155 hours

Energy consumed = Power in kW × Time in hours = 16.5 × 15 = 247.5 kWh

1 unit = 1kWh.

So, the total energy consumption = 247.5 units If the cost per unit is 2.5, then the total cost of energy consumption ̇=247.5 × 2.5 = 618.75/-

Construction

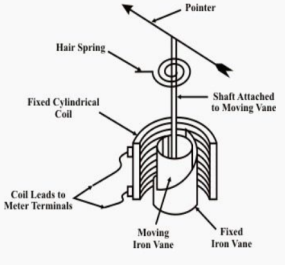

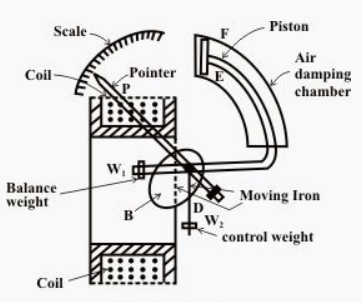

The moving element is a plate or soft iron. The plate is placed such that is moves freely in the magnetic field of stationary coil. These stationary coils are electromagnets. These magnets are temporary magnets whose field strength varies according to the amount of current passing through it. They can be used for both AC as well as DC.

Operation

These instruments use moving iron to measure the flow of current or voltages. When the iron is placed near magnetic field it is attracted towards the field. The force of attraction depends upon the strength of field.

The stationary coil of copper or aluminium wire acts as electromagnet when current passes through it. The plate when passes through this coil increases the inductance of stationary coil. The electromagnets attract the plate. The plate passes through coil from the least reluctance path. This plate experiences a repulsion due to electromagnets. The repulsion force increases the strength of the coil inductance. This happens because the inductance and reluctances are inversely proportional to each other.

One iron vane is held fixed to the coil frame and other is free to rotate, carrying with it the pointer shaft. Two irons lie in the magnetic field produced by the coil that consists of only few turns if the instrument is an ammeter or of many turns if the instrument is a voltmeter. Current in the coil induces both vanes to become magnetized and repulsion between the similarly magnetized vanes produces a proportional rotation

The moving iron instrument can be classified as

i) Repulsive moving iron instrument: It has two vanes one is fixed and the other is moving. When current passes through stationary coil the vane gets magnetized and a repulsive force is generated between them. Due to this repulsion the moving coil moves away from the fixed vane.

The spring coil provides controlling torque. The damping torque induced opposes the movement of the coil. These instruments are not affected by the direction of current flow.

Ii) Attractive moving iron instrument: In this the iron plate is attracted from the weaker field towards the stronger one. The stationary coil is flat and has narrow opening. The flat disc of iron core is moving element. The current through stationary coil produces the magnetic field and attracts the iron coil.

The iron plate then gets attracted from low magnetic field to high magnetic field. The strength through which the iron plate is deflected is directly proportional to the current flowing through it.

Advantages:

They are low cost instruments. They are easy to assemble. They have less friction error. They are used in both AC and DC.

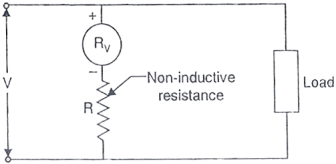

Moving coil type voltmeter:

Construction:

This consists of a magnet system made of materials like alcomax and alnico giving high field strength. There is a moving coil freely moving between the permanent magnets. This coil is wound with copper wire and placed in aluminium rectangular case. The torque is due to movement of aluminium in magnetic field. The spring is connected to measure the deflection produced. The meter connected to the spring shows the reading.

Working Principle:

It is called as Permanent magnet moving coil (PMMC). They measure only DC. This instrument measures the current through coil by angular deflection in magnetic field. A coil is placed between two permanent magnets in these types of instrument to produce magnetic field. The current carrying conductor when placed in the field experiences a force which is proportional to the amount of current through it. When the torques are balanced the moving coil stops. The angular deflection can be measured.

The deflection torque equation is given as

Td=NBldI

N: Number of turns

B: Magnetic flux density

l: length of moving coil

d: width of moving coil

I: Electric current

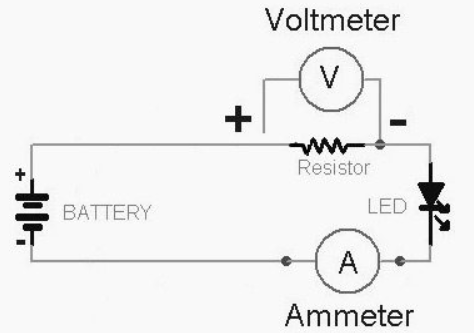

The below circuit extends the range of voltmeter by connecting resistance in series with the meter.

The external resistance connected will be

R= [V-V1/V1] x RV

RV: Voltmeter resistance

R: external resistance

V1: voltage across voltmeter

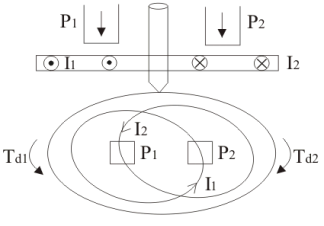

Induction type meter:

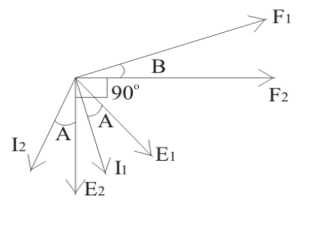

In all induction meters we have two fluxes which are produced by two different alternating currents on a metallic disc. Due to alternating fluxes there is an induced emf, the emf produced at one point (as shown in the figure given below) interacts with the alternating current of the other side resulting in the production of torque.

Let F1 =flux at point 1

F2= flux at point 2

Then

F1 = Fm1 sinwt

F2= Fm2 sin (wt-B)

B=phase difference between two fluxes.

The induced emf for both points will be

E1= -

E2= -

The value of eddy current at point 1 is

I1 = E1/Z = K x f x F1

The phasor is shown below

The deflection torque at point 1 will be

Td1= K x F2 x I1x cos(90-B+A) = K x F1 x (f/Z) cos(90-B+A) x F2

The deflection torque at point 2 will be

Td2= K x F1 x (f/Z) x cos(90+B+A) x F2

Total torque is

Td1- Td2 = K x F1 x F2 x (f/Z) sinB cos A

The torque for moving iron instrument is T=

This can be used for both AC and DC.

The moving element is a plate or soft iron. The plate is placed such that is moves freely in the magnetic field of stationary coil. These stationary coils are electromagnets. These magnets are temporary magnets whose field strength varies according to the amount of current passing through it.

They are classified as

i) Repulsive moving iron instrument: It has two vanes one is fixed and the other is moving. When current passes through stationary coil the vane gets magnetized and a repulsive force is generated between them. Due to this repulsion the moving coil moves away from the fixed vane. The spring coil provides controlling torque. The damping torque induced opposes the movement of the coil. These instruments are not affected by the direction of current flow.

Ii) Attractive moving iron instrument: In this the iron plate is attracted from the weaker field towards the stronger one. The stationary coil is flat and has narrow opening. The flat disc of iron core is moving element. The current through stationary coil produces the magnetic field and attracts the iron coil.

Moving coil type ammeter:

The basic principle of operation is same as discussed for voltmeter in above section. The deflection torque is given as

Td= BiNlb Nm

B: flux density

i: current through coil

l: length of coil

b: breadth of coil

N: number of turns in coil

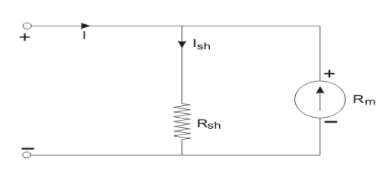

The range of instrument can be increased by adding a resistance in parallel as shown below.

Rsh=

Rm: Ammeter resistance

Ish: current through shunt resistance

I: total current

Induction type Ammeter

The working principle is same as discussed in above section. They are of two types:

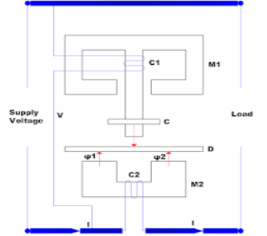

i) Split phase type: It has two magnets M1 and M2 in series. The shunt resistance R is connected to M2. The current in M2 lags line current. The deflection torque is Td = φ1m φ2m sinα

Ii) Shaded Pole Type: In this case the exciting coil is placed on poles. The current proportion to current or voltage is measured.

In the air gap of electromagnet aluminium disc mounted on a spindle is inserted. The spring is attached to the pointer and both are mounted on spindle. The spring provides the controlling torque.

The deflection torque is Td = φ1φ2 sinα

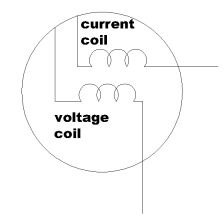

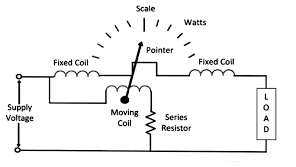

This instrument is used to measure the electric power of electric circuits. It has current and voltage coils. The wattmeter measures the power of the electric circuit.

P= VI cosφ

There are two types of wattmeter

i) Electro-dynamometer type wattmeter

They are moving coil of instruments. The fixed coil produces the operating field. When AC flows through fixed coil magnetic field is produced. The moving coil starts moving and the pointer fluctuates. They are highly accurate.

Ii) Induction Type wattmeter

They are used for both AC and DC. It consists of two electromagnets and one is excited by the current with exciting winding. This winding is connected in series. The exciting coil is in parallel to the circuit. The winding of first magnet carries line current and other coil carries voltage. The coil connected to supply and flux lags 90o to voltage. The torque is proportional to the power in the load circuit. Due to this torque the spring fluctuates and pointer notes the reading.

Uses: They are used in laboratories, industries, transmission line and power distribution.

These meters measure power consumption. They are used in our houses also. There are basically two types:

i) Electric Motor energy meters: They are further classified as

a) Ampere hour mercury meter: It consists of copper disc mounted on spindle. The disc revolves around the magnets present. The gap between the magnets is filled with mercury.

Here the current to be measured flows through the mercury radially into the centre of disc. It flows out through the spindle and bearings. The magnetic field due to M2 exerts a force on the right-hand side of disc producing the driving torque.

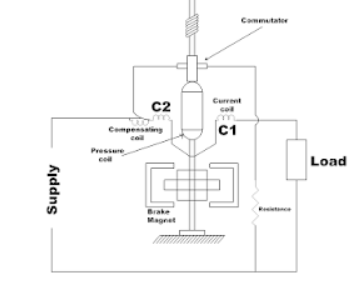

b) Commutator motor energy meter: They consists of wound winding armature and a commutator.

It has two fixed coils C1 and C2. The coil is wounded with copper wire and is connected in series with supply. The electromagnetic field is produced in both the coils and this field is proportional to the current to be measured. This field rotates the armature. The current is proportional to supply voltage. Due to the reaction between electromagnetic field and armature torque is produced. The braking torque is produced due to the eddy currents. This eddy current is produced in gap in which the disc which is in between the two magnets.

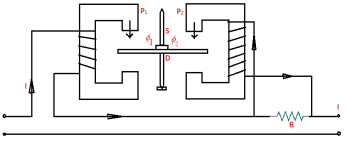

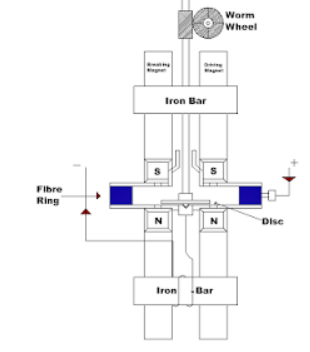

c) Induction type single phase energy meter: These are AC meters. These are the domestic energy meters which are widely used. They measure power in k-watthours.

It has two magnets M1 and M2. The first magnet is known as series magnet and the second magnet is known as shunt magnet. The first magnet is excited by line current. The electromagnet produces alternating flux φ1. This flux φ1 is proportional φ1 to the phase with line current. The second magnet produces the lagging flux φ2 which is proportion to supply voltage.

The two fluxes and the eddy current react and produces driving torque on the disc. The two magnets produce barking torque.

Ii) Electrolytic Energy meters: It is ampere-hour energy meter used in only DC circuits. They work on the principle of faraday law of electrolysis. They can be employed for AC circuits with using rectifiers.

Uses: They are used in domestic areas for calculation of power consumption. They are also used in industrial areas for controlling electric power.