Unit - 4

Buttress

Introduction

The dam consisting of slopping deck or multiple arch or massive head is called buttress dam. Buttresses are compression member.

Types of buttress dams

a) Multiple arch type of buttress dam

b) Deck type of buttress dam

c) Massive head type of buttress dam

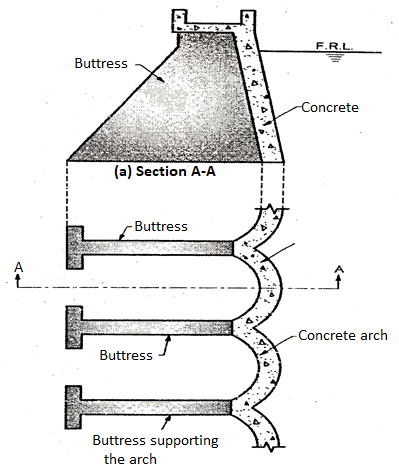

a) Multiple arch type of buttress dam

In such a type, the deck slab is replaced by horizontal arches which are further supported by buttresses as shown in fig. Arches in such dam are made of concrete and generally their span is small.

Fig 1: Multiple arch type buttress dam

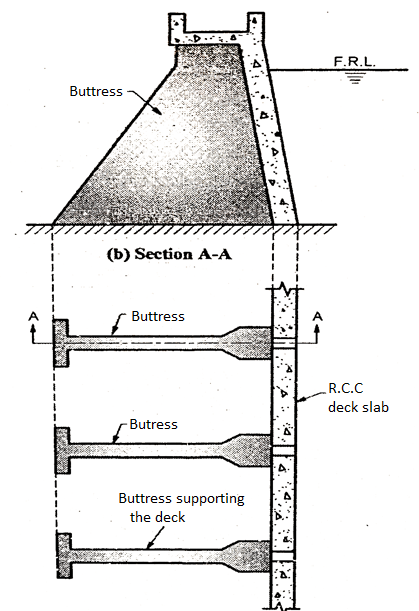

b) Deck type of buttress dam

In such type, there is a slopping deck which is supported by buttresses as shown in fig.

The deck is made of R.C.C. Slab supported between the buttress equally spaced.

Fig 2: Deck type of buttress dam

c) Massive head type of buttress dam

In such a type, no deck is provided. But the upstream edges of buttresses are made flared so as to form a massive head.

Key takeaways:

The deck is made of R.C.C. Slab supported between the buttress equally spaced.

- The deck slab or flat slab type buttress dams are also known as Ambursen type buttress dams in honor of Nils F Ambursen who in 1903 built the first flat slab type of buttress dam.

- In order to provide a wide base for the slab supported by buttress the upstream and of the buttress where it joins the slab is usually made wide by providing haunch or corbel.

- The combination of the flat slab and the buttress proved hard to model without producing artificial stress concentrations.

Consequently only the buttress was modelled and analysed.

- The load applied on the buttress is equivalent to the load transferred from a 5m long flat slab to the buttress.

- As the shear strength of the rock concrete interface highly depends on the stiffness assigned by the users, and o calibration data exists.

- The flat slab has a 1:0.8 inclination and rests on buttresses with a centre-centre distance 5.0m.

- It is 0.3m thik at the top with an increasing thickness of 30mm per vertical meter.

- In addition, the dam has a vertical isolation wall on the downstream side. All of the buttresses have an opening on the inside of the isolation wall.

- These dams are less massive than gravity dam.

- It save more cost of construction because power house and water treatment plant can be installed in between buttresses.

- The water load act normal to the inclined deck.

- Periodic inspection is possible due to access from the back of upstream face.

- It does not required special design.

- It is suitable at the location where strong abutment are not available.

- Buttress are compression member.

- It required skill labour.

- Buttress dam is more susceptible to willful damage.

- Deterioration of upstream concrete surface has danger effects on buttress dams with very thin concrete surface.

- It requires more material as compared to arch dam.

- Buttress dams are not suitable for small length in compression with height.

Key Takeaways:

- In addition, the dam has a vertical isolation wall on the downstream side. All of the buttresses have an opening on the inside of the isolation wall.

References:

- Tech-max publication

- Techno max publication

- Foundation engineering by Dr. B.C. Punmia, Laxmi Publication.

- Geotechnical engineering by p. Purushottam Raj, Tata MC Grawhill