Unit - 5

Embankment dam

- The dams which are constructed of earthen material such as gravel sand, silt, clay are called as earthen or embankment dam.

- Rock fill dam is type of water retaining barrier. It is constructed with the fragmentary rock to form an embankment. Support necessary to withstand reservoir water pressure.

- The main type of earthen dam

a) Homogeneous type embankment dam

b) Diaphragam type earthen dam

c) Zoned type embankment dam

2. Type of earth dam based on method of construction

a) Rolled fill earth dam

b) Hydraulic fill earth dam

c) Semi-hydraulic earth dam

- Homogeneous embankment type of dam

- It is one of the type of earthen dam which consist of earthen embankment of simple type and made in a single material hence it is homogeneous throughout

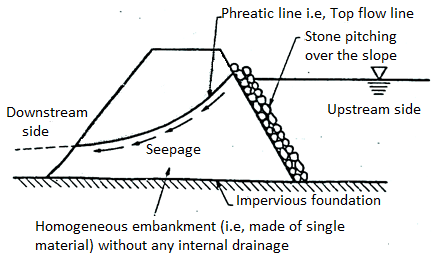

- Fig. Shows homogeneous type embankment dam without any internal drainage system.

Fig 1: Homogeneous type embankment of dam

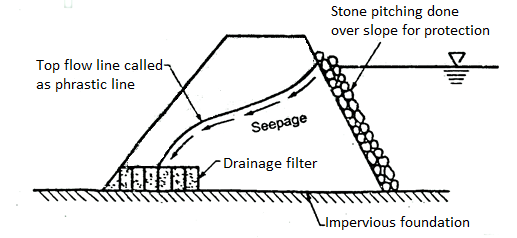

- Fig. shows homogeneous embankment type of dam with provision of a drainage filter.

Fig 2: Homogeneous embankment with the drainage filter system

- When only one type of material is locally available and which is economical, then a purely homogeneous section is used.

- This type of homogeneous section is used for low to moderately high dams and also for levees.

- A purely homogeneous section creates great problem of see page and section has to make a big section or a huge section so as to make the whole structure more safe against piping, stability etc.

- Hence due to fact of piping and stability, a homogeneous section is built-up with a internal drainage system like a horizontal drainage filter as shown in Fig. 6.1.2; rock toe etc.

- Internal drainage system keeps the top seepage line (phreatic line) properly within the body of the dam. Hence internal drainage system is more useful and always provided nearly all types of embankments.

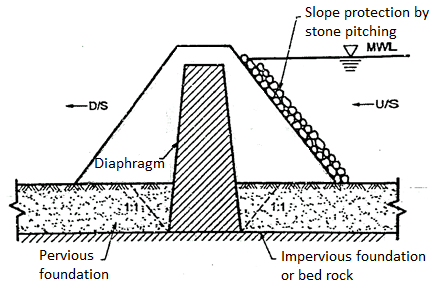

2. Diaphragm type of embankment dam

- This type of embankment dam consists of an impervious core called as diaphragm which is surrounded by earth or rock fill.

- Impervious core or diaphragm is made of impervious soils, timber, concrete, steel or any other suitable material. Diaphragm serves as a obstacles or water barrier so as to avoid the seepage through the dam.

- Diaphragm is located at the centre of the dam section or located or placed at the upstream face as a blanket. Diaphragm should be well connected to the bed rock or to a very impervious foundation material.

- Due to this connection between diaphragm and bed rock or impervious foundation, the possible excessive under seepage through the existing pervious foundation can be prevented.

- Note that diaphragm type of embankment dam and zoned embankment dam are differentiated in point of view of their thickness of core.

- When thickness of the diaphragm type of embankment is less than 10 m at any elevation or less than the height (h) of the embankment, then it is in the category of diaphragm type; but when the thickness becomes equal or more than the 10m, than it is in the type of zoned embankment.

Fig 3: Diaphragm type embankment dam

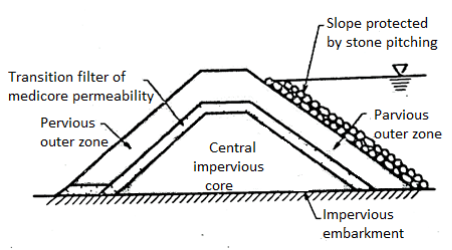

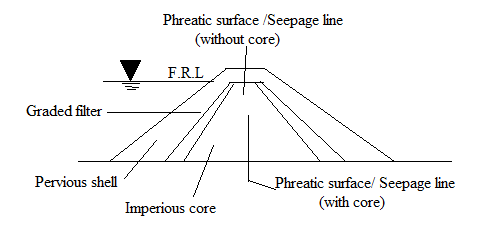

3. Zoned type embankment dam

- This type of embankment consists of usually a central impervious core covered by a transition zone which is surrounded by a pervious outer zone.

- Central core is useful to check the seepage. The transition zone is advantageous for preventing the piping through cracks which may likely to set up in the central core.

- The outer zone provides stability to the central impervious fill and also distribute the load over the larger area of foundations.

- Clay is highly impervious, but sometimes it does not make the best core, if it expands and shrinks in large extent.

- Hence clay is sometimes mixed with fine gravel or fine sand so as to make the most suitable material for the central core sometimes silty clay or silts can be used as the central core materials.

- In outer shell, the coarse sand and gravels which acts as a freely draining material are used.

Fig 4: Zoned type embankment dam

- In between, inner zone and outer zone, the transition filters are provided. When there is an abrupt change of permeability from one zone to the another zone, then in such circumstances, transition filters are best suited and hence provided.

4. Rolled fill earth dam

- In such type of earth dam, the embankment is constructed by placing suitable soil material in thin layers about 150 mm to 300 mm and these layers are further compacted with the help of rollers.

- The soil obtained from burrow pits are brought to the site and properly spread with bulldozers in layers which are further compacted by rollers of designed weights.

- For low embankments like levees or bunds, the ordinary road rollers are preferably used but for dams, the power-operated rollers are suitably used.

- Note that, the moisture content of the soil fill in the core should be properly controlled. The best compaction can be obtained at a moisture content somewhere near to the optimum moisture content. Compaction of coarse gravel cannot be done in proper way by rolling, hence it is done by vibrating equipment.

5. Hydraulic fill earth dam

- Definition: Dam which is constructed by excavating and transporting soils by using water is called as hydraulic-fill earth dam.

- In such dam, pipes (i.e. flumes) are placed along the outer side or edge of the embankment and soil materials mixed with water P is pumped into pipes called as flumes.

- Through the outlets, slush is discharged into flumes at suitable intervals along their length slush which is flowing to the centre of the bank, gets settle down.

- After getting the discharge near the outer edge, the coarser particles starts depositing and fine aggregates is carried and settle at the centre and finally it makes a zoned embankment which is relatively impervious central core.

- In such dam, high pore pressures develop in the core material because fill get saturated when placed and hence stability of the dam should be checked for pore pressures.

- Due to the slow drainage from the core, this type of embankment is susceptible to settlement for long periods. Hence hydraulic fill method is not in use these days but rolled-fill method is generally and universally used in modern days.

Key Takeaways:

- When only one type of material is locally available and which is economical, then a purely homogeneous section is used.

Causes:

The following are the points due to which earthen dam may fail.

- Improper construction methods and techniques.

- Improper maintenance.

- Improper design due to insufficient in investigation.

Categories of the Failure of Earthen Dams

1. Hydraulic failure

(i) Erosion of upstream and downstream face

(ii) Overtopping

(iii) Toe erosion

(iv) Gullying

(v) Frost erosion

2. Seepage Failure

(i) Piping through dam

(ii) Piping through foundation

3. Structural Failure

(1) Slide in embankment

(ii) Foundation slide

(iii) Failure due to earth quake

(iv) Failure due to holes caused by burrowing animals

(v) Failure by spreading

(vi) Failure due to leaching of water soluble salts

- Hydraulic failure

These types of failures occur due to following reasons:

i) Erosion of upstream and downstream face

- Such failure may occurs due to waves which are caused by flow of water. This type of erosion occurs due to improper store pitching on upstream side of dam. Erosion of downstream may occurs due to heavy rain falling directly over the downstream face and erosive action of moving water.

Ii) Overtopping

- In this type of hydraulic failure the water of the reservoir may flow over the top of the dam.

- Such type of failure may occur due to

(i) Insufficient free board.

(ii) If excess flood water enters into reservoir.

(iii) If length of spillway is less.

To overcome such type of erosion one should provide sufficient free board, sufficient spillway length and more top width.

Iii) Toe erosion

- In such erosion toe of dam may get eroded due to current of water which may come from spillway bucket and tailwater.

- To avoid such failure stone pitching should be provided upto a height slightly more than the tail water depth.

Iv) Gullying

- Formation of gullies will also result in failure of dam.

- To safe guard against external erosion upstream face is properly protected with stone called as pitching and downstream face is by turfing and stone laying and by providing berms.

v) Frost erosion

- In the areas of low temperature frost may occur which may leads to more seepage during summer.

For this purpose in such areas additional measures should be adopted.

- The preliminary design of an embankment dam is done on the basis of existing dams of similar characteristics and the design which is finalised by inspecting the adequacy of the selected section for any worst loading conditions.

- Empirical rules are frequently used in the design of an embankment dam.

- For preliminary designs, selection of suitable values of top width, free board, upstream and downstream slopes, drainage arrangement etc have prime importance.

- Free board

- It is the vertical distance between the maximum reservoir level and the top of the damn or crown or crest of dam normal freeboard is the vertical distance between normal pool level or spillway crest and top of the dam.

- For wave action, the minimum height of the freeboard is generally 1.5 h: where his a wave pressure.

= 0.032

= 0.032 FOR F

FOR F 32 km

32 km

- Hydraulic failure of embankment type of earth dam is mostly due to the overtoring of dams. Therefore, the sufficient freeboard should be kept so s to prevent the possibility of overlapping.

2. Width

- The top width and bottom width are the important task in the design of embankment type of dam. The top width for large embankment type of dam should be sufficient so as to keep the seepage line within the dam for reservoir completely filled with water.

3. Upstream slope and downstream slopes

Side slopes depends upon the following factors:

(i) type of dam

(ii) nature of dam

(iii) foundation materials

(iv) height of dam

Key Takeaways:

- To avoid such failure stone pitching should be provided upto a height slightly more than the tail water depth.

The following criteria should be followed for safe design of earth dam is:

(1) Dam should not be overturn and hence according to that necessary measures should be taken.

(2) Both slopes i.e. U/S slope and D/S slope should be stable under worst condition.

(3) Seepage should be within D/S face.

(4) Earth dam should be safe against over-tapping during the worst condition of floods.

(5) Upstream and downstream slopes of earth dam should be safe at the time of construction and after construction.

(6) U/s slope of earth dam should be safe when there occurs sudden-drawdown conditions.

(7) The d/s slope of earth dam should be safe when there is steady seepage condition.

(8) The earth dam as a whole should resist the earthquake impact or seismic waves.

(9) Shear stresses developed at the foundation should be within the safe limit.

(10) The upstream slope should be protected against erosion caused by waves.

(11) D/s slope and top of the earth dam should be protected against erosion caused by rain and wind.

(12) The part of the earth dam d/s of the impervious core should be property drained.

(13) Construction of earth dam should be economical, hence materials available nearly the dam site should be used.

Definition: The flowing of water through the pores of the soil is called as seepage.

Definition: When seepage takes place through the body of dam it is called horizontal piping and if it is through foundation it is called vertical piping.

Various Methods of Control of Seepage through Embankment

1. Provision of impervious core

2. Provision of rock toe

3. Horizontal drainage blanket

4. Relief well

5. Chimney Drain

- Provision of impervious core

For reducing seepage through body of dam a core of impervious material such as silty clay or clayey silt is provided which forms barrier within the body of dam against seepage water it is selected depending upon availability of materials topography and site etc.

Fig 5: Impervious core

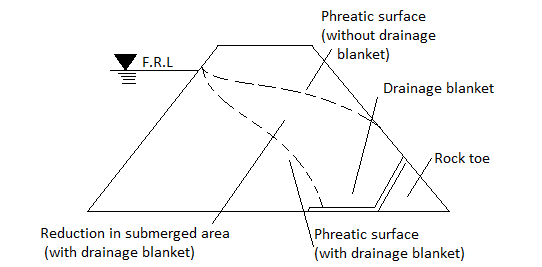

2. Provision of rock toe

It also helps in reducing seepage as it changes path of seepage line and prevent sloughing of the downstream toe.

Fig 6: Provision of rock toe and drainage blanket

3. Horizontal drainage blanket

The seepage can be controlled by providing horizontal drainage blanket along with rock toe.

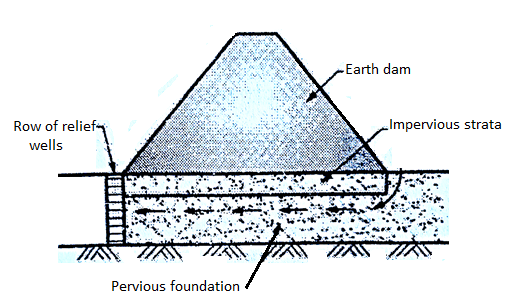

4. Relief wall

The main purpose of relief well is to decrease the sub-stratum uplift pressure downstream of the dam. If the relief well is not provided, there will be formation of sand boils and possibly sub-surface piping.

Fig 7: Relief wall

Relief wells intercept the seepage and control the outlet for seepage. They type of seepage control system was first used by U.S. Corporation of Engineers.

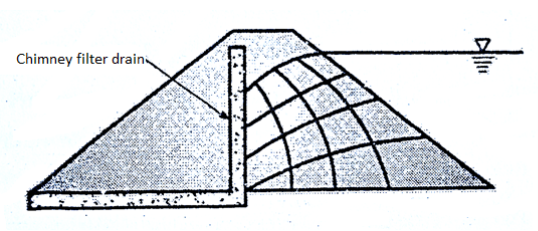

5. Chimney Drain

- The horizontal permeability is more than vertical for high degree of embankment stratification and it causes the greater horizontal spread of seepage.

- To control this seepage, a vertical drain called as chimney drain is provided which can completely intercept the embankment seepage.

Fig 8: Chimney filter drain

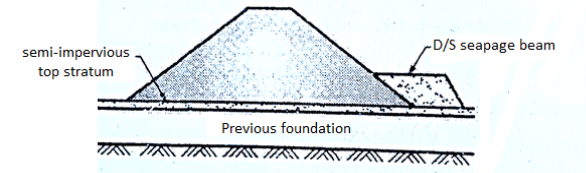

Seepage through foundation

Seepage through the foundations can be controlled by providing the following elements:

1. Impervious cutoff

2. Upstream impervious blanket.

3. Drainage trenches.

4. Relief wells

5. Downstream seepage berms

Fig. Shows downstream seepage berms.

Fig 9: Downstream seepage berm

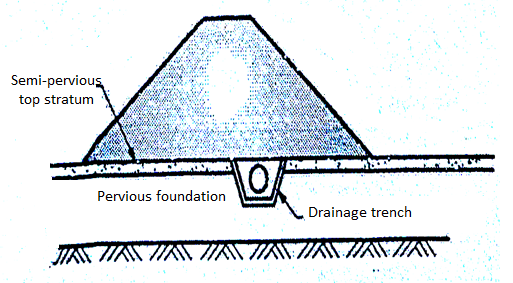

Fig. Shows drainage trenches

Fig 10: Drainage trench

Remedial Measures

- Design capacity of spillway accurately

- Provide sufficient free board

- Stone pitching and wave breakers on upstream face

- Provide thick riprap or rock toe on downstream face

- Protect downstream face by turfing

- Provide berm at suitable height.

- Provide extra free board

- Provide C.O.T. And impervious heating in dam.

- Provide rock toe at downstream toe.

- Care should be taken that excessive pore pressure should not be formed during construction of dam.

- Avoid steep slope, regular maintenance of slope.

- Earthquake pressure should be considered while designing dam.

Key Takeaways:

Seepage should be within D/S face.

References:

- Tech-max publication

- Techno max publication

- Foundation engineering by Dr. B.C. Punmia, Laxmi Publication.

- Geotechnical engineering by p. Purushottam Raj, Tata MC Grawhill