Unit - 1

Engineering Properties and Classification

Field Identification Test of Soil:

- Many times, laboratory tests are neither feasible nor practicable.

- At such instances, if a name tag can be put to a soil, a knowledgeable soil engineer will be able to gain much data from simply identifying the oil type.

- Field tests and field identification is thus a great tool in soil engineering.

- The soils to be identified in field may be coarse grained soil or fine grained soil.

Coarse Grained Soil:

- On the field coarse grained soils are identified by visual inspection and must be described on the bases of grading, grain-shape, colour, in-situ strength, structural features and presence of fines etc.

Grading:

- By visual inspection one can judge the coarse grain soil by its grading and can classify soil as well-graded, uniformly graded or poorly graded.

Grain shape:

- Grains can be defined on the field based on their shape, usually term used to describe the grain shape are angular, sub-angular and rounded.

Colour:

- Based on the colour of soil at field, soil can be expressed as white, yellow, brown, red brown etc.

Strength and structure:

- The term compact and loose are used to determine in-situ strength of deposit of coarse grained soil.

- The structure of coarse grained soils recognized in the field can be described as homogeneous or stratified.

Presence of fines:

- If soil contains some organic matter; it should be indicated.

- If it has some fines, and not causing cohesion, it should also be noted.

Fine Grained Soil:

- Following test are carried out for identification of fine grained soil.

- For this, the soil is sieved on site through 425 micron sieve and the fraction passing through is taken for the tests.

Dry strength test:

- The prepared sample is completely dried in sun or by air drying. Its strength is tested by breaking lump between fingers.

- Resistance to breaking, termed as plasticity and is considerably influenced by the colloidal fraction content of the soil.

- If the dry sample can be easily powdered it is said to have low dry strength, thus indicates dry strength is a measure of the silt or sandy silt.

- If considerable finger pressure is required to break the lump, it has medium dry strength, thus indicates silty clays and clays of low plasticity.

- If the lump cannot be powered by fingers at all, it has a high dry strength which represents a lightly plastic clay.

- The presence of water soluble cementing materials, such as calcium carbonate or iron oxides, may also cause high dry strength.

- Soil with high strength is treated with a little ilute hydrochloric acid. A strong reaction indicates that the strength may be due to calcium carbonate as cementing agent rather than colloidal clay.

Dilatancy Test:

- Dilatancy means reaction to shaking. About SCC soil sample is taken and enough water is added to nearly saturate it.

- The pat of soil is placed in the open palm of the hand and shaken horizontally be striking vigorously against the other hand several times. The pat is then squeezed between the fingers.

- The appearance and disappearance of water with shaking and squeezing is called a positive reaction. This reaction is called quick if water appears and disappears slowly and no reaction if water condition does not appear to change.

- The type of reaction is observed and recorded. Inorganic sits show a quick reaction where as clays show no reaction or slow reaction.

Toughness Test:

- The soil sample used in dilatency test is dried by working and moulding till it reaches the consistency of putty.

- The time required to dry the sample indicative of its plasticity. Further, the moisture content is reduced by rolling and re-rolling the soil into a thread of 3 mm diameter reaches the plastic limit.

- The resistance to moulding at plastic limit is called the toughness. After the thread crumbles, the pieces are lumped together and the slight kneading action is continued until the lump also crumbles.

- If the lump can still be moulded slightly drier than plastic limit and if high pressure is required to roll the thread between the palms of the hand, the soil is said to have high toughness.

- Medium toughness is indicated by medium thread and a lump formed of the threads slightly below the plastic limit will crumble.

- While low toughness is indicated by a weak thread that breaks easily and cannot be dumped together when drier than plastic limit.

- Non-plastic soils cannot be rolled into 3 mm diameter threads at any water content.

Organic silt or clay:

- If the amount of organic matter is small it is difficult to identify.

- Organic soil have a distinctive odour when fresh and wet.

- By heating the wet soil sample, odour can be made more noticeable.

- Fibrous organic soils, such as muck or peat, are dark brown to black in distinctive odour.

Other identification tests:

- High plasticity is indicated on the field, if we cut the dry o: slightly moist lump of soil with a knife blade, it produces a shiny soil surface. A dull surface indicates clay or silt of low plasticity.

- Silt sticks to fingers will wash away easily and brush off, if dry, whereas wet clay sticks to the fingers, gives a greasy feel and does not was easily.

- In soil suspension of water of about 10 cm depth.

- Clay-size particles will remain in suspension for several hours or even days.

- Within 5 to 60 minutes silt will settle.

- Whereas sand will settle easily with is half a minute.

- Determination of water content by oven-drying method as per IS code IS-2809-1972.

- This is the commonly adopted and simplest method for determination of water content of a soil sample in the laboratory.

- The method basically consists of drying a weighed moist sample of soil, in an oven controlled temperature for a period of 24 hours, after which the dry weight of the sample is taken.

- The drying of soil is recommended at a temperature of 105°C 110°C as temperatures higher than 110°C may break the crystalline structure of clay particles result in loss of water of crystallisation thus giving wrong results.

- A lower temperature of 60° is recommended for highly organic soils as at 110°C, oxidation of organic matter may take place.

- Sand and gravels requires less time to dry i.e. 4 to 6 hours but routine laboratory procedure is fc. Drying for 24 hours at 105°C-110°C.

- A clean, non-corrodible container is weighed within 0.01 gm accuracy.

- About 30-40 gm of moist soil sample is placed in it and weighed accurately. It is then placed in the oven for drying at 110°C for 24 hours.

- After 24 hours, it is taken out, allowed to cool and weighed again.

- The water content is then calculated as shown below:

Let W₁ = Weight of container

W2= Weight of container with moist sample

W3= Weight of container with dried sample

Weight of water Ww = W2-W3

Weight of solids Ws= W3-W1

Water content W = x100

x100

- The table below gives the minimum quantity of soil sample to be taken for test.

Sr.No | Size of particles more than 90 % passing through | Minimum quantity (gm) |

1 | 425 micron-IS sieve | 25 |

2 | 2 mm | 50 |

3 | 4.75 mm | 200 |

4 | 10 mm | 300 |

5 | 20 mm | 500 |

6 | 40 mm | 1000 |

- (Determination of specific gravity by pycnometer: IS 2720 part 3, section 1 1980, 1987).

- Pycnometer is a bottle with a lid in the form of inverted cone with a hole top. An empty dried pycnometer is weighed, say w₁.

- Next about 300 g of soil dried in the oven and cooled in the dessicator is placed in the pycnometer and the pycnometer is weighed again say w2.

- The pycnometer is again filled with water and its weight is noted, w3. Finally, the pycnometer is emptied completely, cleaned and dried and weighed after filling it completely with water w4.

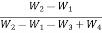

- Now weight of dry soil = W5 =W2-W1

- Weight of equal amount of water=(W2-W1)-(W3-W4)

- Specific Gravity G=

- Psycnometer method is used to determine specific gravity of all soils, but more suitable to coarse grained soil.

- This method is more suitable to find the specific gravity preferably of fine graine soil.

- A density bottle of 50 ml capacity is generally used.

- The procedure of density bottle method is same as pycnometer.

- Thus,

G =

- In this analysis soil is sieved through a set of sieves.

- Sieves are wire screens having square opening made up of spun brass and phosphor bronze or stainless steel sieve cloth.

- According to IS 149-1970, the sicves are designed by the size of square opei.aig in millimetres or microns.

- For gravel, the set of sieves used is 80 mm, 40 mm, 20 mm, 10 mm and 4.75 mm.

- For sand, the set of sieves used is 2.36 mm, 2 mm, 1.7 mm, 1.18 num, 600 , 425 µ, 300 μ and 75 μ.

- The sieves are arranged in descending size from top to bottom.

- The Lid or cover is placed at the top of largest sieve. A receiver known as pan, which has no opening is placed at the bottom of the smallest sieve a receiver known as pan is kept.

Dry sieve analysis:

Material and equipment’s:

- Balance (accurate to 1 gm), set of I.S. Sieves 4.75 mm, 2.36 mm, 1.18 mm, 600 μ, 300 μ. 150 μ 75 μ, wooden mallet, receiver, metal trays.

Procedure:

- Take a representative sample of soil received from field and dry it in the oven. Break the clods in the sample by means of fingers or wooden mallet only.

- Weigh nearly 1 to 2 kg of sample for testing.

- Arrange the various sieves one over the other in order of their mesh opening sieve at the top and smallest at the bottom. A receiver is put at the bottom and a with the largest cover at the top.

- The soil sample is put on the top sieve and the set of sieves is attached to a mechanical sieve shaker. Shake for 10 minutes.

- The part of soil sample retained in sieve is weighed and recorded.

Observations:

Sr.No | IS sieve size | Mass retained(gm) | % Retained | Cumulative % retained | Cumulative % Finer (N) |

1 | 4.75 mm |

|

|

|

|

2 | 2.36 mm |

|

|

|

|

3 | 1.18 mm |

|

|

|

|

4 | 600  |

|

|

|

|

5 | 300  |

|

|

|

|

6 | 150  |

|

|

|

|

7 | 75  |

|

|

|

|

8 | Pan  |

|

|

|

|

Distribution curve:

- The distribution curve is a plot of graph size in mm on the logarithmic scale as the abscissa and the percentage finer on the natural scale as the ordinate. The distribution curve gives at a glance the nature of gradation range of particles.

Characteristic features of distribution curve:

- The soil below which 'N' percentage is finer is known as 'N' percent.

- Effective size. The size usually defined for sands corresponding to 10% finer D10 is known as effective size.

- Uniformity coefficient:

- Coefficient of graduation or curvature :

Large uniformity coefficient means well graded soil, its value close to one means. Uniformly or poorly graded soil.

- Greater effective soil size indicates coarse soil.

- For a well-graded soil C, must be between 1 to 3 and in addition C, must be greater than for gravels and 6 for sands.

Wet sieve analysis:

- Wet sieve analysis is done, when the soil contains substantial quantity of fine particles.

- From the soil sample, all lumps are broken into individual particles, the sample is oven dried.

- After drying the soil sample is soaked in water.

- If required deflocculating agents like sodium hexametaphosphate at the rate 2 of water may be added.

- The sample is stirred and left soaking for period of at least one hour.

- The slurry is sieved through 4.75 mm sieve.

- The portion retained on 4.75 mm sieve is gravel fraction.

- The material passing through 4.75 mm sieve is sieved through a 75 u sieve.

- The material is washed until the wash water becomes clear.

- The material retained on 75 µ sieve is collected and dried in an oven.

- It is then sieved through the set of sieves of sizes 2.36 mm, 2 mm, 1.7 mm, 1.18 mm, 600 μ, 300 μ, and 75 μ.

- The material retained on each sieve is weighed and analyzed.

- The hydrometer method of sedimentation analysis differes from the pipette analysis in the method of taking the observations but the principles of the test being the same in both the cases.

- The hydrometer is an instrument used for determination of specific gravity of liquids. A special type of hydrometer with long neck used for this purpose. The stem is marked from top to the bottom.

- At the time of starting of the sedimentation, the specific gravity of suspension is uniform at all the depths. When sedimentation takes place, the larger particles settle more deeper than the smaller particles.

- This results in greater specifie gravity for lower layers of suspension than that of upper layers.

- The hydrometer measures the specific gravity of suspension, at a point where the centre of the immersed volume is the same as the centre of the bulb. Thus, the hydrometer gives the specific gravity of the suspension at the centre of the bulb. 1000 ml suspension is prepared o explained earlier. The suspension is taken in a jar. It is stirred properly. The jar is placed on the table and stop watchi started. The hydrometer is inserted in the suspension and the first reading is taken after 1, 2, 4, 6 minutes of the sedimentation. The hydrometer is then removed from the jar and rinsed with distilled water and floated in a cylinder containing distilled water with the dispersing agent of same concentration as that of soil suspension.

- Next reading are taken after 8, 15, 30 minutes, 1, 2, 4, 8, 24 hours. The time is measured from the beginning of sedimentation hydrometer is inserted about 20 seconds before the reading.

- The hydrometer is taken out after the reading and floated in the cylinder containing distilled water with the dispersing agent of same concentration as that of soil suspension.

- The depth any layer (1-2) from the free surface (A-B) is the depth at which the specific gravity is measured by the hydrometer.

- As soon as the hydrometer is inserted in jar, the layers of suspension which at level (1-2)rise+ (1’-2’) and those at level (A -B) rises to level (A’-B').

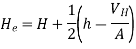

Therefore, the effective depth (He) is  +

+

Where,

VH =Volume of hydrometer

h = Height of bulb

A = Cross-section area of the jar

H= Depth from the free surface (A’-B') to the lowest mark on the stem

- In above equation, it is assumed that the rise in suspension level from (1-2) to (1’-2’) at the centre of the bulb is equal to half the total rise due to the volume of the hydrometer.

Thus,

- The marking on the hydrometer stem gives the specific gravity of the suspension at the centre of the bulb. The hydrometer readings are recorded after subtracting unity from the value of specific gravity and multiplying remaining quantity by 1000.

This is the standard method used in laboratory.

Materials and equipment:

- A pipette, a jar and a number of sampling bottles.

Procedure:

- 500 ml of soil suspension is required in this method.

- The suspension is taken in the sedimentation tube.

- A 10 ml capacity pipette is used for extracting of sample. The pipette is fitted with suction inlet.

- The sedimentation tube is placed in a constant temperature bath at 27° C for one hour.

- The suspension is thoroughly mixed in the sedimentation tube after taking out a constant temperature bath.

- The tube is again kept in the constant temperature bath after thoroughly mixing.

- As soon as the tube is placed in the bath it is taken as beginning of the sedimentation.

- To record the time stop watch is started.

- The constant temperature bath is kept just below the tip of the pipette.

- The pipette is slowly lowered in to the sedimentation tube.

- Generally take the samples at 100 mm depth below the surface.

- Generally the first sample is taken after two minutes of the start of sedimentation. More samples are taken out after 4, 8, 15 and 30 minutes and 1, 2, 4, 8, 12 and 24 hours.

- Exact time at which sample is taken is noted.

- The samples taken out are dried in an oven at 100° C to 110° C for 24 hours to obtain the mass of solids per ml.

Calculation:

% finer and diameter of particle is calculated as shown below:

At time t=0, 10 ml contains mass (Md)0, (Initial uniform suspension)

At time t=t1, at depth H: 10 ml contains (Md)t1

At time t=t2, at depth H: 10 ml contains (Md)t2

Hence,

% finer (N1) =

(N2) =

And diameter:

D₁ = 0.0301

D₂ = 0.0301

- This method is very accurate laboratory method for the particle size distribution.

- But apparatus is quite delicate and expensive and requires a very sensitive weighing balance.

- The Atterberg limits are a primary degree of the important water contents of a fine-grained soil: its shrinkage limit, plastic limit, and liquid limit.

- Depending on its water content material, a soil may also seem in one in every of 4 states: solid, semi-solid, plastic and liquid. In every nation, the consistency and conduct of a soil is exclusive and therefore so are its engineering properties. Thus, the boundary among every nation may be described primarily based totally on a extrade withinside the soil's conduct. The Atterberg limits may be used to differentiate among silt and clay, and to differentiate among exclusive forms of silts and clays. The water content material at which the soils extrade from one nation to the alternative are referred to as consistency limits or Atterberg's limit.

- These limits had been created through Albert Atterberg, a Swedish chemist and agronomist in 1911.They had been later subtle through Arthur Casagrande, an Austrian-born American geotechnical engineer and near collaborator of Karl Terzaghi (each pioneers of soil mechanics).

- Distinctions in soil are utilized in assessing the soils which are to have systems constructed on them. Soils whilst moist preserve water, and a few enlarge in extent (smectite clay). The quantity of growth is associated with the cappotential of the soil to absorb water and its structural make-up (the form of minerals present: clay, silt, or sand). These checks are specifically used on clayey or silty soils considering the fact that those are the soils that enlarge and decrease whilst the moisture content material varies. Clays and silts engage with water and therefore extrade sizes and feature various shear strengths. Thus those checks are used broadly withinside the initial ranges of designing any shape to make certain that the soil can have the proper quantity of shear energy and now no longer an excessive amount of extrade in extent because it expands and shrinks with exclusive moisture contents.

Liquidity index:

- The liquidity index (LI) is used for scaling the herbal water content material of a soil pattern to the limits.

- It may be calculated as a ratio of distinction among herbal water content material, plastic restrict, and liquid restrict:

LI=(W-PL)/(LL-PL)

Wherein W is the herbal water content material.

Consistency index:

- The consistency index (Ic) suggests the consistency (firmness) of a soil.

- It is calculated as CI = (LL-W)/(LL-PL), wherein W is the present water content material.

- Soil on the liquid restrict may have a consistency index of 0, even as soil on the plastic restrict may have a consistency index of one and if W > LL, Ic is negative. That approach soil is withinside the liquid state.

- More over, sum of Liquidity index and Consistency index same to 1 (one)

Sensitivity:

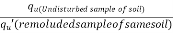

- The ratio of unconfined compressive strength of an undisturbed sample of soil to unconfined compressive strength of the remoulded sample of same soil at the same water content as in undisturbed soil is called as sensitivity (St)

St =

Where, qu=unconfined compressive strength of an undisturbed sample of soil or clay

qu’ = unconfined compressive strength of remoulded sample of soil or clay at the same water content as in the undisturbed soil.

- Sensitivity is a measure of the loss in strength of soils and remoulding on the consistency of a cohesive soil.

- Following table shows natural clay deposits classified into four different categories based on the value of sensitivity.

Sr.no | Sensitivity | Classification |

1 | 1-14 | Normal |

2 | 4-8 | Sensitive |

3 | 8-16 | Very sensitive |

4 | 16-32 | Slightly quick |

5 | 32-64 | Medium quick |

6 | Greater than 64 | Quick |

7 | Less than 1 | Stiff clay |

Table: Sensitivity classification soils

Thixotropy:

- Thixotropy is a Greek word in which thix means touch and tropo means change, overall meaning of thixtropy is any change which occurs by touch.

- Thixotropy is the property of certain clays or soil by virtue of it gradually regains its lost strength with time if remoulded clay is allowed to rest without change in water content.

- In short, if a remoulded soil sample having the sensitivity more than one is allowed to stand without change in water content and disturbance, then it may regain some parts of its original strength and stiffness. This increase in strength of soil sample is termed as thixotropy .

- Thixotropy has more practical importance in geotechnical engineering In pile-driving operations, thixotropy plays important role For example. There is a strength loss of soil, when a pile is driron into the ground In such case, one can easily know regaining of shear strength after the pile has been driven and left in place for some time with the help of thixotropy.

Key Takeaways:

- The ratio of unconfined compressive strength of an undisturbed sample of soil to unconfined compressive strength of the remoulded sample of same soil at the same water content as in undisturbed soil is called as sensitivity (St).

- Thixotropy is a Greek word in which thix means touch and tropo means change, overall meaning of thixtropy is any change which occurs by touch.

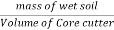

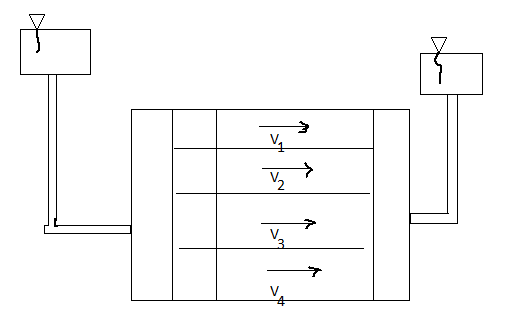

- The core cutter method consists of driving a core cutter of known volume usually 1000 CC into the soil after placing it on cleaned soil surface.

- The core cutter is usually provided with a 25 mm high dolly.

- The driving of core - cutter is accomplished by hitting the dolly mounted on the core cutter with the rammer.

- The cutter filled with the soil is removed by cutting under it with a knife or sharp edge. The extra soil is trimmed off. The cutter with the soil is weighed.

- The volume of the core cutter is calculated from the inner dimensions. The weight of empty core-cutter is also taken. Then the insitu unit weight is determined by dividing the weight of soil in the core-cutter by the volume of the core-cutter.

- For determining the dry unit weight, a piece of the soil is taken and its water content w, is determined by oven drying method.

- Then the dry density can be found from the bulk density as follow:

Bulk density  =

=

Bulk unit weight, r= 9.81  kN/m²

kN/m²

Dry density  =

=  (g/cm³)

(g/cm³)

Dry unit weight  =

=  (kN/m³)

(kN/m³)

Where w=water content

The core-cutter is shown in Fig.

Procedure:

- Measure inside dimension of core cutter and calculate volume.

- Find the mass of the core cutter (without a dolly).

- Clean top of soil on site and level it place dolly on top of the core cutter and drive into the soil with help and rammer until about 1 to 1.5 cm of dolly remain above surface.

- Dig out container which is containing soil from ground. Remove dolly with help of straight edge trim flat and the end of cutter.

- Find mass of cutter fall with soil and find out water content (w.).

- Repeat procedure 2 to 3 locations nearby and get average dry density.

The core-cutter method cannot be used for loose soils or non-cohesive soils. Under these conditions, the sand replacement method is better suited.

Material and equipments:

- Sand pouring cylinder of about 3 litre capacity, mounted above a pouring cone and separated by a shutter cover plate and a shutter.

- Cylindrical calibrating container, 10 cm internal diameter and 15 cm internal depth, fitted with a flange approximately 5 cm wide and about 5 mm thick.

- Glass plate about 45 cm square and 1 cm thick

- Metal tray with a central circular hole of diameter equal to the diameter of the pouring cone. Tools for excavating the hole, balance accurate to lg.

- Container for water content determination.

- Clean, closely graded natural sand passing the 600 micron IS sieve and retained the 300 micron IS sieve.

Test procedure:

This method includes two steps

- Determination of density of sand.

- Determination of density of soil.

1.Determination of density of sand:

- Fill the clean closely graded sand in the sand pouring cylinder upto a height of 1cm below the top. Determine the total initial mass of the cylinder plus sand (M₁). This total initial mass should be maintained constant throughout the tests for which the calibration is used.

- Allow the sand of volume equivalent to that of the excavated hole in the soil (or equal to that of the calibrating container) to run out of cylinder by opening the shutter. Close the shutter and place the cylinder on glass plate.

- Open the shutter and allow the sand to run out. Close the value when no further movement of sand is observed. Remove the cylinder carefully. Weigh the sand collected on the glass surface. Its mass (M₂) will give the mass of sand filling the pouring cone. Repeat this step at least three times and take the mean mass (M₂). Put the sand back into the cylinder, to have the same constant mass (M₁).

- Determination of mass of sand in the cone.

- Mass of sand (+ cylinder) before pouring(M1)(g)

- Mean mass of sand in cone (M₂) (g)

Determination of bulk density of sand:

- Determine the volume (V) of the calibrating container by filling it with water, full to the brim and finding the mass of water. This volume should be checked by calculating it from the measured internal dimensions of the container.

- Place the sand pouring cylinder concentrically on the top of the calibrating container, after being filled to constant mass (M₁) open the shutter and permit the sand to run into the container. When no further movement of sand is seen, close the shutter. Remove the pouring cylinder and find its mass (M₁) to the nearest gram. M₁. Put the sand into the sand

- Repeat above step at least thrice and find the mean mass pouring cylinder.

- V- volume of calibrating container (M₁).

- Mean mass of sand (+ cylinder) after pouring M3 (g).

- Mass of sand filling calibrating container.

- M’=M1-M3-M2(g)

- Bulk density of sand Ps=

(g/cm³)

(g/cm³)

2.Determination of dry density of soil:

- Expose about 45 cm square area of the soil to be tested and trim it down to the level surface. Keep the tray on the level surface and excavate a circular hole of approximately 10 em diameter and 15 cm deep and collect all the excavated soil in the tray. Find the mass (M) of the excavated soil.

- Remove the tray, and place the sand pouring cylinder, so that the base of the cylinder concentrically covers the hole. The cylinder should have its constant mass MI. Open the shutter and permit the sand to run into the hole. Close the shutter when no further movement of and is seen, Remove the cylinder and determine its mass (M4).

- Keep a representative sample of the excavated soil for water content.

- Mass of wet soil from the hole (m) (g).

- Mass of sand (+ cylinder) after pouting in the hole (M4) (g).

- Mass of sand in hole M" = MI-M4-M2 (g).

- Bulk density of soil

- Bulk unit weight of soil =

=9.81 P (kN/m3)

=9.81 P (kN/m3) - Dry density

=

=  (g/cm³)

(g/cm³) - Dry unit weight,

=

= (kN/m²)

(kN/m²)

Where, w=water content

- The volume of a sample is determined by water displacement. As soil mass disintegrates when it comes in contact with water, it is coated with a paraffin wax to make it impervious.

- A test sample is trimmed to more or less a regular shape and weighed (M).

- It is then coated with thin layer of paraffin by dipping in molten wax.

- The specimen is allowed to cool and weighed (MI).

- Difference between the two weights viz M and MI will be the weights of wax.

- The waxed sample is then immersed in a water displacement container.

- The volume of water displaced by the specimen equals the volume of the waxed sample.

- The actual volume of the sample is less than the water of waxed sample.

- If unit weight of wax is known, the volume wax can be determined.

Total volume of soil, V=

Where,

V₁ = Volume of waxed sample

V = Volume of sample

M₁=Mass of waxed sample

M =Mass of sample

= Unit weight of paraffin wax

= Unit weight of paraffin wax

Bulk density of soil,

Dry density,

Unit weight,

Water content (w) is determined by taking soil from middle of the sample.

Dry unit weight of soil.

- "Definition: Permeability is defined as "The property of a porous material which permits the passage or seepage of water (or other fluids) through its interconnecting voids".

- If water flow easily through voids of soil, then soil is highly pervious or permeable and when the permeability is extremely low it is called impervious or impermeable.

Coefficient of Permeability:

- Definition: The coefficient of permeability (K) is "The average velocity of flow that will occur through the total cross-sectional area of soil under unit hydraulic gradient" and unit is cm/sec, m/day, feet/day

- According to USBR soil having the coefficient of permeability greater than 10 mm/sec such soils are permeable soils.

- Soils having values less than 10 mm/sec are impermeable soils.

- The soils which have in between values are semi-permeable soils.

Key Takeaways:

Permeability is defined as "The property of a porous material which permits the passage or seepage of water (or other fluids) through its interconnecting voids.

- In 1856 Darcy studied and demonstrated experimentally, the velocity of laminar flow through homogeneous soil mass, which states that, "The rate of flow or the discharge per unit time is proportional to the hydraulic gradient."

q= K.i.A

V=q/A

V i, V=Ki

i, V=Ki

Where,

q= discharge per unit time

A= total c/s area of soil mass, perpendicular to the direction of flow

i =hydraulic gradient K Darcy's coefficient of permeability

v =velocity of flow, or average discharge velocity

- If a soil sample of length 1 and cross-sectional area A, is subjected differential head of water hA-hB, the hydraulic gradient i will be equal to (hA-hB)/L and

We have,

q=KA (hA-hB)/L

When hydraulic gradient i = 1, then k=v

Key Takeaways:

Darcy’s law states that, "The rate of flow or the discharge per unit time is proportional to the hydraulic gradient."

Permeability depends on many factors. Following are the main factors that affect permeability:

Grain size:

- Grain size of the soil, or the effective size Dio is one of the factors which affect permeability. Allen Hazen gave the relation.

K = C(D10)2

Where, K Coefficient of permeability in cm/s and D10 is the effective grain size of the soil, C= constant (between 100 to 150)

- The permeability of coarse-grained soil is more than that of fine-grained soil

Properties of pore fluid:

- Permeability is directly proportional to the unit weight of pore fluid and inversely proportional to the viscosity of the pore fluid.

Temperature:

- Since viscosity of the pore fluid decreases with the temperature, permeability increases with temperature, as unit weight of the pore fluid does not change much with change in temperature.

Void ratio:

- Increase in void ratio increases the area available for flow, hence the permeability increases for critical conditions.

K e2

e2

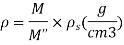

Stratification of soil:

- Stratified soils are those, which are formed by layer upon layer of earth or dust deposited upon one another.

- If the flow is parallel to the layers or stratification, the permeability is maximum while the flow in perpendicular direction to the stratification occurs with minimum permeability.

Entrapped air and organic impurities:

- Organic impurities and entrapped air obstruct the flow and coefficient of permeability is reduced due to their presence.

Adsorbed water:

- Adsorbed water means a thin, microscopic film of water surrounding individual soil grains.

- This water is not free to move and hence reduces the effective pore space and thus decreases the coefficient of permeability.

Degree of saturation:

- The permeability of partially saturated soil is less than that of fully saturated soil.

Shape of particles:

- Permeability is inversely proportional to the specific surface e.g., the angular particles have more specific surface as compare to rounded particles. Therefore, the soil having angular particles is less permeable than soil of rounded particles.

Structure of soil mass:

- For same void ratio the permeability is more for flocculant structure as compare dispended structure.

Key Takeaways:

Factors affecting permeability are as follows:

- Grain size

- Properties of pore fluid

- Temperature

- Void ratio

- Stratification of soil

- Entrapped air and organic impurities

- Hydraulic Conductivity (K) is an crucial hydraulic parameter because it influences the surroundings via way of means of controlling infiltration, irrigation rate, and therefore the water motion via the ground.

- In order to decide Hydraulic Conductivity in a soil column all through unsaturated flow, experiments had been done withinside the laboratory.

- A sandy (S) soil pattern of regarded Hydraulic Conductivity at saturation (KS) changed into located uniformly in a obvious column. Using a pump, water changed into implemented on the floor of the soil column in sure supplies (Qi), even as soil moisture (θ) changed into measured the use of TDR probes.

- At the identical time, soil pore stress (h) changed into measured the use of stress transducers. The cumulative quantity of the outgoing water (V) of the column changed into measured.

- Experimental facts had been outfitted via way of means of Van Genuhten's Hydraulic Conductivity model. The effects of the above experimental technique represent beneficial gear for the simulation of water motion in unsaturated soils and may be the outset for similarly research.

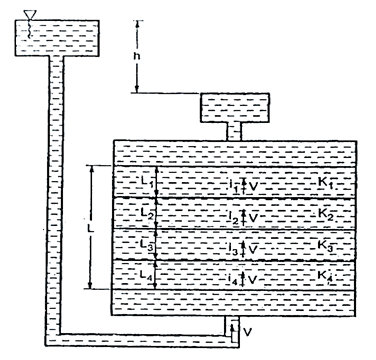

- Stratified soils are those, which are formed by lager upon lager of carth or dust deposited upon one another.

- If the flow is parallel to the lagers or stratification, the permeability is maximum while the flow is perpendicular direction to the stratification occurs with minimum permeability shown fig.

Fig 1: Horizontal strata

Fig 2: Vertical strata

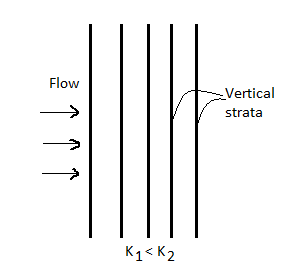

(1) Average permeability parallel to the bedding planes

- Let L1, L2…Ln be thickness of layer.

- K1, K2…Kn be permeability of layer.

- For flow to be parallel to the bedding planes, the hydraulic gradient i will be the same for all the layers.

- However, since V Ki and K is different, the velocity of flow will different in different layers.

Fig 3: Flow parallel to bedding plane

- Let K= average permeability of the soil deposit parallel to the bedding plane.

- Total discharge through the soil deposit sum of discharge through the individual layers.

q=q1, q2…. Qn

Kx =

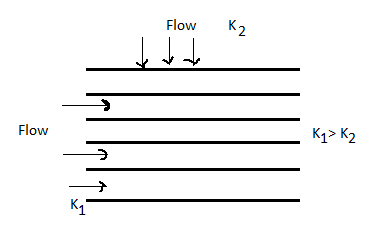

(2) Average permeability perpendicular to the bedding planes

- In this case, the velocity of flow and hence the unit discharge, will be the same through each layer. However, the hydraulic gradient and hence loss through each lager will be different. Denoting the head loss through the lagers by h1,h2….hn, and the total head loss as h we have

h=h1+h2+...hn

But h1=iL1 h2=iL2

h=iL1+iL2+iL3+…

Now, if KZ=average permeability perpendicular to the bedding plane.

We get,

Kz=

Fig 4: Flow perpendicular to bedding plane

- Hence for same void ratio, the soil with rounded particles are more permeable than with angular particles.

Key Takeaways:

Stratified soils are those, which are formed by lager upon lager of carth or dust deposited upon one another. If the flow is parallel to the lagers or stratification, the permeability is maximum while the flow is perpendicular direction to the stratification occurs with minimum permeability.

Soil can be extensively labeled as follows:

- Classification primarily based totally on grain length

- Textural type

- AASHTO type

- Unified soil type

1. Grain length type machine:

- Grain length type structures had been primarily based totally on grain length. In this machine the phrases clay, silt, sand and gravel are used to signify most effective particle length and now no longer to suggest nature of soil type.

- There are numerous type structures fin use, however typically used structures are proven here.

2. Textural Classification:

- The type of soil completely primarily based totally on particle length and their percent distribution is referred to as textural type machine.

- This machine specially names the soil relying on the share of sand, silt and clay. The triangular charts are used to categorise soil through this machine.

3. AASHTO type:

- AASHTO type is in any other case referred to as PRA type machine. It became in the beginning advanced in 1920 through the U.S. Bureau of Public Roads for the type of soil for dual carriageway subgrade use.

- This machine is advanced primarily based totally on particle length and plasticity traits of soil mass.

- After a few revision, this machine became followed through the AASHTO in 1945. In this machine the soils are divided into seven essential corporations. Some of the essential corporations similarly divided into subgroups.

- A soil is classed through intending from left to proper at the type chart to discover first the organization into which the soil check information will fill.

- Soil having best fractions are similarly labeled primarily based totally on their organization index. The organization index is described through the subsequent equation.

Group index = (F – 35)[0.2 + 0.005 (LL – 40)] + 0.01(F – 15)(PI – 10)

F – Percentage passing 0.075mm length

LL – Liquid limit

PI – Plasticity index

4. Unified soil type:

- Unified soil type machine became in the beginning advanced through Casagrande (1948) and became referred to as airfield type machine.

- It became followed with a few amendment through the U.S. Bureau of Reclamation and the U.S. Corps of Engineers.

- This machine is primarily based totally on each grain length and plasticity traits of soil.

- The equal machine with minor amendment became followed through ISI for wellknown engineering purpose (IS1498 – 1970). IS machine divides soil into 3 essential corporations, coarse grained, best grained and natural soils and different miscellaneous soil materials.

- Coarse grained soils are people with greater than 50% of the cloth large than 0.075mm length.

- Coarse grained soils are similarly labeled into gravels (G) and sands (S). The gravels and sands are similarly divided into 4 classes in keeping with gradation, silt or clay content.

- Fine grained soils are the ones for which greater than 50% of soil finer than 0.half mm sieve length. They are divided into 3 sub-divisions as silt (M), clay, and natural salts and clays (O). Primarily based totally on their plasticity nature they may be delivered with L, M and H image to signify low plastic, medium plastic and excessive plastic respectively.

- A soil class device is basically to facilitate communique among extraordinary businesses of engineers, broadly separated.

- The class device does now no longer do away with the want for precise soil research and testing.

- The classification primarily based totally on grain length or texture.

- Atterberg changed into the primary to indicate homes apart from which may be used for class.

- At that time, those have been proposed for agricultural motive however have been later regularly occurring in soil engineering.

- Very few herbal structures are ordered in this sort of manner as to allow a wholly herbal class. The periodic table (Mendelejew 1869) might be the handiest instance of a herbal class system. Soil class structures may be grouped into nominal (unmarried level) structures, tables (dimensional), or reference bases (Krasilnikov 2002). Nominal structures and tables finally grade into taxonomies as new hierarchies are added.

- Soils constitute a range of people, with populations too severa to comprehend. Some soils range handiest in minor respects and are tough to distinguish, while others may also range widely.

- Soil class objectives to lessen the range of people and therefore carry comprehension on the rate of distinct information. Archetypes (prototypes) are the factor of departure for maximum soil class structures, accompanied through diagnostic houses, which can be used for differentiation.

- In maximum landscapes a restricted range of archetypical soils are found, with intergrades among those. In different landscapes those intergrades would possibly themselves be archetypical, while the archetypical soils of the primary instance arise as intergrades.

- This means that archetypical soils of various areas or nations could range. Coupled with the reality that soil technological know-how is a tremendously younger technological know-how, it might be the purpose for the proliferation of soil class structures internationally.

- Creating unique archetypes in soil class results in disaster (Smith 1986). Few soil houses are unique to a particular soil and people soils that fall out after except for or extra soil houses are very tough to classify.

- The SA Soil Taxonomy (Soil Classification Working Group 1991) is essentially pushed through conceptual soil genetic classes, described through qualitative morphological criteria. In comparison, the USDA Soil Taxonomy (Soil Survey Staff 2003) and WRB (WRB 2007) use quantitative soil houses as differentiating criteria.

- It is based on USCS with the modification that fine-grained soils are sun-divided into 3 groups of low, medium and high compressibility, instead of 2 groups as in the case of USCS.

- Low compressibility (L): LL < 35

- Medium compressibility (I): 35 < LL < 50

- High compressibility (H): LL > 50

- The soil is classified into 18 groups: 8 groups of coarse-grained, 9 groups of fine-grained and 1 group of Peat.

- The basic soil components as per ISSCS are as shown in the table below.

Soil | Soil components | Symbol | Particle size range and description |

(i)Coarse- grained components | Boulder

Cobble

Gravel

Sand | None

None

G

S | Rounded to angular, bulky, hard , rock, particle, average diameter more than 300 mm Rounded to angular, bulky, hard, rock particle, average diameter smaller than 300 mm but retained on 80 mm IS sieve. Rounded to angular, bulky, hard, rock particle, passing 80 mm IS sieve but retained on 4.75mm IS sieve Coarse: 80mm to 20mm IS sieve Fine: 20mm to 4.75mm IS sieve Rounded to angular, bulky, hard, rock particle; passing 4.75 mm IS sieve, but retained on 75-micron sieve Coarse: 4.75 mm to 2.0 mm IS sieve Medium: 2.0 mm to 425 micron IS sieve Fine: 425-micron to 65-micron IS sieve

|

(ii)Fine-grained components | Silt

Clay

Organic matter | M

C

O | Particles smaller than 75 micron IS sieve, identified by behaviour, that is slightly plastic or non-plastic regardless of moisture and exhibits little or no strength when air-dried

Particles smaller than75 micron IS sieve : identified by behaviour that is, it can be made to exhibit plastic properties within a certain considerable strength when air dried.

Organic matter in various sizes and stages of decomposition. |

- A plasticity chart is used as a help in classification. It is the plot of liquid limit against plasticity index. Fixed lines are printed on the chart, dividing it in to different areas.

- Liquid limit wL and plasticity index Ip is determined for the given soil and the point is plotted on the plasticity chart.

- If it falls in a particular region, it is classified as that soil type. Plasticity chart is shown in Fig.

Numericals:

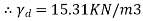

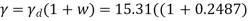

Q. The Void ratio and Specific gravity of sample of clay are 0.73 and 2.7 respectively. If the voids are 92% saturated find the bulk density, dry density and the water content?

Given:

e =0.73

G=2.7

S=92%

Find:

1)Water content(W)

W=

∴W =24.87%

2)Bulk density( and dry density(

and dry density(

∴

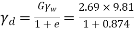

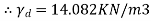

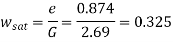

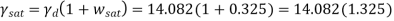

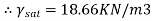

Q. A Soil sample in its natural state has, when fully saturated, a water content of 32.5%. Determine the void ratio, dry density and saturated unit weights. Assume G=2.69.

Given:

w =32.5%

G=2.69

Find: Void ratio(e), Dry unit weights( (

( )

)

We know,

For fully saturated S=1

e =w.G=

∴e =0.874

Dry unit weight

For fully saturated soil S=1

∴e=

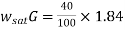

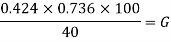

Q.A saturated clay has a water content of 40% and bulk specific gravity is 1.84.Determine the void ratio, and specific gravity of particles.

Given:

G=1.84

w=40%

e=

e=0.736

We know, n=

n=

n=0.424

∴G=0.78

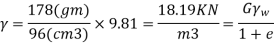

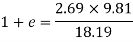

Q.A saturated soil sample weighting 1.78 gm has a volume of 96cc.If G=2.67 determine the void ratio, water content and unit weight of the soil?

Given:

W=178gm

V=96cc

G=2.67

Find: e=?,

18.19=

1+e=1.45

∴e= 1.45-1 =0.45

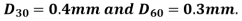

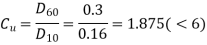

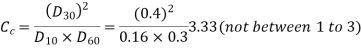

Q. The grading curve of a soil gives the effective size as 0.16mm, Find Cu and Cc.Classify the soil.

Find Cu and Cc.Classify the soil.

Does not meet the requirement of well graded sand, given soil is poorly graded sand.

References:

- Soil Mechanics and Foundation Engineering by Dr.B.C.Punmia, Laxmi Publication

- Geotechnical Engineering by T.N.Ranamurthy & T G Sitharam, S Chand Publications.

- Principles of Geotechnical Engineering by Braj M.Das, Cengage Learning.

- Geotechnical Engineering by P.Purushothma Raj, Tata Mc Grawhill.