Unit - 3

DC-DC Buck and Boost Converter

A chopper is a DC equivalent to an AC transformer having continuously variable turn ratio. Like a transformer, a it can be used to step up or step down the fixed DC input voltage. On this basis, there are two types of chopper: Step-up and Step-down Chopper. A chopper whose average value of DC output voltage is more than the fixed DC input voltage is called Step-up Chopper. While, a chopper whose average value of DC output voltage is less than the DC input voltage is called Step-down chopper.

Working Principle of Chopper:

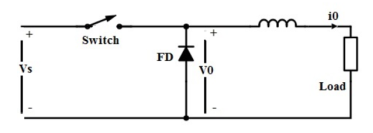

A chopper is a high speed ON/OFF switch. It connected source to load and disconnects the load from the source at a fast speed. Figure below represents the simple circuit to show its working principle.

Figure 1. Chopper

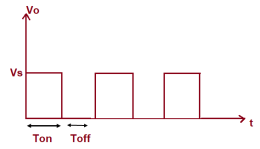

In this circuit, the switch SW is chopper. This switch can be made ON and OFF at a very high speed. In this way, the load may be connected and disconnected from the supply source Vs. When the switch is ON, the load voltage is equal to the source voltage Vs and when the switch is OFF, load voltage becomes equal to ZERO. Thus, a chopped voltage across the load is obtained. The output voltage i.e. voltage across the load is shown in figure below.

Figure 2. Output waveforms

It should be noted here that, when the switch SW is made OFF, the load current finds its path through free- wheeling diode D. Therefore, diode D acts as a short and hence the voltage across the load becomes zero. Inductor in the chopper is an essential thing. This inductor makes diode D forward biased when the switch SW is OFF.

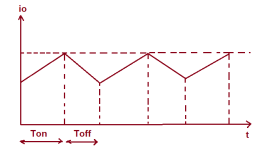

It should also be noted that, even though the switch SW is made OFF, the load current doesn’t become zero. Rather, it flows through the free- wheeling diode, inductor L and load. In fact, the load current is continuous as shown below.

Figure 3. Load current

It may be seen from the above waveform of output current of chopper that, during ON time, the current rises whereas during OFF time, the load current io decays.

The time for which chopper connects the load from source is called ON time i.e. TON. Whereas, the time for which load is disconnects from source is called OFF time i.e. TOFF.

Duty Cycle:

Duty cycle of chopper is defined as the ratio of ON time to the total time period. It is denoted by symbol α. Total time period is the sum of ON and OFF time.

Duty Cycle = TON / (TON+TOFF)

Assuming (TON+TOFF) = T, duty cycle is given as below.

Duty Cycle, α = (TON / T)

Calculation of Output Voltage:

The average output voltage of chopper may be find from the output voltage waveform. It is clear from the o/p voltage waveform that, voltage Vo is available only for TON time period in the total time (TON+TOFF). Therefore, average output voltage Vo may be calculated as shown below.

Vo = TON Vs / (TON+TOFF)

But, TON / (TON+TOFF) = α

Hence,

Vo = αVs

Thus, the output voltage may be controlled by controlling the duty cycle. This duty cycle may be controlled in various ways which we will discuss in the next post. From the expression of ouput voltage, it is also clear that, the output voltage is independent of the load current.

The expression for chopper output voltage may also be written as below.

Vo = TON Vs / (TON+TOFF)

= Vs TON / T

Assuming 1/T = Chopping frequency

Vo = f Vs TON.

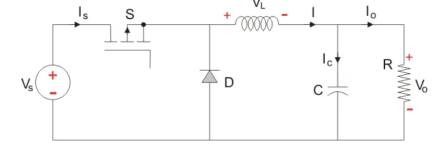

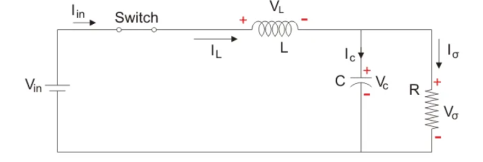

A typical Buck converter is shown below.

Figure 4. Buck converter

The input voltage source is connected to a controllable solid- state device which operates as a switch. The solid-state device can be a Power MOSFET or IGBT.

The second switch used is a diode. The switch and the diode are connected to a low-pass LC filter which is appropriately designed to reduce the current and voltage ripples. The load is a purely resistive load.

The input voltage is constant and the current through load is also constant. The load can be seen as current source.

The controlled switch is turned on and off by using Pulse Width Modulation(PWM).

PWM can be time based or frequency based.

The Buck converter has two modes of operation. The first mode is when the switch is on and conducting.

Mode I: Switch is ON, Diode is OFF

Figure 5. Buck converter circuit(Switch ON)

The voltage across the capacitance in steady state is equal to the output voltage.

Let us say the switch is on for a time TON and is off for a time TOFF. We define the time period, T,

T = TON + T OFF

And the switching frequency

Fswitching = 1/T

Let us now define another term, the duty cycle,

D = TON/T

Let us analyze the Buck converter in steady state operation for this mode using KVL.

Vin = VL + Vo

DiL/dt = ∆ iL/∆t = ∆iL/DT = Vin-Vo/L

Since the switch is closed for a time Ton = DT we can say that ∆t=DT

(∆ iL ) closed= (Vin - Vo/L) DT

While performing the analysis of the Buck converter, we have to keep in mind that

The inductor current is continuous and, this is made possible by selecting an appropriate value of L.

The inductor current in steady state rises from a value with a positive slope to a maximum value during the ON state and then drops back down to the initial value with a negative slope. Therefore the net change of the inductor current over anyone complete cycle is zero.

Mode II: Switch is OFF, Diode is ON

Figure 6. Switch off

Here, the energy stored in the inductor is released and is ultimately dissipated in the load resistance, and this helps to maintain the flow of current through the load. But for analysis we keep the original conventions to analyse the circuit usingKVL.

Let us now analyse the Buck converter in steady state operation for Mode II using KVL.

0 = VL + Vo

VL = L diL/dt = -VO

DiL/dt = ∆ iL/∆t = ∆ iL / (1-D) T = -Vo/L

Since the switch is open for a time

TOFF = T – TON = T -DT = (1-D) T

We can say that

∆t = (1-D) T

(∆ iL) open = ( -Vo/L) (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo) /L .DT + (-Vo/L) DT =0

Vo /Vin = 1/ 1-D

Since the switch is open for a time

TOFF = T – TON = T – DT = (1-D) T

We can say that

∆t = (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero.

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo/L) (1-D) T + (-Vo/L) (1-D)T =0

Vo /Vin = D

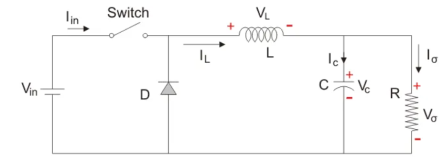

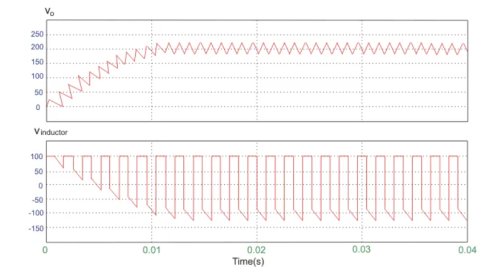

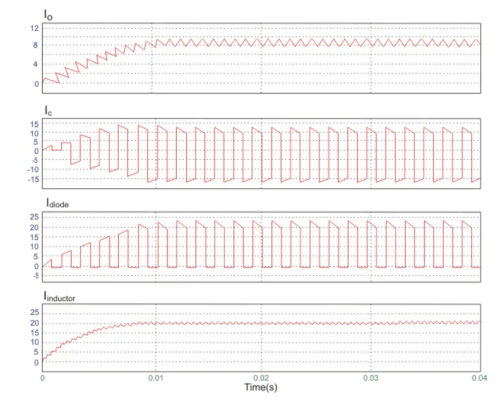

A circuit of a Buck converter and its waveforms is shown below.

The inductance, L, is 20mH and the C is 100µF, and the resistive load is 5Ω. The switching frequency is 1 kHz. The input voltage is 100V DC, and the duty cycle is 0.5.

The voltage waveforms are as shown above and the current waveforms are as shown in the figure below.

Figure 7. Output waveforms

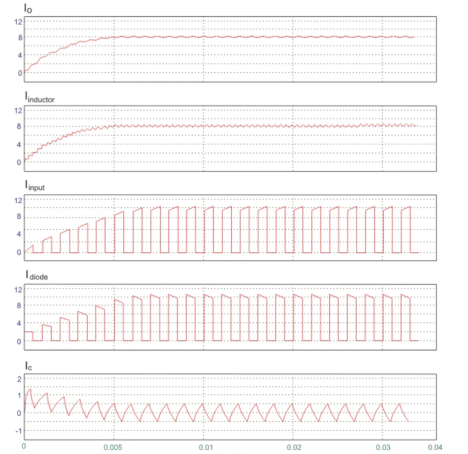

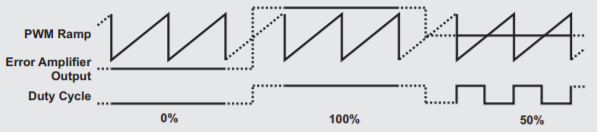

Figure 8. Duty ratio

The buck converter is used to generate a lower output voltage from a higher DC input voltage. If the losses in the switch and catch diode are ignored, then the duty cycle, or the ratio of ON time to the total period, of the converter can be expressed as (1) The duty cycle is determined by the output of the error amplifier and the PWM ramp voltage as shown in Figure 2. The ON time starts on the falling edge of the PWM ramp voltage and stops when the ramp voltage equals the output voltage of the error amplifier. The output of the error amplifier in turn is set so that the feedback portion of the output voltage is equal to the internal reference voltage.

Figure 9. Output of error amplifier

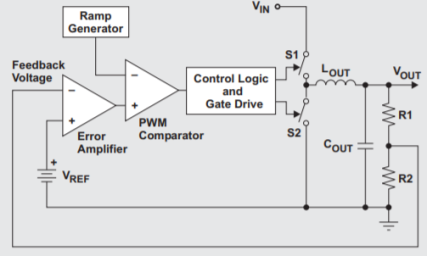

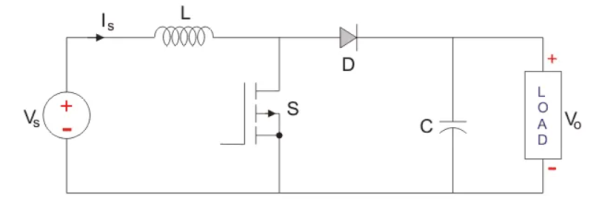

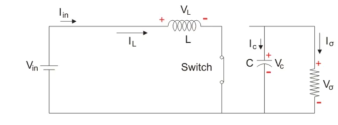

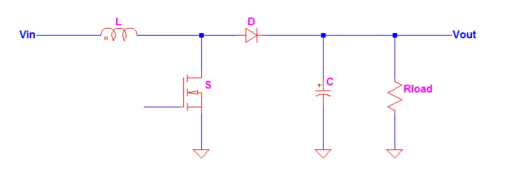

A typical Boost converter is shown below.

The input voltage source is connected to an inductor. The solid-state device which operates as a switch is connected across the source. The second switch used is a diode. The diode is connected to a capacitor, and the load and the two are connected in parallel as shown in the figure above.

The inductor connected to input source leads to a constant input current, and thus the Boost converter is seen as the constant current input source. And the load can be seen as a constant voltage source.

The controlled switch is turned on and off by using Pulse Width Modulation (PWM). The Boost converter has two modes of operation. The first mode is when the switch is on and conducting.

Mode I: Switch is ON, Diode is OFF

The switch is ON and therefore represents a short circuit ideally offering zero resistance to the flow of current so when the switch is ON all the current will flow through the switch and back to the DC input source. Let us say the switch is on for a time TON and is off for a time TOFF. We define the time period, T, as

T = TON + T OFF

And the switching frequency

Fswitching = 1/T.

Let us now define another term, the duty cycle,

D = TON/T

Let us analyze the Boost converter in steady state operation for this mode using KVL.

Vin = VL

VL = L diL /dt = Vin

DiL/dt = ∆ iL/∆t = ∆iL/DT = Vin/L

Since the switch is closed for a time Ton = DT we can say that ∆t=DT

(∆ iL) closed= (Vin/L) DT

Let us analyze the Boost converter in steady state operation for this mode using KVL. Since the switch is closed for a time TON = DT we can say that Δt = DT.

While performing the analysis of the Boost converter, we have to keep in mind that

The inductor current is continuous and this is made possible by selecting an appropriate value of L.

The inductor current in steady state rises from a value with a positive slope to a maximum value during the ON state and then drops back down to the initial value with a negative slope. Therefore, the net change of the inductor current over anyone complete cycle is zero.

Mode II: Switch is OFF, Diode is ON

In this mode, the polarity of the inductor is reversed. The energy stored in the inductor is released and is ultimately dissipated in the load resistance, and this helps to maintain the flow of current in the same direction through the load and also step-up the output voltage as the inductor is now also acting as a source in conjunction with the input source. But for analysis, we keep the original conventions to analyze the circuit using KVL.

Let us now analyse the Boost converter in steady state operation for Mode II using KVL.

Vin = VL + Vo

VL = L diL/dt = Vin -VO

DiL/dt = ∆ iL/∆t = ∆ iL / (1-D) T = Vm-Vo/L

Since the switch is open for a time

TOFF = T – TON = T -DT = (1-D) T

We can say that

∆t = (1-D) T

(∆ iL) open = (Vin -Vo/L) (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo) /L (1-D) T + (-Vo/L) DT =0

Vo /Vin = 1/ 1-D

Since the switch is open for a time

TOFF = T – TON = T – DT = (1-D) T

We can say that

∆t = (1-D) T

It is already established that the net change of the inductor current over any one complete cycle is zero.

(∆ iL) closed + (∆ iL) open =0

(Vin – Vo/L) (1-D) T + (-Vo/L) DT =0

Vo /Vin = 1/ 1-D

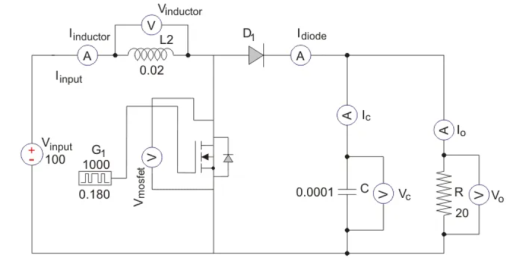

A circuit of a Boost converter and its waveforms are shown below. The inductance, L, is 20mH and the C is 100µF and the resistive load is 20Ω. The switching frequency is 1 kHz. The input voltage is 100V DC and the duty cycle is 0.5.

The voltage waveforms are as shown above and the current waveforms are as shown in the figure below.

The voltage waveforms are as shown above and the current waveforms are as shown in the figure below.

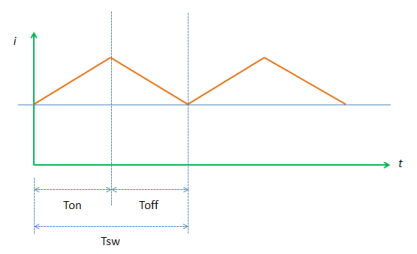

The inductor of the boost converter charges during Ton and discharges during Toff. The inductor current waveform is then resembled like Figure 2 below.

The figure is an inductor waveform of a continuous conduction mode boost converter. A boost converter by the way can operate in three modes; continuous conduction (CCM), discontinuous conduction (DCM) and boundary mode. For CCM the inductor current will not reach zero after every switching cycle. For DCM, the inductor current is reaching zero before the next Ton occur.

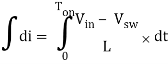

How to Calculate the Duty Cycle of Boost Converter – Analysis during Ton

During Ton, the switch S is on. The diode will be reversed biased and this time the load is being supplied by the energy stored in the capacitor C. The inductor will charge. The flow of the current is from Vin to inductor L then to switch S. By KVL,

Vin – VL – Vsw = 0

Then expressing VL

VL = Vin – Vsw …………………..(1)

The voltage across inductor is also defined by below formula.

VL = L di/dt ……………(2)

Expressing the change in current di

Di = VL/L dt ……………………...(3)

Substitute 1 to 3

Di = (Vin – Vsw)/L dt ……………(4)

Then we will get rid of the variable dt by integrating the equation from 0 to Ton.

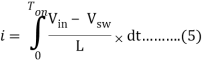

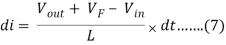

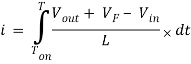

How to Calculate the Duty Cycle of Boost Converter – Analysis during Toff

During Toff, the inductor reverses its polarity and the diode at this time w ill be forward biased and the load will be supplied by the energy in the inductor. The energy on the inductor will start to decay. The flow of current is from Vin to diode D then to the load. Applying KVL,

Vin + VL – VF - Vout = 0

Expressing VL,

VL = Vout + VF – Vin ………….(6)

Substituting [Eq. 6] to [Eq. 3] will result to

Then we will eliminate the variable dt through integration from Ton to T.

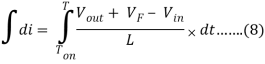

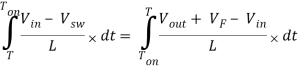

Now go back to Figure 2, the magnitude of the inductor current during Ton and Toff is equal. Therefore, we can equate [Eq. 5] and [Eq. 8].

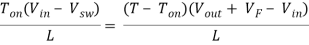

Ton(Vin – Vsw) = (T – Ton)(Vout + VF – Vin)

Then substitute Ton = DT

DTV in – DTV sw = T(1 – D)(Vout + VF – Vin)

Then solving for the duty cycle, D

D = (Vout + VF – Vin)/(Vout + VF – Vsw ) …………………(9)

Eq. 9

Assuming ideal values (diode and switch voltage drops are zero)

D = (Vout – Vin)/Vout ………….(10)

Output Voltage:

The relationship of voltage and current for an inductor is:

I = 1/L  , or

, or

V = L di/dt

For a constant rectangular pulse:

I = Vt /L + i0

From this we can see that the current is a linear ramp, when the voltage is a constant pulse.

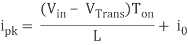

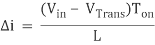

When the transistor switches on the current is:

, or

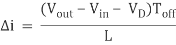

And when the transistor switches off the current is:

i0 = ipk – (Vout – Vin + VD)Toff/L , or

(Equation 1)

Where VD is the voltage drop across the diode, and VTrans is the voltage drop across the transistor. Note that the continuous/discontinuous boundary occurs when io is zero.

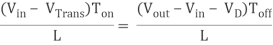

By equating through delta i, we can solve for Vout:

Vin Ton – VTrans Ton = Vout Toff – Vin Toff + VDToff

Vin Ton + VinToff = VoutToff + VTransTon + VDToff

Vin – VTrans D = (Vout + VD)(1 – D)

Vout = (Vin – VTransD)/(1 – D) - VD

We can also solve for the duty cycle as follows,

DVout + DVD – VTrans D = Vout – Vin + VD

D = ( Vout – Vin + VD)/(Vout + VD – VTrans)

If we neglect the voltage drops across the transistor and diode then:

Vout = Vin/(1 – D)

So, it is clear that the output voltage is related directly to the duty cycle of the pulses.

References:

- Fundamentals of Power Electronics Book by Robert Warren Erickson

- Power Electronics: Principles and Applications Book by Joseph Vithayathil

- Introduction to power electronics Book by Denis Fewson

- R. W. Erickson and D. Maksimovic, “Fundamentals of Power Electronics”, Springer Science & Business Media, 2007.

- L. Umanand, “Power Electronics: Essentials and Applications”, Wiley India, 2009.