Unit – 4

First law of flow processes

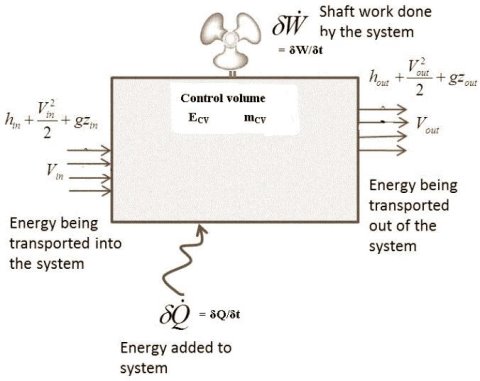

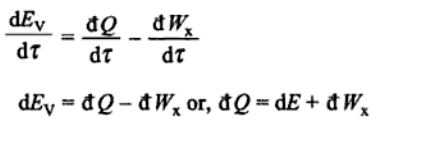

First law of thermodynamics applied to control volume:

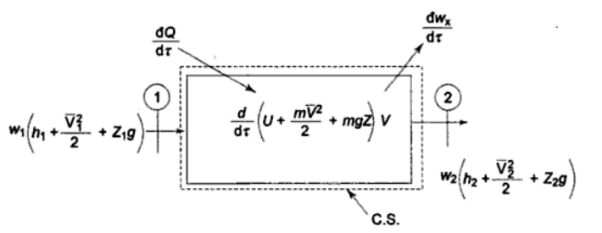

As shown in the diagram above, consider the control volume having inflow of energy.

The system is producing some shaft work as shown in the figure.

There is a continuous influx and outflux of the fluid in the system.

The rate of heat energy addition to the control volume = δQ/δt

The rate of work energy providing by control volume to the surrounding = δW/δt.

The mass flow rate entering to the control volume = dm1/dt

The mass flow rate leaving the control volume =dm2/dt

Rate of change of mass in control volume = dmCV/dt

According to principle of conservation of mass, we will have following equation

(Mass flow rate entering to the system) - (Mass flow rate leaving the system) = Rate of change of mass in control volume

(dm1/dt) - (dm2/dt) = dmCV/dt

E = u + pv + V2/2 + gz

E = h + V2/2 + gz

Ein = hin + V2in/2 + gzin = h1 + V21/2 + gz1

E1 = h1 + V21/2 + gz1

Eout = hout + V2out/2 + gzout = h2 + V22/2 + gz2

E2 = h2 + V22/2 + gz2

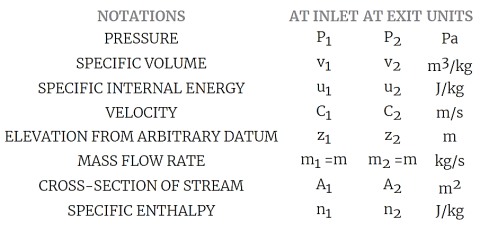

Steady Flow System -

Defined as the system in which the mass flow rate into the system is equal to mass flow rate out of the system.

Mass flow rate in m1 = Mass flow rate out, m2 = constant = m

Consider the flow of fluid through a pipe of cross-sectional area A,

Specific volume V, at Velocity C.

Volume flow rate = A (m2) × C (m/s)

Mass flow rate m (kg/s) = Volume flow rate / Specific volume

m =AC/V = ρAC= Continuity Equation

Heat transfer rate to the system = Q [ J/s]

Work transfer rate from the system = W [ J/s]

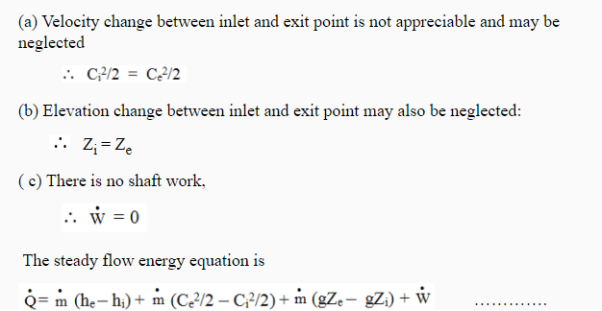

Assumptions-

- There is no accumulation or decrease of mass in the control volume at any time.

- The rate of mass transfers at inlet and exit are equal.

- The state and energy of the fluid at inlet, exit and in the control volume do not vary with time.

- The rate of heat and work transfers across the control volume are constant.

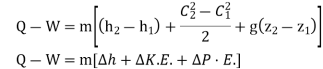

S.F.E.E. On unit time basis -

Total energy flow rate into the control = total energy flow rate out of control volume.

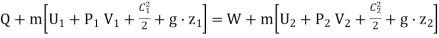

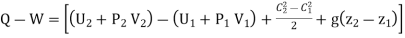

Q+ m [Internal energy + Flow work + KE + PE ]1 = W +m [Internal energy + Flow work + KE + PE]2

Enthalpy

Enthalpy

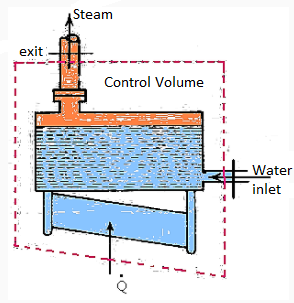

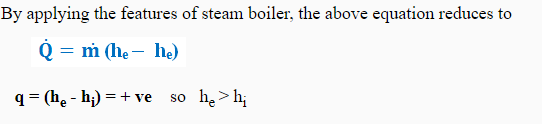

Boiler - A boiler is a device used for steam generation at constant pressure.

Heat is supplied to boiler drum externally by combustion of fuel in presence of air. Products of combustion are called Flue gases.

For a boiler - W =0, ΔK.E.=0 and Δ P.E.=0

On using these conditions S.F.E. Equation,

Q = m (h2 - h1)

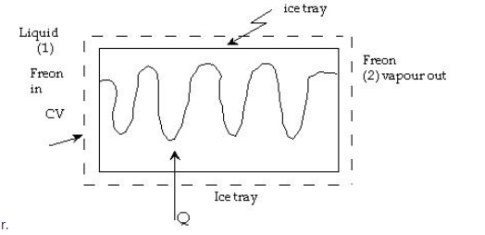

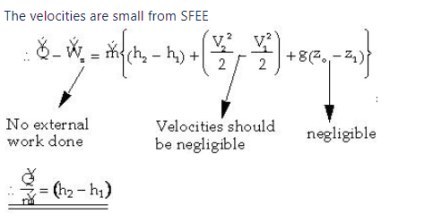

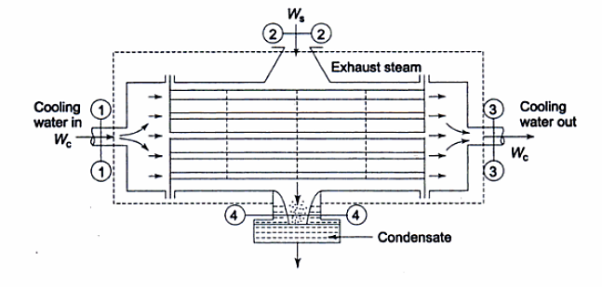

Condenser -

A condenser is a device used for steam condensation at constant pressure.

For a condenser - W =0, ΔK.E.=0 and Δ P.E.=0

On using these conditions S.F.E.Equation,

Q = m (h1 – h2)

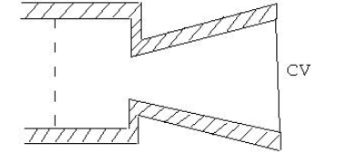

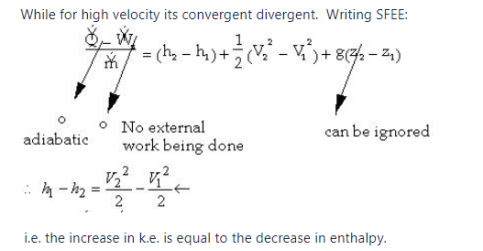

Nozzle: In case of a nozzle as the enthalpy of the fluid decreases and pressure drops simultaneously the flow of fluid is accelerated. This is generally used to convert the part of the energy of steam into kinetic energy of steam supplied to the turbine.

For this system, ∆PE=0,W=0,Q=0

Applying the energy equation to the system,

h1+(C12/2)=h2+(C22/2)h1+(C12/2)=h2+(C22/2)

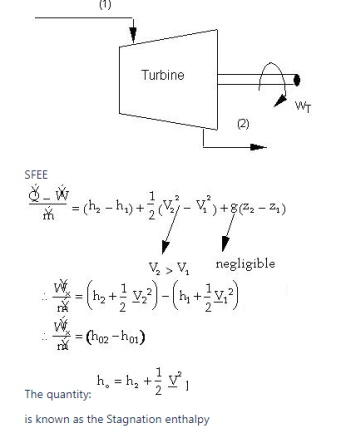

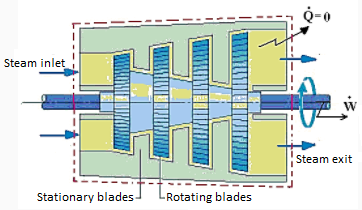

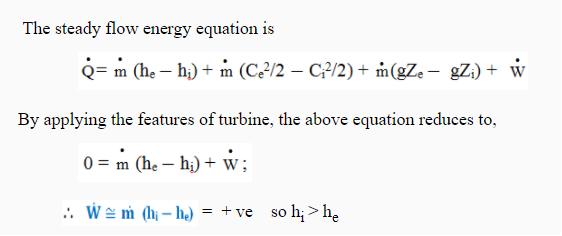

Turbine: In a steam or gas turbine steam or gas is passed through the turbine and part of its energy is converted into work in the turbine. This output of the turbine runs a generator to produce electricity. The steam or gas leaves the turbine at lower pressure or temperature.

Applying energy equation to the system,

Here, Z1=Z2

h1+(C12/2)−Q=h2+(C22/2)+W

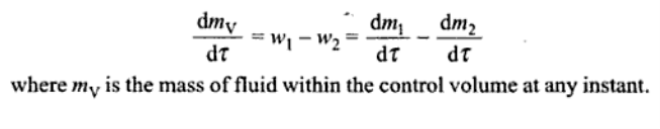

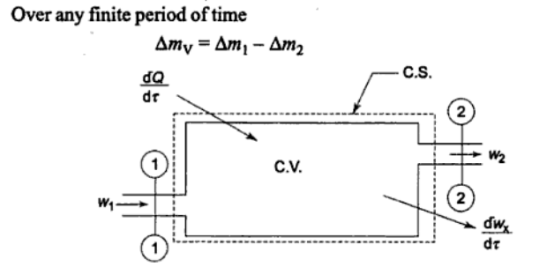

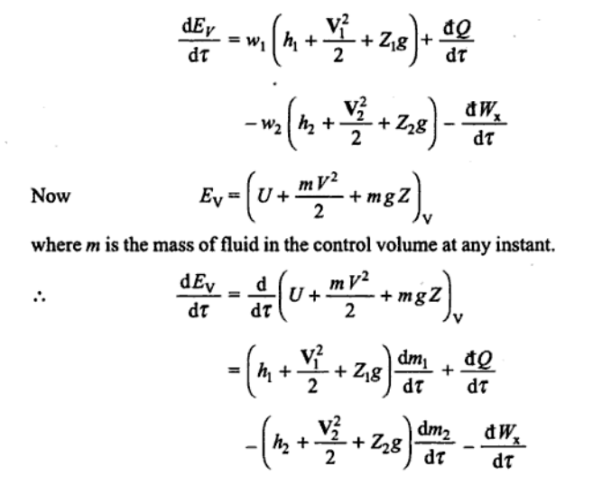

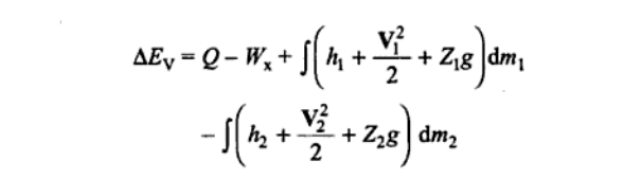

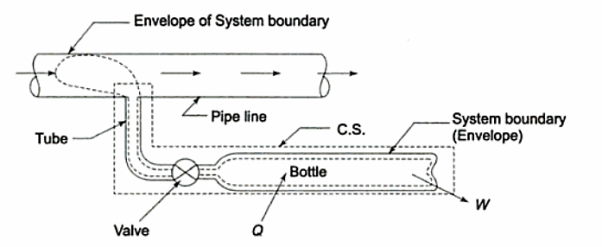

Many flows process are not steady, such processes are analysed by control volume method.

Rate of mass of fluid accumulated = net rate of mass flow across control surface

Rate of energy increase = Rate of energy inflow - Rate of energy

For steady flow

So,

Steady Flow Process:

- Boilers

- Condensers/Evaporators (Heat Exchangers)

There is no external work done, and energy exchange in the form of heat is confined only between the two fluids, i.e., there is no external heat interaction or heat loss.

- Turbine

- Pumps

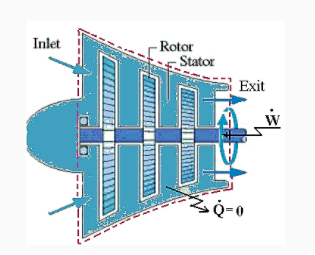

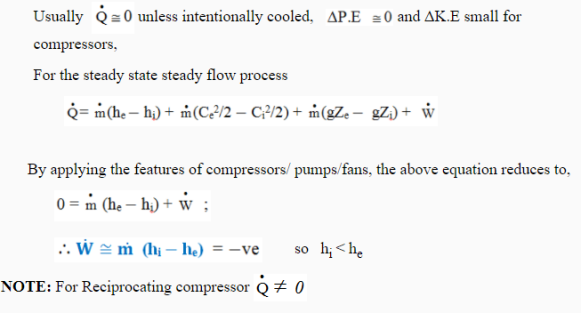

A compressor is a device that uses shaft work input to increase the pressure of a gas passing through it.

Pump: A pump is similar to a compressor, but it handles liquids.

Fan: A fan moves air with a slight pressure rise.

Unsteady Flow Process:

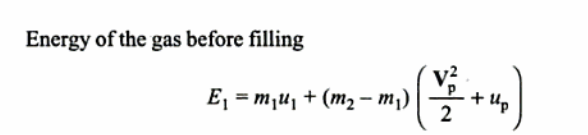

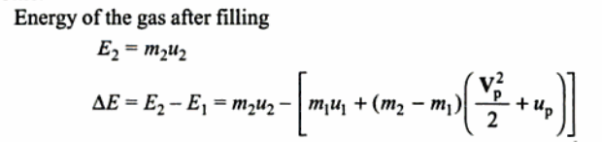

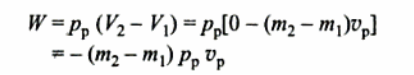

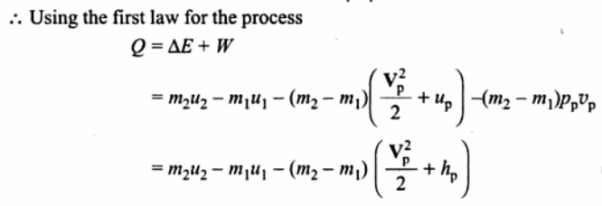

PE terms are neglected & since the gas are not in motion, KE terms have been omitted.

Change in volume of gas because of collapse of envelope to zero volume.

References:

- Basic and Applied Thermodynamics by PK Nag, MCGRAW HILL INDIA.

- Thermodynamics for Engineers by Kroos & Potter, Cengage Learning.

- Thermodynamics by Shavit and Gutfinger, CRC Press.

- Thermodynamics- An Engineering Approach by Cengel, MCGRAW HILL INDIA.

- Basic Engineering Thermodynamics, Joel, Pearson.