Unit - 2

Vapour Power Cycle

Basic Rankine Cycle:

The Rankine cycle is a cycle that converts heat into work. The heat is supplied externally to a William John Macquorn Rankine closed loop, which usually uses water. This cycle generates about 90% of all electric power used throughout the world.

In a real Rankine cycle, the compression by the pump and the expansion in the turbine are not isentropic. In other words, these processes are irreversible and entropy is increased during the two processes. This somewhat increases the power required by the pump and decreases the power generated by the turbine.

This cycle is the fundamental operating cycle for all the power plants where an operating fluid is continuously evaporated and condensed.

The Rankine cycle is the major working pattern of all force plants where a working liquid is constantly evaporated and condensed.

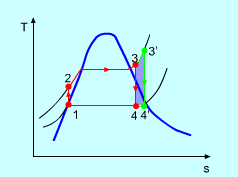

Figure 1: Rankine Cycle

1-2 Isentropic Pressure:

The squeezing element of the condensate is raised in the feed siphon. Considering the low unequivocal volume of fluid, the siphon work is moderately little and regularly excused in thermodynamic estimations.

2-3 Isobaric Heat Transfer

High-pressure fluid enters the heater from the feed siphon (1-2) and is warmed to the immersion temperature (2). Further extension of energy causes dissipation of the fluid until it is totally changed over to immersed steam (3)

3-4 Isentropic Expansions:

The vapour is extended in the turbine, in this way making work which may be changed over to power. In practice the extension is limited by the temperature of the cooling medium and by the disintegration of the turbine cutting edges by liquid entrainment in the fume stream as the cycle moves further into the two-stage district. Leave fume attributes should be more noteworthy than 90%.

4-1 Isobaric Heat Rejection:

The vapour liquid mixture leaving the turbine (3-4) is condensed at low pressure generally in a surface condenser utilizing cooling water. In very much planned and looked after condensers, the pressing factor of the vapour is well below atmospheric pressing, moving toward the immersion pressing factor of the working liquid at the cooling water temperature.

- Work done on pump, per kg of water: WP= h2 – h1

Energy added in steam generator: q1= h3 – h2

- Work delivered by turbine: WT= h3 – h4

Energy rejected in the condenser, q2 =h4 – h1

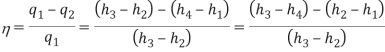

- The thermal efficiency of the Rankine cycle is given by:

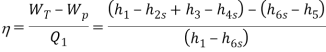

Reheating of Steam:

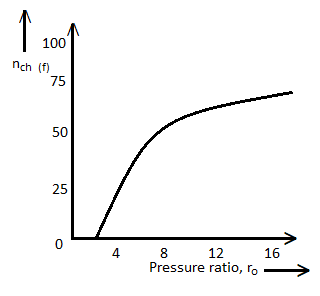

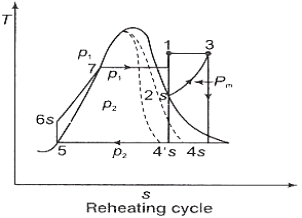

In the warm cycle, the extension of steam from the initial state 1 to the condenser pressure is completed in at least two or more stages relying on the quantity of reheat utilized.

Cycle efficiency: improves with reheat, anyway the cycle productivity in a solitary warm plant is affected by pressure at which steam is warmed. The efficiency increment as the reheat pressing factor is brought down and arrives at a top at a pressing factor proportion somewhere in the range of 0.20 and 0.25.

Warming steam likewise increment the organization yield of turbine

Figure 2: Reheating Cycle

Reheating steam also increase the network output of turbine.

Advantages of Re‑heating:

1) Due to reheating, network done increments.

2) Heat supply increments.

3) Thermal effectiveness tangle increment or diminishing relying on the mean temperature of warmth expansion.

4) Due to reheating, the turbine exit dryness fraction increases so moisture decreases ‑ so blade erosion becomes minimum ‑ so life of the turbine will be increased.

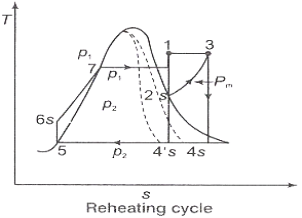

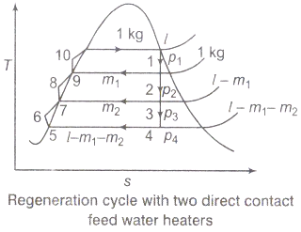

Regeneration:

(i)The mean temperature of heat addition (thus proficiency) can likewise be expanded by reducing the amount of heat added at low temperatures in the economizer part of steam generator.

(ii) In the recovery cycle energy is exchanged inside between the extending fluid in the turbine and the compressed liquid before heat expansion.

(iii)Ideal regenerative cycle does not influence work output from turbine, it is more productive with high steam rate.

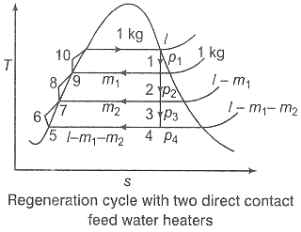

Fig 3: Regeneration Cycle

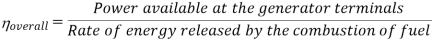

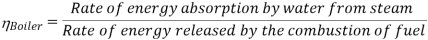

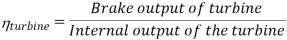

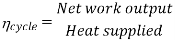

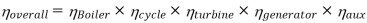

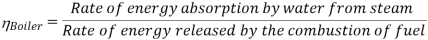

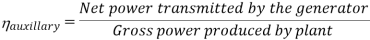

Efficiency of Steam Power Plant: Overall efficiency of the steam per plant is given by

- Reheating of steam improved the thermal efficiency of the plant, net work output of turbine, reduction in blade erosion (or natures of steam improve).

- By regeneration thermal efficiency of the plant can be increased but it does not affect work output from turbine.

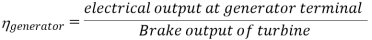

Combined Cycle Power Generation:

It is a gathering of heat engine that works with a comparative wellspring of heat. The standard of consolidated cycle power generation is that the exhaust of one heat engine is utilized as the source of heat for another heat engine. This process increases the overall efficiency of a heat engine.

Advantages of Regeneration cycle:

- Heat provided to evaporator gets decreased.

- Thermal effectiveness is increase since the normal temperature of heat addition to the cycle is increase.

- Due to bleeding in the turbine, erosion of turbine due to moisture is reduced.

Characteristics of Ideal Working Fluid

1) The fluid ought to have high critical temperature and the saturation pressure at the temperature of heat rejection ought to be over the climatic pressing factor.

2) Specific heat of fluid ought to be little.

3) The saturated vapour line of T-s outline near the turbine extension measure.

4) The freezing point of the fluid should be below the room temperature

5) The liquid ought to be synthetically steady, non-poisonous, non-destructive, not exorbitantly viscous and low in expense.

Superheating the steam to a high temperature

Figure 4: The effect of Superheating the Steam to a Higher Temperature

The impact of superheating the steam to a high temperature on the Rankine cycle proficiency is outlined on a T-s graph on the left. By superheating the stream to a high temperature (from state 3 to state 3'), the normal steam temperature during heat expansion can be increased. The blue zone is the net work expanded due to superheating the steam to a high temperature.

Key Takeaways:

1) Internal irreversibility of Rankine cycle (Genuine cycle) is brought about by fluid frictions throttling and mixing.

2) Externally, irreversibility of the Rankine cycle is caused because of the temperature distinction between the burning gases and the working liquid on a similar side and the temperature contrast between the consolidating working liquid and the condenser cooling water on the sink side.

3) Due to reheating, the turbine exit dryness fraction increases so moisture decreases ‑ so blade erosion becomes minimum ‑ so life of the turbine will be increased.

The strategy for exergy analysis focuses on the quantitative assessment of the exergy misfortunes (irreversibility) related with a framework. Consequently, it is needed to compute the irreversibility in all the parts of the power cycle for the estimation of exergy efficiency. The irreversibility or exergy misfortune in every one of the segments is determined for the predetermined dead state (P0, T0).

Boiler:

The mass flow rate of steam (ms) needed to be created in the boiler to deliver a output of 500MW power can be acquired from the energy balance as given below:

Ms = 500×1ooo kW/Wnet kg/s (1)

Using this, the mass of the flue gas (mg) required to obtain the required mass flow rate of steam can be found by the energy balance equation i.e.,

Heat gained by the steam = Heat lost by the flue gas

Ms (h1 − h4) = mg (hA − hB)

Mg = ms (h1−h4)/(hA−hB) (2)

Exergy or Accessibility at state point 1

E1 = ms (h1 − T0s1) kW (3)

Exergy or Accessibility at state point 4

E4 = ms (h4− T0s4) kW (4)

Irreversibility in the boiler is,

IBOILER = (EA− EB) − (E1− E4) kW (5)

Substituting the E1, E4 from Eq. (3) & (4)

IBOILER = mg (EA− EB) – ms [(h1− h4) − T0 (s1− s4)] kW (6)

Steam Turbine:

The irreversibility in the steam turbine is given by

ITURBINE = T0 ms (s2− s1) kW (7)

Condenser:

Mass flow rate of cooling water circulated to condense ms,

Kg /s of steam is obtained from the energy balance is

mcwcpw(Twi − Two) = ms(h2− h3)

mcw = ms (h2−h3)/cpw(Twi−Two) (8)

Irreversibility in the condenser,

ICONDENSER = T0[ms(s2− s3) − (mcwcpwln (Two/Twi)]kW (9)

Exhaust:

Irreversibility of the exhaust,

IEXHAUST = EB (10)

Pump:

Irreversibility rate in the boiler feed pump,

IPUMP = msT0(s2− s1)kW (11)

Total Irreversibility:

Total Irreversibility is,

ITOTAL = [IBOILER + ITURBINE + ICONDENSER + IEXHAUST + IPUMP]kW (12)

Fractional Exergy loss:

The meaning of the fractional exergy loss of the segment is the ratio of irreversibility of the individual part to the total irreversibility of the cycle. Its worth is assessed for all the parts of the cycle. It gives the data with respect to the deficiency of valuable energy in all parts for various working factors. The fractional exergy misfortune equations of every segment are as per the following,

Fractional exergy loss in the boiler is IBOILER/ ⅀I × 100 (13)

Fractional exergy loss in the turbine is

ITURBINE/ ⅀I × 100 (14)

Fractional exergy loss in the condenser is,

ICONDENSER / ⅀I × 100 (15)

Fractional exergy loss in the Pump is,

IPUMP/⅀I × 100 (16)

Fractional exergy loss in the exhaust is,

IEXHAUST / ⅀I × 100 (17)

Supercritical Rankine cycle is also the thermodynamic cycle of supercritical water reactors. The supercritical water reactor (SCWR) is a concept of Generation IV reactor, that is operated at supercritical pressure (i.e., greater than 22.1 MPa). The term supercritical in this context refers to the thermodynamic critical point of water (Tcr = 374 °C; Pcr = 22.1 Mpa), and must not be confused with the criticality of the reactor core, that describes changes in the neutron population in the reactor core.

As we discussed the thermal efficiency can be improved “simply” by an increase in the temperature of the steam entering the turbine. But this temperature is restricted by metallurgical limitations imposed by the materials and design of the reactor pressure vessel and primary piping. The reactor vessel and the primary piping must withstand high pressures and great stresses at elevated temperatures. But currently, improved materials and methods of fabrication have permitted significant increases in the maximum pressures, with corresponding increases in thermal efficiency. The thermal power plants are currently designed to operate on the supercritical Rankine cycle (i.e., with steam pressures exceeding the critical pressure of water 22.1 Mpa, and turbine inlet temperatures exceeding 600 °C). Supercritical fossil fuel power plants, that are operated at supercritical pressure, have efficiencies around 43%. Most efficient and also very complex coal-fired power plants that are operated at “ultra-critical” pressures (i.e., around 30 Mpa) and use multiple stage reheat reach about 48% efficiency.

Specific Entropy [kj/kgK]

Figure 5: Supercritical Rankine cycle

Key takeaway:

Most efficient and also very complex coal-fired power plants that are operated at “ultra-critical” pressures (i.e., around 30 Mpa) and use multiple stage reheat reach about 48% efficiency.

OTTO CYCLE:

Otto cycle is a thermodynamic cycle upon which a spark ignition engine works. Spark Ignition (or SI) engine uses petrol (or Gasoline) as fuel. Otto cycle was invented by Nicolas Otto in 1876.

Spark ignition engine is a type of internal combustion engines.

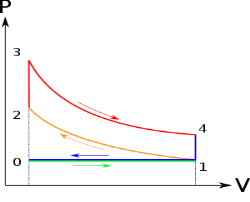

Below are P-V and T-S Diagrams of the Otto Cycle.

Figure 6: P-v and t-s diagram of otto cycle

Otto Cycle is comprised of four processes (apart from the intake and exhaust process)

Process 1-2: This process comes after intake process. In case of SI engines, intake is a mixture of gasoline and air, also known as charge. In this process charge is compressed in isentropic manner. Temperature raised from T1 to T2 and volume decrease from V1 to V2.

Process 2-3: In this process the fuel gets blasted with the help of external spark (that is why the engine is known as spark ignition engine). This process is a constant volume heat addition process. Temperature raised from T2 to T3

Q2-3= CV(T3-T2)

Process 3-4: After the combustion process, the exhaust gases expend. This process is an isentropic expansion process. No heat is interchanged. The temperature fall from T3 to T4 and volume increase from V3 to V4.

Process 4-1: After the expansion process, exhaust valve opens. This results into sudden drop of pressure inside engine cylinder. This process is a constant volume heat rejection process.

Q4-1= CV(T4-T1)

Process 0-1 is the intake process and process 1-0 is the exhaust process.

Efficiency η = 1 – 1 / (r)y-1

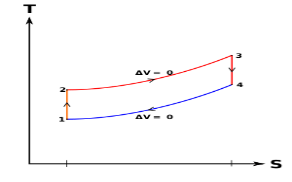

DIESEL CYCLE

Diesel cycle is a gas power cycle invented by Rudolph Diesel in the year 1897. It is widely used in diesel engines.

Diesel cycle is similar to Otto cycle except in the fact that it has one constant pressure process instead of a constant volume process (in Otto cycle).

Diesel cycle can be understood well if you refer its p-V and T-s diagrams.

P-V and T-s Diagrams of Diesel Cycle:

|

|

Figure 7: Diesel Cycles

Processes in Diesel Cycle:

Diesel cycle has four processes. They are:

- Process 1-2: Isentropic (Reversible adiabatic) Compression

- Process 2-3: Constant Pressure (Isobaric) Heat Addition

- Process 3-4: Isentropic Expansion

- Process 4-1: Constant Volume (Isochoric) Heat Rejection

Process 1-2: Isentropic Compression

In this process, the piston moves from Bottom Dead Centre (BDC) to Top Dead Centre (TDC) position. Air is compressed is entropically inside the cylinder. Pressure of air increases from p1 to p2, temperature increases from T1 to T2, and volume decreases from V1 to V2. Entropy remains constant (i.e., s1 = s2). Work is done on the system in this process (denoted by Win in the diagrams above).

Process 2-3: Constant Pressure Heat Addition

In this process, heat is added at constant pressure from an external heat source. Volume increases from V2 to V3, temperature increases from T2 to T3 and entropy increases from s2 to s3.

Heat added in process 2-3 is given by

Qin = mCP(T3 − T2) kJ ………… (i)

Where,

m→ Mass of air in kg

Cp → Specific heat at constant pressure in kJ/kg K

T2 → Temperature at point 2 in K

T3 → Temperature at point 3 in K

Process 3-4: Isentropic Expansion

Here the compressed and heated air is expanded isentropic ally inside the cylinder. The piston is forced from TDC to BDC in the cylinder. Pressure of air decreases from p3 to p4, temperature decreases from T3 to T4, and volume increases from V3 to V4. Entropy remains constant (i.e., s3 = s4). Work is done by the system in this process (denoted by Wout in the p-V and T-s diagrams above).

Process 4-1: Constant Volume Heat Rejection

In this process, heat is rejected at constant volume (V4 = V1). Pressure decreases from P4 to P1, temperature decreases from T4 to T1 and entropy decreases from s4 to s1.

Heat rejected in process 4-1 is given by

Qout = mCv(T4 − T1) kJ ………… (ii)

Where,

m→ Mass of air in kg

Cv → Specific heat at constant volume in kJ/kgK

T2 → Temperature at point 2 in K

T3 → Temperature at point 3 in K

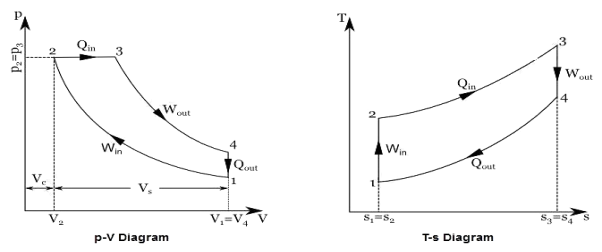

Dual cycle:

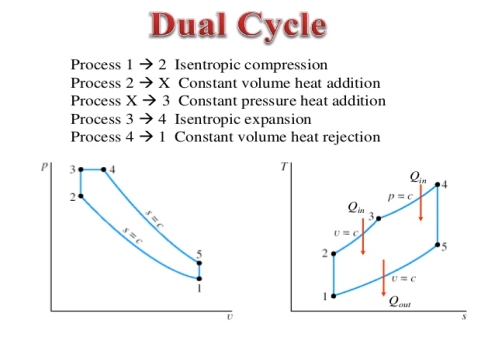

The combustion process in a spark ignition engine does not occur exactly at constant volume, nor does the combustion process in an actual compression ignition engine occur exactly at constant pressure, therefore another idealized cycle known as Dual cycle has been developed that more closely approximate the actual spark-ignition and compression-ignition engines. The p-v and T-s diagrams of Dual cycle are shown in Fig. 45.1. In this cycle, part of heat addition occurs at constant volume while the rest is at constant pressure. The dual cycle is also called mixed or limited pressure cycle.

Figure 8: Dual cycle

In a dual cycle, the system executing the cycle undergoes a series of five processes: two isentropic (reversible adiabatic) processes alternated with two isochoric process and one isobaric process:

Dual cycle – PV Diagram

Isentropic compression (compression stroke) – The gas is compressed adiabatically from state 1 to state 2, as the piston moves from intake valve closing point (1) to top dead centre. The surroundings do work on the gas, increasing its internal energy (temperature) and compressing it. On the other hand the entropy remains unchanged. The changes in volumes and its ratio (V1 / V2) are known as the compression ratio. The compression ratio is smaller than the expansion ratio.

Isochoric compression (ignition phase) – In this phase (between state 2 and state 3) there is a constant-volume (the piston is at rest) heat transfer to the air from an external source while the piston is at rest at top dead center. This process is similar to the isochoric process in the Otto cycle. It is intended to represent the ignition of the fuel–air mixture injected into the chamber and the subsequent rapid burning. The pressure rises and the ratio (P3 / P2) is known as the “explosion ratio”.

Isobaric expansion (power stroke) – In this phase (between state 3 and state 4) there is a constant-pressure (idealized model) heat transfer to the air from an external source (combustion of the fuel) while the piston is moving toward the V4. During the constant pressure process, energy enters the system as heat Qadd, and a part of work is done by moving piston.

Isentropic expansion (power stroke) – The gas expands adiabatically from state 4 to state 5, as the piston moves from V3 to bottom dead center. The gas does work on the surroundings (piston) and loses an amount of internal energy equal to the work that leaves the system. Again the entropy remains unchanged.

Isochoric decompression (exhaust stroke) – In this phase the cycle completes by a constant-volume process in which heat is rejected from the air while the piston is at bottom dead center. The working gas pressure drops instantaneously from point 5 to point 1. The exhaust valve opens at point 5. The exhaust stroke is directly after this decompression. As the piston moves from bottom dead center (point 1) to top dead center (point 0) with the exhaust valve opened, the gaseous mixture is vented to the atmosphere and the process starts anew.

During the Dual cycle, work is done on the gas by the piston between states 1 and 2 (isentropic compression). Work is done by the gas on the piston between stages 2 and 3 (isobaric heat addition) and between stages 2 and 3 (isentropic expansion). The difference between the work done by the gas and the work done on the gas is the network produced by the cycle and it corresponds to the area enclosed by the cycle curve. The work produced by the cycle times the rate of the cycle (cycles per second) is equal to the power produced by the Diesel engine.

Key Takeaways:

There are three major types of Gas Power Cycles:

- Otto Cycles

- Diesel Cycle

- Dual Cycle

It is theoretical cycle for gas turbines. It is also known as constant pressure cycle for a perfect gas. The basic component of Brayton Cycle is as shown in given figure-

Figure 9: Brayton Cycle

The components are compressor, heat exchanger, turbine and cooler.

There occur two isentropic processes and two constant pressure processes. Compression and expansion of working fluid is done by isentropic process while addition and rejection of heat is done at constant pressure. In above figure, we can see the p-v and T-s diagram for the cycle.

Process 1-2: Air is being compressed is entropically by compressor between the pressure range p1 to p2.

Process 2-3: It is constant pressure heat pressure heat addition process. In this process temperature increases from T2 to T3 at constant pressure.

Process 3-4: The air is expanded is entropically pressure p2 to p1 and the temperature drops from T3 to T4.

Process 4-1: It is constant pressure heat rejection process as temperature reduces from T4 to T1.

Now, Work done per cycle=Heat added/cycle-Heat rejected/cycle

Heat addition in process 2-3=mCp(T3-T2)

Heat rejected in process 4-1= mCp(T4-T1)

Work done per cycle=mCp(T3-T2)-MCp(T4-T1)

From process 1-2

Similarly from process 3-4

Putting the values  and

and  in equation

in equation

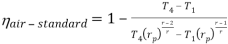

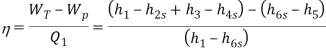

The above equation shows that the efficiency of the ideal Brayton cycle increases with the pressure ratio.

Figure 10: Effect of pressure ratio on the efficiency of Brayton Cycle

Key Takeaways:

It is theoretical cycle for gas turbines. It is also known as constant pressure cycle for a perfect gas.

Effect of Reheating of Steam:

In the warm cycle, the extension of steam from the initial state 1 to the condenser pressure is completed in at least two or more stages relying on the quantity of reheat utilized.

Cycle efficiency: improves with reheat, anyway the cycle productivity in a solitary warm plant is affected by pressure at which steam is warmed. The efficiency increment as the reheat pressing factor is brought down and arrives at a top at a pressing factor proportion somewhere in the range of 0.20 and 0.25.

Warming steam likewise increment the organization yield of turbine

Fig 11: Reheating Cycle

Reheating steam also increase the network output of turbine.

Advantages of Re‑heating:

- Due to reheating, network done increments.

- Heat supply increments.

- Thermal effectiveness tangle increment or diminishing relying on the mean temperature of warmth expansion.

- Due to reheating, the turbine exit dryness fraction increases so moisture decreases ‑ so blade erosion becomes minimum ‑ so life of the turbine will be increased.

Regeneration:

(i) The mean temperature of heat addition (thus proficiency) can likewise be expanded by reducing the amount of heat added at low temperatures in the economizer part of steam generator.

(ii) In the recovery cycle energy is exchanged inside between the extending fluid in the turbine and the compressed liquid before heat expansion.

(iii) Ideal regenerative cycle does not influence work output from turbine, it is more productive with high steam rate.

Fig 12: Regeneration Cycle

Efficiency of Steam Power Plant: Overall efficiency of the steam per plant is given by

Key Takeaways:

- Reheating of steam improved the thermal efficiency of the plant, net work output of turbine, reduction in blade erosion (or natures of steam improve).

- By regeneration thermal efficiency of the plant can be increased but it does not affect work output from turbine.

Vapour Power Cycle

Generally water is used a working fluid in vapour power cycle as it is discovered to be superior to some other liquid, yet it is a long way from being the ideal one. The binary cycle is an attempt to overcome a portion of the shortcomings of water and to move toward the ideal working liquid by utilizing two liquids. The main attractive qualities of the working liquid appropriate for vapour cycles are:

a. High basic temperature and a protected most extreme pressing factor.

b. Low-triple point temperature

c. Condenser pressure isn't excessively low.

d. High enthalpy of vaporization

e. High thermal conductivity

f. It should be promptly accessible, modest, inert and non-harmful.

Figure 13: Mercury-steam vapour power cycle

Figure 14: Vapor power Cycle

Therefore, it can be concluded that no single working fluids may have desirable requirements of working fluid. Different working fluids may have different attractive feature in them, but not all. In such cases two vapour cycles operating on two different working fluids are put together, one is high temperature region and the other in low temperature region and the arrangement is called binary vapour cycle.

The layout of mercury-steam vapour power cycle is shown in figure. Along with the depiction of T-S diagram figure. Since mercury having high critical temperature (898oC) and low critical pressure (180 bar) which makes a suitable working fluid will act as high temperature cycle (toppling cycle) and steam cycle will act as low temperature cycle.

Here mercury vapour are generated in mercury boiler and sent for expansion in mercury turbine and expanded fluid leaves turbine to condenser. In condenser, the water is used for extracting heat from the mercury so as to condensate it. The amount water entering mercury condenser. The mercury condenser also act as steam boiler for super heating of heat liberated during condensation of mercury is too large to evaporate the water entering of seam an auxiliary boiler may be employed or superheating may be realized in the mercury boiler itself. From the cycle,

Since pump works are very small, it may be neglected. Work from Mercury Turbine, WHg =mg (ha -hb)

Work from Steam Turbine, Wsteam = msteam (h1 -h2)

Pump work, Wpump = mHg (hd -hc)+msteam (h4 -h3)

Key Takeaways:

Heat supplied to the cycle, Qin =mHg (ha -hd)+msteam [(h1 -h6)+(h5 -h4)]

Heat rejected= Qout =mstream(h2-h3)

Efficiency of binary vapour cycle η =W net /Qin

Net work done =W net= Heat supplied =Qin =mHg (ha -hd) +msteam [(h1 -h6)+(h5 -h4 )]

Combined power cycle:

The proceeded with mission for higher warm efficiencies has brought about rather inventive alterations to traditional force plants. The parallel fume cycle examined later is one such alteration. A more well-known alteration includes a gas power cycle besting a fume power cycle, which is known as the joined gas–fume cycle, or simply the consolidated cycle. The joined pattern of most noteworthy interest is the gas-turbine (Brayton) cycle beating a steam turbine

Rankine cycle which has a higher warm effectiveness than both of the cycles executed exclusively Gas-turbine cycles normally work at impressively higher temperatures than steam cycles. The greatest liquid temperature at the turbine bay is about 620°C (1150°F) for current steam power plants, yet over 1425°C (2600°F) for gas-turbine power plants. It is over 1500°C at the burner exit of turbojet motors. The utilization of higher temperatures in gas turbines is made conceivable by on-going improvements in cooling the turbine cutting edges and covering the edges with high-temperature-safe materials, for example, earthenware production. In view of the higher normal temperature at which warmth is provided, gas-turbine cycles have a more prominent potential for higher warm efficiencies. Notwithstanding, the gas-turbine cycles have one inalienable hindrance: The gas leaves the gas turbine at high temperatures (as a rule above 500°C) which deletes any possible increases in the warm productivity. The circumstance can be improved to some degree by utilizing recovery, yet the improvement is restricted. It bodes well to exploit the entirely attractive qualities of the gas-turbine cycle at high temperatures and to utilize the high temperature fumes gases as the fuel hotspot for the lining cycle, for example, a steam power cycle. The outcome is a joined gas–steam cycle, as appeared

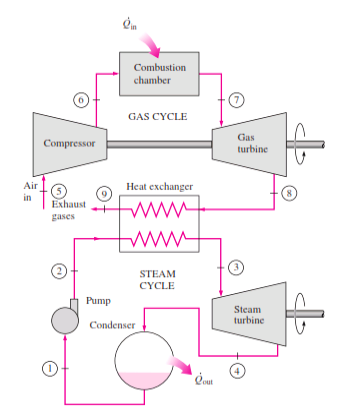

Figure 15: Combined gas–steam power plant

In this cycle, energy is recovered from the exhaust gases by transferring it to the steam in a heat exchanger that serves as the boiler. In general, more than one gas turbine is needed to supply sufficient heat to the steam. Also, the steam cycle may involve regeneration as well as reheating. Energy for the reheating process can be supplied by burning some additional fuel in the oxygen-rich exhaust gases. Recent developments in gas-turbine technology have made the combined gas–steam cycle economically very attractive. The combined cycle increases the efficiency without increasing the initial cost greatly. Consequently, many new power plants operate on combined cycles, and many more existing steam- or gas-turbine plants are being converted to combined-cycle power plants. Thermal efficiencies well over 40 percent are reported as a result of conversion.

Figure 16: Combined Gas Cycle

Kay Takeaways:

In this cycle, energy is recovered from the exhaust gases by transferring it to the steam in a heat exchanger that serves as the boiler. In general, more than one gas turbine is needed to supply sufficient heat to the steam. Also, the steam cycle may involve regeneration as well as reheating.

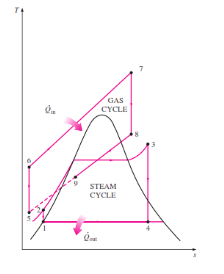

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air-conditioning of buildings and automobiles.

Vapor-compression cycle refrigeration is a process that uses the physics of phase change heat transfer and the unique properties of a refrigerant to transfer heat from a relatively cold source to a hot medium. Simply stated, refrigeration systems efficiently move heat from a cold source to a hot heat sink (normally air). The components in the basic refrigeration system are the compressor, condenser, expansion valve, and evaporator.

The heart of the system is the compressor. The compressor takes in a low temperature, low pressure refrigerant vapor, and compresses it into a high temperature, high pressure vapor. This high temperature/pressure vapor then enters the condenser where heat is removed to either air or water. As the heat is removed, the energy stored in the high pressure gas is released and the refrigerant gives up its latent heat as it reverts to a hot liquid.

This hot, high temperature liquid then exits the condenser and enters the expansion valve, where it undergoes a pressure drop causing some of the hot gas to vaporize. This lowers the temperature of the refrigerant stream. The refrigerant at the exit of the expansion valve is a low temperature two-phase fluid.

This two-phase fluid enters the evaporator where it is exposed to the heat source. The heat from the source boils off the refrigerant through phase change heat transfer, and the low temperature, low pressure gas enters the compressor, completing the cycle.

It is useful to understand the refrigerant cycle in the quadrant shown in Figure 13. The high pressure, high temperature upper half allows the refrigerant to become significantly hotter than ambient air, forcing heat transfer into a habitually hot environment.

Figure 17: Vapor Compression System

The low temperature, low pressure half of the cycle allows the refrigerant to absorb heat from a source that is not as hot as the environment. The compressor does the work to raise the pressure, and the expansion valve assures that adequate pressure is retained in the condenser for heat transfer.

The vapor compression cycle can be used to cool air, liquid, or cold plates. All that is required to accomplish this is to modify the evaporator to accommodate the systems that are being cooled. To create an air cooling system, the evaporator acts as a refrigerant to an air heat exchanger. The air cooling system is used in buildings, automobiles, and in electronics enclosures where air cooled rack-mounted equipment is being cooled.

To cool liquid, the evaporator again acts as a refrigerant, this time to a liquid heat exchanger, with the pumped liquid being cooled by the evaporating refrigerant. The liquid cooled system is used for systems such as lasers, electronics, and medical devices that are designed for liquid cooling.

Figure 18: Vapor Compression Cycle

The thermodynamics of the vapor compression cycle can be analyzed on a temperature versus entropy diagram as depicted in Figure 2. At point 1 in the diagram, the circulating refrigerant enters the compressor as a saturated vapor. From point 1 to point 2, the vapor is entropically compressed (compressed at constant entropy) and exits the compressor as a superheated vapor. Superheat is the amount of heat added above the boiling point.

From point 2 to point 3, the vapor travels through part of the condenser which removes the superheat by cooling the vapor. Between point 3 and point 4, the vapor travels through the remainder of the condenser and is condensed into a saturated liquid. The condensation process occurs at essentially constant pressure.

Between points 4 and 5, the saturated liquid refrigerant passes through the expansion valve and undergoes an abrupt decrease of pressure. That process results in the adiabatic flash evaporation and auto-refrigeration of a portion of the liquid (typically, less than half of the liquid flashes). The adiabatic flash evaporation process is isenthalpic (occurs at constant enthalpy).

Between points 5 and 1, the cold and partially vaporized refrigerant travels through the coil or tubes in the evaporator where it is totally vaporized by the warm air (from the space being refrigerated) that a fan circulates across the coil or tubes in the evaporator. The evaporator operates at essentially constant pressure and boils off all available liquid there after adding 4–8 kelvins of superheat to the refrigerant in order to make sure the liquid has evaporated completely. This is a safeguard for the compressor, as it cannot pump liquid. The resulting refrigerant vapor returns to the compressor inlet at point 1 to complete the thermodynamic cycle.

The above discussion is based on the ideal vapor-compression refrigeration cycle which does not take into account real world items like frictional pressure drop in the system, slight internal irreversibility during the compression of the refrigerant vapor, or non-ideal gas behaviour.

A refrigerant is a working fluid used in the refrigeration cycle of air conditioning systems and heat pumps where in most cases they undergo a repeated phase transition from a liquid to a gas and back again.

The most common refrigerant include Chlorofluorocarbons (CFCs), Hydrochlorofluorocarbons (HCFCs), Hydrofluorocarbons (HFCs), and Natural Refrigerants. Freons or halocarbons are synthetically produced. The classification also depends on their chemical elements chlorine (Cl), hydrogen (H), carbon (C), and Florine (F)

Physical Properties of Refrigerants

- Low Freezing Point. Refrigerants should have low freezing point than the normal operating conditions.

- Low Condensing Pressure.

- High Evaporator Pressure.

- High Critical Pressure.

- High Vapor Density.

- High Dielectric strength. .

- High Latent Heat of Vaporization.

- High Heat Transfer Coefficient.

Key Takeaways:

The vapour compression cycle can be used to cool air, liquid, or cold plates. All that is required to accomplish this is to modify the evaporator to accommodate the systems that are being cooled. To create an air cooling system, the evaporator acts as a refrigerant to an air heat exchanger

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.