Unit - 6

Analysis of steam turbines

A steam turbine is a prime mover in which the potential energy of the steam is transformed into kinetic energy and later in its turn is transformed into the mechanical energy of rotation of the turbine shaft.

Classification:

Most common classification of steam turbine-

(i) Impulse Turbine

(ii) Reaction Turbine

Other classifications are: -

(i) According to the number of pressure stages

(ii) According to the type of steam flow

(iii) According to the number of shafts/cylinders

(iv) According to the method of governing

(v) According to the steam conditions at inlet to turbine

According to the action of steam:

- Impulse turbine: In impulse turbine, steam coming out through a fixed nozzle at a very high velocity strikes the blades fixed on the periphery of a rotor. The blades change the direction of steam flow without changing its pressure. The force due to change of momentum causes the rotation of the turbine shaft. Ex: De-Laval, Curtis and Rateau Turbines

- Reaction turbine: In reaction turbine, steam expands both in fixed and moving blades continuously as the steam passes over them. The pressure drop occurs continuously over both moving and fixed blades.

- Combination of impulse and reaction turbine

- According to the number of pressure stages:

- Single stage turbines: These turbines are mostly used for driving centrifugal compressors, blowers and other similar machinery.

- Multistage Impulse and Reaction turbines: They are made in a wide range of power capacities varying from small to large.

2. According to the type of steam flow:

- Axial turbines: In these turbines, steam flows in a direction parallel to the axis of the turbine rotor.

- Radial turbines: In these turbines, steam flows in a direction perpendicular to the axis of the turbine, one or more low pressure stages are made axial.

3. According to the number of shafts:

- Single shaft turbines

- Multi-shaft turbines

4. According to the method of governing:

- Turbines with throttle governing: In these turbines, fresh steam enter through one or more (depending on the power developed) simultaneously operated throttle valves.

- Turbines with nozzle governing: In these turbines, fresh steam enters through one or more consecutively opening regulators.

- Turbines with by-pass governing: In these turbines, the steam besides being fed to the first stage is also directly fed to one, two or even three intermediate stages of the turbine.

5. According to the steam conditions at inlet to turbine:

- Low pressure turbines: These turbines use steam at a pressure of 1.2 ata to 2 atm.

- Medium pressure turbines: These turbines use steam up to a pressure of 40 atm.

- High pressure turbines: These turbines use steam at a pressure above 40 atm.

- Very high-pressure turbines: These turbines use steam at a pressure of 170 atm and higher and temperatures of 550°C and higher.

- Supercritical pressure turbines: These turbines use steam at a pressure of 225 atm and higher.

Simple impulse principle:

- The impulse turbine consists basically of a rotor mounted on a shaft that is free to rotate in a set of bearings.

- The outer rim of the rotor carries a set of curved blades, and the whole assembly is enclosed in an airtight case.

- Nozzles direct steam against the blades and turn the rotor. The energy to rotate an impulse turbine is derived from the kinetic energy of the steam flowing through the nozzles.

- The term impulse means that the force that turns the turbine comes from the impact of the steam on the blades.

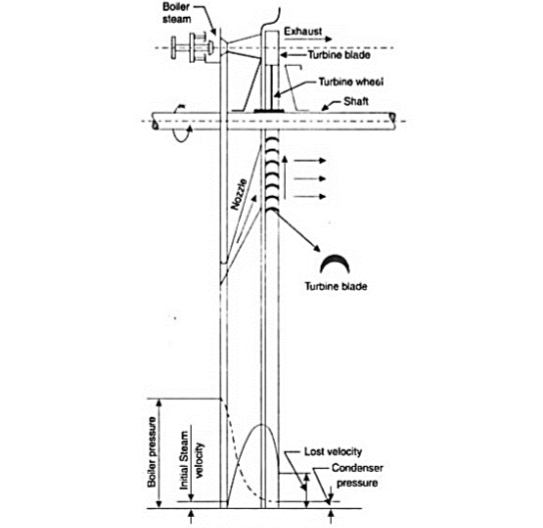

Construction and Working of impulse turbine:

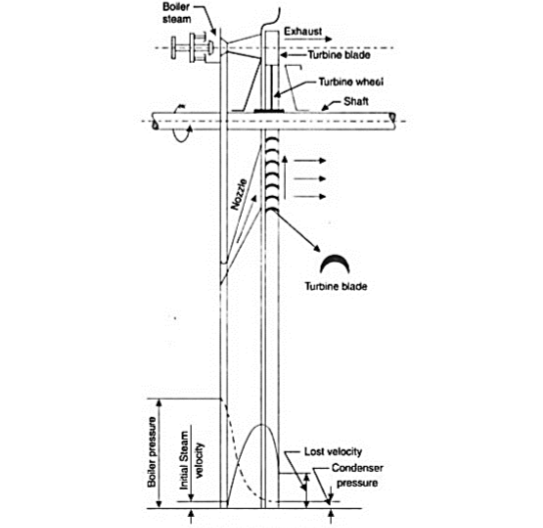

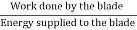

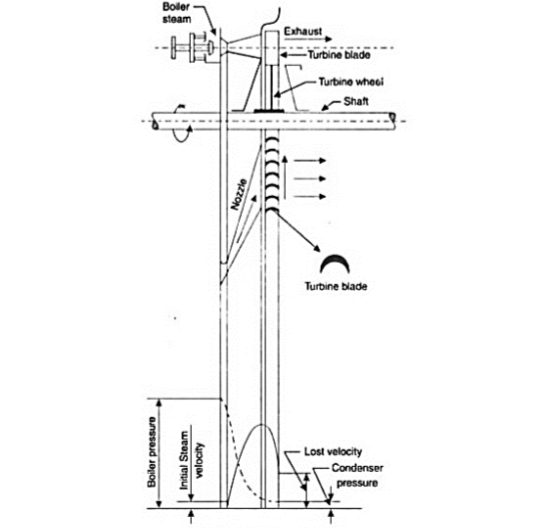

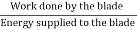

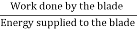

- The uppermost portion of the diagram shows a longitudinal section through the upper half of the turbine.

- The middle portion shows the actual shape of the nozzle and blading.

- The bottom portion shows the variation of absolute velocity and absolute pressure during the flow of steam through passage of nozzles and blades.

- The expansion of steam from its initial pressure (steam chest pressure) to final pressure (condenser pressure) takes place in one set of nozzles.

- Due to high drop in pressure in the nozzles, the velocity of steam in the nozzles increases.

- The steam leaves the nozzle with a very high velocity and strikes the blades of the turbine mounted on a wheel with this high velocity.

- The loss of energy due to this higher exit velocity is commonly known as carry over loss (or) leaving loss.

- The pressure of the steam when it moves over the blades remains constant but the velocity decreases.

- The exit/leaving/lost velocity may amount to 3.3 percent of the nozzle outlet velocity.

- Also, since all the KE is to be absorbed by one ring of the moving blades only, the velocity of wheel is too high (varying from 25000 to 30000 RPM).

- However, this wheel or rotor speed can be reduced by adopting the method of compounding of turbines.

Figure 1: Simple impulse turbine

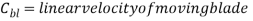

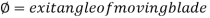

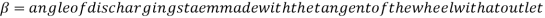

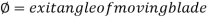

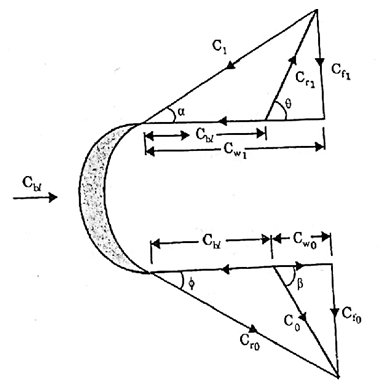

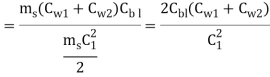

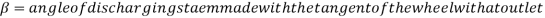

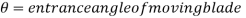

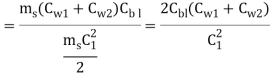

Velocity diagram for steam turbine:

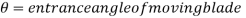

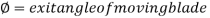

For the convenience of solving the problem related to the turbine we can make the velocity diagram as shown in fig.2.

Figure 2: Velocity diagram for moving blade

Tangential force on the wheel = Mass of the steam * acceleration

Mass of steam/seconds * change in velocity

=

Figure 3: Velocity triangle of moving blade

Work done on blade / second = Force * distance travelled / second

Power on blade second is given by-

Blade or diagram efficiency =

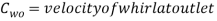

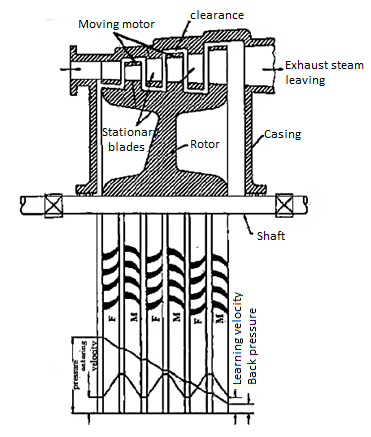

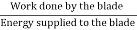

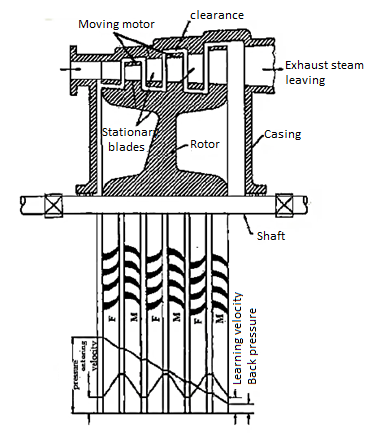

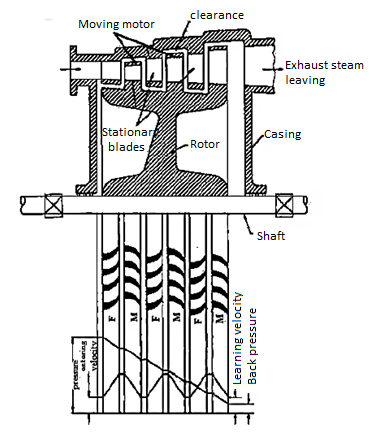

Reaction turbine

- A turbine in which steam pressure decreases gradually while expanding through the moving blades as well as the fixed blades is known as reaction turbine.

- It consists of a large number of stages, each stage consisting of set of fixed and moving blades. The heat drop takes place throughout in both fixed and moving blades.

- No nozzles are provided in a reaction turbine. The fixed blades act both as nozzles in which velocity of steam increased and direct the steam to enter the ring of moving blades. As pressure drop takes place both in the fixed and moving blades, all the blades are nozzle shaped.

- The steam expands while flowing over the moving blades and thus gives reaction to the moving blades. Hence the turbine is called reaction turbine.

- The fixed blades are attached to the casing whereas moving blades are fixed with the rotor.

- It is also called Parson’s reaction turbine.

Figure 4: Reaction Turbine

Key Takeaways:

Difference between Impulse turbine and Reaction turbine:

Impulse Turbine | Reaction Turbine |

The steam completely expands in the nozzle and its pressure remains constant during its flow through the blade passages. | The steam expands partially in the nozzle and further expansion takes place in the rotor blades. |

The relative velocity of steam passing over the blade remains constant in the absence of friction. | The relative velocity of steam passing over the blade increases as the steam expands while passing over the blade. |

The steam velocity is very high and therefore the speed of turbine is high. | The steam velocity is not very high and therefore the speed of turbine is low. |

The pressure on both ends of the moving blade is same. | The pressure on both ends of the moving blade is different |

For the same power developed, as pressure drop is more, the number of stages required are less. | For the same power developed, as pressure drop is small, the number of stages required are more. |

Blades are symmetrical | Blades are asymmetrical |

The blade efficiency curve is less flat. | The blade efficiency curve is more - flat |

- If high velocity of steam is allowed to flow through one row of moving blades, it produces a rotor speed of about 30000 rpm which is too high for practical use.

- It is therefore essential to incorporate some improvements for practical use and also to achieve high performance.

- This is possible by making use of more than one set of nozzles, and rotors, in a series, keyed to the shaft so that either the steam pressure or the jet velocity is absorbed by the turbine in stages. This is called compounding of turbines.

- The high rotational speed of the turbine can be reduced by the following methods of compounding:

1)Velocity compounding

2)Pressure compounding, and

3)Pressure-Velocity compounding.

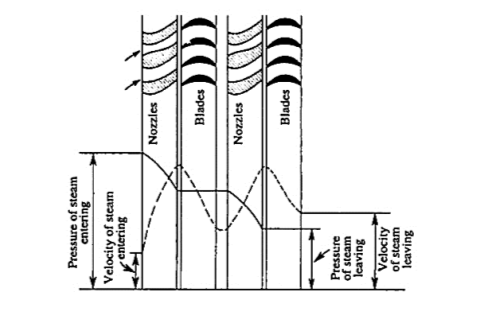

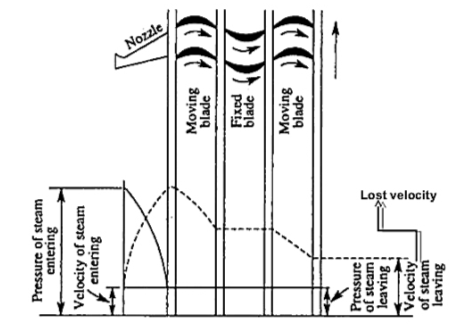

6.2.1. Velocity compounding:

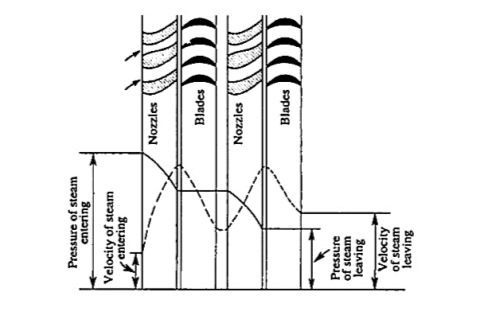

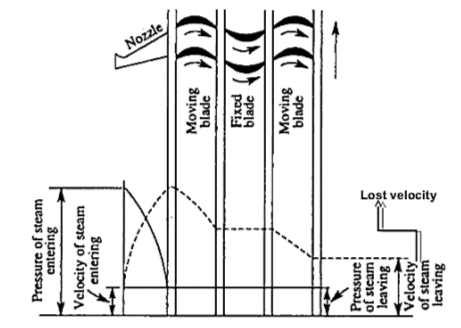

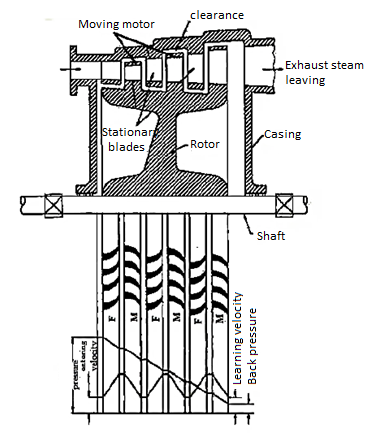

Figure 5: Velocity compounding

- It consists of a set of nozzles and a few rows of moving blades which are fixed to the shaft and rows of fixed blades which are attached to the casing.

- As shown in figure, the two rows of moving blades are separated by a row of fixed blades.

- The high velocity steam first enters the first row of moving blades, where some portion of the velocity is absorbed.

- Then it enters the ring of fixed blades where the direction of steam is changed to suit the second ring of moving blades. There is no change in the velocity as the steam passes over the fixed blades.

- The steam then passes on to the second row of moving blades where the velocity is further reduced. Thus, a fall in velocity occurs every time when the steam passes over the row of moving blades. Steam thus leaves the turbine with a low velocity.

- The variation of pressure and velocity of steam as it passes over the moving and fixed blades is shown in the figure. It is clear from the figure that the pressure drop takes place only in the nozzle and there is no further drop of pressure as it passes over the moving blades.

- This method of velocity compounding is used in Curtis turbine after it was first proposed by C.G. Curtis.

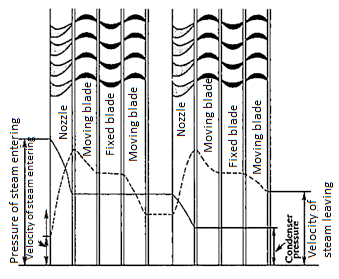

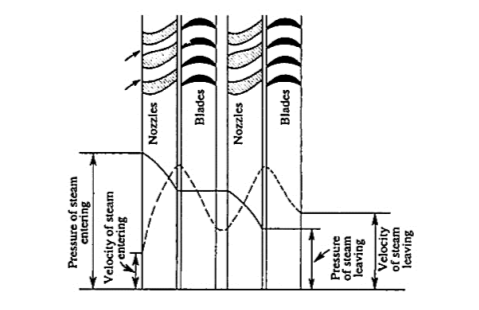

6.2.2. Pressure compounding:

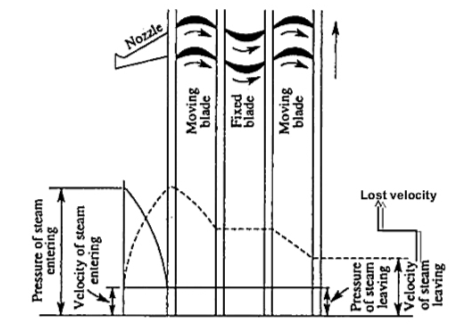

Figure 6: Pressure compounding

- It consists of a number of fixed nozzles which are incorporated between the rings of moving blades. The moving blades are keyed to the shaft.

- Here the pressure drop is done in a number of stages. Each stage consists of a set of nozzles and a ring of moving blades.

- Steam from the boiler passes through the first set of nozzles where it expands partially. Nearly all its velocity is absorbed when it passes over the first set of moving blades.

- It is further passed to the second set of fixed nozzles where it is partially expanded again and through the second set of moving blades where the velocity of steam is almost absorbed. This process is repeated till steam leaves at condenser pressure.

- By reducing the pressure in stages, the velocity of steam entering the moving blades is considerably reduced. Hence the speed of the rotor is reduced. Rateau&Zoelly turbines use this method of compounding.

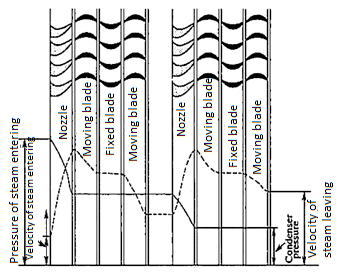

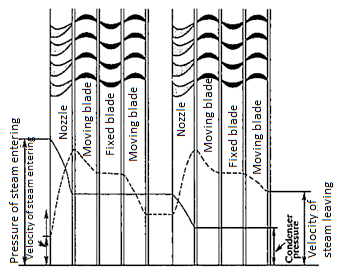

6.2.3. Pressure-velocity compounding:

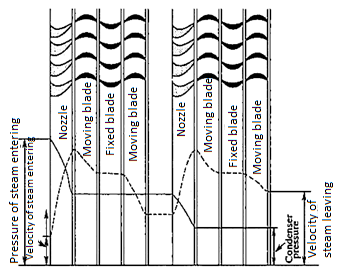

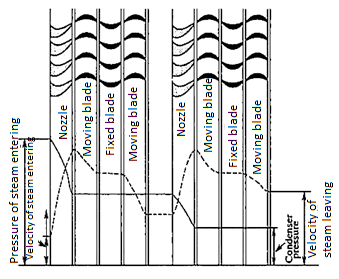

The pressure-velocity compounding is the compounding is the combination of the above two types of compounding. In fact series of velocity-compounded impulse stages is called a pressure velocity compounded turbine. Each stage consists of rings of fixed and moving blades.

Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

- In this method of compounding, both pressure and velocity compounding methods are utilized.

- The total drop in steam pressure is carried out in two stages and the velocity obtained in each stage is also compounded.

- The stages consist of fixed nozzle, moving blades, fixed blades, moving blade in sequence.

- The ring of nozzles is fixed at the beginning of each stage and pressure remains constant during each stage.

- The pressure of steam only drops in nozzle and remain constant while travelling over moving blades and fixed blades.

- This method of compounding is used in Curtis and More turbines.

Figure 7: Pressure-velocity compounding

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.

Unit - 6

Analysis of steam turbines

A steam turbine is a prime mover in which the potential energy of the steam is transformed into kinetic energy and later in its turn is transformed into the mechanical energy of rotation of the turbine shaft.

Classification:

Most common classification of steam turbine-

(i) Impulse Turbine

(ii) Reaction Turbine

Other classifications are: -

(i) According to the number of pressure stages

(ii) According to the type of steam flow

(iii) According to the number of shafts/cylinders

(iv) According to the method of governing

(v) According to the steam conditions at inlet to turbine

According to the action of steam:

- Impulse turbine: In impulse turbine, steam coming out through a fixed nozzle at a very high velocity strikes the blades fixed on the periphery of a rotor. The blades change the direction of steam flow without changing its pressure. The force due to change of momentum causes the rotation of the turbine shaft. Ex: De-Laval, Curtis and Rateau Turbines

- Reaction turbine: In reaction turbine, steam expands both in fixed and moving blades continuously as the steam passes over them. The pressure drop occurs continuously over both moving and fixed blades.

- Combination of impulse and reaction turbine

- According to the number of pressure stages:

- Single stage turbines: These turbines are mostly used for driving centrifugal compressors, blowers and other similar machinery.

- Multistage Impulse and Reaction turbines: They are made in a wide range of power capacities varying from small to large.

2. According to the type of steam flow:

- Axial turbines: In these turbines, steam flows in a direction parallel to the axis of the turbine rotor.

- Radial turbines: In these turbines, steam flows in a direction perpendicular to the axis of the turbine, one or more low pressure stages are made axial.

3. According to the number of shafts:

- Single shaft turbines

- Multi-shaft turbines

4. According to the method of governing:

- Turbines with throttle governing: In these turbines, fresh steam enter through one or more (depending on the power developed) simultaneously operated throttle valves.

- Turbines with nozzle governing: In these turbines, fresh steam enters through one or more consecutively opening regulators.

- Turbines with by-pass governing: In these turbines, the steam besides being fed to the first stage is also directly fed to one, two or even three intermediate stages of the turbine.

5. According to the steam conditions at inlet to turbine:

- Low pressure turbines: These turbines use steam at a pressure of 1.2 ata to 2 atm.

- Medium pressure turbines: These turbines use steam up to a pressure of 40 atm.

- High pressure turbines: These turbines use steam at a pressure above 40 atm.

- Very high-pressure turbines: These turbines use steam at a pressure of 170 atm and higher and temperatures of 550°C and higher.

- Supercritical pressure turbines: These turbines use steam at a pressure of 225 atm and higher.

Simple impulse principle:

- The impulse turbine consists basically of a rotor mounted on a shaft that is free to rotate in a set of bearings.

- The outer rim of the rotor carries a set of curved blades, and the whole assembly is enclosed in an airtight case.

- Nozzles direct steam against the blades and turn the rotor. The energy to rotate an impulse turbine is derived from the kinetic energy of the steam flowing through the nozzles.

- The term impulse means that the force that turns the turbine comes from the impact of the steam on the blades.

Construction and Working of impulse turbine:

- The uppermost portion of the diagram shows a longitudinal section through the upper half of the turbine.

- The middle portion shows the actual shape of the nozzle and blading.

- The bottom portion shows the variation of absolute velocity and absolute pressure during the flow of steam through passage of nozzles and blades.

- The expansion of steam from its initial pressure (steam chest pressure) to final pressure (condenser pressure) takes place in one set of nozzles.

- Due to high drop in pressure in the nozzles, the velocity of steam in the nozzles increases.

- The steam leaves the nozzle with a very high velocity and strikes the blades of the turbine mounted on a wheel with this high velocity.

- The loss of energy due to this higher exit velocity is commonly known as carry over loss (or) leaving loss.

- The pressure of the steam when it moves over the blades remains constant but the velocity decreases.

- The exit/leaving/lost velocity may amount to 3.3 percent of the nozzle outlet velocity.

- Also, since all the KE is to be absorbed by one ring of the moving blades only, the velocity of wheel is too high (varying from 25000 to 30000 RPM).

- However, this wheel or rotor speed can be reduced by adopting the method of compounding of turbines.

Figure 1: Simple impulse turbine

Velocity diagram for steam turbine:

For the convenience of solving the problem related to the turbine we can make the velocity diagram as shown in fig.2.

Figure 2: Velocity diagram for moving blade

Tangential force on the wheel = Mass of the steam * acceleration

Mass of steam/seconds * change in velocity

=

Figure 3: Velocity triangle of moving blade

Work done on blade / second = Force * distance travelled / second

Power on blade second is given by-

Blade or diagram efficiency =

Reaction turbine

- A turbine in which steam pressure decreases gradually while expanding through the moving blades as well as the fixed blades is known as reaction turbine.

- It consists of a large number of stages, each stage consisting of set of fixed and moving blades. The heat drop takes place throughout in both fixed and moving blades.

- No nozzles are provided in a reaction turbine. The fixed blades act both as nozzles in which velocity of steam increased and direct the steam to enter the ring of moving blades. As pressure drop takes place both in the fixed and moving blades, all the blades are nozzle shaped.

- The steam expands while flowing over the moving blades and thus gives reaction to the moving blades. Hence the turbine is called reaction turbine.

- The fixed blades are attached to the casing whereas moving blades are fixed with the rotor.

- It is also called Parson’s reaction turbine.

Figure 4: Reaction Turbine

Key Takeaways:

Difference between Impulse turbine and Reaction turbine:

Impulse Turbine | Reaction Turbine |

The steam completely expands in the nozzle and its pressure remains constant during its flow through the blade passages. | The steam expands partially in the nozzle and further expansion takes place in the rotor blades. |

The relative velocity of steam passing over the blade remains constant in the absence of friction. | The relative velocity of steam passing over the blade increases as the steam expands while passing over the blade. |

The steam velocity is very high and therefore the speed of turbine is high. | The steam velocity is not very high and therefore the speed of turbine is low. |

The pressure on both ends of the moving blade is same. | The pressure on both ends of the moving blade is different |

For the same power developed, as pressure drop is more, the number of stages required are less. | For the same power developed, as pressure drop is small, the number of stages required are more. |

Blades are symmetrical | Blades are asymmetrical |

The blade efficiency curve is less flat. | The blade efficiency curve is more - flat |

- If high velocity of steam is allowed to flow through one row of moving blades, it produces a rotor speed of about 30000 rpm which is too high for practical use.

- It is therefore essential to incorporate some improvements for practical use and also to achieve high performance.

- This is possible by making use of more than one set of nozzles, and rotors, in a series, keyed to the shaft so that either the steam pressure or the jet velocity is absorbed by the turbine in stages. This is called compounding of turbines.

- The high rotational speed of the turbine can be reduced by the following methods of compounding:

1)Velocity compounding

2)Pressure compounding, and

3)Pressure-Velocity compounding.

6.2.1. Velocity compounding:

Figure 5: Velocity compounding

- It consists of a set of nozzles and a few rows of moving blades which are fixed to the shaft and rows of fixed blades which are attached to the casing.

- As shown in figure, the two rows of moving blades are separated by a row of fixed blades.

- The high velocity steam first enters the first row of moving blades, where some portion of the velocity is absorbed.

- Then it enters the ring of fixed blades where the direction of steam is changed to suit the second ring of moving blades. There is no change in the velocity as the steam passes over the fixed blades.

- The steam then passes on to the second row of moving blades where the velocity is further reduced. Thus, a fall in velocity occurs every time when the steam passes over the row of moving blades. Steam thus leaves the turbine with a low velocity.

- The variation of pressure and velocity of steam as it passes over the moving and fixed blades is shown in the figure. It is clear from the figure that the pressure drop takes place only in the nozzle and there is no further drop of pressure as it passes over the moving blades.

- This method of velocity compounding is used in Curtis turbine after it was first proposed by C.G. Curtis.

6.2.2. Pressure compounding:

Figure 6: Pressure compounding

- It consists of a number of fixed nozzles which are incorporated between the rings of moving blades. The moving blades are keyed to the shaft.

- Here the pressure drop is done in a number of stages. Each stage consists of a set of nozzles and a ring of moving blades.

- Steam from the boiler passes through the first set of nozzles where it expands partially. Nearly all its velocity is absorbed when it passes over the first set of moving blades.

- It is further passed to the second set of fixed nozzles where it is partially expanded again and through the second set of moving blades where the velocity of steam is almost absorbed. This process is repeated till steam leaves at condenser pressure.

- By reducing the pressure in stages, the velocity of steam entering the moving blades is considerably reduced. Hence the speed of the rotor is reduced. Rateau&Zoelly turbines use this method of compounding.

6.2.3. Pressure-velocity compounding:

The pressure-velocity compounding is the compounding is the combination of the above two types of compounding. In fact series of velocity-compounded impulse stages is called a pressure velocity compounded turbine. Each stage consists of rings of fixed and moving blades.

Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

- In this method of compounding, both pressure and velocity compounding methods are utilized.

- The total drop in steam pressure is carried out in two stages and the velocity obtained in each stage is also compounded.

- The stages consist of fixed nozzle, moving blades, fixed blades, moving blade in sequence.

- The ring of nozzles is fixed at the beginning of each stage and pressure remains constant during each stage.

- The pressure of steam only drops in nozzle and remain constant while travelling over moving blades and fixed blades.

- This method of compounding is used in Curtis and More turbines.

Figure 7: Pressure-velocity compounding

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.

Unit - 6

Analysis of steam turbines

Unit - 6

Analysis of steam turbines

A steam turbine is a prime mover in which the potential energy of the steam is transformed into kinetic energy and later in its turn is transformed into the mechanical energy of rotation of the turbine shaft.

Classification:

Most common classification of steam turbine-

(i) Impulse Turbine

(ii) Reaction Turbine

Other classifications are: -

(i) According to the number of pressure stages

(ii) According to the type of steam flow

(iii) According to the number of shafts/cylinders

(iv) According to the method of governing

(v) According to the steam conditions at inlet to turbine

According to the action of steam:

- Impulse turbine: In impulse turbine, steam coming out through a fixed nozzle at a very high velocity strikes the blades fixed on the periphery of a rotor. The blades change the direction of steam flow without changing its pressure. The force due to change of momentum causes the rotation of the turbine shaft. Ex: De-Laval, Curtis and Rateau Turbines

- Reaction turbine: In reaction turbine, steam expands both in fixed and moving blades continuously as the steam passes over them. The pressure drop occurs continuously over both moving and fixed blades.

- Combination of impulse and reaction turbine

- According to the number of pressure stages:

- Single stage turbines: These turbines are mostly used for driving centrifugal compressors, blowers and other similar machinery.

- Multistage Impulse and Reaction turbines: They are made in a wide range of power capacities varying from small to large.

2. According to the type of steam flow:

- Axial turbines: In these turbines, steam flows in a direction parallel to the axis of the turbine rotor.

- Radial turbines: In these turbines, steam flows in a direction perpendicular to the axis of the turbine, one or more low pressure stages are made axial.

3. According to the number of shafts:

- Single shaft turbines

- Multi-shaft turbines

4. According to the method of governing:

- Turbines with throttle governing: In these turbines, fresh steam enter through one or more (depending on the power developed) simultaneously operated throttle valves.

- Turbines with nozzle governing: In these turbines, fresh steam enters through one or more consecutively opening regulators.

- Turbines with by-pass governing: In these turbines, the steam besides being fed to the first stage is also directly fed to one, two or even three intermediate stages of the turbine.

5. According to the steam conditions at inlet to turbine:

- Low pressure turbines: These turbines use steam at a pressure of 1.2 ata to 2 atm.

- Medium pressure turbines: These turbines use steam up to a pressure of 40 atm.

- High pressure turbines: These turbines use steam at a pressure above 40 atm.

- Very high-pressure turbines: These turbines use steam at a pressure of 170 atm and higher and temperatures of 550°C and higher.

- Supercritical pressure turbines: These turbines use steam at a pressure of 225 atm and higher.

Simple impulse principle:

- The impulse turbine consists basically of a rotor mounted on a shaft that is free to rotate in a set of bearings.

- The outer rim of the rotor carries a set of curved blades, and the whole assembly is enclosed in an airtight case.

- Nozzles direct steam against the blades and turn the rotor. The energy to rotate an impulse turbine is derived from the kinetic energy of the steam flowing through the nozzles.

- The term impulse means that the force that turns the turbine comes from the impact of the steam on the blades.

Construction and Working of impulse turbine:

- The uppermost portion of the diagram shows a longitudinal section through the upper half of the turbine.

- The middle portion shows the actual shape of the nozzle and blading.

- The bottom portion shows the variation of absolute velocity and absolute pressure during the flow of steam through passage of nozzles and blades.

- The expansion of steam from its initial pressure (steam chest pressure) to final pressure (condenser pressure) takes place in one set of nozzles.

- Due to high drop in pressure in the nozzles, the velocity of steam in the nozzles increases.

- The steam leaves the nozzle with a very high velocity and strikes the blades of the turbine mounted on a wheel with this high velocity.

- The loss of energy due to this higher exit velocity is commonly known as carry over loss (or) leaving loss.

- The pressure of the steam when it moves over the blades remains constant but the velocity decreases.

- The exit/leaving/lost velocity may amount to 3.3 percent of the nozzle outlet velocity.

- Also, since all the KE is to be absorbed by one ring of the moving blades only, the velocity of wheel is too high (varying from 25000 to 30000 RPM).

- However, this wheel or rotor speed can be reduced by adopting the method of compounding of turbines.

Figure 1: Simple impulse turbine

Velocity diagram for steam turbine:

For the convenience of solving the problem related to the turbine we can make the velocity diagram as shown in fig.2.

Figure 2: Velocity diagram for moving blade

Tangential force on the wheel = Mass of the steam * acceleration

Mass of steam/seconds * change in velocity

=

Figure 3: Velocity triangle of moving blade

Work done on blade / second = Force * distance travelled / second

Power on blade second is given by-

Blade or diagram efficiency =

Reaction turbine

- A turbine in which steam pressure decreases gradually while expanding through the moving blades as well as the fixed blades is known as reaction turbine.

- It consists of a large number of stages, each stage consisting of set of fixed and moving blades. The heat drop takes place throughout in both fixed and moving blades.

- No nozzles are provided in a reaction turbine. The fixed blades act both as nozzles in which velocity of steam increased and direct the steam to enter the ring of moving blades. As pressure drop takes place both in the fixed and moving blades, all the blades are nozzle shaped.

- The steam expands while flowing over the moving blades and thus gives reaction to the moving blades. Hence the turbine is called reaction turbine.

- The fixed blades are attached to the casing whereas moving blades are fixed with the rotor.

- It is also called Parson’s reaction turbine.

Figure 4: Reaction Turbine

Key Takeaways:

Difference between Impulse turbine and Reaction turbine:

Impulse Turbine | Reaction Turbine |

The steam completely expands in the nozzle and its pressure remains constant during its flow through the blade passages. | The steam expands partially in the nozzle and further expansion takes place in the rotor blades. |

The relative velocity of steam passing over the blade remains constant in the absence of friction. | The relative velocity of steam passing over the blade increases as the steam expands while passing over the blade. |

The steam velocity is very high and therefore the speed of turbine is high. | The steam velocity is not very high and therefore the speed of turbine is low. |

The pressure on both ends of the moving blade is same. | The pressure on both ends of the moving blade is different |

For the same power developed, as pressure drop is more, the number of stages required are less. | For the same power developed, as pressure drop is small, the number of stages required are more. |

Blades are symmetrical | Blades are asymmetrical |

The blade efficiency curve is less flat. | The blade efficiency curve is more - flat |

- If high velocity of steam is allowed to flow through one row of moving blades, it produces a rotor speed of about 30000 rpm which is too high for practical use.

- It is therefore essential to incorporate some improvements for practical use and also to achieve high performance.

- This is possible by making use of more than one set of nozzles, and rotors, in a series, keyed to the shaft so that either the steam pressure or the jet velocity is absorbed by the turbine in stages. This is called compounding of turbines.

- The high rotational speed of the turbine can be reduced by the following methods of compounding:

1)Velocity compounding

2)Pressure compounding, and

3)Pressure-Velocity compounding.

6.2.1. Velocity compounding:

Figure 5: Velocity compounding

- It consists of a set of nozzles and a few rows of moving blades which are fixed to the shaft and rows of fixed blades which are attached to the casing.

- As shown in figure, the two rows of moving blades are separated by a row of fixed blades.

- The high velocity steam first enters the first row of moving blades, where some portion of the velocity is absorbed.

- Then it enters the ring of fixed blades where the direction of steam is changed to suit the second ring of moving blades. There is no change in the velocity as the steam passes over the fixed blades.

- The steam then passes on to the second row of moving blades where the velocity is further reduced. Thus, a fall in velocity occurs every time when the steam passes over the row of moving blades. Steam thus leaves the turbine with a low velocity.

- The variation of pressure and velocity of steam as it passes over the moving and fixed blades is shown in the figure. It is clear from the figure that the pressure drop takes place only in the nozzle and there is no further drop of pressure as it passes over the moving blades.

- This method of velocity compounding is used in Curtis turbine after it was first proposed by C.G. Curtis.

6.2.2. Pressure compounding:

Figure 6: Pressure compounding

- It consists of a number of fixed nozzles which are incorporated between the rings of moving blades. The moving blades are keyed to the shaft.

- Here the pressure drop is done in a number of stages. Each stage consists of a set of nozzles and a ring of moving blades.

- Steam from the boiler passes through the first set of nozzles where it expands partially. Nearly all its velocity is absorbed when it passes over the first set of moving blades.

- It is further passed to the second set of fixed nozzles where it is partially expanded again and through the second set of moving blades where the velocity of steam is almost absorbed. This process is repeated till steam leaves at condenser pressure.

- By reducing the pressure in stages, the velocity of steam entering the moving blades is considerably reduced. Hence the speed of the rotor is reduced. Rateau&Zoelly turbines use this method of compounding.

6.2.3. Pressure-velocity compounding:

The pressure-velocity compounding is the compounding is the combination of the above two types of compounding. In fact series of velocity-compounded impulse stages is called a pressure velocity compounded turbine. Each stage consists of rings of fixed and moving blades.

Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

- In this method of compounding, both pressure and velocity compounding methods are utilized.

- The total drop in steam pressure is carried out in two stages and the velocity obtained in each stage is also compounded.

- The stages consist of fixed nozzle, moving blades, fixed blades, moving blade in sequence.

- The ring of nozzles is fixed at the beginning of each stage and pressure remains constant during each stage.

- The pressure of steam only drops in nozzle and remain constant while travelling over moving blades and fixed blades.

- This method of compounding is used in Curtis and More turbines.

Figure 7: Pressure-velocity compounding

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.

Unit - 6

Analysis of steam turbines

Unit - 6

Analysis of steam turbines

A steam turbine is a prime mover in which the potential energy of the steam is transformed into kinetic energy and later in its turn is transformed into the mechanical energy of rotation of the turbine shaft.

Classification:

Most common classification of steam turbine-

(i) Impulse Turbine

(ii) Reaction Turbine

Other classifications are: -

(i) According to the number of pressure stages

(ii) According to the type of steam flow

(iii) According to the number of shafts/cylinders

(iv) According to the method of governing

(v) According to the steam conditions at inlet to turbine

According to the action of steam:

- Impulse turbine: In impulse turbine, steam coming out through a fixed nozzle at a very high velocity strikes the blades fixed on the periphery of a rotor. The blades change the direction of steam flow without changing its pressure. The force due to change of momentum causes the rotation of the turbine shaft. Ex: De-Laval, Curtis and Rateau Turbines

- Reaction turbine: In reaction turbine, steam expands both in fixed and moving blades continuously as the steam passes over them. The pressure drop occurs continuously over both moving and fixed blades.

- Combination of impulse and reaction turbine

- According to the number of pressure stages:

- Single stage turbines: These turbines are mostly used for driving centrifugal compressors, blowers and other similar machinery.

- Multistage Impulse and Reaction turbines: They are made in a wide range of power capacities varying from small to large.

2. According to the type of steam flow:

- Axial turbines: In these turbines, steam flows in a direction parallel to the axis of the turbine rotor.

- Radial turbines: In these turbines, steam flows in a direction perpendicular to the axis of the turbine, one or more low pressure stages are made axial.

3. According to the number of shafts:

- Single shaft turbines

- Multi-shaft turbines

4. According to the method of governing:

- Turbines with throttle governing: In these turbines, fresh steam enter through one or more (depending on the power developed) simultaneously operated throttle valves.

- Turbines with nozzle governing: In these turbines, fresh steam enters through one or more consecutively opening regulators.

- Turbines with by-pass governing: In these turbines, the steam besides being fed to the first stage is also directly fed to one, two or even three intermediate stages of the turbine.

5. According to the steam conditions at inlet to turbine:

- Low pressure turbines: These turbines use steam at a pressure of 1.2 ata to 2 atm.

- Medium pressure turbines: These turbines use steam up to a pressure of 40 atm.

- High pressure turbines: These turbines use steam at a pressure above 40 atm.

- Very high-pressure turbines: These turbines use steam at a pressure of 170 atm and higher and temperatures of 550°C and higher.

- Supercritical pressure turbines: These turbines use steam at a pressure of 225 atm and higher.

Simple impulse principle:

- The impulse turbine consists basically of a rotor mounted on a shaft that is free to rotate in a set of bearings.

- The outer rim of the rotor carries a set of curved blades, and the whole assembly is enclosed in an airtight case.

- Nozzles direct steam against the blades and turn the rotor. The energy to rotate an impulse turbine is derived from the kinetic energy of the steam flowing through the nozzles.

- The term impulse means that the force that turns the turbine comes from the impact of the steam on the blades.

Construction and Working of impulse turbine:

- The uppermost portion of the diagram shows a longitudinal section through the upper half of the turbine.

- The middle portion shows the actual shape of the nozzle and blading.

- The bottom portion shows the variation of absolute velocity and absolute pressure during the flow of steam through passage of nozzles and blades.

- The expansion of steam from its initial pressure (steam chest pressure) to final pressure (condenser pressure) takes place in one set of nozzles.

- Due to high drop in pressure in the nozzles, the velocity of steam in the nozzles increases.

- The steam leaves the nozzle with a very high velocity and strikes the blades of the turbine mounted on a wheel with this high velocity.

- The loss of energy due to this higher exit velocity is commonly known as carry over loss (or) leaving loss.

- The pressure of the steam when it moves over the blades remains constant but the velocity decreases.

- The exit/leaving/lost velocity may amount to 3.3 percent of the nozzle outlet velocity.

- Also, since all the KE is to be absorbed by one ring of the moving blades only, the velocity of wheel is too high (varying from 25000 to 30000 RPM).

- However, this wheel or rotor speed can be reduced by adopting the method of compounding of turbines.

Figure 1: Simple impulse turbine

Velocity diagram for steam turbine:

For the convenience of solving the problem related to the turbine we can make the velocity diagram as shown in fig.2.

Figure 2: Velocity diagram for moving blade

Tangential force on the wheel = Mass of the steam * acceleration

Mass of steam/seconds * change in velocity

=

Figure 3: Velocity triangle of moving blade

Work done on blade / second = Force * distance travelled / second

Power on blade second is given by-

Blade or diagram efficiency =

Reaction turbine

- A turbine in which steam pressure decreases gradually while expanding through the moving blades as well as the fixed blades is known as reaction turbine.

- It consists of a large number of stages, each stage consisting of set of fixed and moving blades. The heat drop takes place throughout in both fixed and moving blades.

- No nozzles are provided in a reaction turbine. The fixed blades act both as nozzles in which velocity of steam increased and direct the steam to enter the ring of moving blades. As pressure drop takes place both in the fixed and moving blades, all the blades are nozzle shaped.

- The steam expands while flowing over the moving blades and thus gives reaction to the moving blades. Hence the turbine is called reaction turbine.

- The fixed blades are attached to the casing whereas moving blades are fixed with the rotor.

- It is also called Parson’s reaction turbine.

Figure 4: Reaction Turbine

Key Takeaways:

Difference between Impulse turbine and Reaction turbine:

Impulse Turbine | Reaction Turbine |

The steam completely expands in the nozzle and its pressure remains constant during its flow through the blade passages. | The steam expands partially in the nozzle and further expansion takes place in the rotor blades. |

The relative velocity of steam passing over the blade remains constant in the absence of friction. | The relative velocity of steam passing over the blade increases as the steam expands while passing over the blade. |

The steam velocity is very high and therefore the speed of turbine is high. | The steam velocity is not very high and therefore the speed of turbine is low. |

The pressure on both ends of the moving blade is same. | The pressure on both ends of the moving blade is different |

For the same power developed, as pressure drop is more, the number of stages required are less. | For the same power developed, as pressure drop is small, the number of stages required are more. |

Blades are symmetrical | Blades are asymmetrical |

The blade efficiency curve is less flat. | The blade efficiency curve is more - flat |

- If high velocity of steam is allowed to flow through one row of moving blades, it produces a rotor speed of about 30000 rpm which is too high for practical use.

- It is therefore essential to incorporate some improvements for practical use and also to achieve high performance.

- This is possible by making use of more than one set of nozzles, and rotors, in a series, keyed to the shaft so that either the steam pressure or the jet velocity is absorbed by the turbine in stages. This is called compounding of turbines.

- The high rotational speed of the turbine can be reduced by the following methods of compounding:

1)Velocity compounding

2)Pressure compounding, and

3)Pressure-Velocity compounding.

6.2.1. Velocity compounding:

Figure 5: Velocity compounding

- It consists of a set of nozzles and a few rows of moving blades which are fixed to the shaft and rows of fixed blades which are attached to the casing.

- As shown in figure, the two rows of moving blades are separated by a row of fixed blades.

- The high velocity steam first enters the first row of moving blades, where some portion of the velocity is absorbed.

- Then it enters the ring of fixed blades where the direction of steam is changed to suit the second ring of moving blades. There is no change in the velocity as the steam passes over the fixed blades.

- The steam then passes on to the second row of moving blades where the velocity is further reduced. Thus, a fall in velocity occurs every time when the steam passes over the row of moving blades. Steam thus leaves the turbine with a low velocity.

- The variation of pressure and velocity of steam as it passes over the moving and fixed blades is shown in the figure. It is clear from the figure that the pressure drop takes place only in the nozzle and there is no further drop of pressure as it passes over the moving blades.

- This method of velocity compounding is used in Curtis turbine after it was first proposed by C.G. Curtis.

6.2.2. Pressure compounding:

Figure 6: Pressure compounding

- It consists of a number of fixed nozzles which are incorporated between the rings of moving blades. The moving blades are keyed to the shaft.

- Here the pressure drop is done in a number of stages. Each stage consists of a set of nozzles and a ring of moving blades.

- Steam from the boiler passes through the first set of nozzles where it expands partially. Nearly all its velocity is absorbed when it passes over the first set of moving blades.

- It is further passed to the second set of fixed nozzles where it is partially expanded again and through the second set of moving blades where the velocity of steam is almost absorbed. This process is repeated till steam leaves at condenser pressure.

- By reducing the pressure in stages, the velocity of steam entering the moving blades is considerably reduced. Hence the speed of the rotor is reduced. Rateau&Zoelly turbines use this method of compounding.

6.2.3. Pressure-velocity compounding:

The pressure-velocity compounding is the compounding is the combination of the above two types of compounding. In fact series of velocity-compounded impulse stages is called a pressure velocity compounded turbine. Each stage consists of rings of fixed and moving blades.

Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

- In this method of compounding, both pressure and velocity compounding methods are utilized.

- The total drop in steam pressure is carried out in two stages and the velocity obtained in each stage is also compounded.

- The stages consist of fixed nozzle, moving blades, fixed blades, moving blade in sequence.

- The ring of nozzles is fixed at the beginning of each stage and pressure remains constant during each stage.

- The pressure of steam only drops in nozzle and remain constant while travelling over moving blades and fixed blades.

- This method of compounding is used in Curtis and More turbines.

Figure 7: Pressure-velocity compounding

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.

Unit - 6

Analysis of steam turbines

A steam turbine is a prime mover in which the potential energy of the steam is transformed into kinetic energy and later in its turn is transformed into the mechanical energy of rotation of the turbine shaft.

Classification:

Most common classification of steam turbine-

(i) Impulse Turbine

(ii) Reaction Turbine

Other classifications are: -

(i) According to the number of pressure stages

(ii) According to the type of steam flow

(iii) According to the number of shafts/cylinders

(iv) According to the method of governing

(v) According to the steam conditions at inlet to turbine

According to the action of steam:

- Impulse turbine: In impulse turbine, steam coming out through a fixed nozzle at a very high velocity strikes the blades fixed on the periphery of a rotor. The blades change the direction of steam flow without changing its pressure. The force due to change of momentum causes the rotation of the turbine shaft. Ex: De-Laval, Curtis and Rateau Turbines

- Reaction turbine: In reaction turbine, steam expands both in fixed and moving blades continuously as the steam passes over them. The pressure drop occurs continuously over both moving and fixed blades.

- Combination of impulse and reaction turbine

- According to the number of pressure stages:

- Single stage turbines: These turbines are mostly used for driving centrifugal compressors, blowers and other similar machinery.

- Multistage Impulse and Reaction turbines: They are made in a wide range of power capacities varying from small to large.

2. According to the type of steam flow:

- Axial turbines: In these turbines, steam flows in a direction parallel to the axis of the turbine rotor.

- Radial turbines: In these turbines, steam flows in a direction perpendicular to the axis of the turbine, one or more low pressure stages are made axial.

3. According to the number of shafts:

- Single shaft turbines

- Multi-shaft turbines

4. According to the method of governing:

- Turbines with throttle governing: In these turbines, fresh steam enter through one or more (depending on the power developed) simultaneously operated throttle valves.

- Turbines with nozzle governing: In these turbines, fresh steam enters through one or more consecutively opening regulators.

- Turbines with by-pass governing: In these turbines, the steam besides being fed to the first stage is also directly fed to one, two or even three intermediate stages of the turbine.

5. According to the steam conditions at inlet to turbine:

- Low pressure turbines: These turbines use steam at a pressure of 1.2 ata to 2 atm.

- Medium pressure turbines: These turbines use steam up to a pressure of 40 atm.

- High pressure turbines: These turbines use steam at a pressure above 40 atm.

- Very high-pressure turbines: These turbines use steam at a pressure of 170 atm and higher and temperatures of 550°C and higher.

- Supercritical pressure turbines: These turbines use steam at a pressure of 225 atm and higher.

Simple impulse principle:

- The impulse turbine consists basically of a rotor mounted on a shaft that is free to rotate in a set of bearings.

- The outer rim of the rotor carries a set of curved blades, and the whole assembly is enclosed in an airtight case.

- Nozzles direct steam against the blades and turn the rotor. The energy to rotate an impulse turbine is derived from the kinetic energy of the steam flowing through the nozzles.

- The term impulse means that the force that turns the turbine comes from the impact of the steam on the blades.

Construction and Working of impulse turbine:

- The uppermost portion of the diagram shows a longitudinal section through the upper half of the turbine.

- The middle portion shows the actual shape of the nozzle and blading.

- The bottom portion shows the variation of absolute velocity and absolute pressure during the flow of steam through passage of nozzles and blades.

- The expansion of steam from its initial pressure (steam chest pressure) to final pressure (condenser pressure) takes place in one set of nozzles.

- Due to high drop in pressure in the nozzles, the velocity of steam in the nozzles increases.

- The steam leaves the nozzle with a very high velocity and strikes the blades of the turbine mounted on a wheel with this high velocity.

- The loss of energy due to this higher exit velocity is commonly known as carry over loss (or) leaving loss.

- The pressure of the steam when it moves over the blades remains constant but the velocity decreases.

- The exit/leaving/lost velocity may amount to 3.3 percent of the nozzle outlet velocity.

- Also, since all the KE is to be absorbed by one ring of the moving blades only, the velocity of wheel is too high (varying from 25000 to 30000 RPM).

- However, this wheel or rotor speed can be reduced by adopting the method of compounding of turbines.

Figure 1: Simple impulse turbine

Velocity diagram for steam turbine:

For the convenience of solving the problem related to the turbine we can make the velocity diagram as shown in fig.2.

Figure 2: Velocity diagram for moving blade

Tangential force on the wheel = Mass of the steam * acceleration

Mass of steam/seconds * change in velocity

=

Figure 3: Velocity triangle of moving blade

Work done on blade / second = Force * distance travelled / second

Power on blade second is given by-

Blade or diagram efficiency =

Reaction turbine

- A turbine in which steam pressure decreases gradually while expanding through the moving blades as well as the fixed blades is known as reaction turbine.

- It consists of a large number of stages, each stage consisting of set of fixed and moving blades. The heat drop takes place throughout in both fixed and moving blades.

- No nozzles are provided in a reaction turbine. The fixed blades act both as nozzles in which velocity of steam increased and direct the steam to enter the ring of moving blades. As pressure drop takes place both in the fixed and moving blades, all the blades are nozzle shaped.

- The steam expands while flowing over the moving blades and thus gives reaction to the moving blades. Hence the turbine is called reaction turbine.

- The fixed blades are attached to the casing whereas moving blades are fixed with the rotor.

- It is also called Parson’s reaction turbine.

Figure 4: Reaction Turbine

Key Takeaways:

Difference between Impulse turbine and Reaction turbine:

Impulse Turbine | Reaction Turbine |

The steam completely expands in the nozzle and its pressure remains constant during its flow through the blade passages. | The steam expands partially in the nozzle and further expansion takes place in the rotor blades. |

The relative velocity of steam passing over the blade remains constant in the absence of friction. | The relative velocity of steam passing over the blade increases as the steam expands while passing over the blade. |

The steam velocity is very high and therefore the speed of turbine is high. | The steam velocity is not very high and therefore the speed of turbine is low. |

The pressure on both ends of the moving blade is same. | The pressure on both ends of the moving blade is different |

For the same power developed, as pressure drop is more, the number of stages required are less. | For the same power developed, as pressure drop is small, the number of stages required are more. |

Blades are symmetrical | Blades are asymmetrical |

The blade efficiency curve is less flat. | The blade efficiency curve is more - flat |

- If high velocity of steam is allowed to flow through one row of moving blades, it produces a rotor speed of about 30000 rpm which is too high for practical use.

- It is therefore essential to incorporate some improvements for practical use and also to achieve high performance.

- This is possible by making use of more than one set of nozzles, and rotors, in a series, keyed to the shaft so that either the steam pressure or the jet velocity is absorbed by the turbine in stages. This is called compounding of turbines.

- The high rotational speed of the turbine can be reduced by the following methods of compounding:

1)Velocity compounding

2)Pressure compounding, and

3)Pressure-Velocity compounding.

6.2.1. Velocity compounding:

Figure 5: Velocity compounding

- It consists of a set of nozzles and a few rows of moving blades which are fixed to the shaft and rows of fixed blades which are attached to the casing.

- As shown in figure, the two rows of moving blades are separated by a row of fixed blades.

- The high velocity steam first enters the first row of moving blades, where some portion of the velocity is absorbed.

- Then it enters the ring of fixed blades where the direction of steam is changed to suit the second ring of moving blades. There is no change in the velocity as the steam passes over the fixed blades.

- The steam then passes on to the second row of moving blades where the velocity is further reduced. Thus, a fall in velocity occurs every time when the steam passes over the row of moving blades. Steam thus leaves the turbine with a low velocity.

- The variation of pressure and velocity of steam as it passes over the moving and fixed blades is shown in the figure. It is clear from the figure that the pressure drop takes place only in the nozzle and there is no further drop of pressure as it passes over the moving blades.

- This method of velocity compounding is used in Curtis turbine after it was first proposed by C.G. Curtis.

6.2.2. Pressure compounding:

Figure 6: Pressure compounding

- It consists of a number of fixed nozzles which are incorporated between the rings of moving blades. The moving blades are keyed to the shaft.

- Here the pressure drop is done in a number of stages. Each stage consists of a set of nozzles and a ring of moving blades.

- Steam from the boiler passes through the first set of nozzles where it expands partially. Nearly all its velocity is absorbed when it passes over the first set of moving blades.

- It is further passed to the second set of fixed nozzles where it is partially expanded again and through the second set of moving blades where the velocity of steam is almost absorbed. This process is repeated till steam leaves at condenser pressure.

- By reducing the pressure in stages, the velocity of steam entering the moving blades is considerably reduced. Hence the speed of the rotor is reduced. Rateau&Zoelly turbines use this method of compounding.

6.2.3. Pressure-velocity compounding:

The pressure-velocity compounding is the compounding is the combination of the above two types of compounding. In fact series of velocity-compounded impulse stages is called a pressure velocity compounded turbine. Each stage consists of rings of fixed and moving blades.

Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

- In this method of compounding, both pressure and velocity compounding methods are utilized.

- The total drop in steam pressure is carried out in two stages and the velocity obtained in each stage is also compounded.

- The stages consist of fixed nozzle, moving blades, fixed blades, moving blade in sequence.

- The ring of nozzles is fixed at the beginning of each stage and pressure remains constant during each stage.

- The pressure of steam only drops in nozzle and remain constant while travelling over moving blades and fixed blades.

- This method of compounding is used in Curtis and More turbines.

Figure 7: Pressure-velocity compounding

References:

1. Sonntag, R. E, Borgnakke, C. And Van Wylen, G. J., 2003, 6th Edition, Fundamentals of Thermodynamics, John Wiley and Sons.

2. Jones, J. B. And Duggan, R. E., 1996, Engineering Thermodynamics, Prentice-Hall of India

3. Moran, M. J. And Shapiro, H. N., 1999, Fundamentals of Engineering Thermodynamics, John Wiley and Sons.

4. Yunus A. Cengel; Michael A. Boles, Thermodynamics: An Engineering Approach, McGraw- Hill.

5. Nag, P.K, 1995, Engineering Thermodynamics, Tata McGraw-Hill Publishing Co. Ltd.