Unit - 4

Involute and cycloidal gear profiles

Involute Gear Profile

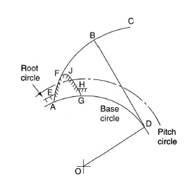

Involute profile is obtained by the locus of a point on a straight line when it rolls about a circumference of a circle without slipping. The circle about which the straight-line rolls is known as the base circle. Figure 2 shows the generation of involute profile in which the line BD is rolling about the base circle with center O and the path ABC shows the involute profile traced by the line.

Figure 1. Involute profile

Cycloidal Profile

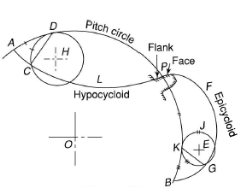

Cycloidal profile is obtained by the locus of a point on the circumference of a circle when it rolls on a straight line without slipping. Gear tooth are made by two kind of cycloidal profiles. Face of gear tooth have epicycloid profile while flank have hypocycloid profile. Figure 3 shows the cycloidal profile of gear teeth.

Epicycloid profile is obtained by the locus of a point on the circumference of a circle when it rolls on the circumference of another circle without slipping, while hypocycloid profile is obtained by the locus of a point the circumference of a circle when it rolls inside the circumference of another circle.

Figure 2. Cycloidal Profile of gear teeth

Gear parameters listed below.

- Path of contact

- Arc of contact

- Contact ratio

Path of contact

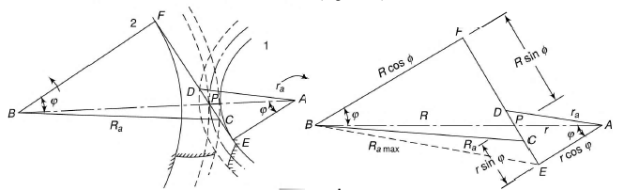

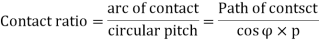

In order to calculate the path of contact of gear consider the figure 4 which shows the two gears in contact. In which smaller gear is termed as the pinion while lager gear is known as the wheel.

Figure 3. Two gears in contact

Path of contact is given by the line CD shown in the figure 4. In the given figure:

R = radius of pitch circle for the wheel

r = radius of pitch circle for pinion

Ra = radius of addendum circle for wheel

ra = radius of addendum circle for pinion

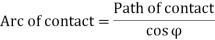

Arc of contact

Arc of contact is the path on the pitch circle of pinion and the wheel from start of their engagement to the end of the disengagement. The arc of contact is calculated by the given formula.

Contact ratio

It is also known as the number of pairs of teeth in contact during meshing of a pair of gears. During the meshing of teeth all the teeth lying in between the arc of contact are the number of pairs of teeth in contact. We can define the contact ratio as the ratio of arc of contact to the circular pitch.

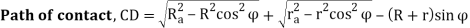

This law states the necessary condition for the constant angular velocity for two mating gears i.e. the common normal at the point of contact of the gears in mesh must pass through the pitch point, and the ration in which the pitch point divides the common normal is the inverse ratio of the angular velocity of the mating gears.

Figure 4. Gear teeth profile in mesh

Consider the figure.5 in which point C and D are the contact point on gear 1 and 2 respectively, line n-n is the common normal at the point of contact and point P is the pitch point. So, the necessary condition for the constant angular velocity is:

Where, 1= angular velocity of gear 1.

2= angular velocity of gear 2.

Conjugate Action

If the meshing gears are shaped in such a way that they produce a constant angular velocity ratio, such surfaces are termed as conjugate surfaces. This act of producing constant angular velocity ratio by two meshing gear is known as conjugate action.

Spur gears or directly-reduce gears are the only kind of equipment. They encompass a cylinder or disk with tooth projecting radially. Viewing the equipment at ninety stages from the shaft duration (aspect on) the teeth faces are directly and aligned parallel to the axis of rotation. Looking down the duration of the shaft, a teeth's pass phase is commonly now no longer triangular. Instead of being directly (as in a triangle) the edges of the pass phase have a curved form (commonly involute and much less typically cyclical) to reap a steady pressure ratio. Spur gears mesh collectively effectively best if suited for parallel shafts

No axial thrust is created with the aid of using the teeth loads. Spur gears are exceptional at slight speeds however have a tendency to be noisy at excessive speeds. Spur equipment may be categorized into stress angles, 20° being the modern-day enterprise popular and 14½° being the former (frequently located in older equipment). Spur equipment tooth are synthetic as both involute profile and cycloidal profile. When gears are in mesh it's far feasible that an involute element of 1 will touch a non-involute part of the opposite equipment.

Undercutting (reducing the teeth narrower toward its base) is once in a while used to keep away from interference however is commonly now no longer appropriate due to the fact the reduced thickness leaves the teeth weaker at its base. In this example Corrected gears are used. In corrected gears the Cutter rack is shifted upwards or downwards.[clarification needed]

Spur gears may be categorized into predominant categories: External and Internal. Gears with tooth at the outdoor of the cylinder are recognized as "outside gears". Gears with tooth at the inner aspect of the cylinder are recognized as "inner gears". An outside equipment can mesh with an outside equipment or an inner equipment. When outside gears mesh collectively they rotate with inside the contrary directions.

An inner equipment can best mesh with an outside equipment and the gears rotate with inside the identical direction. Due to the near positioning of shafts, inner equipment assemblies are extra compact than outside equipment assemblies.

The smaller range of tooth can obtain a extra dependable tools transmission whilst the middle distance is fixed But small range of tooth will produce the hassle of undercutting is an vital hassle in designing and production gears with small numbers of tooth Conditions of undercutting for gears range with the profile and production strategies When undercutting happens the generated tools teeth is relatively weak and the transmission capability of tools set is drastically decreased The conjugate location of the teeth profile is reduced and the teeth touch pressure is improved hastily on the discontinuity of the teeth floor

The provider existence Of the tools set is therefore decreased.

Beside undercutting can also additionally motive dulling put on of the cutter on its corners.

For a majority of these reasons undercutting is unwanted and ought to be prevented. Many gears utilized in plane and different transmissions have length obstacles primarily based totally at the minimal range of tooth that may be reduce on a pinion without undercutting the tooth If the range of tooth is made fewer than this minimal a weaker teeth can be produced due to the undercutting happens clearly and will increase because the range of tooth reduce decreases.

Gear designers presently have strategies to be had for lowering undercut These strategies may be used one by one or in aggregate with one another

The first technique is to growth the stress attitude

An growth with inside the stress attitude of the tools will permit a lower with inside the range of tooth without undercutting The 2nd tools layout technique is using long- brief addendum layout This technique is finished with the aid of using growing the addendum of the pinion and the lowering the addendum of the tools with the aid of using an equal .,quantity But the 2 strategies will convey the top pointing without the undercutting whilst the range of tooth is smaller In different words the top pointing and the undercut of root of involute tools are hard to take away concurrently whilst the range of the tooth is smaller.

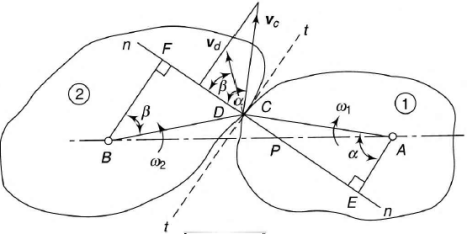

Spur gear contact ratio

To assure continuous smooth tooth action, as one pair of teeth ceases action a succeeding pair of teeth must already have come into engagement. It is desirable to have as much overlap as is possible. A measure of this overlap action is the contact ratio. This is a ratio of the length of the line-of-action to the base pitch. Figure shows the geometry for a spur gear pair, which is the simplest case, and is representative of the concept for all gear types. The length-of-action is determined from the intersection of the line-of-action and the outside radii. The ratio of the length-of-action to the base pitch is determined from:

It is good practice to maintain a contact ratio of 1.2 or greater. Under no circumstances should the ratio drop below 1.1, calculated for all tolerances at their worst case values.

A contact ratio between 1 and 2 means that part of the time two pairs of teeth are in contact and during the remaining time one pair is in contact. A ratio between 2 and 3 means 2 or 3 pairs of teeth are always in contact. Such a high ratio is generally not obtained with external spur gears, but can be developed in the meshing of internal gears, helical gears, or specially designed nonstandard external spur gears.

When considering all types of gears, contact ratio is composed of two components:

- Radial contact ratio (plane of rotation perpendicular to axes), εα

- Overlap contact ratio (axial), εβ

The sum is the total contact ratio, εɣ.

The overlap contact ratio component exists only in gear pairs that have helical or spiral tooth forms.

Interference/Undercutting

Locking of meshed gear teeth due non-conjugate or non-involute profile is termed as the interference. Non-conjugate gear teeth profile causes improper sliding of gear teeth which results in rough action and binding. Rough action and binding cause different sliding velocity of mating gears and results in locking.

- Use of a larger pressure angle (having a larger pressure angle results in a smaller base circle. As a result, more of the tooth profiles become involute)

- Under-cutting of tooth (A portion of teeth below the base circle is cut off. When teeth are produced by this process, the tip of one tooth of a gear will not contact the non-involute portion of the tooth of other gear)

- Tooth stubbing (In this process a portion of the tip of the teeth is removed, thus preventing that portion of the tip of tooth in contacting the non-involute portion of the other meshing tooth).

- Increasing the number of teeth on the gear can also eliminate the chances of interference.

- Increasing slightly the center distance between the meshing gears would also eliminate interference.

- Tooth profile modification or profile shifting (Using profile shifted gears (gears with non-standard profile) can also be an option to eliminate interference. In profile shifted meshing gears, the addendum on the pinion is shorter compared with standard gears).

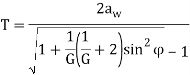

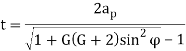

Minimum number of teeth to avoid interference

- For wheel

- For pinion

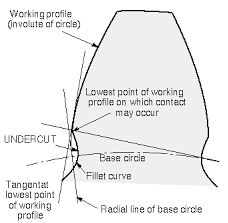

Undercutting

In case of involute gear profile addendum of mating gears removes some part in the dedendum if there is interference. This removed portion in the dedendum is known as the undercut and the process of removal of the material from at the root of gears is known as undercutting. Figure 6 shows the undercutting in the gears.

The profile of tooth inside the base circle is radial.If the addendum of mating gear is more than the limiting value, it interferes with the dedendum of pinion and therefore two gears get locked.

However, if a cutting rack having similar teeth is used to cut the teeth in the pinion, it will remove that portion of the pinion tooth which would have interfered with gear.

A gear having its material removed in this manner is said to undercut and the process, undercutting.

In a pinion with small number of teeth, this can seriously weaken the tooth. However, when the actual gear meshes with the undercut pinion, no interference occurs.

Undercutting will not take place if teeth are designed to avoid interference.

Helical Gear:

The tooth of a helical tools are set at an attitude (relative to axis of the tools) and take the form of a helix. This lets in the tooth to mesh gradually, beginning as factor touch and growing into line touch as engagement progresses. One of the maximum considerable advantages of helical gears over spur gears is much less noise, in particular at medium- to high-speeds. Also, with helical gears, a couple of tooth are usually in mesh, because of this that much less load on every character enamel.

This consequences in a smoother transition of forces from one enamel to the next, in order that vibrations, surprise loads, and put on are reduced. But the willing attitude of the tooth additionally reasons sliding touch among the tooth, which produces axial forces and heat, reducing efficiency. These axial forces play a good sized position in bearing choice for helical gears. Because the bearings need to resist each radial and axial forces, helical gears require thrust or curler bearings, that are commonly large (and extra expensive) than the easy bearings used with spur gears.

The axial forces range in percentage to the significance of the tangent of the helix attitude. Although large helix angles offer better pace and smoother motion, the helix attitude is commonly constrained to forty five ranges because of the manufacturing of axial forces.

Bevel Gear

Two vital ideas in gearing are pitch floor and pitch attitude. The pitch floor of a equipment is the imaginary toothless floor which you could have through averaging out the peaks and valleys of the person tooth. The pitch floor of an regular equipment is the form of a cylinder. The pitch attitude of a equipment is the attitude among the face of the pitch floor and the axis. The maximum acquainted forms of bevel gears have pitch angles of much less than ninety tiers and consequently are cone-shaped.

This kind of bevel equipment is known as outside due to the fact the equipment tooth factor outward. The pitch surfaces of meshed outside bevel gears are coaxial with the equipment shafts; the apexes of the 2 surfaces are on the factor of intersection of the shaft axes. The use of a proper bevel equipment has even extra significance for the reliability of the axle than some other spare part. Bevel gears which have pitch angles of extra than 90 tiers have tooth that factor inward and are known as inner bevel gears. Bevel gears which have pitch angles of precisely ninety tiers have tooth that factor outward parallel with the axis and resemble the factors on a crown. That's why this kind of bevel equipment is known as a crown equipment.

Worm Gear

The factors also are known as the bug screw and bug equipment. The terminology is regularly burdened with the aid of using obscure use of the time period bug equipment to consult the bug, the bug wheel, or the bug force as a unit.

The bug force later seemed with inside the Indian subcontinent, to be used in curler cotton gins, throughout the Delhi Sultanate with inside the 13th or fourteenth centuries A gearbox designed the use of a bug and bug wheel is significantly smaller than one crafted from undeniable spur gears, and has its force axes at 90° to every other.

With a single-begin bug, for every 360° flip of the bug, the bug wheel advances with the aid of using most effective one enamel. Therefore, no matter the bug's length (practical engineering limits notwithstanding), the equipment ratio is the "length of the bug wheel - to - 1". Given a single-begin bug, a 20-enamel bug wheel reduces the velocity with the aid of using the ratio of 20:1. With spur gears, a equipment of 12 tooth ought to healthy with a 240-enamel equipment to reap the equal 20:1 ratio. Therefore, if the diametrical pitch (DP) of every equipment is the equal, then, in phrases of the bodily length of the 240 enamel equipment to that of the 20 enamel equipment, the bug association is significantly smaller in volume.

Rack & pinion gears

A rack and pinion is a kind of linear actuator that accommodates a round equipment (the pinion) enticing a linear equipment (the rack), which function to translate rotational movement into linear movement.

Driving the rack linearly will purpose the pinion to be pushed right into a rotation. A rack and pinion power can use each directly and helical gears. Though a few endorse Helical gears are stated for “quieter” operation, there may be no technology to assist this theory. Helical racks at the same time as being extra affordable, have established to growth aspect torque at the datums, growing working temperature main to untimely wear.

The most pressure that may be transmitted in a rack and pinion mechanism is decided with the aid of using the teeth pitch and the scale of the pinion in addition to the equipment ratio. For example, in a rack railway, the rotation of a pinion set up on a locomotive or a railroad automobile engages a rack located among the rails and facilitates to transport the educate up a steep gradient. For each pair of conjugate involute profile, there may be a primary rack. This primary rack is the profile of the conjugate equipment of countless pitch radius (i.e. a toothed directly edge)

Epicyclic gear train kinematics

An epicyclic tools teach (additionally called a planetary gearset) includes gears established in order that the middle of 1 tools revolves across the middle of the different.

A service connects the facilities of the 2 gears and rotates the planet and solar gears mesh in order that their pitch circles roll without slip. A factor at the pitch circle of the planet tools strains an epicycloid curve. In this simplified case, the solar tools is constant and the planetary tools(s) roll across the solar tools.

An epicyclic tools teach may be assembled so the planet tools rolls at the interior of the pitch circle of a constant, outer tools ring, or ring tools, on occasion known as an annular tools. In this case, the curve traced via way of means of a factor at the pitch circle of the planet is a hypocycloid. The aggregate of epicycle tools trains with a planet enticing each a solar tools and a hoop tools is known as a planetary tools teach.

In this case, the hoop tools is typically constant and the solar tools is driven. Epicyclic gearing or planetary gearing is a tools device consisting of 1 or extra outer, or planet, gears or pinions, revolving approximately a significant solar tools or solar wheel.

Typically, the planet gears are established on a movable arm or service, which itself may also rotate relative to the solar tools. Epicyclic gearing structures additionally comprise the usage of an outer ring tools or annulus, which meshes with the planet gears. Planetary gears (or epicyclic gears) are commonly categorised as easy or compound planetary gears. Simple planetary gears have one solar, one ring, one service, and one planet set.

Compound planetary gears contain one or extra of the subsequent 3 styles of structures: meshed-planet (there are at the least extra planets in mesh with every different in every planet teach), stepped-planet (there exists a shaft connection among planets in every planet teach), and multi-level structures (the device carries or extra planet sets).

Compared to easy planetary gears, compound planetary gears have the benefits of large discount ratio, better torque-to-weight ratio, and extra bendy configurations. The axes of all gears are typically parallel, however for unique instances like pencil sharpeners and differentials, they may be located at an angle, introducing factors of bevel tools (see below). Further, the solar, planet service and ring axes are typically coaxial. Bookwheel, from Agostino Ramelli's Le various et artifiose machine, 1588 Epicyclic gearing is likewise to be had which includes a solar, a service, and planets which mesh with every different. One planet meshes with the solar tools, at the same time as the second one planet meshes with the hoop tools. For this case, whilst the service is constant, the hoop tools rotates withinside the identical route because the solar tools, therefore imparting a reversal in route as compared to traditional epicyclic gearing.

Regular gear train kinematics

An epicyclical tools educate (additionally referred to as a planetary gear set) includes gears installed in order that the middle of 1 tools revolves across the middle of the different.

An epicyclical tools educate may be assembled so the planet tools rolls at the internal of the pitch circle of a constant, outer tools ring, or ring tools, every now and then known as an annular tools. In this case, the curve traced with the aid of using a factor at the pitch circle of the planet is a hypocycloid.

Typically, the planet gears are installed on a movable arm or service, which itself can also additionally rotate relative to the solar tools. Epicyclic gearing structures additionally contain the usage of an outer ring tools or annulus, which meshes with the planet gears. Planetary gears (or epicyclic gears) are generally labeled as easy or compound planetary gears.

Simple planetary gears have one solar, one ring, one service, and one planet set. Compound planetary gears contain one or extra of the subsequent 3 sorts of structures: meshed-planet (there are as a minimum extra planets in mesh with every different in every planet educate), stepped-planet (there exists a shaft connection among planets in every planet educate), and multi-level structures (the device includes or extra planet sets).

Compared to easy planetary gears, compound planetary gears have the benefits of large discount ratio, better torque-to-weight ratio, and extra bendy configurations.

The axes of all gears are normally parallel, however for unique instances like pencil sharpeners and differentials, they may be located at an angle, introducing factors of bevel tools (see below).

Further, the solar, planet service and ring axes are normally coaxial. Bookwheel, from Agostino Ramelli's Le numerous et artifiose machine, 1588 Epicyclic gearing is likewise to be had which includes a solar, a service, and planets which mesh with every different.

One planet meshes with the solar tools, whilst the second one planet meshes with the hoop tools. For this case, while the service is constant, the hoop tools rotates with inside the identical path because the solar tools, hence supplying a reversal in path in comparison to conventional epicyclical gearing.

Gears are used for the transmission of movement via engagement of tools tooth which will both bring about an acceleration or discount of velocity. These tooth may be implemented in diverse forms, the maximum not unusual place being the involute tools teeth profile. A tools teach is made whilst a mixture of gears in mesh are used to transmit movement. A common utility of epicyclic tools trains is conducting a massive velocity discount in a small space.

A planetary or epicyclic tools teach is one form of tools teach used to transmit movement. Epicyclic tools trains encompass or extra gears set up in order that the middle of 1 tools revolves across the middle of the alternative. Epicyclic tools trains additionally called a planetary tools teach are tools trains with relative motions of axes. A service connects the facilities of the 2 gears and rotates to hold one tools, referred to as the planet tools, round the alternative referred to as the solar tools.

All the planets are set up to a unmarried rotating member, referred to as a cage, arm, service. As the planet service turns, it promises low-velocity, excessive-torque output. In a few structures each member rotates, however many have at the least one element isn't always rotating. Three primary configurations exist of planetary gears for diverse applications: Two inputs, one output and no constant element. This mechanism combines the velocity of the 2 inputs. One enter, outputs, and no constant element.

This creates a differential that splits the enter torque to the 2 exclusive outputs. One enter, one output, and one constant element. This will lessen the lessen velocity of the enter. The precise issues that the planetary tools set clear up make the mechanism appealing to engineers in lots of exclusive industries. Advantages of the usage of a planetary tools teach are low vibration, excessive velocity discount ratio, and the low price for the whole teach layout.

Some of the not unusual place makes use of for planetary tools transmissions are robot arms, hybrid car energy transmissions and turbine generators. Despite the benefits of epicyclic tools trains inclusive of compact structure, light-weight and excessive energy density, they'll have exceedingly low performance as compared to easy tools structures. The precept energy losses in tools trains are as a result of sliding friction among meshing tools teeth surfaces, churning of lubrication oils and friction in shaft assist bearings.

References:

1. Thomas Bevan, Theory of Machines, 3rd edition, CBS Publishers & Distributors, 2005.

2. CleghornW.L., Mechanisms of Machines, Oxford University Press, 2005.

3. Robert L. Norton, Kinematics and Dynamics of Machinery, Tata McGraw Hill, 2009.

4. Ghosh A. And Mallick A.K., Theory of Mechanisms and Machines, Affiliated East West Pvt. Ltd, New Delhi, 1988.