Unit - 4

Port fuel injection

Fuel injection is the advent of gas in an inner combustion engine, maximum generally car engines, via way of means of the way of an injector. This article specializes in gas injection in reciprocating piston and rotary piston engines.

Port Fuel Injection:

- Port Fuel injection is whilst gasoline (both fuel and diesel fuels) is injected previous to the valve and cylinder, wherein the combustion takes place.

- The consumption valve may have a gasoline injection machine that sprays gasoline into the air entering the engine. From there the spark plugs ignite the pressurized slurry of air and gasoline, pushing the cylinder head down and spinning the crankshaft. Now, that is going on at every of the cylinders, so when you have a V6 engine with port injection, and it takes place so fast which you won’t even word the cycle besides with the aid of using noise.

- With port gasoline injection, the cleansing impact of the consumption manifold ports and valves promotes better exhaust fuel line recirculation rates. Improved noise traits at low speeds. Increased limp-domestic capability. Port injection sprays gasoline into the consumption ports, wherein it mixes with the incoming air.

- When the consumption valve opens, the gasoline combination is pulled into the engine cylinder. With direct injection, the injectors are with inside the cylinder head and spray gasoline without delay into the combustion chamber, blending with the air charge.

- The fuelling port fuelling injection is the most well-known pressure tool for fuelling engines worldwide. The powertrain tool convinces with low costs, reduced era and new, innovative similarly developments. When the usage of engines with a specific usual overall performance of approx.

- The complex high-pressure control requirements (tool pressure as lots as 350 bar) are overlooked as are the high-pressure pump, the high-pressure sensor, the volume control valve and the high-pressure injectors for multi-aspect injections.

- The cease end result is a far much less complex injection control through the usage of variances regarding the injection time frame. The strong combustion manner of the fuelling port fuelling injection moreover tolerates fuelling of lower quality.

![Schematic of a Port Fuel Injector [1]](https://glossaread-contain.s3.ap-south-1.amazonaws.com/epub/1642644606_1416776.png)

Fig: Port fuel injection

Direct Injection

- Firstly, Diesel Direct Injection (DI) is a fundamental sort of gasoline injection device which many in advance technology diesel engines used. The easy DI diesel engines inject the gasoline into the combustion chamber above the piston immediately. The compression of air with inside the combustion chamber increases its temperature above 400oC. Then, it ignites the diesel-gasoline injected into the combustion chamber.

- Hence, the diesel engines also are regarded as ‘Compression Ignition’ engines. Instead of getting the gasoline jumbled together with the air previous to the valve, direct injection places the slurry of gasoline immediately into the combustion chamber.

- This changed into a extensive development at the carburetor device and boasts greater electricity thru the device while not having an excessive amount of gasoline be utilized. While older gasoline injection structures may be automatically initiated in cars made with inside the 1900s, maximum injection structures at the moment are electronically managed thru an engine’s ECU (Electronic Control Unit) and feature greater green capabilities.

- Most structures now are closed loop (higher air/gasoline mixtures) structures with an Oxygen Sensor relaying records to an ECU which controls the real blend of air to gasoline. Most vehicles constructed for the reason that Nineteen Nineties have direct injection engines.

- For the lay individual, the labyrinth of hoses, twine harnesses, manifolds and tubing underneath a vehicle hood may seem intimidating. The maximum vital variations among an instantaneous injection engine and a general fuel engine are how they supply gas and the way the gas mixes with incoming air.

- These simple premises make a incredible distinction in an engine's normal efficiency. First, the gas travels through pump from the gas tank, thru the gas line and into gas injectors which are hooked up into the engine.

- The injectors spray fuel into the air consumption manifold, in which gas and air blend collectively right into a first-class mist. At exactly timed intervals, consumption valves open, similar to the exceptional cylinders of the engine. As a cylinder's consumption valve opens, a piston in that cylinder descends, sucking the gas-air mist from the air manifold above into the chamber below.

- As the piston ascends as soon as greater, it squeezes (compresses) the gas-air blend till its miles almost 9 instances as dense because it became to start with. Then, that cylinder's precise spark plug fires, igniting the chamber right into a high-pressure, high-strength explosion.

- This little bang pushes the piston go into reverse with incredible force, inflicting it to show the crankshaft and in the end ship electricity to the wheels.

The fuel system of Direct Injection consists of following parts:

- Fuel Injection Pump (FIP)

- Injectors

- High-Pressure Lines

- Fuel feed pump

- Fuel Filter

- Governor

Advantages of conventional Direct Injection:

- Higher low-end torque

- Sturdiness

- Lower maintenance

- Longer engine life

Disadvantages of conventional Direct Injection:

- Higher NVH (Noise, Vibrations & Harshness) levels

- Sluggish in operation

- Lower engine speeds & BHP

- Heavier engine components

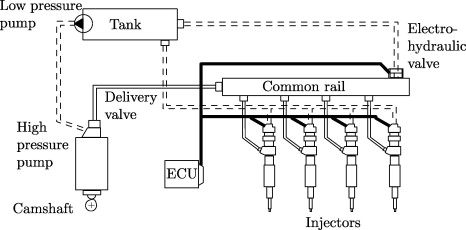

Common Rail Injection:

- A now no longer unusual place rail is one of the most crucial components in a diesel and gasoline direct injection tool. The major difference amongst an instantaneous and a favored injection is the transport of fuel line and the way how this one mixes with incoming air. The now no longer unusual place rail is a prolonged metal cylinder. Common rail engines require a totally quick to no heating-up time, depending on the ambient temperature, and convey lower engine noise and emissions than older systems.

- Diesel engines have historically used numerous sorts of fuel line injection. Two now no longer unusual place types encompass the unit-injection tool and the distributor/inline-pump systems. While the ones older systems provide accurate fuel line quantity and injection timing control, they may be confined with the resource of the usage of several factors:

- A now no longer unusual place rail is one of the most crucial components in a diesel and gasoline direct injection tool. The important difference amongst an instantaneous and a favored injection is the delivery of fuel line and the way how this one mixes with incoming air. The now no longer unusual place rail is a prolonged metallic cylinder.

Common rail engines require a totally short to no heating-up time, depending on the ambient temperature, and convey lower engine noise and emissions than older systems.

Fig: Common Rail injection

Diesel engines have historically used various styles of fuel line injection. Two now no longer unusual place kinds encompass the unit-injection tool and the distributor/inline-pump systems.

They are cam driven, and injection strain is proportional to engine velocity. This normally manner that the very best injection strain can best be done at the very best engine velocity and the most viable injection strain decreases as engine velocity decreases.

With unit or distributor structures, the injection strain is tied to the immediately strain of a unmarried pumping occasion without a accumulator, accordingly the connection is greater outstanding and troublesome.

- They are confined with inside the wide variety and timing of injection activities that may be commanded at some stage in a unmarried combustion occasion. While more than one injection activities are viable with those older structures, it's miles plenty greater tough and luxurious to achieve.

- Lower gasoline pump height torque necessities.

- As excessive velocity direct injection (HSDI) engines developed, greater of the power to combine the air with gasoline got here from the gasoline spray momentum in preference to the swirl mechanisms hired in older, IDI combustion structures.

- Only excessive strain gasoline injection structures had been capable of offer the combination power and appropriate spray practice wanted for low PM and HC emissions.

- To generate the power required to inject the gasoline in about 1 millisecond, the traditional distributor pump could ought to offer almost 1 kW of hydraulic strength in four (in a 4-cylinder engine) 1 ms bursts in line with pump revolution, accordingly setting extensive stress at the force shaft.

- One of the motives at the back of the fashion closer to not unusual place rail structures became to reduce the most pump torque requirement.

- While the strength and common torque necessities of the not unusual place rail pump had been similar, excessive strain gasoline transport is to an accumulator and accordingly the height go with the drift rate (and height torque required to force the pump) does now no longer ought to coincide with the injection occasion as is the case with the distributor

- Pump discharge go with the drift may be unfold out over an extended part of the engine cycle to hold pump torque call for greater even.

- A gasoline deliver device wherein or greater excessive-strain pumps deliver a not unusualplace manifold or rail. Timing valves decide the timing and quantity of gasoline transport to the cylinder injectors. The advantages of not unusual place rail era are smokeless operation, decrease, strong strolling speeds (right all the way down to approximately 10 rpm for 2-stroke engines) and decreased gasoline intake at element load.

- With mechanical injection structures the gasoline injection strain is a characteristic of engine velocity and engine load. When the injection strain drops at decrease loads, the gasoline droplets develop larger and there isn't sufficient time to finish combustion of those droplets. The end result is the cloud of smoke.

- Common-rail injection era gives the opportunity to keep excessive injection strain all of the manner right all the way down to idling and to achieve “ no smoke at any load”.

- The not unusual place rail is a manifold strolling alongside the period of the engine at simply under the cylinder cowl level. It affords a sure garage quantity for the gasoline oil, and has provision for damping strain waves.

- Fuel is introduced from the not unusual place rail via a separate injection manipulate unit for every engine cylinder to the same old gasoline injection valves. The manipulate gadgets adjust the timing of gasoline injection, manipulate the quantity of gasoline injected, and set the form of the injection pattern.

- The 3 gasoline injection valves in every cylinder cowl are one by one managed in order that they will be programmed to perform one by one or in unison as necessary.

References:

1. Obert E. F, “Internal Combustion Engines and Air Pollution”, Harper and Row Publication Inc. NY, 1973.

2. Heisler H, “Advanced Engine Technology”, Edward Arnold, 1995.

3. Heywood J. B, “Internal Combustion Engine Fundamentals”, McGraw Hill Book Co. NY, 1989

4. Heldt P. M, “High Speed Combustion Engines”, Oxford & IBH publishing Co. India, 1985.

5. Stockel M W, Stockel T S and Johanson C, “Auto Fundamentals”, The Goodheart, Wilcox Co. Inc., Illinois, 1996.