UNIT - 4

Fibre Optics Communication

OPTICAL FIBRE

A cable that is used to transmit the data through fibres (threads) or plastic (glass) is known as an optical fibre cable. This cable includes a pack of glass threads that transmits modulated messages over light waves.

Principle: Optical Fibre works on the principle of Total Internal Reflection.

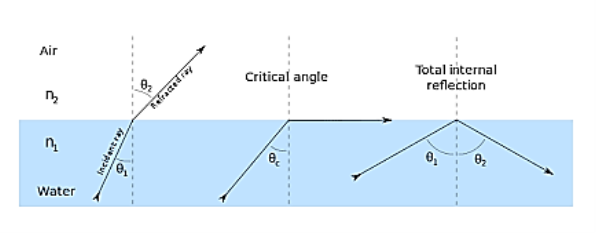

Total internal reflection:

When the light ray travels from denser medium to rarer medium the refracted ray bends away from the normal. When the angle of incidence is greater than the critical angle, the refracted ray again reflects into the same medium. This phenomenon is called total internal reflection. The refracted ray bends towards the normal as the ray travels from rarer medium to denser medium. The refracted ray bends away from the normal as it travels from denser medium to rarer medium.

|

When light passes from a medium with one index of refraction (m1), to another medium with a lower index of refraction (m2), it bends or refracts away from an imaginary line perpendicular to the surface (normal line). As the angle of the beam through m1 becomes greater with respect to the normal line, the refracted light through m2 bends further away from the line.

At one particular angle (critical angle), the refracted light will not go into m2, but instead will travel along the surface between the two media (sine [critical angle] = n2/n1 where n1 and n2 are the indices of refraction [n1 is greater than n2]). If the beam through m1 is greater than the critical angle, then the refracted beam will be reflected entirely back into m1 (total internal reflection), even though m2 may be transparent.

In physics, the critical angle is described with respect to the normal line. In fiber optics, the critical angle is described with respect to the parallel axis running down the middle of the fiber. Therefore, the fiber-optic critical angle = (90 degrees - physics critical angle).

In an optical fiber, the light travels through the core (m1, high index of refraction) by constantly reflecting from the cladding (m2, lower index of refraction) because the angle of the light is always greater than the critical angle. Light reflects from the cladding no matter what angle the fiber itself gets bent at, even if it's a full circle.

Because the cladding does not absorb any light from the core, the light wave can travel great distances. However, some of the light signal degrades within the fiber, mostly due to impurities in the glass. The extent that the signal degrades depends upon the purity of the glass and the wavelength of the transmitted light

When the angle of incidence (θ1) is progressively increased, there will be progressive increase of refractive angle (θ2). At some condition (θ1) the refractive angle (θ2) becomes 90o to the normal. When this happens the refracted light ray travels along the interface. The angle of incidence (θ1) at the point at which the refractive angle (θ1) becomes 90 degree is called the critical angle.

It is denoted by θc. The critical angle is defined as the minimum angle of incidence (θ1) at which the ray strikes the interface of two media and causes an angle of refraction (θ2) equal to 90o. Figure 1 shows critical angle refraction

Hence at critical angle θ1= θc and θ2= 90o . Using Snell‘s law: n1 sin θ1 = n2 sin θ2 n1 sin θc = n2 sin90o sin θc = n2 / n1 θc = sin-1 (n2 / n1) |

The actual value of critical angle is dependent upon combination of materials present on each side of boundary.

CHARACTERISTICS OF OPTICAL FIBRE

- It has a large bandwidth.

- The optical frequency of 2 x 1014 Hz can be used and hence the system has higher bandwidth.

- Thus optical fibres have greater information-carrying capacity due to greater bandwidth.

- In an optical fibre system transmission loss are as low as 0.1 db/km.

- Optical fibre is of small size and lightweight as compared to electrical fibre.

- Optical fibre communication is free from electromagnetic interference.

- Optical fibre does not carry high voltage and current hence they are safer than electrical cable.

- Optical Fibres are flexible and have high tensile strength. Thus, can be bent or twisted easily.

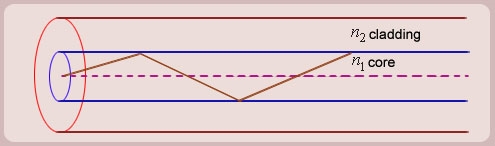

Figure 2: Optical Fibre |

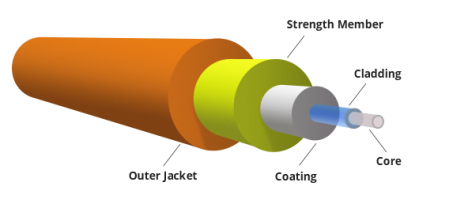

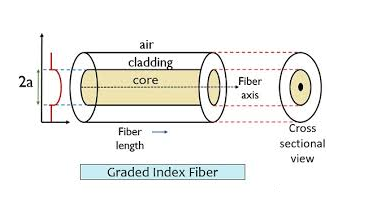

CONSTRUCTION OF OPTICAL FIBRE

It consists of a very thin fibre of silica or glass or plastic of a high refractive index called the core. The core has a diameter of 10 um to 100 um. The core is enclosed by a cover of glass or plastic called cladding. The refractive index of the cladding is less than that of the core (which is a must condition for the working of the optical fibre). The difference between the two indicates is very small of order 10-3. The core and the cladding are enclosed in an outer protective jacket made of plastic to provide strength to the optical fibre. The refractive index can change from core to cladding abruptly (as in step-index fibre) or gradually (as in graded-index fibre).

Figure 3: Representation of Optical Fibre |

WORKING OF OPTICAL FIBRE

When a ray of light is incident on the core of the optical fibre at a small angle, it suffers refraction and strikes the core-cladding interface, As the diameter of the fibre is very small hence the angle of incidence is greater than the critical angle. Therefore, the ray suffers total internal reflection at the core-cladding interface and strikes the opposite interface. At this interface also, the angle of incidence is greater than the critical angle, so it again suffers total internal reflection. Thus, the ray of light reaches the other end of the fibre after suffering repeated total internal reflections along the length of the fibre. At the other end, the ray suffers refraction and emerges out of the optical fibre.

We can see that the light travels in the core in a guided manner. Hence the communication through the optical fibre is sometimes referred to as an optical waveguide.

Fiber optics is a medium for carrying information from one point to another in the form of light. Unlike the copper form of transmission, fiber optics is not electrical in nature. A basic fiber optic system consists of a transmitting device that converts an electrical signal into a light signal, an optical fiber cable that carries the light, and a receiver that accepts the light signal and converts it back into an electrical signal. The complexity of a fiber optic system can range from very simple (i.e., local area network) to extremely sophisticated and expensive (i.e., long-distance telephone or cable television trunking).

At the transmitting source, the light signals are encoded with data, the same data you see on the screen of a computer. So, the optical fiber transmits “data” by light to a receiving end, where the light signal is decoded as data. Therefore, fiber optics is actually a transmission medium – a “pipe” to carry signals over long distances at very high speeds.

Fiber optic data transmission systems send information over fiber by turning electronic signals into light. Light refers to more than the portion of the electromagnetic spectrum that is near to what is visible to the human eye. The electromagnetic spectrum is composed of visible and near-infrared light like that transmitted by fiber, and all other wavelengths used to transmit signals such as AM and FM radio and television. Only a very small part of it is perceived by the human eye as light.

Optical fibres have largely replaced copper wire communications in core networks in the developed world, because of its advantages over electrical transmission. Here are the main advantages of fiber optic transmission

1. Enormous Bandwidth

2. Low Transmission Loss

3. Electric Isolation

4. Signal Security

5. Small Size and Less Weight

6. Immunity Cross Talk

1. Enormous bandwidth: The information-carrying capacity of a transmission system is directly proportional to the frequency of the transmitted signals. In the coaxial cable transmission, the bandwidth range is up to around 500MHz only. Whereas in optical fibre communication, the bandwidth range is large as 105 GHz.

2. Low transmission loss: The transmission loss is very low in optical fibres (i.e.KmdB/2.0) than compare with the conventional communication system. Hence for long-distance communication fibres are preferred.

3. Electric isolation: Since fibre optic materials are insulators, they do not exhibit earth and interface problems. Hence communicate through fibre even in an electrical dangerous environment.

4. Signal security: The transmitted signal through the fibre does not radiate, unlike the copper cables, a transmitted signal cannot be drawn from fibre without tampering with it. Thus, the optical fibre communication provides 100% signal security.

5. Small size and less weight: The size of the fibre ranges from 10μm to 50μm, which is very small. The space occupied by the fibre cable is negligibly small compared to conventional electrical cables. Optical fibres are light in weight.

6. Immunity cross-talk: Since the optical fibres are dielectric waveguides, they are free from any electromagnetic interference and radio frequency interference. Since optical interference among different fibres is not possible, cross talk is negligible even many fibres are cabled together.

Disadvantages of Optical Fibre

The disadvantages of optical fibre include the following

- The main disadvantages of these cables are installation is expensive and difficult to fix together.

- The optical fibre cables are very difficult to merge & there will be a loss of the beam within the cable while scattering.

- Fibre optic cables are compact and highly vulnerable while fitting

- These cables are more delicate than copper wires.

- Special devices are needed to check the transmission of fibre cables.

Key Takeaways

- A cable that is used to transmit the data through fibres (threads) or plastic (glass) is known as an optical fibre cable. This cable includes a pack of glass threads that transmits modulated messages over light waves.

- Principle: Optical Fibre works on the principle of Total Internal Reflection.

- It consists of a very thin fibre of silica or glass or plastic of a high refractive index called the core. The core has a diameter of 10 um to 100 um.

- The core is enclosed by a cover of glass or plastic called cladding. The refractive index of the cladding is less than that of the core.

- The core and the cladding are enclosed in an outer protective jacket made of plastic to provide strength to the optical fibre.

- Light propagates inside an optical fiber by virtue of multiple TIRs at the core-cladding interface.

- The refractive index of the core glass is greater than that of the cladding.

OPTICAL FIBRE AS A DIELECTRIC WAVE GUIDE

Light propagates inside an optical fiber by virtue of multiple TIRs at the core-cladding interface. The refractive index of the core glass is greater than that of the cladding. This meets the first condition for a TIR. All the light energy that is launched into the optical fiber through its tip does not get guided along the fiber. Only those light rays propagate through the fiber which is launched into the fiber at such an angle that the refracted ray inside the core of the optical fiber is incident on the core-cladding interface at an angle greater than the critical angle of the core with respect to the cladding.

1. Optical fiber is basically a solid glass rod. The diameter of rod is so small that it looks like a fiber.

2. Optical fiber is a dielectric waveguide. The light travels like an electromagnetic wave inside the waveguide. The dielectric waveguide is different from a metallic waveguide which is used at microwave and millimeter wave frequencies.

3. In a metallic waveguide, there is a complete shielding of electromagnetic radiation but in an optical fiber the electromagnetic radiation is not just confined inside the fiber but also extends outside the fiber.

4. The light gets guided inside the structure, through the basic phenomenon of total internal reflection.

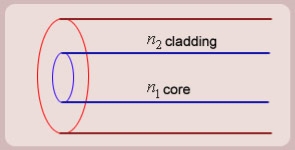

5. The optical fiber consists of two concentric cylinders; the inside solid cylinder is called the core and the surrounding shell is called the cladding. (See Fig 12)

Figure 4: Schematic of an optical fiber |

6. For the light to propagate inside the fiber through total internal reflections at core-cladding interface, the refractive index of the core must be greater than the refractive index of the cladding. That is n1>n2.

SIMPLE RAY MODEL

|

Figure 5: (optical fiber with core, cladding and total internally reflected ray)

For propagation of light inside the core there are two possibilities.

1. A light ray is launched in a plane containing the axis of the fiber. We can then see the light ray after total internal reflection travels in the same plane i.e., the ray is confined to the plane in which it was launched and never leave the plane. In this situation the rays will always cross the axis of the fiber. These are called the Meridional rays.

2. The other possibility is that the ray is not launched in a plane containing the axis of the fiber.

For example, if the ray is launched at some angle such that it does not intersect the axis of the fiber, then after total internal reflection it will go to some other plane. We can see that in this situation the ray will never intersect the axis of the fiber. The ray essentially will spiral around the axis of fiber. These rays are called the Skew rays.

So it can be concluded that if the light is to propagate inside an optical fiber it could be through two types of rays

a) Meridional rays: The rays which always pass through the axis of fiber giving high optical intensity at the center of the core of the fiber.

b) Skew Rays: The rays which never intersect the axis of the fiber, giving low optical intensity at the center and high intensity towards the rim of the fiber.

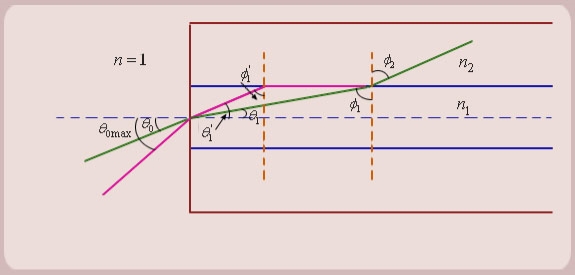

Propagation of Meridional Rays

Propagation of Meridional Rays

Figure 6: Propagation of Meridional Rays |

- Let us consider figure 6. A ray is launched from outside (air) at an angle θ0 , from the axis of the fiber.

The question is, under what conditions the ray is ultimately guided inside the core due to total internal reflections at the core cladding boundary.

2. Let the ray makes an angle θ1 with the axis of the fiber inside the core, and let the ray make an angle ϕ1 with core -cladding interface. Let ϕ2 be the angle of refraction in the cladding.

If ϕ1 < critical angle the ray is refracted in cladding. The ray which goes to cladding is lost and is not useful for communication. The ray which is confined to the core is useful for optical communication.

3. Now as we increase the launching angle θ0, the angle θ1 also increases. Since θ1 + ϕ1 =

ϕ1 decreases and at some point becomes less than the critical angle. When ϕ1 equals the critical angle, ϕ2 equals

|

4. Let us apply Snell’s law at the launching point and at the core-cladding interface for the maximum launching angle θ0max.

For this case let θ1 = θ’1 and ϕ1 = ϕ’1 we then have

|

now,

|

So, the sine of the maximum angle at which the ray will be guided inside the fiber is given by square root of the difference of squares of the refractive indices of the core and cladding. The quantity is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber.

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber.

Key Takeaways

- Optical fiber is a dielectric waveguide. The light travels like an electromagnetic wave inside the waveguide.

- If the light is to propagate inside an optical fiber it could be through two types of rays; Meridional rays and Skew Rays.

- The quantity

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber. It is given by NA = ( n12- n22 )1/2

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber. It is given by NA = ( n12- n22 )1/2

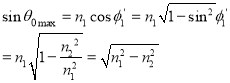

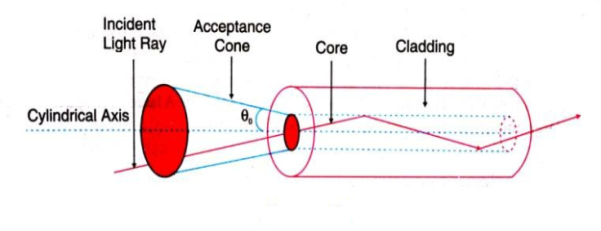

ACCEPTANCE ANGLE

Definition: Acceptance angle is defined as the maximum angle of incidence at the interface of air medium and core medium for which the light ray enters into the core and travels along with the interface of core and cladding.

Let n0 be the refractive indices of air

n1 be the refractive indices of core

n2 be the refractive indices of cladding

Let a light ray OA is an incident on the interface of air medium and core medium with an angle of incidence θ0

The light ray refracts into the core medium with an angle of refraction θ1 and the refracted ray AB is again incident on the interface of core and cladding with an angle of the incident (90- θ1)

If (90- θ1) is equal to the critical angle of core and cladding media then the ray travels along with the interface of core and cladding along the path BC. If the angle of the incident at the interface of air and core θ1< θ0 then (90- θ1) will be greater than the critical angle. Therefore,

The total internal reflection takes place.

According to Snell’s law at point A

n0 Sin θ0 = n1 Sin θ1 Sin θ0= (n1 / n0) Sin θ1 ………(1) According to Snell’s law at point B n1 Sin(90- θ1) = n2 Sin90 ………(2) n1 Cosθ1 = n2 as (Sin90=1) Cosθ1 = n2 /n1 Sinθ1 = (1-Cos2 θ1)1/2 Sinθ1= (1- (n2 /n1)2)1/2 Sinθ1= ( n12- n22 )1/2/ n1 ………(3) We know Sin θ0= (n1 / n0) Sin θ1 from equation (1) Substitute the value of Sinθ1 from equation (3) Sinθ0= (n1 / n0) *( n12- n22 )1/2/ n1 On simplification Sinθ0= ( n12- n22 )1/2/ n0 θ0=Sin-1 ( n12- n22 )1/2/ n0 Acceptance Angle is θ0=Sin-1 ( n12- n22 )1/2/ n0 ………(4) |

ACCEPTANCE CONE

Figure 8: Acceptance cone |

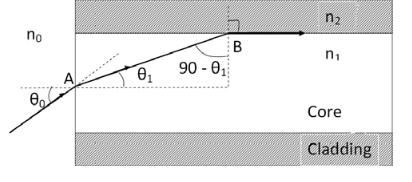

NUMERICAL APERTURE

NA = Sin(acceptance angle) NA = Sin {Sin-1 (( n12- n22 )1/2/ n0)} from equation (4) NA = (( n12- n22 )1/2/ n0) ………(5) If the refractive index of the air medium is unity i.e. n0=1 put in (5) NA = ( n12- n22 )1/2 ………(6) |

Fractional change in refractive index

∆= (n1- n2)/ n1 n1∆ = (n1- n2) ………(7) from equation (6), we have NA = {( n1- n2 )( n1+n2 )}1/2 NA = { n1∆ (n1+n2 )}1/2 as n1∆ = (n1- n2) by Eq(7) NA = { n1∆ 2n1}1/2 n1 ≈ n2, so n1+n2 =2n1 NA = n1{2∆}1/2 This gives the relation between Numerical aperture and Fractional change in refractive index. |

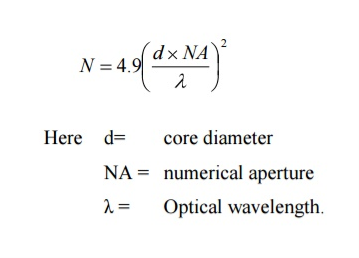

NORMALIZED FREQUENCY Or V-NUMBER

An optical fibre is characterized by one more important parameter, known as V-number which is more generally called normalized frequency of the fibre. It is given by the relation

V – number determines how many modes a fiber can support, It is given by, V = Where d is the diameter of the core, l is the wavelength of light used NA is the numerical aperture of the fibre. V = Or V = If V ≤ 2.405, then the fibre is single mode fibre (SMF)

If V > 2.405, then the fibre is multimode fibre (MMF) |

Example: Consider a multimode step index fibre with n1 = 1.53 and n2 = 1.50 and λ= 1μm. If the core radius = 50 μm then calculate the normalized frequency of the fibre (V) and the number of guided mode.

Solution:

d = 2r = 2 x 50 x 10-6 m V = =94.72= normalized frequency Total number of guided mode = M = V2/2 = 4486. |

Key Takeaways

- Acceptance angle is defined as the maximum angle of incidence at the interface of air medium and core medium for which the light ray enters into the core and travels along with the interface of core and cladding.

- Acceptance Angle is given by θ0=Sin-1 ( n12- n22 )1/2/ n0

- In three dimensions, the light rays contained within the cone having a full angle 2θ0 are accepted and transmitted along with the fibre. Therefore, the cone is called the acceptance cone.

- Numerical aperture is defined as the light gathering capacity of an optical fibre and it is directly proportional to the acceptance angle. Numerically it is equal to the sin of the acceptance angle.

- Numerical aperture is given by NA = n1{2∆}1/2

- V Number is given by V =

NA

NA

One of the important properties of optical fiber is signal attenuation. It is also known as fiber loss or signal loss. The signal attenuation of fiber determines the maximum distance between transmitter and receiver. The attenuation also determines the number of repeaters required, maintaining repeater is a costly affair. Another important property of optical fiber is distortion mechanism. As the signal pulse travels along the fiber length it becomes more broader. After sufficient length the broad pulses starts overlapping with adjacent pulses. This creates error in the receiver. Hence the distortion limits the information carrying capacity of fiber.

Attenuation in Optical Fibres

- Attenuation is a measure of decay of signal strength or loss of light power that occurs as light pulses propagate through the length of the fibre

- In optical fibres the attenuation is mainly caused by two physical factors absorption and scattering losses. Absorption is because of fibre material and scattering due to structural imperfection within the fibre.

- Nearly 90 % of total attenuation is caused by Rayleigh scattering only. Micro bending of optical fibre also contributes to the attenuation of signal.

- The rate at which light is absorbed is dependent on the wavelength of the light and the characteristics of particular glass. Glass is a silicon compound; by adding different additional chemicals to the basic silicon dioxide the optical properties of the glass can be changed.

- The Rayleigh scattering is wavelength dependent and reduces rapidly as the wavelength of the incident radiation increases.

- The attenuation of fibre is governed by the materials from which it is fabricated, the manufacturing process and the refractive index profile chosen.

- Attenuation loss is measured in dB/km.

As attenuation leads to a loss of power along the fibre, the output power is significantly less than the couples power. Let the couples optical power is P(0) i.e. at origin (z =0).Then the power at distance z is given by,

P(z) = P(0)

Where, αp is fibre attenuation constant (per km).

αp =  ln

ln

αp (dB/km ) = 10.  log

log

αp (dB/km ) = 4.343 αp/km

This parameter is known as fibre loss or fibre attenuation. Attenuation is also a function of wavelength.

Example: When mean optical power launched into an 8 km length of fibre is 12 μW, the mean optical power at the fibre output is 3 μW. Determine

Overall signal attenuation in dB.

The overall signal attenuation for a 10 km optical link using the same fibre with splices at 1 km intervals, each giving an attenuation of 1 dB.

Solution:

Given :z=8km

P(0) = 120 μW

P(z) = 3 μW

a) Overall attenuation is given by,

αp (dB/km ) = 10. log

b) Overall attenuation for 10 km, Attenuation per km = αp (dB/km ) = = Attenuation in 10 km link = 2.00 x 10 = 20 dB In 10 km link there will be 9 splices at 1 km interval. Each splices introducing attenuation of 1 dB. Total attenuation = 20 dB + 9 dB = 29 dB

|

Losses in optical fiber:

- Absorption loss

- Scattering loss

- Radiative loss or Bending loss

- Dispersion loss

1. Absorption:

Absorption loss is because of the material composition and fabrication process of fiber. Absorption loss results in dissipation of some optical power as hear in the fiber cable. Although glass fibers are extremely pure, some impurities still remain as residue after purification. The amount of absorption by these impurities depends on their concentration and light wavelength.

Usually, absorption of light occurs due to imperfections of the atomic structure such as missing molecules, (OH-), hydroxyl ions, high density cluster of atoms etc., which absorbs light.

a. Intrinsic absorption: Intrinsic absorption in the ultraviolet region is caused by electronic absorption bands. Basically, absorption occurs when a light particle (photon) interacts with an electron and excites it to a higher energy level. The main cause of intrinsic absorption in the infrared region is the characteristic vibration frequency of atomic bonds. In silica glass, absorption is caused by the vibration of silicon-oxygen (Si-O) bonds. The interaction between the vibrating bond and the electromagnetic field of the optical signal causes intrinsic absorption. Light energy is transferred from the electromagnetic field to the bond.

b. Extrinsic absorption: Extrinsic absorption is much more significant than intrinsic Caused by impurities introduced into the fiber material during manufacture – Iron, nickel, and chromium Caused by transition of metal ions to higher energy level. Modern fabrication techniques can reduce impurity levels.

2. Scattering:

Basically, scattering losses are caused by the interaction of light with density fluctuations within a fiber. Density changes are produced when optical fibers are manufactured.

a) Linear Scattering Losses: Linear scattering occurs when optical energy is transferred from the dominant mode of operation to adjacent modes. It is proportional to the input optical power injected into the dominant mode. Scattering is also a wavelength dependent loss, which occurs inside the fibers. Since the glass is used in fabrication of fibers, the disordered structure of glass will make some variations in the refractive index inside the fiber. As a result, if light is passed through the atoms in the fiber, a portion of light is scattered (elastic scattering). This type of scattering is called Raleigh scattering. Linear scattering is divided into two categories: Mie scattering and Rayleigh scattering.

|

b) Non- Linear Scattering Losses: Scattering loss in a fiber also occurs due to fiber non-linearity’s i.e. if the optical power at the output of the fiber does not change proportionately with the power change at the input of the fiber, the optical fiber is said to be operating in the non-linear mode. Non- Linear scattering is divided into two categories: Stimulated Raman Scattering and Stimulated Brillouin Scattering.

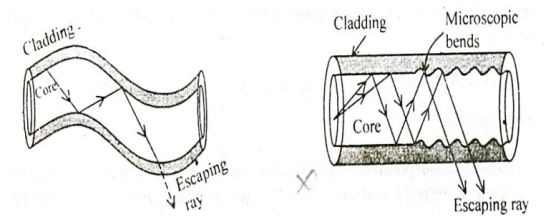

3. Radiative loss or Bending loss

Radiative losses also called bending losses. Radiative loss occur when the fibre is curved. Radiative loss occurs in fibers due to bending of finite radius of curvature in optical fibers. The types of bends are

a) Macroscopic bends

b) Microscopic bends

a. Macroscopic bends: If the radius of the core is large compared to fiber diameter, it may cause large-curvature at the position where the fiber cable turns at the corner. At these corners the light will not satisfy the condition for total internal reflection and hence it escapes out from the fiber. This is called as macroscopic / macro bending losses. Also note that this loss is negligible for small bends.

Figure 9: Bending loss

|

b. Microscopic bends: Micro-bends losses are caused due to non-uniformities or micro bends inside the fiber as shown. This micro bends in fiber appears due to non-uniform pressures created during the cabling of the fiber or even during the manufacturing itself. This lead to loss of light by leakage through the fiber.

4. Dispersion Loss

Dispersion: A light pulse launched into a fibre decreases in the fibre. It also spreads during its travel. The pulse received at the output is wider than input pulse.

It means that the pulse becomes distorted as it is propagated through the fibre. Such a distortion arises due to dispersion effects.

Dispersion is typically measured in Nano seconds per kilometre (ns/km).

There are three mechanisms which contribute to the distortion of the light pulse in a fibre. They are known as:

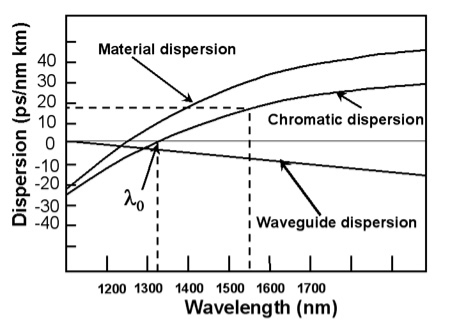

a) Material dispersion

b) Wave guide dispersion

c) Chromatic Dispersion

d) Modal Dispersion

a) Material Dispersion

Material dispersion is also called as chromatic dispersion. Material dispersion exists due to change in index of refraction for different wavelengths. A light ray contains components of various wavelengths. The time delay is different for different wavelength components. This results in time dispersion of pulse at the receiving end of fibre.

Light waves of different wavelengths travel at different speeds in a medium. The short wavelength waves travel slower than long wavelength waves. Consequently, narrow pulses of light tend to broaden as they travel down the optical fibre. This is known as material dispersion.

The material dispersion for unit length (L = 1) is given by

D =

Where c = Light velocity

λ = Center wavelength

= Second derivative of index of refraction w.r.t wavelength.

= Second derivative of index of refraction w.r.t wavelength.

Negative sign shows that the upper sideband signal (lowest wavelength) arrives before the lower sideband (highest wavelength).

The unit of dispersion is : ps/nm/km. The amount of material dispersion depends upon the chemical composition of glass.

Example: An LED operating at 850 nm has a spectral width of 45 nm. What is the pulse spreading in ns/km due to material dispersion?

Solution:

Given: λ = 850 nm σ = 45 nm R.M.S pulse broadening due to material dispersion is given by, σm= σLM Considering length L = 1 metre Dmat = For LED source operating at 850 nm, M = M = 9.8 ps/nm/km σm= 441 ns/km

|

b) Waveguide Dispersion

- Waveguide dispersion is caused by the difference in the index of refraction between the core and cladding, resulting in a ‘drag’ effect between the core and cladding portions of the power.

- Waveguide dispersion is significant only in fibres carrying fewer than 5-10 modes. Since multimode optical fibres carry hundreds of modes, they will not have observable waveguide dispersion.

- The group delay (τwg) arising due to waveguide dispersion.

τwg =  [ n2 +n2 ∆

[ n2 +n2 ∆  ]

]

Where, b = Normalized propagation

constant k = 2π / λ (group velocity)

Normalized frequency V,

V = ka

τwg =  [ n2 +n2 ∆

[ n2 +n2 ∆  ]

]

The second term  is waveguide dispersion and is mode dependent term.

is waveguide dispersion and is mode dependent term.

As frequency is a function of wavelength, the group velocity of the energy varies with frequency. This produces additional losses (waveguide dispersion). The propagation constant (b) varies with wavelength, the causes of which are independent of material dispersion.

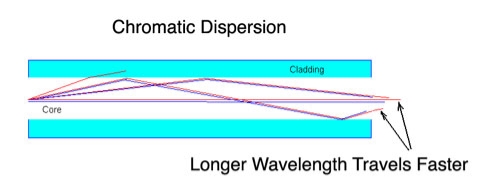

c) Chromatic Dispersion

The combination of material dispersion and waveguide dispersion is called chromatic dispersion. These losses primarily concern the spectral width of transmitter and choice of correct wavelength.

Figure 10: Chromatic Dispersion

Material dispersion and waveguide dispersion effects vary in opposite senses as the wavelength increased, but at an optimum wavelength, two effects almost cancel each other and chromatic dispersion is at minimum. Attenuation is therefore also at minimum and makes highly attractive Operating wavelength.

Figure 11: Dispersion-Wavelength variation |

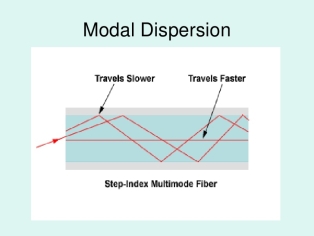

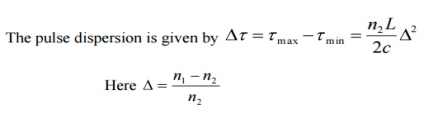

a) Modal Dispersion

As only a certain number of modes can propagate down the fibre, each of these modes carries the modulation signal and each one is incident on the boundary at a different angle, they will each have their own individual propagation times. The net effect is spreading of pulse; this form o dispersion is called modal dispersion.

Figure 12: Modal Dispersion |

- Modal dispersion takes place in multimode fibres. It is moderately present in graded index fibres and almost eliminated in single mode step index fibres.

- Modal dispersion is given by

∆tmodal =

Where ∆tmodal = Dispersion

n1= Core refractive index

Z = Total fibre length

c = Velocity of light in air.

The above equation can also be written as

∆tmodal =

The modal dispersion ∆tmodal describes the optical pulse spreading due to modal effects optical pulse width can be converted to electrical rise time through the relationship.

tr mod = 0.44 (∆tmodal)πr2

Key Takeaways

- Attenuation is a measure of decay of signal strength or loss of light power that occurs as light pulses propagate through the length of the fibre

- In optical fibres the attenuation is mainly caused by two physical factors absorption and scattering losses. Absorption is because of fibre material and scattering due to structural imperfection within the fibre.

- Nearly 90 % of total attenuation is caused by Rayleigh scattering only. Micro bending of optical fibre also contributes to the attenuation of signal.

- Losses in optical fiber can be Absorption loss, Scattering loss, Radiative loss or Bending loss, Dispersion loss.

- Absorption loss is because of the material composition and fabrication process of fiber. It can be Intrinsic absorption and Extrinsic absorption.

- Scattering losses are caused by the interaction of light with density fluctuations within a fiber. It can be Linear scattering loss and Non- Linear Scattering Losses.

- Radiative loss occurs in fibers due to bending of finite radius of curvature in optical fibers. The types of bends are Macroscopic bends and Microscopic bends.

- It means that the pulse becomes distorted as it is propagated through the fibre. Such a distortion arises due to dispersion effects.

- The pulse becomes distorted as it is propagated through the fibre. Such a distortion arises due to dispersion effects. There are three mechanisms which contribute to the distortion of the light pulse in a fibre. They are known as Material dispersion, Wave guide dispersion Chromatic Dispersion and Modal Dispersion.

The types of optical fibres depend on the refractive index, materials used, and mode of propagation of light.

The classification based on the materials used is as follows:

- Plastic Optical Fibres: The polymethylmethacrylate is used as a core material for the transmission of light.

Example:

Core: polymethyl methacrylate : Cladding: Co- Polymer

Core: Polystyrene : Cladding: Methyl methacrylate

- Glass Fibres: It consists of extremely fine glass fibres.

Example:

Core: SiO2 Cladding: SiO2

Core: GeO2- SiO2 Cladding: SiO2

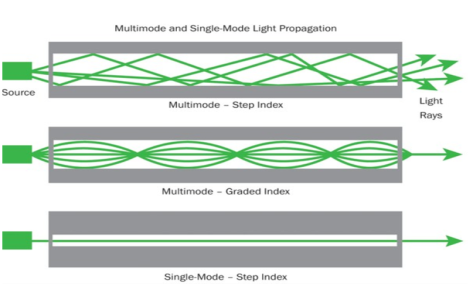

The classification based on the mode of propagation of light is as follows:

Mode of propagation:

Light propagates as electromagnetic waves through an optical fibre. All waves, having ray directions above the critical angle will be trapped within the fibre due to total internal reflection. However, all such waves do not propagate through the fibre. Only certain ray directions are allowed to propagate. The allowed directions correspond to the modes of the fibre. In simple terms, modes can be visualized as the possible number of paths of light in an optical fibre.

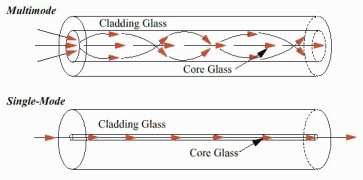

- Single-Mode Fibres:

These fibres are used for long-distance transmission of signals. In general, the single-mode fibres are step-index fibres. These types of fibres are made from doped silica. It has a very small core diameter so that it can allow only one mode of propagation and hence called single-mode fibres.

The cladding diameter must be very large compared to the core diameter. Thus in the case of single-mode fibre, the optical loss is very much reduced. The structure of a single-mode fibre is given below.

Structure: Core diameter: 5-10μm Cladding diameter: Generally around 125μm Protective layer: 250 to 1000μm Numerical aperture: 0.08 to 0.10 Bandwidth: More than 50MHz km.

|

Application:

Because of high bandwidth, they are used in long-haul communication systems.

Figure 13: Single Mode and Multimode Fibre |

- Multimode Fibres:

These fibres are used for short-distance transmission of signals. The multi-mode fibres are useful in manufacturing both for step-index and graded-index fibres. The multi-mode fibres are made by multi-component glass compounds such as Glass – Clad Glass, Silica – Clad – Silica, doped silica, etc. Here the core diameter is very large compared to single-mode fibres, so that it can allow many modes to propagate through it and hence called Multi-mode fibres. The cladding diameter is also larger than the diameter of the single-mode fibres. The structure of the multimode fibre is as shown in the figure above.

Structure: Core diameter : 50-350μm Cladding diameter : 125μm - 500μm Protective layer : 250 to 1100μm Numerical aperture : 0.12 to 0.5 Bandwidth : Less than 50MHz km.

|

The total number of modes possible for such an electromagnetic waveguide is

|

Application:

Because of its less bandwidth, it is very useful in short-haul communication systems.

The classification based on the refractive index is as follows:

- Step Index Single-mode Fibres

It consists of a core surrounded by the cladding, which has a single uniform index of refraction. Step index-single mode fibres: A single-mode step-index fibre consists of a very thin core of uniform refractive index surrounded by a cladding of refractive index lower than that of the core. The refractive index abruptly changes at the core-cladding boundary. Light travels along a side path, i.e., along the axis only. So zero-order modes are supported by Single Mode Fibre.

Figure 14: Step Index Single-mode Fibres |

- Step index-Multimode fibres

A multimode step-index fibre consists of a core of uniform refractive index surrounded by a cladding of refractive index lower than that of the core. The refractive index abruptly changes at the core-cladding boundary. The core is of large diameter. Light follows zigzag paths inside the fibre. Many such zigzag paths of propagation are permitted in Multi-Mode Fibre. The Numerical Aperture of a Multi-mode fibre is larger as the core diameter of the fibre is larger

Figure 15: Step index-Multimode fibres |

- Graded Index Fibres:

The refractive index of the optical fibre decreases as the radial distance from the fibre axis increases. GRIN fibre is one in which the refractive index varies radially, decreasing continuously in a parabolic manner from the maximum value of n1, at the center of the core to a constant value of n2 at the core-cladding interface.

In graded-index fibre, light rays travel at different speeds in different parts of the fibre because the refractive index varies throughout the fibre. Near the outer edge, the refractive index is lower. As a result, rays near the outer edge travel faster than the rays at the center of the core. Because of this, rays arrive at the end of the fibre at approximately the same time. In effect light rays that arrive at the end of the fibre are continuously refocused as they travel down the fibre. All rays take the same amount of time in traversing the fibre. This leads to small pulse dispersion.

Figure 16: Graded Index Fibres |

|

For a parabolic index fibre, the pulse dispersion is reduced by a factor of about 200 in comparison to step-index fibre. It is because of this reason that first and second-generation optical communication systems used near parabolic index fibres.

Key Takeaways

- The types of optical fibres depend on the refractive index, materials used, and mode of propagation of light.

- The classification based on the materials is of two type plastic optical fibres and glass fibres.

- The classification based on the mode of propagation is of two type single mode fibre and multimode fibre.

- The classification based on the refractive index is of three types step index single mode fibre, step index multimode fibre and graded index fibre.

Optical fibres are extensively used in a communication system.

Optical fibres are in the exchange of information between different computers

Optical fibres are used in pressure sensors in biomedical and engine control.

Reference Books

- Fundamentals of optics-Jenkins and White. McGraw Hill Publication

- A Text Book of Optics Subrahmanyam, BrijIal, S. Chand Publication

- Optics by Ajay Ghatak

- Engineering physics - Avadhanalu and Kshirsagar, S.Chand Publication