UNIT-4

Chemical Fuels

A fuel is a material which can react with other substance to release energy in the form of heat energy, the energy is otherwise used to do work. Initially this concept was applied only to those materials that are able to produce chemical energy, but has now applied to other sources of heat energy like nuclear energy.

Fuels release heat energy that is converted to mechanical energy through heat engine, during other times the heat energy for cooking or for industry processes, or the illumination that comes from combustion. The fuels are also used in cell organisms in a process called cellular respiration, where oxidation of organic molecules occur to release energy. The most source of fuel used by humans are hydrocarbons and related oxygen molecules, but other substances are also utilised, including radioactive metals.

Definition

Coal, is nothing but the primary fossil fuel, that is rich in carbon, coal is usually black or brown in colour, and occur in stratified sedimentary deposits

Chemical fuels, by a process called combustion react with substances around them to release energy. The chemical energy produced during combustion is not stored in the chemical bonds of the fuel but is stored in the weak double bond of molecular oxygen.

Chemical fuels are divided in two ways. First, based on their physical properties, as a solid, liquid or gas. Secondly, on the basis of their occurrence: primary (natural fuel) and secondary (artificial fuel). Thus, a general classification of chemical fuels is:

General types of chemical fuels | ||

| Primary (natural) | Secondary (artificial) |

Solid fuels | Coal, peat, dung wood etc. | Coke and charcoal |

Liquid fuels | Petroleum | Diesel, ethanol, naphtha, diesel tar, coal gasoline, kerosene |

Gaseous fuels | Natural gas | Coke, gas. CNG, propane, methane water gas. Hydrogen, oven gas, coal gas. |

Solid fuel refers to different types of solid material that are used as fuel to produce energy and provide heating, that is released by combustion., Solid fuels include fuel tablets, wood, charcoal, peat and pellets made from wood, rye, grains, wheat. Solid rocket fuel technology also uses solid fuel. Solid fuels have been used by humanity for many years to create fire

Liquid fuels need to take the shape of the container; the fumes of liquid fuels are flammable. These fuels are combustible or energy-generating molecules that can be used to produce mechanical energy usually kinetic energy.

Most of the liquid fuels are produced from the fossil remains of the dead animals and plants when exposed to the heat and pressure inside the Earth’s crust, there are however other types of liquid fuels like hydrogen fuel, jet fuel, ethanol and bio-diesel.

Fuel gas is in gaseous form under ordinary conditions, many fuels are composed of hydrocarbons (like methane and propane) carbon monoxide, hydrogen or may exist in the form of mixtures. Gaseous fuels are potential sources of heat and light energy. And can be distributed and transmitted through pipes from the beginning to directly to the place of consumption. Fuel gas is contrasted with solid and liquid fuels, though some fuel gases are liquefied for storage purposes

Requirements of a good fuel

- A fuel that is readily available is an ideal fuel

- A good fuel is cheap and not very expensive e.

- They burn easily in the air at a moderate rate

- Good fuels release large amount of energy.

- The fuel should not leave any residual substances which are undesirable and harmful to us.

- The fuel should be environment friendly and not affect the environment adversely.

Calorific Value

It is the heat liberated by the combustion of the fuel, the heat required to evaporate the water should be neglected, is called the High Calorific value. It is the maximum heat liberated by complete combustion of fuel; HCV is also called gross calorific value.

If we subtract from the higher calorific value, an amount of heat required to evaporate the water formed, we get Lower Calorific Value (LCV) or Net Calorific Value (LCV) or Net Calorific Value of the fuel.

No definite agreement is to be found in the literature on fuel as to whether the lower calorific value shall be found simply by subtracting latent heat of steam or both the latent heat and sensible heat in cooling from 100°C, from the gross calorific value of the fuel; in the latter case fixing the temperature becomes mandatory to which the products are finally reduced. In literature the net calorific value of the fuel is obtained by subtracting from higher calorific value the amount 2466 kJ/kg (latent heat of dry and saturated steam at STP (15°C) conditions) (amount of water formed because of the combustion of 1 kg fuel.)

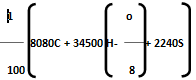

Theoretical Calculation of Calorific Value Using Dulong’s formula

The calorific value of a fuel can be theoretically determined by using Dulong’s formula. It is assumed that heat evolved comes from the combustion of carbon, hydrogen, and sulphur present in the fuel. The total heat evolved is equal of heat evolved by the combustion of individual constituent’s present.

The calorific value of hydrogen = 34500 Cal/gm.

Calorific value of carbon = 8080 Cal/gm

Calorific value of sulphur = 2240 Cal/gm.

Then, Dulong’s formula is HCV =

|

Where, C, H, O, S are percentage fractional weight of carbon, hydrogen, oxygen and sulphur respectively obtained from the analysis of 1 gm of the fuel.

|

represents the available hydrogen.

It is assumed that oxygen present in fuel combines with hydrogen to form water. 8 parts by weight of oxygen combines with one part by weight of hydrogen, to form water. So actual heating value of hydrogen is obtained by above expression.

A sample of coal has following composition by mass C = 70 %, O = 8 %, H = 10 %, N = 3 %, S = 2%, Ash = 7 %. Calculate H.C.V. and L.C.V. using Dulong formula [Difficulty level-high]

Solution: HCV = 1/100[8080 C+34500(H-O/8) +2240 S] = 1/100[8080 + 70+34500(10-8/8) +2240 X 2] = 1/100 [565600 + 34500 (10-1) X 4480] = 1/100 [565600 + 310500 + 4480] = 1/100 [880580] = 8805.80kcal/kg LCV = [ HCV- 9/100 H X 587] kcal/kg = [8805.80-9/100 x 587] = [8805.80- 528.30] = 8277.80 kcal/kg

Answer: HCV/GCV = 8805.80kcal/kg

LCV/NCV = 8277.80 kcal/kg

The classification of coal is based on its ranking, that refers to the degree of coalification. The ranking of coal is determined by depth of burial and to which the coal was subjected over time, as the temperature increases, peat gets converted to lignite which is a very soft and low ranked coal.as temperature increases lignite is transformed into subbituminous coal and then into bituminous coal.at higher temperatures, that accompanies deformation intensely following the folding and faulting of the earth’s crust. The highest rank of coal is produced the Anthracites. The increase in coal corresponds to the increase in the amount of fixed carbon and decrease in the amount of moisture and other volatile material in coal. generally, the calorific (heat) value of coal is increased in ranking from lignite through bituminous coal. In addition, the terms used for various coal ranks vary from country to country.

Analysis of Coal

Coal, is nothing but the primary fossil fuel, that is rich in carbon, coal is usually black or brown in colour, and occur in stratified sedimentary deposits.

The key difference between proximate and ultimate analysis of coal is that proximate analysis is the technique used to analyse the moisture content, ash content and fixed carbon of coal whereas ultimate analysis is the technique used to analyse the chemical composition of coal.

The technique of proximate analysis involves the determination of the different compounds present in a mixture. Ultimate analysis, on the other hand, involves the determination of the number and types of different chemical elements present in a particular compound. Therefore, these two techniques are related to each other.

Proximate analysis of coal is the process of determining the presence of different compounds and their amounts in coal. The technique of proximate analysis was developed by Henneberg and Stohmann (German scientists) in 1860. This analysis technique involves the partitioning of compounds into different categories depending on the chemical properties of these compounds. Mainly, there are six categories of compounds as moisture, ash, crude protein, crude lipid, crude fibre, and nitrogen-free extracts. In the process of proximate analysis of coal, the moisture content of coal, ash content of coal and the fixed carbon content of coal are determined.

The ultimate analysis of coal is the process of determining different chemical elements present in coal. This technique allows us to get more comprehensive results compared to the proximate analysis process.

In this analysis technique, we test moisture, ash, carbon, hydrogen, nitrogen, sulphur and oxygen content of the sample to determine the elemental composition of the coal sample. Therefore, each and every chemical element in the sample is analysed through chemical routes and then we can express the contents as percentages with respect to the total mass of the sample. Mostly, this analysis technique is useful in the coal and coke industry.

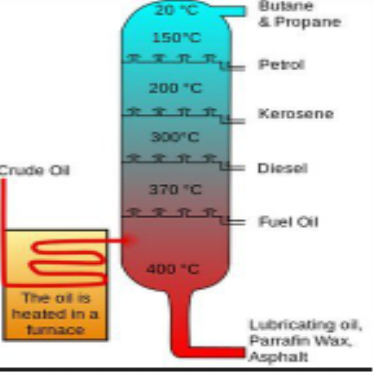

Petroleum Fractionation

Petroleum fractionation can be a single, one-time process, that is called equilibrium distillation, or a gradual, step-by-step vaporization known as fractional distillation. The fractionation process can be further distilled or rectified the vaporizing agent is the water vapour obtained on being heated whereas fractionation is carries out under atmospheric pressure or whereas the same heating temperature, the equilibrium distillation separates the fraction less precisely than fractional distillation, the yield of petroleum is more. In labs the batch fractional distillation is extensively used for rectification of the vapour phase.

The refining industry uses the combination of equilibrium distillation and rectification of the vapour and also liquid phases, this method allows the distillation of petroleum in plants that operate continuously, this combination shows a lot of accuracy in the separation and economises on the amount of fuel consumed to heat the petroleum. The use of water vapour helps in lowering the operation of temperatures and results in higher yields as well as higher concentrations of high-boiling constituents in the residue.

|

Fig; 1 Fractional Distillation of petroleum

Composition and uses of Gasoline

Gasoline is obtained as a refined product of petroleum that consists of a mixture of hydrocarbons, additives, and blending agents. Gasoline can show variation in its composition that depends on the product specifications, or the crude oils used, the refinery processes or the overall balance of the product.

The typical composition of gasoline hydrocarbons (% volume) is as follows:

4-8% alkanes; 2-5% alkenes; 25-40% isoalkanes; 3-7% cycloalkanes; l-4% cycloalkenes; and 20-50% total aromatics (0.5-2.5% benzene) (IARC 1989). To improve the stability and performance of a gasoline, to the hydrocarbon mixture is added additives and blending agents are added. These compounds include anti-rust agents, anti-icing agents anti-knock agents, anti-oxidants, metal deactivators, lead scavengers, upper-cylinder lubricants, detergents, and dyes at the end of the production process, finished gasoline typically contains more than 150 separate compounds although as many as 1,000 compounds have been identified in some blends

Uses

Gasoline is most often used in vehicles vans cars and buses, gasoline is also used in a wide range of things we use every day in our life, like leaf blowers and lawn movers and small boats. Some larger vehicles like trucks and ships use diesel instead of gasoline.

Composition of Diesel and uses

Diesel is composed of about 75% saturated hydrocarbons (primarily paraffin including n, iso, and cycloparaffins), and 25% aromatic hydrocarbons (that include naphthalene’s and alkylbenzenes). The average chemical formula for common diesel fuel is C12H23, ranging from approx. C10H20 to C15H28.

Uses

- Transportation. Diesel fuel is the most common energy source for the buses used to transport school

- Freight. According to the US Energy Information Administration, approximately 94 percent of freight shipped used diesel for its shipment.

- Construction. Diesel fuel is largely used in the construction industry for equipment’s such as forklifts, cranes.

- Agriculture- over two thirds of the tractors, cultivators, harvesters and other farm equipment use diesel.

Kerosene

Uses

- Kerosene forms the light and lamping fuel, people in villages and campers prefer kerosene lamps due to its longevity, and easy for transportation, the flame can be easily adjusted accordingly.

- Kerosene heaters don’t require electricity, it’s a versatile heating oil and easily portable.

- Kerosene I s also used as a jet fuel, it is highly combustible and meets the demand of the jet.

- Stage effects, circus performers, and other live performances that include fire use kerosene because of its low flame temperature.it is also used as an alternative for other flame sources

- As it is a derivative of petroleum, it is used as a solvent and chemical lubricant.

Cracking and its significance

The process of cracking yields light oil, middle oils that is used in diesel fuel, heavy residual oils and also solid carbonaceous product like coke etc. Gases such as methane, ethane. Ethylene, propane, propylene and butylene are also produced during cracking. The end product formed in the process can directly go into fuel blending or can be subjected to future process, until oils of desired weight are produced. The gases can be used in the refinery’s fuel system, Certain raw materials are also produced from the petrochemical plants, where a large number of end products can be obtained from them like synthetic rubber, plastic and also agricultural products.

Catalytically Cracking by moving bed method

Cracking of petroleum yields light oils at different ranges (corresponding to gasoline), the middle-range oils used in diesel fuel, and the residual heavy oils, a solid carbonaceous product known as coke, and such gases as butylene, propylene, propane ethane and methane. Based on the product that is formed the oil could go directly into blending or may further undergo cracking reactions or other refinery process, until the oils of desired weight are obtained. the gases formed can be used in the refinery, for the petrochemical plants they form an important raw material. From the raw materials huge end products are formed that range from synthetic rubber and agricultural chemicals.

An improved process of Catalytic cracking was done in 1940, the process involved using powdered catalyst or a fluidised one. During the 1950s, fuels used in automobile and jets were in much demand. Thus, hydrocracking was applied to petroleum refining. This process uses hydrogen gas to improve the hydrogen-carbon ratio in the cracked molecules and to arrive at a broader range of end products, such as gasoline, kerosene (used in jet fuel), and diesel fuel.

Knocking, this usually occurs in an internal combustion engine, where sharp sounds occurs due to the premature combustion from the part of the compressed air-fuel mixture present in the cylinder. When an engine functions smoothly in the combustion chamber, the charge burns with the flame front smoothly progressing from the point of ignition. In some cases, depending upon the composition of the fuel, at high compression ratios, some of the charge may ignite spontaneously ahead of the flame front resulting in burning in an uncontrolled manner that produces pressure waves of high frequency. The waves are responsible for forcing parts of the engine to vibrate and produce audible sound.

The effects of Knocking can cause overheating of the spark-plug points, erosion of the combustion chamber surface, and rough, inefficient operation.

Fuel rating

Octane Number and Cetane Number are the standards to measure the tendency of fuel to ignite spontaneously. The performance of gasoline is measured by the Octane number on the other hand the cetane number measures the performance of diesel. The reason why petrol can’t be used in diesel engine and diesel can’t be used in a petrol engine is that when the fuel that has high octane number will have low cetane number and high cetane number fuel has low octane number.

As per the Standard operating conditions the Octane number of a fuel defines the percentage of Iso-butene present in a mixture of Iso-octane and heptane. When used in a gasoline engine the Octane rating signifies the ability to resist auto ignition. As air and fuel are compressed together, gasoline tends to ignite a spark at the end of compression by a spark plug. If gasoline with low octane number is used it creates problems during ignition and tends to adapt to auto combustion easily due to excess of heat and pressure effects on the other hand, fuels that have high octane value takes more time to burn but provides maximum efficiency to the gasoline engine.

Cetane is a type of chemical compound known as a Hexadecane. Cetane number is opposite to octane number, and measures how quickly the engine burns inside a compressed engine. Cetane compounds tend to ignite spontaneously under compression, therefore they are assigned as cetane number of hundred. Cetane number of a fuel can be defined as the percentage volume of n-hexadecane in the mixture of n-hexadecane and 1-methylnaphthalene which is responsible to provide ignition delay period.

CNG composition and uses

Uses

- CNG burns cleaner as compared to diesel and petrol, the carbon monoxide emissions are less y 80% and shows 44% hydrocarbons are produced in vehicles that use gasoline. Natural Gas still contributes to greenhouse gas emissions, in case of leakage, CNG is not a threat as they are nontoxic and do not show any form of contamination to ground water

- CNG cars also run quieter producing less noise, thereby reducing noise pollution. than gasoline and diesel vehicles.

- Safety

CNG is less flammable that has a flammability rating of approximately 5 percent - 15 percent, and is safe compared to other fuels.

- In cases of collision CNG cylinders are safe in terms of size, structure and location, comparatively they are less dangerous than gasoline and diesel tanks. These cylinders that show higher pressure and temperature have safety devices which are designed to release the gases.

- The maintenance cost will be drastically reduced as the oil changes and tune us will be less frequent.

LPG composition and uses.

The gases propane, butane, butylene propylene and isobutane are the primary components of liquefied petroleum gas (LPG). LPG is a highly flammable, LPG is used as fuel in some automobiles, a mixture of hydrocarbons gases forms a fuel in most cooking and other household applications. Propane and butane are the active components of LPG.

- LPG is a mixture of commercial butane and commercial propane having both saturated and unsaturated hydrocarbons.

- LPG is widely used mainly in the form of cylinders across the world as fuel container in industries, agriculture, sailing, fishing and recreation. It most homes they are used to heat water for cooking, they are very economical and used efficiently in heat off grid homes.

Ignition temperature of a fuel

May cause many hazards, therefore for an ideal fuel, the ignition temperature should be higher than the room temperature.

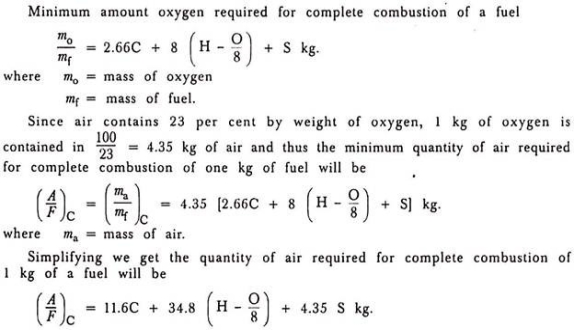

Calculation of air quantities by weight and volume required for combustion of a fuel.

The oxygen for the combustion of a fuel is to be obtained from the atmospheric air although in some cases a certain amount of oxygen is a constituent of the fuel. Air is a mixture of oxygen, nitrogen, a small amount of carbon dioxide and small traces of rare gases such as neon, argon, krypton, etc.

For all practical purposes we assume that air is made up of 23% by weight of oxygen, the remaining 77% being nitrogen. If considered by volume, air consists of 21% of oxygen and 79% of nitrogen. When we know the amount of oxygen necessary for the combustion of a fuel, we can determine the amount of air necessary for the complete combustion of one kg of fuel.

Let us consider 1 kg of a fuel, the ultimate analysis of which shows that carbon is C kg, hydrogen H kg, oxygen O kg and sulphur S kg.

1 kg of carbon requires 8/3 kg of oxygen for its complete combustion; therefore, C kg of carbon will require C x 8/3 kg of oxygen which is equivalent to 2.66C kg of oxygen (considering up to two places of decimal).

1 kg of hydrogen requires 8 kg of oxygen; therefore, H kg of hydrogen requires 8H kg of oxygen.

1 kg of sulphur requires 1 kg of oxygen; therefore, S kg of sulphur requires S kg of oxygen.

Therefore, the quantity of oxygen required for combustion of 1 kg of the fuel is:

(2.66C + 8H + S) kg.

If the fuel contains O kg of oxygen; then it is taken into account

∴ Oxygen required from air for the complete combustion of fuel will be (2.66C + 8H + S – O) which can be written as 2.66C + 8 (H – O/8) + S, the term in the bracket being known as the available hydrogen. Thus, we get the formula for determination of minimum quantity of oxygen for complete combustion of a solid or liquid fuel whose ultimate analysis is known.

The formula can be written as under:

Key Takeaway

- Chemical fuels are substances that release energy by reacting with substances around them, most notably by the process of combustion. Most of the chemical energy released in combustion was not stored in the chemical bonds of the fuel, but in the weak double bond of molecular oxygen. Most chemical fuels are found in nature in the form of crude oil, natural gas, and coal.

Reference:

- An Introduction to Coal Technology by Nobert Berkowitz

- Advanced Organic Chemistry Part B: Reaction & Synthesis Francis.A. Cary Richard J. Sundberg

- Reaction Mechanisms in Organic chemistry – Dr. Mukul Ray