UNIT-5

Green chemistry and Composites

Green chemistry also known as sustainable chemistry, is a branch of chemistry that deals with the development and design of processes and products in order to reduce or completely remove the produce of toxic substances. They are not same as the environmental chemistry. Green chemistry mainly focusses on the production of particles that are sustainable and environment friendly like non-renewable resources and methods to control the environment.

The Principles of Green Chemistry

The twelve principles illustrated in the year 1988 by the American chemists’ Paul Anastas and John Warner to lays the foundation for green chemistry are given below:

- Prevention of waste: Once the waste is generated, it is always preferred to be cleaned up thus preventing the formation of waste products.

- Avoiding the generation of hazardous chemicals: In industries the toxic and hazardous chemicals that are involved in various processes and reactions pose a threat to human health, this must be optimized to generate such toxic substances

- Atom economy: Any process when taken into consideration involves some amount of wastage. Through green chemistry all, the synthetic processes and methods need to consume and incorporate all the raw materials so that the final product is obtained with minimal wastage. This concept however has to be strictly followed

- The design of safe chemicals: when chemical products are prepared for various chemical processes care should be taken to make the chemical environmentally friendly and also nontoxic to humans.

- Design of safe auxiliaries and solvents: The use of solvents and auxiliary is a common feature in any process, however the use of these should be minimized for all process and if they are used, the usage should be less and non-hazardous in every possible way.

- Energy efficiency: The energy used for various processes should be minimised and the available energy usage should be minimal.

- Incorporation of renewable feedstock: in the processes that are involved in chemical analysis, the usage of raw materials and feedstock should be of renewable variety they must always be preferred over the non-renewable materials.

- Reduction in the generation of derivatives: The derivatives that are not necessary during process, must be minimized as they use plenty of reagents and chemicals that results in excess waste of chemicals.

- Incorporation of Catalysis: In chemical processes, the energy required for the processes and chemical reactions should be reduced and the use of chemical catalysts and catalytic reagents must be introduced.

- Designing the chemicals for degradation: Degradation of chemicals is an important feature as care has to be taken care when a chemical is being prepare for any specific fiction, they should be environmentally friendly and the chemical breaks down into nontoxic chemicals.

- Incorporating real-time analysis: The real time analysis of any product or any process should be monitored to ensure any toxic substances are produced during the process, various methodologies should be implemented that real time data is available for monitoring the process, this helps to stop and dangerous substances during any stage of the process

- Incorporation of safe chemistry for the prevention of accidents: All the chemicals prepared should be safe and should not cause any accidents during the workplace as explosion and fire can occur if the substances are not carefully prepared, chemicals used should be therefore help to develop a safer environment for the process to take place in.

The common plants used for biodiesel production is Soybean and oil palm. Microorganisms such as algae and bacteria also form sources of biodiesel, they seem promising but are economically difficult to develop Few species of algae have up to 40% lipids by weight that can be converted to synthetic petroleum or biodiesel.it is estimated that few algae and cyanobacteria yield between 10 and 100 times more fuel per unit area than plant-based biofuels.

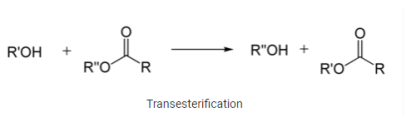

Transesterification is a reaction that is organic in nature this occurs when the R group of an alcohol is exchanged with R’ group of an ester. this usually occurs in the presence of a catalyst that may be acidic or basic to the reaction mixture. However, enzymes such as lipases which are catalytic in nature can also be used. Given below is the illustration of the reaction.

|

When the reaction takes place in the presence of an acid catalyst, the reaction proceeds through the carbonyl group by the donation of a proton. However, if a base catalyst is used a proton is taken away from the alcohol group that results in the formation of highly nucleophilic alkoxide ion.

It is important to note that the ethyl and methyl esters can be used to form esters with large alkoxy groups through the process of transesterification. This reaction occurs by heating the ester that may be methyl or ethyl in the presence of an acid or base catalyst, and the alkoxy group in alcohol, that evaporates the small amounts of alcohol in order to drive the equilibrium reaction in the required direction.

Applications of Transesterification

- They play a crucial role in the synthesis of polymer, where the di-esters and diols are subjected to transesterification to produce macromolecules.

- It is also used in recycling of plastic that helps in reducing the polyester inti its monomers.

- Triglycerides through transesterification can be used to prepare Biodiesel

- This reaction is also used in the synthesis of certain derivatives of enols. For example, vinyl ethers can be prepared from vinyl acetate via transesterification.

Carbon neutrality is a concept that deals with achieving net zero carbon dioxide emissions, this is done by balancing the emissions of carbon dioxide, done by balancing carbon dioxide emissions with removal by carbon offsetting, or by completely eliminate the emissions of carbon dioxide the concept is used in the processes involving releasing of carbon dioxide associated with carbon dioxide production and industrial processes

The emissions of carbon dioxide are balanced with carbon offsets, the process by which reduction or avoiding greenhouse gas emissions or removing carbon dioxide from the atmosphere to make up for emissions elsewhere. If the total greenhouse gasses emitted is equal to the total amount avoided or removed then the two effectively cancel each other out and the net emissions are 'neutral'.

- The carbon emissions by low carbon economy are brought down to zero by changing energy sources and industry processes. Usage of renewable energy like wind, solar, geothermal as well as nuclear power to a large extent reduces emissions.in fact both renewable and non-renewable energy produce carbon dioxide in some form or the other, it should be noticed that renewable energy shows very minimal or zero carbon emissions.

A composite material which is the short form of composite material, it’s a material formed from two or more constituents have different physical and chemical properties, when these constituents are put together, a new material is formed, that does not have the properties of the individual elements. However, the individual components remain separate and distinct within the finished structure, distinguishing composites from solids solutions and mixtures.

Composites are extremely versatile products - their benefits being:

HIGH STRENGTH TO WEIGHT RATIO

Fibre composites are extensively used because of their strong weight, therefore when these are refined, the resulting laminate characteristics can be developed. for e.g., if a common laminate of 3mm chopped strand mat is compared to a ply of 3mm, the common laminate is quite flexible, is shows a lot of bending than the ply. Therefore, stiffness can’t be mixed with strength in this case.

LIGHTWEIGHT

If a standard Fibreglass laminate is considered it has a specific gravity in the region of 1.5, when compared to Alloy of 2.7 or steel of 7.8. looking at carbon laminates, the strength is many more times than that of steel

E.g. A DVD case lid was produced using carbon fibre to reduce the case's overall weight so that it could be carried as cabin baggage

FIRE RESISTANCE

The ability for composites to withstand fire has been steadily improving over the years. There are two types of systems to be considered:

Fire Retardant – Additives such as antimony and chlorinated resins form the components of composites that are self-extinguishing, they release carbon dioxide while burning, eventually when the flame source is removed it gets self-extinguished.

Fire Resistant – they are achieved either phenolic resins, they are cured with formaldehyde and require very high temperature after curing to get real resistance.

Other materials are also available that are fire resistant. They form a blanket at the back of the laminate and also a thin fibre film giving a gel coating to the outer layer.

CHEMICAL & WEATHERING RESISTANCE

The resin used in the production of the composite material decides the weathering properties and also how they combat a vast range of chemicals. A careful selection during this step can bring about a good composite that can withstand extreme conditions, as a reason of this feature they are used in the manufacture of chemical storage tanks, pipes, chimneys and ducts, boat hulls and vehicle bodies.

COLOUR

During manufacture any colour shade can be incorporated into the product, by pigmentation of the gelcoat used. If a translucent product is required soluble dyes are used, costs are therefore reduced by no further finishing or painting.

Dark colours are however not recommended, as they form excess heat on the surface and prints of the resin matrix is seen cures more and shrinks, bringing the fibres to the surface. In extreme cases delamination can occur.

TRANSLUCENCY

Polyester resins are widely used to manufacture translucent mouldings and sheets. Light transmission of up to 85% can be achieved.

DESIGN FLEXIBILITY

Because of the versatility of composites, product design is only limited to one’s imagination.

LOW THERMAL CONDUCTIVITY

Fibreglass Developments has been involved in the development and production of specialized meat containers which maintain prime cuts of chilled meat at the correct temperature for Export markets. They are manufactured using the RTM process, with special reinforcing and foam inserts.

MANUFACTURING ECONOMY

Fibreglass Developments produces several models of fuel pump covers for Fuel quip. Fibreglass is an ideal material for producing items of this type for many reasons, including being very economical.

Composite material is a material they are composed of two or more distinct phases (matrix phase and dispersed phase) and they are also known to have significant bulk properties different from those of any of the constituents.

Matrix phase

The matrix phase is the primary phase that has a continuous character called the Matrix, this phase is less ductile and less hard, they are also known to share the load of the dispersed phase.

Dispersed (reinforcing) phase

The secondary phase is the dispersed phase, they are embedded in the matrix phase in a discontinuous manner, they are also sometimes called reinforcing phase as they are much stronger than the matrix phase.

Many of common materials like metallic alloys, ceramic that are doped and mixed polymers have minute amounts of dispersed phases in their structure. however, they do not come under composite materials as they hold properties similar to steel and iron or their basic constituents.

There are two classification systems of composite materials.

One of them is based on the matrix material (metal, ceramic, polymer) and the second is based on the material structure:

(based on matrix material)

These composites consist of a metallic matrix (aluminium, magnesium, iron etc) and a and a dispersed ceramic like oxides and carbides or metallic phase like lead, tungsten.

Ceramic Matrix Composites (CMC)

These composites consist of ceramic matrix and fibres that are embedded that belong to other ceramic material.

Polymer Matrix Composites (PMC)

These composites are composed mainly of matrix that belong to thermostat, or thermosetting polymers, PVC, nylon that are embedded in steel carbon or Kevlar fibres in dispersed phase

Applications of Composites

- Aerospace

In aviation, a large-scale application of composite material is in demand by major airbus and Boeing sectors, NASA also seeks the composite manufacturers for innovative space in spacecraft and Rockets.

- Architecture

Composites can offer value to large scale projects in terms of designing and architecture and also its use in commercial and residential places. There is substantial growth in the use of composites in the architecture field.

- Automotive

The composites help in making vehicles lighter and more efficient in terms of fuel. As the largest composites market, the automotive has adapted to the composite market, they are also useful in groundbreakingly and vehicle designs.

- Energy

The composite materials help in the usage of wind, solar power and also improve the efficiency of traditional energy supply.

- Infrastructure

Composites are used all over the world to help construct and repair a wide variety of infrastructure applications, from buildings and bridges to roads and railways.

- Marine

The hulls in marines are made lighter and also resistant to damage, Composites can be found in many more areas of a maritime vessel, including interior moldings and furniture on super yachts.

- Pipe & Tank

Fibber-reinforced polymer composite pipes are used for everything from sewer upgrades and wastewater projects to desalination, oil and gas applications. When corrosion becomes a problem with pipes made with traditional materials, FRP is a solution.

- Sports & Recreation

From football helmets and hockey sticks to kayaks and bobsleds, carbon fibre and fiberglass composite materials help athletes reach their highest performance capabilities and provide durable, lightweight equipment.

- Transportation

While CFRP in cars gets most of the attention, composites can also play a big role in increasing fuel efficiency in trucks.

Key Takeaway

Green Chemistry is at the frontiers of this continuously-evolving interdisciplinary science and publishes research that attempts to reduce the environmental impact of the chemical enterprise by developing a technology base that is inherently non-toxic to living things and the environment

Green chemistry consists of chemicals and chemical processes designed to reduce or eliminate negative environmental impacts. The use and production of these chemicals may involve reduced waste products, non-toxic components, and improved efficiency.

References:

Green Chemistry A Textbook by V.K Ahluwalia

Green Chemistry Fundamentals and Applications by Suresh.C. Ameta, Rakshit Ameta.