UNIT – 5

LASERS AND FIBER OPTICS

Introduction

LASER stands for “Light Amplification by Stimulated Emission of Radiation”.

L = Light

A = Amplification (by)

S = Stimulated

E = Emission (of)

R = Radiation

PROPERTIES OF LASER

The laser light exhibits some peculiar properties compare with the conventional light. Those are

1. Highly monochromatic

2. Highly coherence

3. Highly directionality

4. Highly intense

5. Laser Speckles

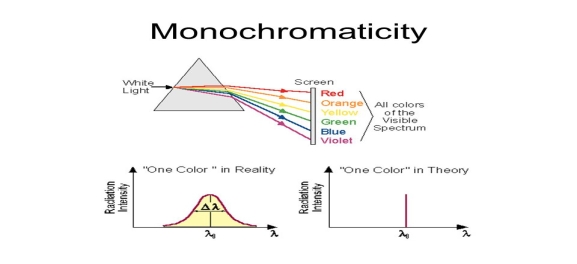

1. Highly monochromatic

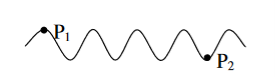

Monochromatic light means a light containing a single colour or wavelength. The photons emitted from ordinary light sources have different energies, frequencies, wavelengths, or colours. Ordinary light is a mixture of waves having different frequencies or wavelengths. The light waves of laser have a single wavelength or colour.

Figure 1: Monochromatic

Therefore, laser light covers a very narrow range of frequencies or wavelengths.

Hence The laser light is more monochromatic than that of a conventional light source. This may be due to the stimulated characteristic of laser light. The bandwidth of the conventional monochromatic light source is 1000 Å. But the bandwidth of an ordinary light source is 10 Å. For high sensitive laser source is 10-8 Å.

|

|

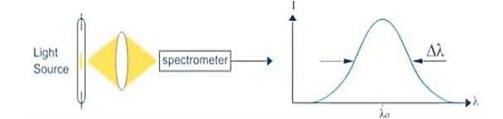

Figure 2: Intensity- wavelength graph for light and laser

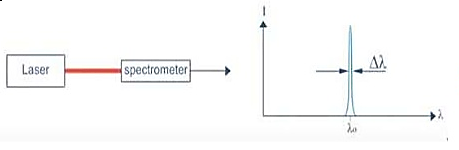

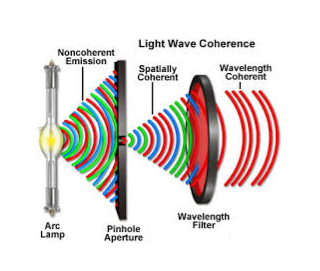

2. Highly coherence

Definition:- A predictable correlation of the amplitude and phase at any one point with another point is called coherence.

Figure 3: Incoherence and coherence

Two waves are said to be coherent, the waves must have

In the case of conventional light, the property of coherence exhibits between a source and its virtual source whereas in the case of laser the property coherence exists between any two or more light waves.

There are two types of coherence

i) Temporal coherence

Ii) Spatial coherence

Temporal coherence (or longitudinal coherence):-

The predictable correlation of amplitude and phase at one point on the wave train w. r. t another point on the same wave train, then the wave is said to be temporal coherence

To understand this, let us consider two points P1 and P2 on the same wave train, which is continuous as shown in the figure.

Figure 4: Wave train

Suppose the phase and amplitude at any one point is known, then we can easily calculate the amplitude and phase for any other point on the same wave train by using the wave equation

y= a sin ( (ct-x))

(ct-x))

Where ‘a’ is the amplitude of the wave and ‘x’ is the displacement of the wave at any instant of time‘t’.

Spatial coherence (or transverse coherence) The predictable correlation of amplitude and phase at one point on the wave train w. r. t another point on a second wave, then the waves are said to be spatial coherence (or transverse coherence)

Figure 5: Spatial coherence

3. Highly directionality

The light ray coming from an ordinary light source travels in all directions, but laser light travels in a single direction. For example, the light emitted from torchlight spreads 1km distance it spreads 1 km distance. But the laser light spreads a few centimetres distance even it travels lacks kilometre distance.

The directionality of the laser beam is expressed in terms of divergence

∆θ =

Where r1 and r2 are the radii of laser beam spots at distances of D1 and D2 respectively from the laser source.

4. Highly Intense or Brightness

We know that the intensity of a wave is the energy per unit time flowing through a unit's normal area. Laser light is highly intense than conventional light. A one mill watt He-Ne laser is highly intense than the sun intensity. This is because of the coherence and directionality of the laser. Suppose when two photons each of amplitude a are in phase with other, then young’s principle of superposition, the resultant amplitude of two photons is 2a and the intensity is 4a2. Since in laser many numbers of photons are in phase with each other, the amplitude of the resulting wave becomes na and hence the intensity of the laser is proportional to n2a2. So 1mW He-Ne laser is highly intense than the sun.

In an ordinary light source, the light spreads out uniformly in all directions. If you look at a 100 Watt lamp filament from a distance of 30 cm, the power entering your eye is less than 1/1000 of a watt. If you look at laser beam X(caution: don’t do it at home, direct laser light can damage your eyes)X, then all the power in the laser would enter your eye. Thus, even a 1 Watt laser would appear many thousand times more intense than a 100 Watt ordinary lamp.

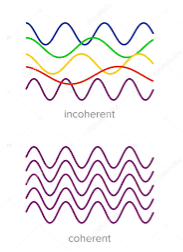

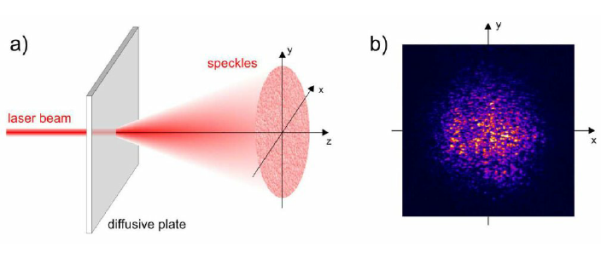

5. Laser Speckles

The term speckle refers to a random granular pattern that can be observed when a highly coherent light beam is diffusely reflected at a surface with a complicated structure. This phenomenon results from the interference of different reflected portions of the incident beam with random relative optical phases.

Figure 6: Laser Speckles

Even minor changes of the conditions, such as of the illuminated spot or the direction of the incident laser beam, can change the detailed shape of a speckle pattern.

When laser light that has been scattered off a rough surface falls on another surface, it forms an "objective speckle pattern". If a photographic plate or another 2-D optical sensor is located within the scattered light field without a lens, a speckle pattern is obtained whose characteristics depend on the geometry of the system and the wavelength of the laser.

Key Takeaways

- LASER stands for “Light Amplification by Stimulated Emission of Radiation”.

- The laser light exhibits some peculiar properties compare with the conventional light. Laser light is highly monochromatic, coherence, directionality, intense and Laser Speckles

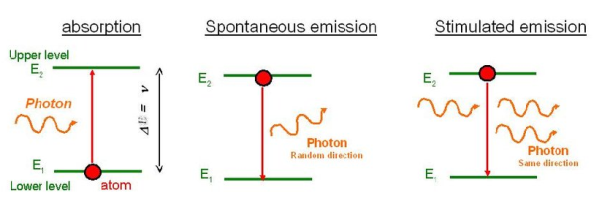

Let us discuss Einstein’s theory of the interaction of electromagnetic radiation with matter. He proposed that electromagnetic radiation interacts with matter in the following three steps.

- Stimulated Absorption

- Spontaneous Emission

- Stimulated Emission

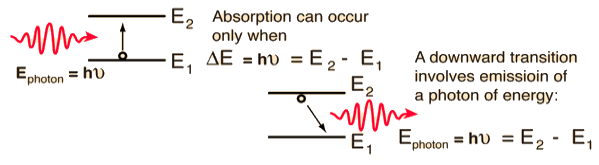

Stimulated Absorption:

Let E1 and E2 be the energies of the ground and excited states of an atom. Suppose, if a photon of energy hν= E1− E2 interacts with an atom present in the ground state, the atom gets excitation from ground state E1 to excited state E2. This process is called stimulated absorption. Stimulated absorption rate depends upon the number of atoms available in the lowest energy state as well as the energy density photons.

Stimulated absorption rate ∝ Number of atoms in the ground state

∝ The density of photons Spontaneous emission

Figure 7: Interaction of Radiation with Matter

Spontaneous Emission:

Let E1 and E2 be the energies of the ground and excited states of an atom. Suppose, if a photon of energy hν= E1− E2 interacts with an atom present in the ground state, the atom gets excitation from ground stateE1 to excited state E2. The excited atom does not stay a long time in the excited state. The excited atom gets de-excitation after its lifetime by emitting a photon of energy hν= E1− E2. This process is called spontaneous emission. Also Spontaneous means by its own. Here excited atom comes to the ground state on its own so it is named as spontaneous emission.

The spontaneous emission rate depends upon the number of atoms present in the excited state.

Spontaneous emission ∝ rate number of atoms in the excited state

Stimulated Emission:

This phenomenon is responsible for producing laser light. Let E1and E2 be the energies of the ground and excited states of an atom. Suppose, if a photon of energy hν= E1− E2 interacts with an atom present in the ground state, the atom gets excitation from ground stateE1 to excited state E2. Let, a photon of energy hν= E1− E2 interacts with the excited atom within their lifetime; the atom gets de-excitation to the ground state by emitting another photon. These photons have the same phase and it follows coherence. This phenomenon is called stimulated emission.

Stimulated emission rate depends upon the number of atoms available in the excited state as well as the energy density of photons.

Stimulated emission rate ∝ number of atoms in the excited state

∝ Density of photons

Key Takeaways

- Einstein gave his theory of the interaction of electromagnetic radiation with matter. He proposed that electromagnetic radiation interacts with matter in the following three steps. Stimulated Absorption, Spontaneous Emission and Stimulated Emission

- Stimulated absorption rate depends upon the number of atoms available in the lowest energy state as well as the energy density photons.

- The spontaneous emission rate depends upon the number of atoms present in the excited state.

- Stimulated emission rate depends upon the number of atoms available in the excited state as well as the energy density of photons.

The distribution of atoms in the two energy levels will change by absorption or emission of radiation. Einstein introduced three empirical coefficients to quantify the change of population of the two levels. Let N1 be the number of atoms per unit volume with energy E1 and N2 be the number of atoms per unit volume with energy E2. Let ‘n’ be the number of photons per unit volume at frequency ‘υ’ such that hυ= E1− E2.

Then, the energy density of photons ρ(υ) = nhυ

Figure 8: Interaction of photons with atoms

When these photons interact with atoms, both upward (absorption) and downward (emission) transition occurs.

At the equilibrium, the upward transitions must be equal to downward transitions.

Upward Transition

Stimulated absorption rate depends upon the number of atoms available in the lowest energy state as well as the energy density photons.

We have seen above that

Stimulated absorption rate ∝ N1 i.e. Number of atoms in the ground state

∝ ρ(υ) i.e. Density of photons spontaneous emission

Stimulated absorption rate = B12N1ρ(υ) ………(1)

Where B12 is the Einstein coefficient of stimulated absorption.

Downward transition

The spontaneous emission rate depends upon the number of atoms present in the excited state.

Spontaneous emission rate ∝ N2 i.e. number of atoms in the excited state

Spontaneous emission rate = A21N2 ………(2)

Where A21 is the Einstein coefficient of spontaneous emission.

Stimulated emission rate depends upon the number of atoms available in the excited state as well as the energy density of photons.

Stimulated emission rate ∝ N2 i.e. number of atoms in the excited state

∝ ρ(υ) i.e. Density of photons

Stimulated emission rate = B21N2ρ(υ) ………(3)

If the system is in equilibrium the upward transitions must be equal to downward transitions.

Upward transitions = downward transitions

B12N1ρ(υ) = A21N2 + B21N2ρ(υ) ………(4)

B12N1ρ(υ) - B21N2ρ(υ) = A21N2

(B12N1- B21N2) ρ(υ) = A21N2

ρ(υ) = ………(5)

………(5)

Divide with B21N2 in numerator and denominator in the right side of the above equation,

ρ(υ) =  =

=  ………(6)

………(6)

ρ(υ) =  =

=  =

= ………(7)

………(7)

We know from Maxwell Boltzmann distribution law

=

=  ………(8)

………(8)

And also from Planck’s law, the radiation density

ρ(υ) =  ………(9)

………(9)

Comparing the two equations (7) and (9)

=

= and

and  =1 ………(10)

=1 ………(10)

The above relations are referred to as Einstein relations.

From the above equation for non-degenerate energy levels, the stimulated emission rate is equal to the stimulated absorption rate at the equilibrium condition.

=

=  ………(11)

………(11)

Key Takeaways

- Einstein introduced three empirical coefficients to quantify the change of population of the two levels.

- At the equilibrium, the upward transitions must be equal to downward transitions.

- The Einstein relations is given as

=

= and

and  =1

=1

Definition

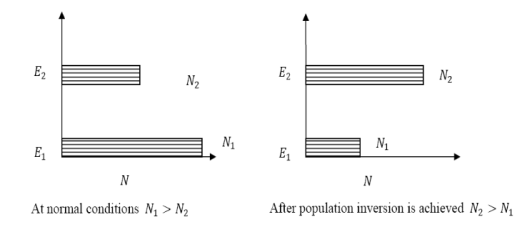

The number of atoms present in the excited state or higher energy state is greater than the number of atoms present in the ground state or lower energy state is called population inversion.

Population inversion as the name suggests that this is an inverted phenomenon. In general, the lower energy level is more populated which means it has more number atoms in the lower energy level as compared to a higher energy level. But by pumping we will obtain a state when the number of atoms present in the higher energy state is greater than the number of atoms present in the lower energy state.

Let us consider a two-level energy system of energies E1 and E2 as shown in the figure.

Let N1 and N2 be the populations that mean several atoms per unit volume of energy levels E1 and E2 respectively.

According to Boltzmann’s distribution the population of an energy level E, at temperature T is given by

Ni=N0

Where N0 is the population of the lower level or ground state and k is Boltzmann’s constant.

From the above relation, the population of energy levels E1 and E2 are

N1=N0

N2=N0

At ordinary conditions N1 >N2 i.e., the population in the ground or lower state is always greater than the population in the excited or higher states. The stage of making, the population of higher energy level is greater than the population of lower energy level is called population inversion i.e. N1 < N2

Figure 9: Population inversion

When the population inversion method is used to enforce more and more atoms to give up photons. This initiates a chain reaction and releasing a massive amount of energy.

This results in a rapid build-up of the energy of emitting one particular wavelength traveling coherently in a fixed direction. This process is called amplification by stimulated emission using population inversion.

This population inversion situation is essential for laser action. For any stimulated emission, the upper energy level or metastable state must have a long lifetime, i.e., the atoms should pause at the metastable state for more time than at the lower level.

Pumping mechanisms of population inversion

For laser action, the pumping mechanism (exciting with external source) maintain a higher population of atoms in the upper energy level relative to that in the lower level.

A system in which population inversion is achieved is called an active system. The method of raising the particles from a lower energy state to a higher energy state is called pumping.

The process of achieving population inversion is called pumping.

This can be done in several ways.

The most commonly used pumping methods are

- Optical pumping

- Electrical discharge pumping

- Chemical pumping

- Thermal Pumping

- Injection current pumping

- Inelastic Atom-Atom Collisions

Optical pumping As the name suggests, in this method, light is used to supply energy to the laser medium. Optical pumping is used in solid laser. Xenon flash tubes are used for optical pumping. Since these materials have very broadband absorption, a sufficient amount of energy is absorbed from the emission band of the flash lamp and population inversion is created. So xenon flash lamp is used to produce more electrons in the higher energy level of the laser medium.

Examples of optically pumped lasers are ruby, Nd: YAG Laser(Neodymium: Yttrium Aluminum Garnet).

Electrical discharge pumping is used in gas lasers. Since gas lasers have a very narrow absorption band pumping then any flash lamp is not possible. Electric discharge refers to the flow of electrons or electric current through a gas, liquid, or solid.

In this method of pumping, electric discharge acts as the pump source or energy source. A high voltage electric discharge (flow of electrons, electric charge, or electric current) is passed through the laser medium or gas. The intense electric field accelerates the electrons to high speeds and they collide with neutral atoms in the gas. As a result, the electrons in the lower energy state gains sufficient energy from external electrons and jumps into the higher energy state

Examples of Electrical discharge pumped lasers are He-Ne laser, CO2 laser, argon-ion laser, etc.

Chemical pumping Chemical reaction may also result in excitation and hence the creation of population inversion in a few systems.

If an atom or a molecule is produced through some chemical reaction and remains excited at the time of production, then it can be used for pumping. The hydrogen fluoride molecule is produced in an excited state when hydrogen and fluorine gas chemically combine. The number of produced excited atoms or molecules is greater than the number of normal state atoms or molecules. Thus, population inversion is achieved.

Examples H2 + F2 → 2HF, in this chemical reaction, hydrogen (H2) and fluorine (F2) molecules are chemically combined to produce hydrogen fluoride molecule (2HF) in an excited state.

Thermal Pumping: Sometimes we can achieve population inversion by heating the laser medium. In thermal pumping, heat acts as the pump source or energy source. In this method, population inversion is achieved by supplying heat into the laser medium.

When heat energy is supplied to the laser medium, the lower energy state electrons gain sufficient energy and jumps into the higher energy level.

The process of achieving population inversion in thermal pumping is almost similar to the optical pumping or electric discharge method, except that in this method heat is used as a pump source instead of light or electric discharge.

Injection current pumping In semiconductors, injection of current through the junction results in creates of population inversion among the minority charge carriers.

Examples of such systems are InP and GaAs.

Inelastic Atom-Atom Collisions: Like the electric discharge method, here also a high voltage electric discharge acts as a pump source. However, in this method, a combination of two types of gases, say X and Y are used. The excited state of gas X is represented as X+ whereas gas Y is represented as Y+. Both X and Y gases have the same excited states (X+ and Y+).

When high voltage electric discharge passes through a laser medium having two types of gases X and Y, the lower energy state electrons in gas X will move to the exciting state X+ similarly the lower energy state electrons in gas Y moves to the excited state Y+.

Initially, during electric discharge, the lower energy state electrons in gas X or atom X gets excited to X+ due to continuous collision with electrons. The excited state electrons in gas X+ now collide with the lower energy state electrons in gas Y. As a result, the lower energy state electrons in gas Y gains sufficient energy and jump into the exciting state Y+. This method is used in the Helium-Neon (He-Ne) laser.

Key Takeaways

- The number of atoms present in the excited state or higher energy state is greater than the number of atoms present in the ground state or lower energy state is called population inversion.

- The condition of population inversion is given as N1 < N2

- The population inversion results in a rapid build-up of the energy of emitting one particular wavelength traveling coherently in a fixed direction. This process is called amplification by stimulated emission using population inversion.

- For laser action, the pumping mechanism (exciting with external source) maintain a higher population of atoms in the upper energy level relative to that in the lower level.

- A system in which population inversion is achieved is called an active system. T

- The process of achieving population inversion is called pumping.

- Pumping can be done in several ways. The most commonly used pumping methods are Optical pumping, Electrical discharge pumping, Chemical pumping Thermal Pumping, Injection current pumping , Inelastic Atom-Atom Collisions

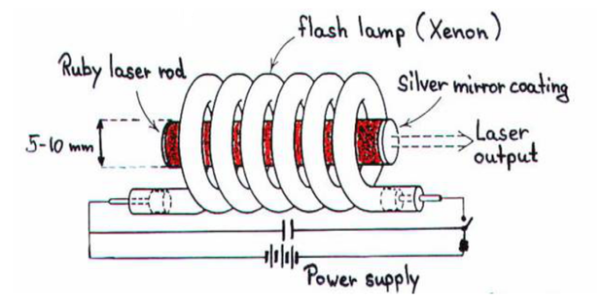

Ruby laser is a three-level solid-state laser and was constructed by Maiman in 1960. Ruby laser is one of the few solid-state lasers that produce visible light. It emits deep red light of wavelength 694.3 nm.

Construction

A ruby laser consists of three important elements: laser medium, the pump source, and the optical resonator.

Laser Medium

Ruby (Al2O3+Cr2O3) is a crystal of Aluminium oxide, in which 0.05% of Al+3 ions are replaced by the Cr+3 ions. The colour of the rod is pink. The active medium or laser medium in the ruby rod is Cr+3 ions. In ruby laser, 4cm length and 5mm diameter rod is generally used. The ruby has good thermal properties.

Figure 10: Ruby laser

The pump source

The ruby rod is surrounded by a xenon flash tube, which provides the pumping light to excite the chromium ions into upper energy levels. The ruby rod was surrounded by a helical xenon flash lamp.

We know that population inversion is required to achieve laser emission. Population inversion is the process of achieving a greater population of a higher energy state than the lower energy state. To achieve population inversion, we need to supply energy to the laser medium i.e. to ruby crystal.

Xenon flash tube emits thousands of joules of energy in few milliseconds, but only a part of that energy is utilized by the chromium ions while the rest energy heats the apparatus. A cooling arrangement is provided to keep the experimental set up at normal temperatures.

Optical resonator

Both the ends of the rods are highly polished and made strictly parallel. The ends are silvered in such a way, one becomes partially reflected the laser beam was emitted through that end and the other end fully reflected to reflect all the rays of light striking it.

Working of ruby laser:

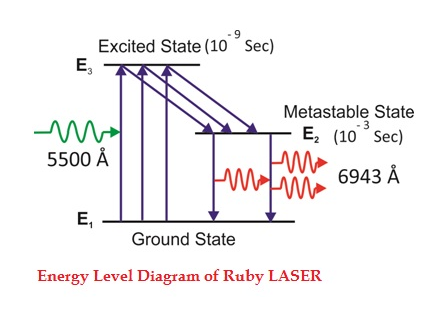

Consider a ruby laser medium consisting of three energy levels E1, E2, E3 with N number of electrons.

We assume that the energy levels will be E1 < E2 < E3. The energy level E1 is known as the ground state or lower energy state, the energy level E2 is known as the metastable state, and the energy level E3 is known as the pump state.

Let us assume that initially most of the electrons are in the lower energy state (E1) and only a tiny number of electrons are in the excited states (E2 and E3).

The energy level diagram of chromium ions is shown in the figure. The chromium ions get excitation into higher energy levels by absorbing 5500Å of wavelength radiation. The excited chromium ions stay in the level E3 for a short interval of time (10-8 to 10-9 Sec). After their life, most of the chromium ions are de-excited from E3 to E1 and a few chromium ions are de-excited from E3 to E2.

Figure 11: Energy Level diagram of ruby laser

The transition between E3 and E2 is non-radioactive i.e. the chromium ions give their energy to the lattice in the form of heat. In the Metastable state, the lifetime of chromium ions is 10-3 sec. The lifetime of chromium ions in the Metastable state is 105 times greater than the lifetime of chromium ions in a higher state.

Due to the continuous working of the flash lamp, the chromium ions are excited to a higher state E3 and returned to the E2 level. After a few milliseconds, the level E2 is more populated than the level E1 and hence the desired population inversion is achieved. The state of population inversion is not a stable one. The process of spontaneous transition is very high. When the excited chromium ion passes spontaneously from E3 to E2it emits one photon of wavelength 6943 Å. The photon reflects back and forth by the silver ends and until it stimulates an excited chromium ion in the E2 state and it to emit a fresh photon in phase with the earlier photon. The process is repeated again and again until the laser beam intensity is reached a sufficient value. When the photon beam becomes sufficiently intense, it emerges through the partially silvered end of the rod. The wavelength 6943 Å is in the red region of the visible spectrum.

Drawbacks of the ruby laser

- The laser requires high pumping power

- The efficiency of a ruby laser is very small

- It is a pulse laser

Application of ruby laser

- Ruby lasers are in optical photography

- Ruby lasers can be used for the measurement of plasma properties such as electron density and temperature.

- Ruby lasers are used to remove the melanin from the skin.

- Ruby laser can be used for the recording of holograms.

Key Takeaways

- Ruby laser is a three-level solid-state laser.

- A ruby laser consists of three important elements: laser medium, the pump source, and the optical resonator.

- Ruby laser is one of the few solid-state lasers that produce visible light. It emits deep red light of wavelength 694.3 nm.

The first He-Ne gas laser was fabricated in 1961 by Ali Javan, Bennett, and Herriott at Bell Telephone Laboratories. Others. Helium-Neon laser is a type of gas laser in which a mixture of helium and neon gas is used as a gain medium. Helium-Neon laser is also known as He-Ne laser. The helium-neon laser was the first continuous-wave laser ever constructed. The helium-neon laser operates at a wavelength of 632.8 nanometres (nm), in the red portion of the visible spectrum.

Ruby laser is a pulse laser, even it has high intense output. For continuous laser beams, gas lasers are used. Using gas lasers, we can achieve high coherence, high directionality, and high monochromaticity beam. The output power of the gas laser is generally in few milliwatts.

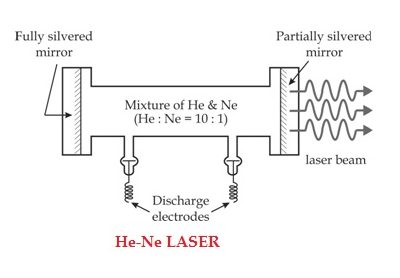

CONSTRUCTION

The helium-neon laser consists of three essential components:

- Pump source (high voltage power supply)

- Gain medium (laser glass tube or discharge glass tube)

- Resonating cavity

Pump source

The gain medium of a helium-neon laser is made up of a mixture of helium and neon gas contained in a glass tube at low pressure. In the He-Ne gas laser, the He and Ne gases are taken in the ratio 10:1 in the discharge tube.

Gain medium

In He-Ne laser 80cm length and 1cm diameter discharge are generally used. The out power of these lasers depends on the length of the discharge tube and the pressure of the gas mixture. Therefore, to achieve population inversion, we need to pump electrons from the lower energy state of the helium. In He-Ne laser, neon atoms are the active centres and have energy levels suitable for laser transitions while helium atoms help in exciting neon atoms.

Figure 12: He-Ne Laser

Resonating cavity

Two reflecting mirrors are fixed on either end of the discharge tube, in that, one is partially reflecting and the other is fully reflecting. The fully silvered mirror will completely reflect the light whereas the partially silvered mirror will reflect most of the light but allows some part of the light to produce the laser beam.

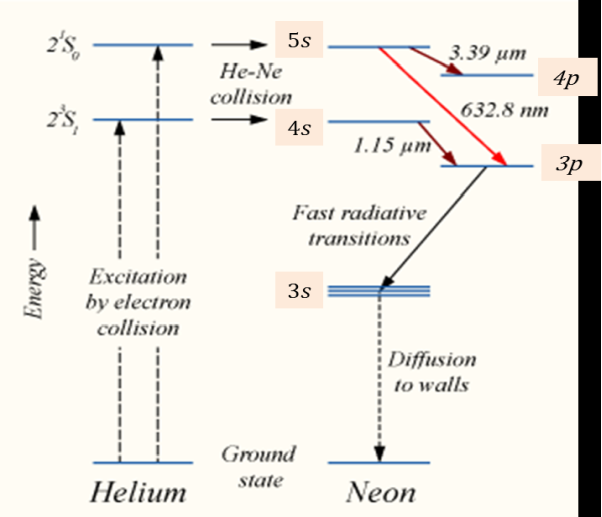

WORKING

When the electric discharge is passing through the gas mixture, the electrons accelerated towards the positive electrode. During their passage, they collide with He atoms and excite them into higher levels. 23s1 and 21s0 form the ground state of the He atom. In higher levels, 23s1 and 21s0, the lifetime of He atoms are more. So there is a maximum possibility of energy transfer between He and Ne atoms through atomic collisions. When He atoms present in the levels 23s1 and 21s0 collide with the Ne atom's present ground state, the Ne atoms get excitation into higher levels 4s and 5s.

Due to the continuous excitation of Ne atoms, we can achieve the population inversion between the higher levels 4s and 5s and lower levels 3p and 4p. The various transitions 5s to 4p, 4s to 3p, and 5s to 3p leads to the emission of wavelengths 3.93μm, 1.51μm, and 6328 Å or 632.8μm.

Figure 13: Energy Level diagram of He-Ne Laser

The first two correspondings to the infrared region while the last wavelength is corresponding to the visible region. The Ne atoms present in the 4s level are de-excited into 3s level, by spontaneously emitting a photon of around wavelength 6000 Å. When a narrow discharge tube is used, the Ne atoms present in the level 3s collide with the walls of the tube and get de-excited to the ground state energy level.

ADVANTAGES OF HELIUM-NEON LASER

- The helium-neon laser emits laser light in the visible portion of the spectrum.

- High stability

- Low cost

- Operates without damage at higher temperatures

DISADVANTAGES OF HELIUM-NEON LASER

- Low efficiency

- Low gain

- Helium-neon lasers are limited to low power tasks

APPLICATIONS OF HELIUM-NEON LASERS

- Helium-neon lasers are used in industries.

- Helium-neon lasers are used in scientific instruments.

Helium-neon lasers are used in the college laboratories

Key Takeaways

- Helium-Neon laser is a type of gas laser in which a mixture of helium and neon gas is used as a gain medium.

- The helium-neon laser was the first continuous-wave laser ever constructed.

- The helium-neon laser consists of three essential components Pump source (high voltage power supply),Gain medium (laser glass tube or discharge glass tube), Resonating cavity

- The helium-neon laser operates at a wavelength of 632.8 nanometres (nm), in the red portion of the visible spectrum.

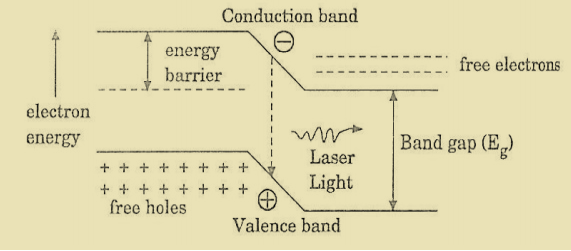

Semiconductor Laser

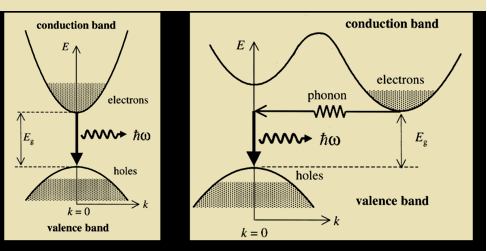

It is a solid-state semiconductor laser. It is a specifically fabricated p-n junction diode. This diode emits laser light when it is forward biased. A semiconductor laser is a device that causes laser oscillation by flowing an electric current to the semiconductor. The mechanism of light emission is the same as a light-emitting diode (LED). Light is generated by flowing the forward current to a p-n junction. In forward bias operation, the p-type layer is connected with the positive terminal, and the n-type layer is connected with the negative terminal, electrons enter from the n-type layer and holes from the p-type layer. When the two meet at the junction, an electron drops into a hole, and light is emitted at the time.

Semiconductor lasers represent one of the most important classes of lasers in use today, not only because of the large variety of direct applications in which they are involved but also because they have found widespread use as pumps for solid-state lasers.

Semiconductor lasers require, for the active medium, a direct gap material, and accordingly, the normal elemental semiconductors like Si or Ge cannot be used. The majority of semiconductor-laser materials are based on a combination of elements belonging to the third group of the periodic table such as Al, Ga, In with elements of the fifth group such as N, P, As, Sb. Examples include the best known GaAs as well as some ternary AlGaAs, InGaAs, and quaternary InGaAsP alloys.

InGaN semiconductor lasers the best candidates for semiconductor laser emission in the very important blue-green spectral region. Semiconductor laser materials are not limited to III–V compounds, however. For the blue-green end of the spectrum, we note that wide-gap semiconductors are using a combination between elements of the second group (such as Cd and Zn) and the sixth group (S, Se).

PRINCIPLE

When a p-n junction diode is forward biased, the electrons from the n – region and the holes from the p- region cross the junction and recombine with each other.

During the recombination process, the light radiation (photons) is released from a certain specified direct bandgap semiconductor like Ga-As. This light radiation is known as recombination radiation.

The photon emitted during recombination stimulates other electrons and holes to recombine. As a result, stimulated emission takes place which produces laser.

Figure 14: Semiconductor Laser

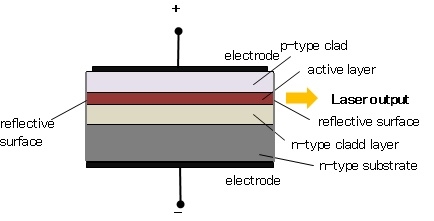

CONSTRUCTION

The basic structure of a semiconductor laser is shown in Figure. The active medium is a p-n junction diode made from the single crystal of gallium arsenide. The active layer called a light emission layer sandwiched between the p- and n-type clad layers i.e. double heterostructure is formed on an n-type substrate and voltage is applied across the p-n junction from the electrodes. This crystal is cut in the form of a platter having a thickness of 0.5μmm. Both edges of the active layer have a mirror-like surface. When a forward voltage is applied, electrons combine with holes at the p-n junction and emit the light.

This light is not a laser yet; it is confined within the active layer because the refractive index of the clad layers is lower than that of the active layer. Besides both ends of the active layer act as a reflecting mirror where the light reciprocates in the active layer. Then, the light is amplified by the stimulated emission process and laser oscillation is generated.

The photon emission is stimulated in a very thin layer of PN junction (in order of few microns). The electrical voltage is applied to the crystal through the electrode fixed on the upper surface. The end faces of the junction diode are well polished and parallel to each other. They act as an optical resonator through which the emitted light comes out.

Figure 15: Construction of semiconductor Laser

WORKING

When the PN junction is forward biased with large applied voltage, the electrons and holes are injected into the junction region in considerable concentration

The region around the junction contains a large number of electrons in the conduction band and a large number of holes in the valence band.

If the population density is high, a condition of population inversion is achieved. The electrons and holes recombine with each other and this recombination produces radiation in the form of light.

When the forward-biased voltage is increased, more and more light photons are emitted and the light production instantly becomes stronger. These photons will trigger a chain of stimulated recombination resulting in the release of photons in phase.

Figure 16: Energy Level diagram of Semiconductor Laser

The photons moving at the plane of the junction travels back and forth by reflection between two sides placed parallel and opposite to each other and grow in strength.

After gaining enough strength, it gives out the laser beam of wavelength 8400Å. The nature of output is a continuous wave or pulsed output. The power output from this laser is 1mW. The wavelength of laser light is given by

Where Eg is the bandgap energy in joule.

ADVANTAGES

- It is very small in dimension.

- The arrangement is simple and compact.

- It exhibits high efficiency.

- It is operated with lesser power than a ruby and CO2 laser.

- The laser output can be easily increased by controlling the junction current

- It requires very little auxiliary equipment

- It can have a continuous wave output or pulsed output.

DISADVANTAGES

- It is difficult to control the mode pattern and mode structure of the laser.

- The output is usually from 5 degrees to 15 degrees i.e., the laser beam has a large divergence.

- The purity and monochromaticity are power than other types of laser

- Threshold current density is very large (400A/mm2).

- It has poor coherence and poor stability.

APPLICATION

- It is widely used in fibre optic communication

- It is used to heal the wounds by infrared radiation

- It is also used as a pain killer

- It is used in laser printers and CD writing and reading.

Key Takeaways

- It is a solid-state semiconductor laser. It is a specifically fabricated p-n junction diode.

- Semiconductor laser is based on the principle that when a p-n junction diode is forward biased, the electrons from the n – region and the holes from the p- region cross the junction and recombine with each other.

- During the recombination process, the light radiation (photons) is released from a certain specified direct bandgap semiconductor like Ga-As. This light radiation is known as recombination radiation.

- The photon emitted during recombination stimulates other electrons and holes to recombine. As a result, stimulated emission takes place which produces laser.

- A semiconductor laser is a device that causes laser oscillation by flowing an electric current to the semiconductor.

- Semiconductor lasers require, for the active medium, a direct gap material, and accordingly, the normal elemental semiconductors like Si or Ge cannot be used.

Applications of lasers because of unique property of laser beam such as coherence, monochromacity, directionality, and high intensity, they are widely used in various fields like

1. Communication

2. Computers

3. Chemistry

4. Photography

5. Industry

6. Medicine

7. Military

8. Scientific Research

1. Communication

In case of optical communication semiconductors laser diodes are used as optical sources and its band width is (1014Hz) is very high compared to the radio and microwave communications. More channels can be sent simultaneously Signal cannot be tapped as the band width is large, more data can be sent. A laser is highly directional and less divergence, hence it has greater potential use in space crafts and submarine. It is used in optical fiber communications to send information over large distances with low loss. Laser light is used in underwater communication networks. Lasers are used in space communication, radars and satellites.

2. Computers

In LAN (local area network), data can be transferred from memory storage of one computer to other computer using laser for short time. Lasers are used in CD-ROMS during recording and reading the data. Lasers are used in computer printers.

3. Chemistry

Lasers are used in molecular structure identification Lasers are also used to accelerate some chemical reactions. Using lasers, new chemical compounds can be created by breaking bonds between atoms are molecules.

4. Photography

Lasers can be used to get 3-D lens less photography. Lasers are also used in the construction of holograms.

5. Industry

Lasers can be used to blast holes in diamonds and hard steel. Lasers are also used as a source of intense heat Carbon dioxide laser is used for cutting drilling of metals and non-metals, such as ceramics plastics glass etc. High power lasers are used to weld or melt any material. Lasers are also used to cut teeth in saws and test the quality of fabric. It is used to cut glass and quartz, used in electronic industries for trimming the components of Integrated Circuits (ICs).Lasers are used for heat treatment in the automotive industry. Laser light is used to collect the information about the prefixed prices of various products in shops and business establishments from the bar code printed on the product. Ultraviolet lasers are used in the semiconductor industries for photolithography. Photolithography is the method used for manufacturing printed circuit board (PCB) and microprocessor by using ultraviolet light. It is also used to drill aerosol nozzles and control orifices within the required precision.

6. Medicine

Pulsed neodymium laser is employed in the treatment of liver cancer. Argon and carbon dioxide lasers are used in the treat men of liver and lungs. Lasers used in the treatment of Glaucoma.

Lasers used in endoscopy to scan the inner parts of the stomach. Lasers used in the elimination of moles and tumors which are developing in the skin tissue and hair removal. It is also used for bloodless surgery.

Lasers are used to destroy kidney stones, in cancer diagnosis and therapy also used for eye lens curvature corrections. Lasers are used to study the internal structure of microorganisms and cells. It is used to create plasma. Lasers are used to remove the caries or decayed portion of the teeth.

7. Military

Lasers can be used as a war weapon. High energy lasers are used to destroy the enemy air-crofts and missiles. Lasers can be used in the detection and ranging likes RADAR. Laser range finders are used to determine the distance to an object. The ring laser gyroscope is used for sensing and measuring very small angle of rotation of the moving objects.

Lasers can be used as a secretive illuminators for reconnaissance during night with high precision.

8. Scientific research

Lasers are used in the field of 3D-photography Lasers used in Recording and reconstruction of hologram. Lasers are employed to create plasma. Lasers are used in Raman spectroscopy to identify the structure of the molecule and to count the number of atoms in a substance. Lasers are used in the Michelson- Morley experiment. A laser beam is used to confirm Doppler shifts in frequency for moving objects. A laser helps in studying the Brownian motion of particles. With the help of a helium-neon laser, it was proved that the velocity of light is same in all directions. Lasers are used to measure the pollutant gases and other contaminants of the atmosphere. Lasers help in determining the rate of rotation of the earth accurately. Lasers are used for detecting earthquakes and underwater nuclear blasts. A gallium arsenide diode laser can be used to setup an invisible fence to protect an area.

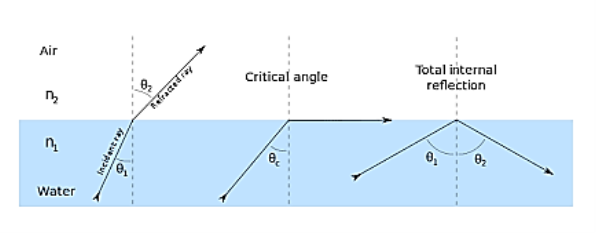

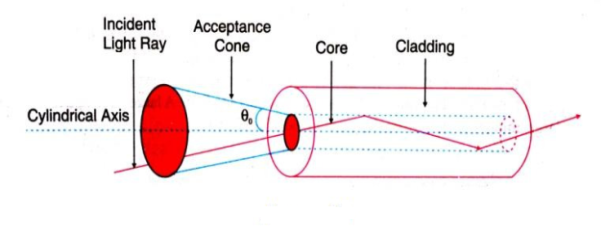

OPTICAL FIBRE

A cable that is used to transmit the data through fibres (threads) or plastic (glass) is known as an optical fibre cable. This cable includes a pack of glass threads that transmits modulated messages over light waves.

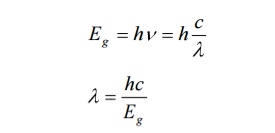

Principle: Optical Fibre works on the principle of Total Internal Reflection.

Total internal reflection:-

When the light ray travels from denser medium to rarer medium the refracted ray bends away from the normal. When the angle of incidence is greater than the critical angle, the refracted ray again reflects into the same medium. This phenomenon is called total internal reflection. The refracted ray bends towards the normal as the ray travels from rarer medium to denser medium. The refracted ray bends away from the normal as it travels from denser medium to rarer medium.

Figure 17 – Total Internal Reflection

When light passes from a medium with one index of refraction (m1), to another medium with a lower index of refraction (m2), it bends or refracts away from an imaginary line perpendicular to the surface (normal line). As the angle of the beam through m1 becomes greater with respect to the normal line, the refracted light through m2 bends further away from the line.

At one particular angle (critical angle), the refracted light will not go into m2, but instead will travel along the surface between the two media (sine [critical angle] = n2/n1 where n1 and n2 are the indices of refraction [n1 is greater than n2]). If the beam through m1 is greater than the critical angle, then the refracted beam will be reflected entirely back into m1 (total internal reflection), even though m2 may be transparent.

In physics, the critical angle is described with respect to the normal line. In fiber optics, the critical angle is described with respect to the parallel axis running down the middle of the fiber. Therefore, the fiber-optic critical angle = (90 degrees - physics critical angle).

In an optical fiber, the light travels through the core (m1, high index of refraction) by constantly reflecting from the cladding (m2, lower index of refraction) because the angle of the light is always greater than the critical angle. Light reflects from the cladding no matter what angle the fiber itself gets bent at, even if it's a full circle.

Because the cladding does not absorb any light from the core, the light wave can travel great distances. However, some of the light signal degrades within the fiber, mostly due to impurities in the glass. The extent that the signal degrades depends upon the purity of the glass and the wavelength of the transmitted light

When the angle of incidence (θ1) is progressively increased, there will be progressive increase of refractive angle (θ2). At some condition (θ1) the refractive angle (θ2) becomes 90o to the normal. When this happens the refracted light ray travels along the interface. The angle of incidence (θ1) at the point at which the refractive angle (θ1) becomes 90 degree is called the critical angle.

It is denoted by θc. The critical angle is defined as the minimum angle of incidence (θ1) at which the ray strikes the interface of two media and causes an angle of refraction (θ2) equal to 90o. Figure 18 shows critical angle refraction

Hence at critical angle θ1= θc and θ2= 90o .

Using Snell‘s law: n1 sin θ1 = n2 sin θ2

n1 sin θc = n2 sin90o

Sin θc = n2 / n1

θc = sin-1 (n2 / n1)

The actual value of critical angle is dependent upon combination of materials present on each side of boundary.

CHARACTERISTICS OF OPTICAL FIBRE

- It has a large bandwidth.

- The optical frequency of 2 x 1014 Hz can be used and hence the system has higher bandwidth.

- Thus optical fibres have greater information-carrying capacity due to greater bandwidth.

- In an optical fibre system transmission losses are as low as 0.1 db/km.

- Optical fibre is of small size and lightweight as compared to electrical fibre.

- Optical fibre communication is free from electromagnetic interference.

- Optical fibre does not carry high voltage and current hence they are safer than electrical cable.

- Optical Fibres are flexible and have high tensile strength. Thus can be bent or twisted easily.

Figure 18: Optical Fibre

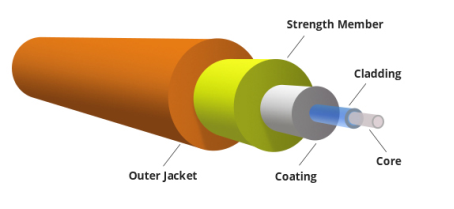

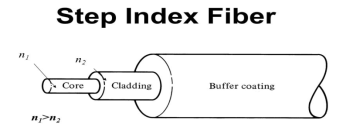

CONSTRUCTION OF OPTICAL FIBRE

It consists of a very thin fibre of silica or glass or plastic of a high refractive index called the core. The core has a diameter of 10 um to 100 um. The core is enclosed by a cover of glass or plastic called cladding. The refractive index of the cladding is less than that of the core (which is a must condition for the working of the optical fibre). The difference between the two indicates is very small of order 10-3. The core and the cladding are enclosed in an outer protective jacket made of plastic to provide strength to the optical fibre. The refractive index can change from core to cladding abruptly (as in step-index fibre) or gradually (as in graded-index fibre).

Figure 19: Representation of Optical Fibre

WORKING OF OPTICAL FIBRE

When a ray of light is incident on the core of the optical fibre at a small angle, it suffers refraction and strikes the core-cladding interface, As the diameter of the fibre is very small hence the angle of incidence is greater than the critical angle. Therefore, the ray suffers total internal reflection at the core-cladding interface and strikes the opposite interface. At this interface also, the angle of incidence is greater than the critical angle, so it again suffers total internal reflection. Thus, the ray of light reaches the other end of the fibre after suffering repeated total internal reflections along the length of the fibre. At the other end, the ray suffers refraction and emerges out of the optical fibre.

We can see that the light travels in the core in a guided manner. Hence the communication through the optical fibre is sometimes referred to as an optical waveguide.

Key Takeaways

- A cable that is used to transmit the data through fibres (threads) or plastic (glass) is known as an optical fibre cable. This cable includes a pack of glass threads that transmits modulated messages over light waves.

- Principle: Optical Fibre works on the principle of Total Internal Reflection.

- It consists of a very thin fibre of silica or glass or plastic of a high refractive index called the core. The core has a diameter of 10 um to 100 um.

- The core is enclosed by a cover of glass or plastic called cladding. The refractive index of the cladding is less than that of the core.

- The core and the cladding are enclosed in an outer protective jacket made of plastic to provide strength to the optical fibre.

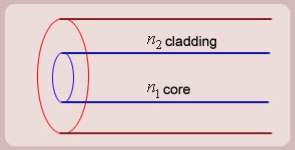

OPTICAL FIBRE AS A DIELECTRIC WAVE GUIDE

Light propagates inside an optical fiber by virtue of multiple TIRs at the core-cladding interface. The refractive index of the core glass is greater than that of the cladding. This meets the first condition for a TIR. All the light energy that is launched into the optical fiber through its tip does not get guided along the fiber. Only those light rays propagate through the fiber which is launched into the fiber at such an angle that the refracted ray inside the core of the optical fiber is incident on the core-cladding interface at an angle greater than the critical angle of the core with respect to the cladding.

1. Optical fiber is basically a solid glass rod. The diameter of rod is so small that it looks like a fiber.

2. Optical fiber is a dielectric waveguide. The light travels like an electromagnetic wave inside the waveguide. The dielectric waveguide is different from a metallic waveguide which is used at microwave and millimeter wave frequencies.

3. In a metallic waveguide, there is a complete shielding of electromagnetic radiation but in an optical fiber the electromagnetic radiation is not just confined inside the fiber but also extends outside the fiber.

4. The light gets guided inside the structure, through the basic phenomenon of total internal reflection.

5. The optical fiber consists of two concentric cylinders; the inside solid cylinder is called the core and the surrounding shell is called the cladding. (See Fig 12)

Figure 20: Schematic of an optical fiber

6. For the light to propagate inside the fiber through total internal reflections at core-cladding interface, the refractive index of the core must be greater than the refractive index of the cladding. That is n1>n2.

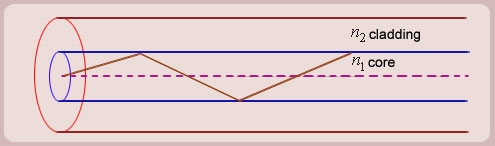

SIMPLE RAY MODEL

Figure 21: (optical fiber with core, cladding and total internally reflected ray)

For propagation of light inside the core there are two possibilities.

1. A light ray is launched in a plane containing the axis of the fiber. We can then see the light ray after total internal reflection travels in the same plane i.e., the ray is confined to the plane in which it was launched and never leave the plane. In this situation the rays will always cross the axis of the fiber. These are called the Meridional rays.

2. The other possibility is that the ray is not launched in a plane containing the axis of the fiber.

For example if the ray is launched at some angle such that it does not intersect the axis of the fiber, then after total internal reflection it will go to some other plane. We can see that in this situation the ray will never intersect the axis of the fiber. The ray essentially will spiral around the axis of fiber. These rays are called the Skew rays.

So it can be concluded that if the light is to propagate inside an optical fiber it could be through two types of rays

a) Meridional rays: The rays which always pass through the axis of fiber giving high optical intensity at the center of the core of the fiber.

b) Skew Rays: The rays which never intersect the axis of the fiber, giving low optical intensity at the center and high intensity towards the rim of the fiber.

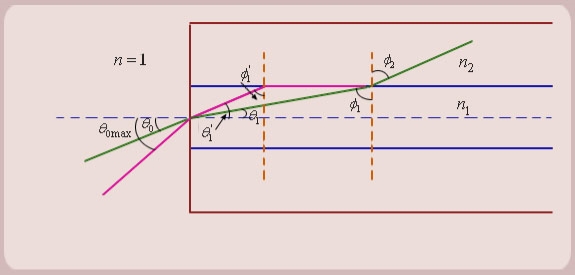

Propagation of Meridional Rays

Figure 22: Propagation of Meridional Rays

- Let us consider figure 22. A ray is launched from outside (air) at an angle θ0 , from the axis of the fiber.

The question is, under what conditions the ray is ultimately guided inside the core due to total internal reflections at the core cladding boundary.

2. Let the ray makes an angle θ1 with the axis of the fiber inside the core, and let the ray make an angle ϕ1 with core -cladding interface. Let ϕ2 be the angle of refraction in the cladding.

If ϕ1 < critical angle the ray is refracted in cladding. The ray which goes to cladding is lost and is not useful for communication. The ray which is confined to the core is useful for optical communication.

3. Now as we increase the launching angle θ0, the angle θ1 also increases. Since θ1 + ϕ1 =

ϕ1 decreases and at some point becomes less than the critical angle. When ϕ1 equals the critical angle, ϕ2 equals  . The maximum launching angle then corresponds to ϕ2 =

. The maximum launching angle then corresponds to ϕ2 = .

.

4. Let us apply Snell’s law at the launching point and at the core-cladding interface for the maximum launching angle θ0max. For this case let θ1 = θ’1 and ϕ1 = ϕ’1

We then have

(since

(since  )

)

Now,

So the sine of the maximum angle at which the ray will be guided inside the fiber is given by square root of the difference of squares of the refractive indices of the core and cladding. The quantity is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber.

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber.

Key Takeaways

- Light propagates inside an optical fiber by virtue of multiple TIRs at the core-cladding interface.

- The refractive index of the core glass is greater than that of the cladding.

- Optical fiber is a dielectric waveguide. The light travels like an electromagnetic wave inside the waveguide.

- If the light is to propagate inside an optical fiber it could be through two types of rays; Meridional rays and Skew Rays.

- The quantity

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber. It is given by NA = ( n12- n22 )1/2

is called the numerical aperture of an optical fiber. The NA is a measure of the power launching efficiently of an optical fiber. It is given by NA = ( n12- n22 )1/2

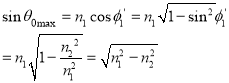

ACCEPTANCE ANGLE

Definition:- Acceptance angle is defined as the maximum angle of incidence at the interface of air medium and core medium for which the light ray enters into the core and travels along with the interface of core and cladding.

Let n0 be the refractive indices of air

n1 be the refractive indices of core

n2 be the refractive indices of cladding

Figure 23: Acceptance angle

Let a light ray OA is an incident on the interface of air medium and core medium with an angle of incidence θ0

The light ray refracts into the core medium with an angle of refraction θ1 and the refracted ray AB is again incident on the interface of core and cladding with an angle of the incident (90- θ1)

If (90- θ1) is equal to the critical angle of core and cladding media then the ray travels along with the interface of core and cladding along the path BC. If the angle of the incident at the interface of air and core θ1< θ0 then (90- θ1) will be greater than the critical angle. Therefore,

The total internal reflection takes place.

According to Snell’s law at point A

n0 Sin θ0 = n1 Sin θ1

Sin θ0= (n1 / n0) Sin θ1 ………(1)

According to Snell’s law at point B

n1 Sin(90- θ1) = n2 Sin90 ………(2)

n1 Cosθ1 = n2 as (Sin90=1)

Cosθ1 = n2 /n1

Sinθ1 = (1-Cos2 θ1)1/2

Sinθ1= (1- (n2 /n1)2)1/2

Sinθ1= ( n12- n22 )1/2/ n1 ………(3)

We know Sin θ0= (n1 / n0) Sin θ1 from equation (1)

Substitute the value of Sinθ1 from equation (3)

Sinθ0= (n1 / n0) *( n12- n22 )1/2/ n1

On simplification

Sinθ0= ( n12- n22 )1/2/ n0

θ0=Sin-1 ( n12- n22 )1/2/ n0

Acceptance Angle is θ0=Sin-1 ( n12- n22 )1/2/ n0 ………(4)

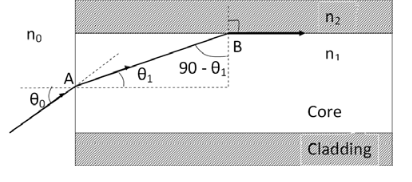

ACCEPTANCE CONE

Acceptance angle is the maximum angle that a light ray can have relative to the axis of the fibre and propagate down the fibre. Thus, only those rays that are incident on the face of the fibre making angles less than θ0 will undergo repeated total internal reflections and reach the other end of the fibre. Hence, larger acceptance angles make it easier to launch light into fibre.

Figure 24: Acceptance cone

In three dimensions, the light rays contained within the cone having a full angle 2θ0 are accepted and transmitted along with the fibre as shown in figure 24. Therefore, the cone is called the acceptance cone. Light incident at an angle beyond θ0 refracts through the cladding and corresponding optical energy is lost.

NUMERICAL APERTURE

Definition: -Numerical aperture is defined as the light gathering capacity of an optical fibre and it is directly proportional to the acceptance angle. Numerically it is equal to the sin of the acceptance angle.

NA = Sin(acceptance angle)

NA = Sin {Sin-1 (( n12- n22 )1/2/ n0)} from equation (4)

NA = (( n12- n22 )1/2/ n0) ………(5)

If the refractive index of the air medium is unity i.e. n0=1 put in (5)

NA = ( n12- n22 )1/2 ………(6)

Fractional change in refractive index

∆= (n1- n2)/ n1

n1∆ = (n1- n2) ………(7)

From equation (6), we have

NA = {( n1- n2 )( n1+n2 )}1/2

NA = { n1∆ (n1+n2 )}1/2 as n1∆ = (n1- n2) by Eq(7)

NA = { n1∆ 2n1}1/2 n1 ≈ n2, so n1+n2 =2n1

NA = n1{2∆}1/2

This gives the relation between Numerical aperture and Fractional change in refractive index.

Key Takeaways

- Acceptance angle is defined as the maximum angle of incidence at the interface of air medium and core medium for which the light ray enters into the core and travels along with the interface of core and cladding.

- Acceptance Angle is given by θ0=Sin-1 ( n12- n22 )1/2/ n0

- In three dimensions, the light rays contained within the cone having a full angle 2θ0 are accepted and transmitted along with the fibre. Therefore, the cone is called the acceptance cone.

- Numerical aperture is defined as the light gathering capacity of an optical fibre and it is directly proportional to the acceptance angle. Numerically it is equal to the sin of the acceptance angle.

- Numerical aperture is given by NA = n1{2∆}1/2

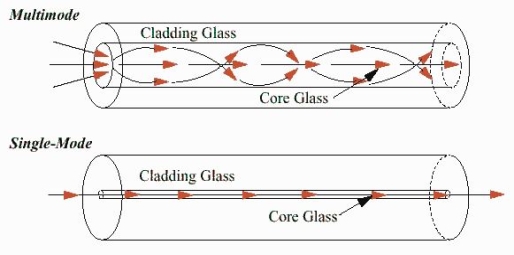

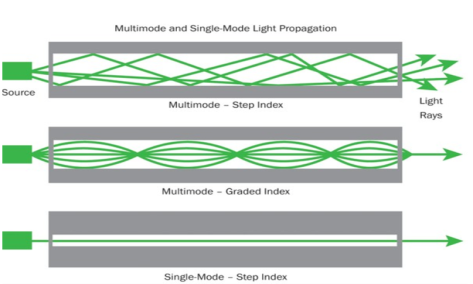

The types of optical fibres depend on the refractive index, materials used, and mode of propagation of light.

The classification based on the materials used is as follows:

- Plastic Optical Fibres: The polymethylmethacrylate is used as a core material for the transmission of light.

Example:

Core: polymethyl methacrylate : Cladding: Co- Polymer

Core: Polystyrene : Cladding: Methyl methacrylate

- Glass Fibres: It consists of extremely fine glass fibres.

Example:

Core: SiO2 Cladding: SiO2

Core: GeO2- SiO2 Cladding: SiO2

The classification based on the mode of propagation of light is as follows:

Mode of propagation:

Light propagates as electromagnetic waves through an optical fibre. All waves, having ray directions above the critical angle will be trapped within the fibre due to total internal reflection. However, all such waves do not propagate through the fibre. Only certain ray directions are allowed to propagate. The allowed directions correspond to the modes of the fibre. In simple terms, modes can be visualized as the possible number of paths of light in an optical fibre.

- Single-Mode Fibres:

These fibres are used for long-distance transmission of signals. In general, the single-mode fibres are step-index fibres. These types of fibres are made from doped silica. It has a very small core diameter so that it can allow only one mode of propagation and hence called single-mode fibres.

The cladding diameter must be very large compared to the core diameter. Thus in the case of single-mode fibre, the optical loss is very much reduced. The structure of a single-mode fibre is given below.

Structure:

Core diameter: 5-10μm

Cladding diameter: Generally around 125μm

Protective layer: 250 to 1000μm

Numerical aperture: 0.08 to 0.10

Bandwidth: More than 50MHz km.

Application:

Because of high bandwidth, they are used in long-haul communication systems.

Figure 25: Single Mode and Multimode Fibre

- Multimode Fibres:

These fibres are used for short-distance transmission of signals. The multi-mode fibres are useful in manufacturing both for step-index and graded-index fibres. The multi-mode fibres are made by multi-component glass compounds such as Glass – Clad Glass, Silica – Clad – Silica, doped silica, etc. Here the core diameter is very large compared to single-mode fibres, so that it can allow many modes to propagate through it and hence called Multi-mode fibres. The cladding diameter is also larger than the diameter of the single-mode fibres. The structure of the multimode fibre is as shown in the figure above.

Structure:

Core diameter : 50-350μm

Cladding diameter : 125μm - 500μm

Protective layer : 250 to 1100μm

Numerical aperture : 0.12 to 0.5

Bandwidth : Less than 50MHz km.

The total number of modes possible for such an electromagnetic waveguide is

Application:

Because of its less bandwidth, it is very useful in short-haul communication systems.

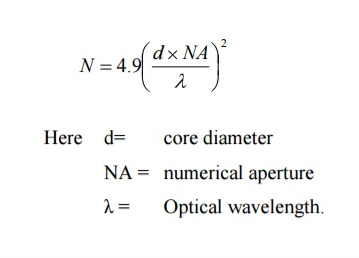

The classification based on the refractive index is as follows:

- Step Index Single-mode Fibres

It consists of a core surrounded by the cladding, which has a single uniform index of refraction. Step index-single mode fibres: A single-mode step-index fibre consists of a very thin core of uniform refractive index surrounded by a cladding of refractive index lower than that of the core. The refractive index abruptly changes at the core-cladding boundary. Light travels along a side path, i.e., along the axis only. So zero-order modes are supported by Single Mode Fibre.

Figure 26: Step Index Single-mode Fibres

- Step index-Multimode fibres

A multimode step-index fibre consists of a core of uniform refractive index surrounded by a cladding of refractive index lower than that of the core. The refractive index abruptly changes at the core-cladding boundary. The core is of large diameter. Light follows zigzag paths inside the fibre. Many such zigzag paths of propagation are permitted in Multi-Mode Fibre. The Numerical Aperture of a Multi-mode fibre is larger as the core diameter of the fibre is larger

Figure: 27 Step index-Multimode fibres

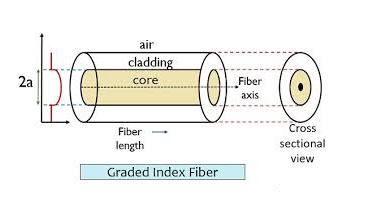

- Graded Index Fibres:

The refractive index of the optical fibre decreases as the radial distance from the fibre axis increases. GRIN fibre is one in which the refractive index varies radially, decreasing continuously in a parabolic manner from the maximum value of n1, at the center of the core to a constant value of n2 at the core-cladding interface.

In graded-index fibre, light rays travel at different speeds in different parts of the fibre because the refractive index varies throughout the fibre. Near the outer edge, the refractive index is lower. As a result, rays near the outer edge travel faster than the rays at the center of the core. Because of this, rays arrive at the end of the fibre at approximately the same time. In effect light rays that arrive at the end of the fibre are continuously refocused as they travel down the fibre. All rays take the same amount of time in traversing the fibre. This leads to small pulse dispersion.

Figure 28: Graded Index Fibres

For a parabolic index fibre, the pulse dispersion is reduced by a factor of about 200 in comparison to step-index fibre. It is because of this reason that first and second-generation optical communication systems used near parabolic index fibres.

Key Takeaways

- The types of optical fibres depend on the refractive index, materials used, and mode of propagation of light.

- The classification based on the materials is of two type plastic optical fibres and glass fibres.

- The classification based on the mode of propagation is of two type single mode fibre and multimode fibre.

- The classification based on the refractive index is of three types step index single mode fibre, step index multimode fibre and graded index fibre.

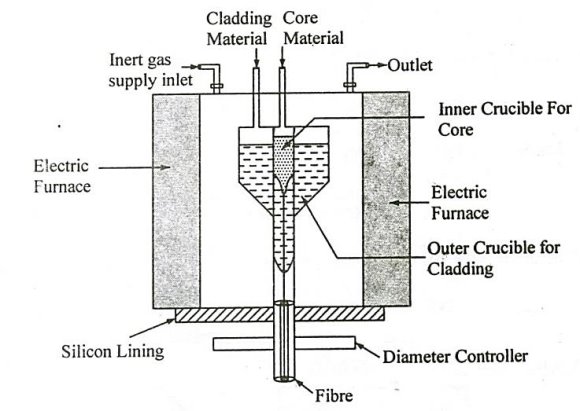

Double-Crucible Method

A method of fabricating an optical waveguide by melting the core and clad glasses in two suitably joined concentric crucibles and then drawing a fiber from the combined melted glass. Low loss fibers are mostly manufactured by using double crucible and vapour phase deposition method.

The double-crucible method is the mainly common direct melt procedure. The double-crucible process combines the molten rods in a single perform by using two concentric crucibles. Optical fibers are drawn by this molten glass by using a same fiber drawing process as into vapour phase oxidation.

Figure 29: Double-Crucible Method

Highly purified glass powders of various refractive indices are fed into the inner crucible for the core in the outer crucible for cladding. The electric furnace is switched on and the materials are heated to very high temperature. The material goes to molten state and the material starts squeezing through the orifice of the crucible. Now the core material will start diffusing into cladding material to form an optical fiber. The fiber is drawn through the bottom surface of the crucible and dopant such as thallium with high rate of diffusion in silica is used to maintain the difference in refractive index.

This Method has become Important in the Production of Inexpensive Fibers by a Continuous Process. The Starting Materials may be Fed in either Powdered Form or by Means of High Purity Preformed Rods.

Double Crucible Mounted inside a Vertical, Silica Lined Muffle Furnace capable of Raising the Melt Temp between 1000-1200°C.An Inert Gas Atmosphere is maintained inside the Furnace. Control of the Core and Cladding Diameters are Maintained by the Fiber Pulling Speed and the Head of Molten Glass in each Crucible. With a Suitable Choice of Materials and Control of the Melt Temperature at the Nozzle, Index Grading can be obtained by Ionic Diffusion.

Both silica and halide glass fibers can be made using a direct-melt double-crucible technique. In this method, glass rods for the core and cladding materials are first made separately by melting mixtures of purified powders to make the appropriate glass composition. These rods are then used as feedstock for each of two concentric crucibles as shown in Figure.

The inner crucible contains molten core glass and the outer one contains the cladding glass. The fibers are drawn from the molten state through orifices in the bottom of the two concentric crucibles in a continuous production process.

Although this method has the advantage of being a continuous process, careful attention must be paid to avoid contaminants during the melting. The main sources of contamination arise from the furnace environment and from the crucible.

Silica crucibles are usually used in preparing the glass feed rods whereas the double concentric crucibles used in the drawing furnace are mad from platinum.

Key Takeaways

- A method of fabricating an optical waveguide by melting the core and clad glasses in two suitably joined concentric crucibles and then drawing a fiber from the combined melted glass.

- Low loss fibers are mostly manufactured by using double crucible and vapour phase deposition method.

One of the important property of optical fiber is signal attenuation. It is also known as fiber loss or signal loss. The signal attenuation of fiber determines the maximum distance between transmitter and receiver. The attenuation also determines the number of repeaters required, maintaining repeater is a costly affair. Another important property of optical fiber is distortion mechanism. As the signal pulse travels along the fiber length it becomes more broader. After sufficient length the broad pulses starts overlapping with adjacent pulses. This creates error in the receiver. Hence the distortion limits the information carrying capacity of fiber.

Attenuation in Optical Fibres

- Attenuation is a measure of decay of signal strength or loss of light power that occurs as light pulses propagate through the length of the fibre

- In optical fibres the attenuation is mainly caused by two physical factors absorption and scattering losses. Absorption is because of fibre material and scattering due to structural imperfection within the fibre.

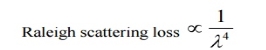

- Nearly 90 % of total attenuation is caused by Rayleigh scattering only. Micro bending of optical fibre also contributes to the attenuation of signal.

- The rate at which light is absorbed is dependent on the wavelength of the light and the characteristics of particular glass. Glass is a silicon compound; by adding different additional chemicals to the basic silicon dioxide the optical properties of the glass can be changed.

- The Rayleigh scattering is wavelength dependent and reduces rapidly as the wavelength of the incident radiation increases.

- The attenuation of fibre is governed by the materials from which it is fabricated, the manufacturing process and the refractive index profile chosen.

- Attenuation loss is measured in dB/km.

As attenuation leads to a loss of power along the fibre, the output power is significantly less than the couples power. Let the couples optical power is P(0) i.e. at origin (z =0).Then the power at distance z is given by,

P(z) = P(0)

Where, αp is fibre attenuation constant (per km).

αp =  ln

ln

αp (dB/km ) = 10.  log

log

αp (dB/km ) = 4.343 αp/km

This parameter is known as fibre loss or fibre attenuation. Attenuation is also a function of wavelength.

Example: When mean optical power launched into an 8 km length of fibre is 12 μW, the mean optical power at the fibre output is 3 μW. Determine

a) Overall signal attenuation in dB.

b) The overall signal attenuation for a 10 km optical link using the same fibre with splices at 1 km intervals, each giving an attenuation of 1 dB.

Solution:

Given :z=8km

P(0) = 120 μW

P(z) = 3 μW

a) Overall attenuation is given by,

αp (dB/km ) = 10. log  = 16.02

= 16.02

b) Overall attenuation for 10 km,

Attenuation per km = αp (dB/km )

=

=  = 2.00 dB/km

= 2.00 dB/km

Attenuation in 10 km link = 2.00 x 10 = 20 dB

In 10 km link there will be 9 splices at 1 km interval. Each splices introducing attenuation of 1 dB.

Total attenuation = 20 dB + 9 dB = 29 dB

Losses in optical fiber:

- Absorption loss

- Scattering loss

- Radiative loss or Bending loss

- Dispersion loss

1. Absorption:

Absorption loss is because of the material composition and fabrication process of fiber. Absorption loss results in dissipation of some optical power as hear in the fiber cable. Although glass fibers are extremely pure, some impurities still remain as residue after purification. The amount of absorption by these impurities depends on their concentration and light wavelength.

Usually absorption of light occurs due to imperfections of the atomic structure such as missing molecules, (OH-), hydroxyl ions, high density cluster of atoms etc., which absorbs light.

a. Intrinsic absorption: Intrinsic absorption in the ultraviolet region is caused by electronic absorption bands. Basically, absorption occurs when a light particle (photon) interacts with an electron and excites it to a higher energy level. The main cause of intrinsic absorption in the infrared region is the characteristic vibration frequency of atomic bonds. In silica glass, absorption is caused by the vibration of silicon-oxygen (Si-O) bonds. The interaction between the vibrating bond and the electromagnetic field of the optical signal causes intrinsic absorption. Light energy is transferred from the electromagnetic field to the bond.

b. Extrinsic absorption: Extrinsic absorption is much more significant than intrinsic Caused by impurities introduced into the fiber material during manufacture – Iron, nickel, and chromium Caused by transition of metal ions to higher energy level. Modern fabrication techniques can reduce impurity levels.

2. Scattering:

Basically, scattering losses are caused by the interaction of light with density fluctuations within a fiber. Density changes are produced when optical fibers are manufactured.

a) Linear Scattering Losses: Linear scattering occurs when optical energy is transferred from the dominant mode of operation to adjacent modes. It is proportional to the input optical power injected into the dominant mode. Scattering is also a wavelength dependent loss, which occurs inside the fibers. Since the glass is used in fabrication of fibers, the disordered structure of glass will make some variations in the refractive index inside the fiber. As a result, if light is passed through the atoms in the fiber, a portion of light is scattered (elastic scattering). This type of scattering is called Raleigh scattering. Linear scattering is divided into two categories: Mie scattering and Rayleigh scattering.

b) Non- Linear Scattering Losses: Scattering loss in a fiber also occurs due to fiber non-linearity’s i.e. if the optical power at the output of the fiber does not change proportionately with the power change at the input of the fiber, the optical fiber is said to be operating in the non-linear mode. Non- Linear scattering is divided into two categories: Stimulated Raman Scattering and Stimulated Brillouin Scattering.

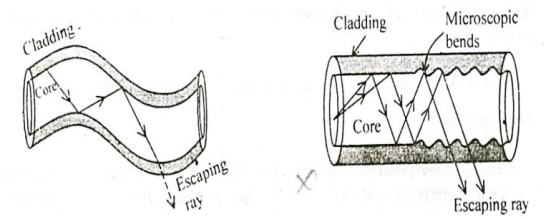

3. Radiative loss or Bending loss

Radiative losses also called bending losses. Radiative loss occur when the fibre is curved. Radiative loss occurs in fibers due to bending of finite radius of curvature in optical fibers. The types of bends are

a) Macroscopic bends

b) Microscopic bends

a. Macroscopic bends: If the radius of the core is large compared to fiber diameter, it may cause large-curvature at the position where the fiber cable turns at the corner. At these corners the light will not satisfy the condition for total internal reflection and hence it escapes out from the fiber. This is called as macroscopic / macro bending losses. Also note that this loss is negligible for small bends.

Figure 30: Bending loss

b. Microscopic bends: Micro-bends losses are caused due to non-uniformities or micro bends inside the fiber as shown. This micro bends in fiber appears due to non-uniform pressures created during the cabling of the fiber or even during the manufacturing itself. This lead to loss of light by leakage through the fiber.

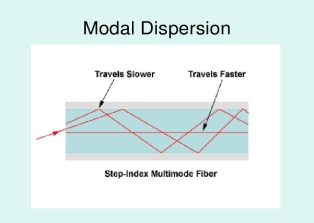

4. Dispersion Loss

Dispersion: A light pulse launched into a fibre decreases in the fibre. It also spreads during its travel. The pulse received at the output is wider than input pulse.

It means that the pulse becomes distorted as it is propagated through the fibre. Such a distortion arises due to dispersion effects.

Dispersion is typically measured in Nano seconds per kilometre (ns/km).

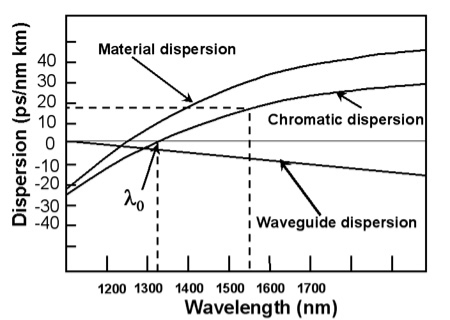

There are three mechanisms which contribute to the distortion of the light pulse in a fibre. They are known as:

a) Material dispersion

b) Wave guide dispersion

c) Chromatic Dispersion

d) Modal Dispersion

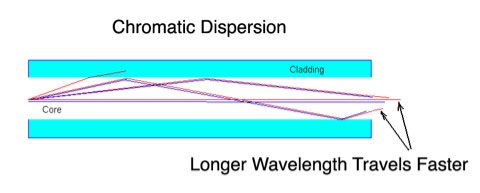

a) Material Dispersion

Material dispersion is also called as chromatic dispersion. Material dispersion exists due to change in index of refraction for different wavelengths. A light ray contains components of various wavelengths. The time delay is different for different wavelength components. This results in time dispersion of pulse at the receiving end of fibre.

Light waves of different wavelengths travel at different speeds in a medium. The short wavelength waves travel slower than long wavelength waves. Consequently, narrow pulses of light tend to broaden as they travel down the optical fibre. This is known as material dispersion.

The material dispersion for unit length (L = 1) is given by

D =

Where c = Light velocity

λ = Center wavelength

= Second derivative of index of refraction w.r.t wavelength.

= Second derivative of index of refraction w.r.t wavelength.

Negative sign shows that the upper sideband signal (lowest wavelength) arrives before the lower sideband (highest wavelength).

The unit of dispersion is : ps/nm/km. The amount of material dispersion depends upon the chemical composition of glass.

Example: An LED operating at 850 nm has a spectral width of 45 nm. What is the pulse spreading in ns/km due to material dispersion?

Solution:

Given :λ = 850 nm

σ = 45 nm

R.M.S pulse broadening due to material dispersion is given by,

σm= σLM

Considering length L = 1 metre

Dmat =

For LED source operating at 850 nm,  = 0.025

= 0.025

M =  by substituting all values we have

by substituting all values we have

M = 9.8 ps/nm/km

σm= 441 ns/km

b) Waveguide Dispersion

- Waveguide dispersion is caused by the difference in the index of refraction between the core and cladding, resulting in a ‘drag’ effect between the core and cladding portions of the power.

- Waveguide dispersion is significant only in fibres carrying fewer than 5-10 modes. Since multimode optical fibres carry hundreds of modes, they will not have observable waveguide dispersion.

- The group delay (τwg) arising due to waveguide dispersion.

τwg =  [ n2 +n2 ∆

[ n2 +n2 ∆  ]

]

Where, b = Normalized propagation

Constant k = 2π / λ (group velocity)

Normalized frequency V,

V = ka

τwg =  [ n2 +n2 ∆

[ n2 +n2 ∆  ]

]

The second term  is waveguide dispersion and is mode dependent term.

is waveguide dispersion and is mode dependent term.

As frequency is a function of wavelength, the group velocity of the energy varies with frequency. This produces additional losses (waveguide dispersion). The propagation constant (b) varies with wavelength, the causes of which are independent of material dispersion.

c) Chromatic Dispersion

The combination of material dispersion and waveguide dispersion is called chromatic dispersion. These losses primarily concern the spectral width of transmitter and choice of correct wavelength.

Figure 31: Chromatic Dispersion

Material dispersion and waveguide dispersion effects vary in opposite senses as the wavelength increased, but at an optimum wavelength, two effects almost cancel each other and chromatic dispersion is at minimum. Attenuation is therefore also at minimum and makes highly attractive Operating wavelength.

Figure 32: Dispersion-Wavelength variation

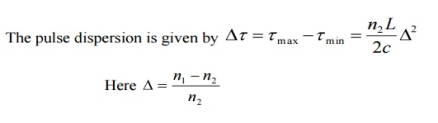

a) Modal Dispersion

As only a certain number of modes can propagate down the fibre, each of these modes carries the modulation signal and each one is incident on the boundary at a different angle, they will each have their own individual propagation times. The net effect is spreading of pulse; this form o dispersion is called modal dispersion.