UNIT 4

SINGLE PHASE INDUCTION MOTOR AND DC MACHINES

4.1.1 Construction and principle of operation

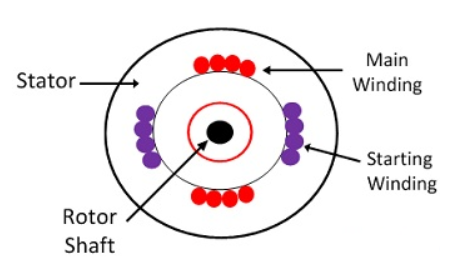

A Single- Phase Induction Motor consists of a single- phase winding which is mounted on the stator of the motor and a cage winding placed on the rotor. A pulsating magnetic field is produced, when the stator winding of the single-phase induction motor shown below is energized by a single- phase supply.

The word Pulsating means that the field builds up in one direction falls to zero and then builds up in the opposite direction. Under these conditions, the rotor of an induction motor does not rotate. Hence, a single -phase induction motor is not self-starting. It requires some special starting means.

If the 1 phase stator winding is excited and the rotor of the motor is rotated by an auxiliary means and the starting device is then removed, the motor continues to rotate in the direction in which it is started.

The performance of the single- phase induction motor is analysed by the two theories. One is known as the Double Revolving Field Theory, and the other is Cross Field Theory.

The double revolving field theory of single- phase induction motor states that a pulsating magnetic field is resolved into two rotating magnetic fields. They are equal in magnitude but opposite in directions. The induction motor responds to each of the magnetic fields separately. The net torque in the motor is equal to the sum of the torque due to each of the two magnetic fields.

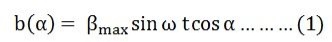

The equation for an alternating magnetic field is given as

Where βmax is the maximum value of the sinusoidally distributed air gap flux density produced by a properly distributed stator winding carrying an alternating current of the frequency ω, and α is the space displacement angle measured from the axis of the stator winding.

So, the equation (1) can be written as

The first term of the right-hand side of the equation (2) represents the revolving field moving in the positive α direction. It is known as a Forward Rotating field. Similarly, the second term shows the revolving field moving in the negative α direction and is known as the Backward Rotating field.

The direction in which the single- phase motor is started initially is known as the positive direction. Both the revolving field rotates at the synchronous speed.

ωs = 2πf in the opposite direction.

Thus, the pulsating magnetic field is resolved into two rotating magnetic fields. Both are equal in magnitude and opposite in direction but at the same frequency.

At the standstill condition, the induced voltages are equal and opposite as a result; the two torques are also equal and opposite. Thus, the net torque is zero and, therefore, a single- phase induction motor has no starting torque.

Methods for Making Single Phase Induction as Self- Starting Motor

The single-phase induction motors are not self-starting because the produced stator flux is alternating in nature and at the starting, the two components of this flux cancel each other and hence there is no net torque. The solution to this problem is that if we make the stator flux rotating type, rather than alternating type, which rotates in one particular direction ,then the induction motor will become self-starting.

Now for producing this rotating magnetic field, we require two alternating flux, having some phase difference angle between them. When these two fluxes interact with each other, they will produce a resultant flux. This resultant flux is rotating in nature and rotates in space in one particular direction only.

Once the motor starts running, we can remove the additional flux. The motor will continue to run under the influence of the main flux only. Depending upon the methods for making asynchronous motor as Self-Starting Motor, there are mainly four types of single -phase induction motor namely,

- Split phase induction motor,

- Capacitor start inductor motor,

- Capacitor start capacitor run induction motor,

- Shaded pole induction motor.

- Permanent split capacitor motor or single value capacitor motor.

4.1.2 Capacitor start & capacitor run motor

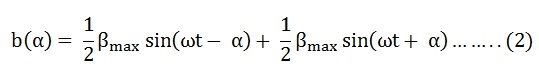

The Capacitor Start Capacitor Run Motor has a cage rotor, and its stator has two windings known as Main and Auxiliary Windings. The two windings are displaced 90 degrees in space. There are two capacitors in this method one is used at the time of the starting and is known as starting capacitor. The other one is used for continuous running of the motor and is known as RUN capacitor.

So this motor is named as Capacitor Start Capacitor Run Motor. This motor is also known as Two Value Capacitor Motor. Connection diagram of the Two valve Capacitor Motor is shown below

There are two capacitors in this motor represented by CS and CR. At the starting, the two capacitors are connected in parallel. The Capacitor Cs is the Starting capacitor is short time rated. It is almost electrolytic. A large amount of current id required to obtain the starting torque. Therefore, the value of the capacitive reactance X should be low in the starting winding. Since, XA = 1/2πfCA, the value of the starting capacitor should be large.

The rated line current is smaller than the starting current at the normal operating condition of the motor. Hence, the value of the capacitive reactance should be large. Since, XR = 1/2πfCR, the value of the run capacitor should be small

As the motor reaches the synchronous speed, the starting capacitor Cs is disconnected from the circuit by a centrifugal switch Sc. The capacitor CR is connected permanently in the circuit and thus it is known as RUN Capacitor. The run capacitor is long time rated and is made of oil filled paper.

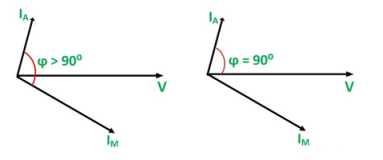

The figure below shows the Phasor Diagram of the Capacitor Start Capacitor Run Motor.

Fig(a) shows the phasor diagram when at the starting both the capacitor are in the circuit and ϕ > 90⁰. Fig (b) shows the phasor when the starting capacitor is disconnected, and ϕ becomes equal to 90⁰.

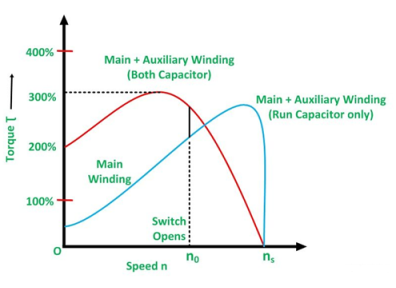

The Torque Speed Characteristic of a Two Value Capacitor Motor is shown below.

This type of motor is quiet and smooth running. They have higher efficiency than the motors that run on the main windings only. They are used for loads of higher inertia requiring frequent starts where the maximum pull-out torque and efficiency required are higher. The Two Value Capacitor Motors are used in pumping equipment, refrigeration, air compressors, etc.

4.1.3 Applications

These are used in low power applications and widely used in domestic applications as well as industrial. And some of those are mentioned below

- Pumps

- Compressors

- Small fans

- Mixers

- Toys

- High speed vacuum cleaners

- Electric shavers

- Drilling machines

4.2.1 Dynamically induced EMF

In dynamically induced electromotive force the magnetic field system is kept stationary, and the conductor is moving, or the magnetic field system is moving, and the conductor is stationary. Thus by following either of the two process the conductor cuts across the magnetic field and the emf is induced in the coil.

4.2.2 Fleming’s Right hand and Left hand rules

The DC motor or direct current motor works on that principal. This is known as motoring action.

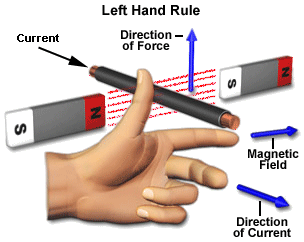

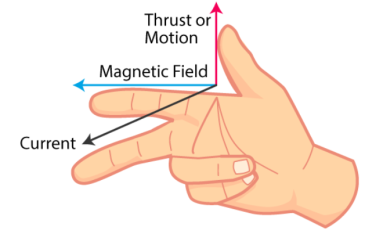

The direction of rotation of a this motor is given by Fleming left hand rule , which states that if the index finger, middle finger, and thumb of your left hand are extended mutually perpendicular to each other and if the index finger represents the direction of magnetic field, middle finger indicates the direction of current, then the thumb represents the direction in which force is experienced by the shaft of the DC motor.

According to Faraday’s law of electromagnetic induction, when a moving conductor is placed inside a magnetic field, a current will be induced in it. If the conductor is forcefully moved inside the magnetic field, there will be a relationship between the direction of applied force, magnetic field and the current. This relation between these three directions is determined by Fleming’s right-hand rule.

4.2.3 Construction and principle of operation of DC generator

A DC generator or direct current generator is one kind of electrical machine, and the main function of this machine is to convert mechanical energy into DC (direct current) electricity. The energy alteration process uses the principle of energetically induced electromotive force.

The DC generator working principle is based on Faraday’s laws of electromagnetic induction.

When a conductor is located in an unstable magnetic field, an electromotive force gets induced within the conductor. The induced e.m.f magnitude can be measured from the equation of the electromotive force of a generator.

If the conductor is present with a closed lane, the current which is induced will flow in the lane.

In this generator, field coils will generate an electromagnetic field as well as the armature conductors are turned into the field. Therefore, an electromagnetically induced electromotive force (e.m.f) will be generated within the armature conductors. The path of induced current will be provided by Fleming’s right-hand rule.

4.2.4 EMF equation

The emf equation of dc generator according to Faraday’s Laws of Electromagnetic Induction is

Eg= PØZN/60 A

Where Φ is a flux or pole within Webber

Z is a total no.of armature conductor

P is a number of poles in a generator

A is a number of parallel lanes within the armature

N is the rotation of armature in r.p.m (revolutions per minute)

E is the induced e.m.f in any parallel lane within the armature

Eg is the generated e.m.f in any one of the parallel lanes

N/60 is the number of turns per second

Time for one turn will be dt = 60/N sec

4.2.5 Types of DC Generators

Generators are classified based on how their fields are excited that is produced. There are three methods of excitation, and thus three main types of DC generators:

- Permanent Magnet DC Generators – Field coils excited by permanent magnets

- Separately Excited DC Generators – Field coils excited by some external source

- Self- Excited DC Generators – Field coils excited by the generator itself

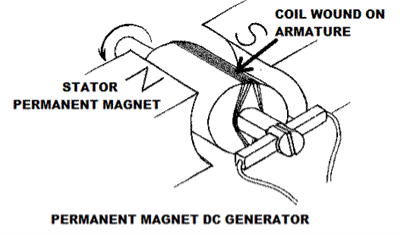

Permanent Magnet DC Generator

When the flux in the magnetic circuit is created through the use of permanent magnets, then it is known as a Permanent magnet DC generator.

It consists of an armature and one or several permanent magnets situated around the armature. This type of DC generator generates does not generate much power.

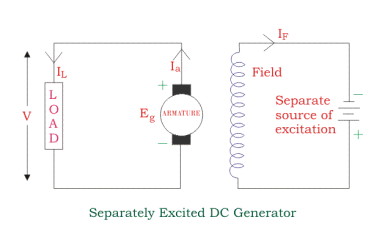

Separately Excited DC Generator

These are the generators whose field magnets are energized by some external DC source, such as a battery.

A circuit diagram of separately excited DC generator is shown in the figure below. The symbols below are:

- Ia = Armature current

- IL = Load current

- V = Terminal voltage

- Eg = Generated EMF (Electromagnetic Force)

Voltage drop in the armature = Ia × Ra (R/sub>a is the armature resistance)

Let,

Ia = I L = I

Then,

Voltage drop across the load V = I Ra

Power generated is equal to Pg = Eg x I

And power delivered to the external load is equal to

P L = V x I

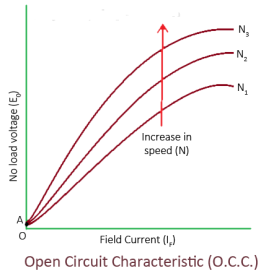

4.2.6 OCC characteristics

Open circuit characteristic is also known as magnetic characteristic or no-load saturation characteristic. This characteristic shows the relation between generated emf at no load (E0) and the field current (If) at a given fixed speed. The O.C.C. Curve is just the magnetization curve and it is practically similar for all type of generators. The data for O.C.C. Curve is obtained by operating the generator at no load and keeping a constant speed. Field current is gradually increased and the corresponding terminal voltage is recorded. The connection arrangement to obtain O.C.C. Curve is as shown in the figure below. For shunt or series excited generators, the field winding is disconnected from the machine and connected across an external supply.

4.2.7 Applications

- They are used for general lighting.

- They are used to charge battery because they can be made to give constant output voltage.

- They are used for giving the excitation to the alternators.

- They are also used for small power supply

4.3.1 Principle of operation of DC Motor

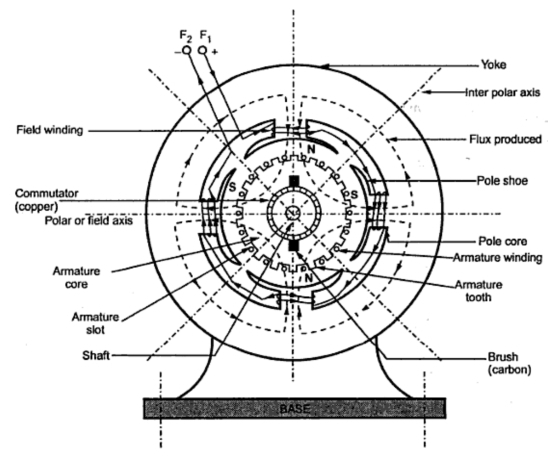

Whether machine is D.C. Generator or motor the construction basically remains the same.

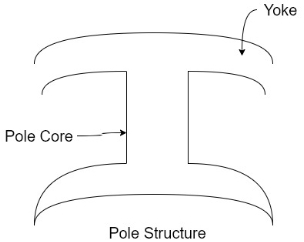

A cross section of typical D.C. Machine

1)Yoke

a) Functions

1. It serve the purpose of outermost cover of the D.C. Machine. So that the insulating materials get protected from harmful atmospheric elements like moisture. Dust and various gases like  , acidic fumes etc.

, acidic fumes etc.

2. It provides mechanical support to the poles.

3. It forms a part of the magnetic circuit.

It provides a path of low reluctance for magnetic flux. The low reluctance path is important to avoid wastage of power to provide same flux large current and hence the power is necessary if the path has high reluctance to produce the same flux.

4.Choice of material: - It is prepared by using cast iron, silicon steel is used which provides high permeability i.e. low reluctance and gives good mechanical strength.

2) Poles

Pole structure

Each Pole is divided into two parts namely

- Pol core

- Pole shoe

Functions of pole core and pole shoe: -

- Pole core basically carries a field winding which is necessary to produce the flux.

- It directs the flux produced through air gap to armature core to the next pole.

- Pole shoe enlarge the area of armature core to come across the flux, which is necessary to produce larger induced e.m.f. To achieve this, sports shoe has been given a particular shape.

Choice of material: -

It is made up of magnetic material like cast iron or cast steel.

As it requires a definite shape and size, laminated construction is used. The laminations of required size and shape are stamped together to get a pole which is then bolted to the yoke.

3) Field Winding (

The field winding is wound on the pole core with a definite direction.

a)Functions:-

To carry current due to which pole core on which the field winding is placed behaves as an electromagnet, producing necessary flux.

As it helps in producing the magnetic field i.e. exciting the poles as an electromagnet it is called Field winding or Exciting winding.

b) Choice of material:-

It has to carry current hence obviously made up of some conducting material.

So aluminium or copper is the choice. But field coils are required to take four types of shape and bent about pole core and copper has good pliability i.e. it can be bend easily. So copper is the proper choice .field winding is divided into various coils called field coils. These are connected in series with each other and wound in such direction around pole cores, such that alternate 'N' and 'S' poles are formed.

The total number of poles is denoted as P.

4) Armature

The armature is further divided into two parts namely

- Armature core

- Armature winding

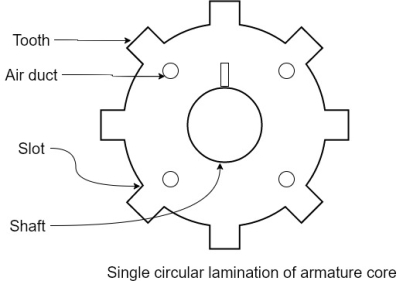

1.Armature core:- Armature core is cylindrical in in shape mounted on the shaft. It consists of slots on its periphery and air ducts to permit the air flow through armature which serves cooling purpose.

a) Functions-

1) Armature core provides house for armature winding i.e. armature conductors.

2)To provide the path of low reluctance to the magnetic flux produced by the field winding.

b) Choice of material: -

As it has to provide a low reluctance path to the flux, it is made up of magnetic material like cast iron or cast steel.

It is made up of laminated construction to keep Eddy current loss as low as possible. A single circular lamination used for the construction of armature core is shown in figure.

3. Armature winding

Armature winding is nothing but the interconnection of the armature conductors placed in the slots provided on the armature core periphery.

When the armature is rotated in case of generator magnetic flux gets cut by armature conductors and e.m.f gets induced in them.

a) Functions

1) curvatures of e.m.f takes place in the armature winding in case of generators.

2) To carry the current supplied in case of D.C. Motors.

3) To do the useful work in the external circuit.

b) Choice of Material: -

As armature winding carries entire current which depends on external load, it has to be made up of conducting material which is copper.

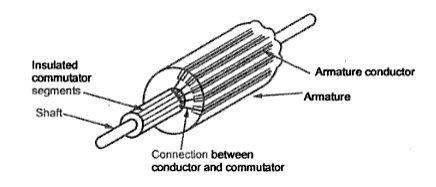

5.Commutator

The basic nature of e.m.f in the armature conductors is alternating. This needs verification in case of D.C. Generator, which is possible by a device called commutator.

a)Functions:

1)To facilitate the collection of current from the armature conductors.

2) To convert internally developed alternating e.m.f to unidirectional (D.C.) e.m.f.

3) To produce unidirectional torque in case of motors

b) Choice of Material:-

As it collects current from armature, it is also made up of copper segments.

It is cylindrical in shape and is made up of wedge-shaped segments of hand drawn high conductivity copper .the segments are insulated from each other by thin layer of Mica.

Each commutator segment is connected to the armature conductor by means of copper lug or strip. This construction is shown in figure above.

6. Brushes and Brush Gear

Brushes are stationary and resting on the surface of the commutator.

a) Function-

To collect current from computer and make it available to stationary external circuit.

b) Choice of Material: -

Brushes are normally made up of soft material like carbon.

To avoid wear and tear of commentator the brushes are made up of soft material like carbon.

7) Bearings

Ball bearings are usually used as they are more reliable. For heavy duty machines roller bearing are preferred.

4.3.2 Types of DC motors

1. DC series motor

2. DC compound motor

3. Short shunt compound motor

4.3.2 Applications

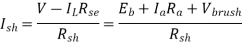

Voltage and current relationship

The voltage across armature and field winding is same equal to the supply voltage V.

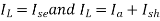

The total current drawn from the supply is denoted as line current

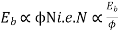

Now flux produced by the field winding is proportional to the current passing through it i.e.

As long as supply voltage is constant which is generally so in practice, the flux produced is constant.

Hence D.C. Shunt motor is called constant flux motor.

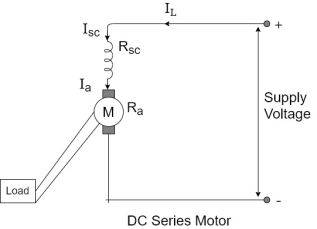

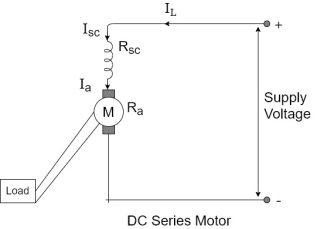

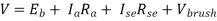

DC series motor

In this type of motor the series field winding is connected in series with armature and the supply as shown in figure. Let  the resistance of all the series field winding then the value of

the resistance of all the series field winding then the value of  is very small and it is made up of small number of turns having large cross section area.

is very small and it is made up of small number of turns having large cross section area.

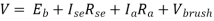

Voltage and current relationship

Let  be the total current drawn from the supply

be the total current drawn from the supply

So

And,.

Supply voltage has to overcome the drop across series field building in addition to  drop across armature winding.

drop across armature winding.

In series motor entire armature current is passing through the series field winding. So flux produced is proportional to the armature current.

for series motor

for series motor

DC compound motor

The compound motor consists of part of the field winding connected in series and part of the field winding connected in parallel with the armature.it is further classified as short shunt compound and long shunt compound motor.

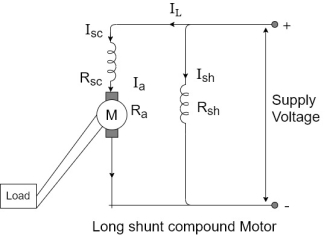

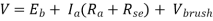

Long shunt compound motor

In this type the shunt field winding is connected across the combination of armature and the series field winding as shown in figure

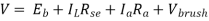

Voltage and current relationship

Let  be the resistance of series field and

be the resistance of series field and  resistance of shunt field winding.

resistance of shunt field winding.

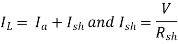

The total current drawn from supply is

So ,.

But,

And,

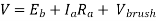

V=

But as

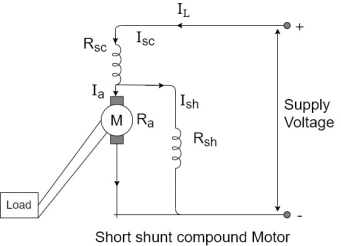

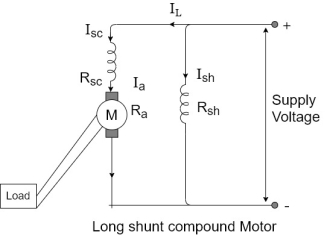

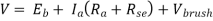

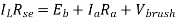

Short shunt compound motor

In this type the shunt field is connected properly in in parallel with armature and the series field is connected in series with the combination as shown in figure.

The entire line current is passing through the series field winding

Now the drop across the shunt field winding is to be calculated from the voltage equation

But,

Drop across shunt field winding=V-

A long shunt compound motor can be of cumulative or differential type. Similarly short shunt compound motor can be cumulative order differential type.

Torque and speed equations

Before analysing the various characteristics of motors, latest device the torque and speed equations as applied to various types of motors

for the torque equation

for the torque equation

This is because  to a constant for a given motor.

to a constant for a given motor.

Now  is the flux produced by the field winding and is proportional to the current passing through the field winding.

is the flux produced by the field winding and is proportional to the current passing through the field winding.

For a D.C. Shunt motor.  Is constant as long as supply voltage is constant. Hence flux is also constant.

Is constant as long as supply voltage is constant. Hence flux is also constant.

for shunt motors

for shunt motors

For DC series motor  same as

same as  . Hence flux is proportional to the armature current

. Hence flux is proportional to the armature current

For series motor lly as

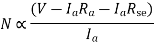

We can write the speed equation as

neglecting brush drop

neglecting brush drop

So for shunt motor the flux is constant

While for series motor flux is proportional to

These relations play an important role in understanding the various characteristics of different type of motors.