UNIT 5

ELECTRICAL INSTALLATIONS

Electrical protection equipment

Prerequisite:

1) Electromagnetism

2) Shock and its effects

3) Effect of temperature on a current carrying conductor or

4) Thermocouple

Learning outcomes at the end of this experiment student will be able to

1) Elaborate need of protect ion equipment in electrical systems

2) Explain the structure and operation of fuse, MCB,MCCB and ELVB.

3) Choose a protective device for its different electrical system with justification

Theory

Electrical power system operates at various voltage level from a 230 volt single phase, 415 volt to 765 kilovolt three phase or even more. Electrical apparatus used may be enclosed (e.g. Motors) or please in open (e.g. Transmission lines). All such equipment undergoes abnormalities in their lifetime due to various reasons. It is necessary to avoid these abnormal operating regions for the safety of the equipment.

Even more important is the safety of the human person which may be endangered due to exposure to live parts under fault or abnormal operating conditions. A small current of the order of 50 mA is sufficient to be fatal. Whenever human security is sacrificed for there exist the possibility of equipment damage, it is necessary to isolate and de energized the equipment. Designing electrical equipment from a safety perspective is also a crucial design issue which will not protect it and provide human safety under abnormal operating conditions. This job is assigned to electrical protection systems. It encompasses apparatus protection and system protection. This is generally carried out by using Switchgear is a generic term which includes all the switching devices associated with power system protection. It also includes or devices associated with control, metering and regulating of electrical power systems. Assembly of such devices in a logical manner forms switchgear. In other words system used for switching, controlling and protecting the electrical power circuits and different types of electrical equipment and known as which gear. The switchgear has to perform the function of carrying, making and breaking the normal load current like a switch and it has to perform the function of clearing the fort in in the power system. In addition to that, it also has the provision of metering and regulating the various parameters of electrical power systems. Thus the transformers, protection relays, measuring instruments, electrical switches, electrical fuses, miniature circuit breaker, lightning arresters or surge arresters, electrical isolators and other associated pieces of equipment.

Following are the major protective equipment used in household electrical appliances:

1) Fuse

2) Miniature circuit breaker (MCB)

3) Earth Leakage Circuit Breaker (ELCB)

4) Moulded Case Circuit Breaker (MCCB)

Fuse

A) Types of fuses and applications

In the field of electronics or electrical, a fuse is an essential device used in various electrical circuits which gives the protection from the overcurrent. It it comprises a strip or a metal wire that dissolves when the heavy flow of current comprises a strip or a metal wire that dissolves when the heavy flow of current supplies through it. Once this device has function in an open circuit, it ought to ji wire or changed based on the type of fuse. A fuse is an automatic disconnection of supply which is frequently shortened to ADS. The alternative of the fuse is a stabilizer or circuit breaker, but they have many different characteristics.

B) Why do we require Fuse?

- These are used to prevent the home appliances from the high current or overload damage. If we use a fuse in the homes, the electrical faults cannot happen in the wiring and it doesn't damage the appliances from the fire of wire burning. When the fuse gets break or damage, then an abrupt sparkle happens which made direct to damage your home appliances. That is the reason we required different types of fuses to guard our home appliances against damage.

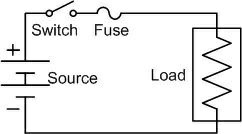

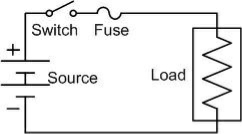

C) Working principle of Fuse

The working principle of the fuse is “ heating consequence of the current”. It is fabricated with a lean strip for thread of metallic wire. The connection of the fuse in an electrical circuit is always in series. When the too much current is produced due to the heavy flow of current in the electrical circuit the fuse get soft and it opens the circuit. The extreme flow of current main direct to the collapse of the wires and prevents the supply. Diffuse can be changed by the new fuse with an appropriate rating. It can be designed with elements like copper, zinc, aluminium and silver. They also perform like a circuit breaker for breaking the circuit while the abrupt fault happens in the circuit. This works like a safety measure for protector for humans from risk. Like this, the fuse works

Fuse rating =

The selection of a fuse can be done by calculating the fuse rating by using the above formula

- Write down the voltage (volts) and power (watts) of the appliance.

- Calculate the fuse rating.

- After the result use the maximum fuse rating. For instance, if the calculated fuse rating is the maximum fuse rating. For example, if the calculated fuse rating is 7.689 amps, you can use an 8 amp fuse.

Different types of Fuses:

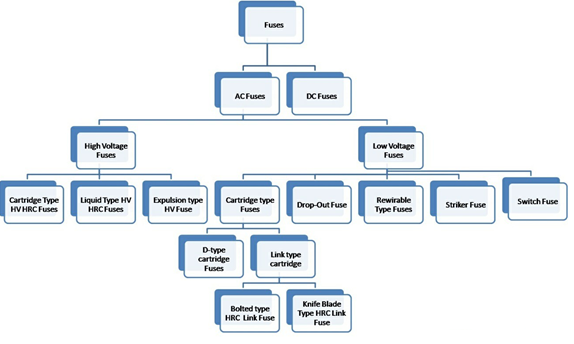

The fuses are classified into to several types based on the application namely AC type fuse and DC type fuse. Again these fuses are classified into several types. The following diagram illustrates the electrical fuse types chart based on the AC fuse and DC fuse.

The fuses are classified into to several types based on the application namely AC type fuse and DC type fuse. Again these fuses are classified into several types. The following diagram illustrates the electrical fuse types chart based on the AC fuse and DC fuse.

DC fuse:

DC fuses are available superior in size and DC supply has a stable value over 0 volts. So it is tough to remove and deactivate the circuit. There will be a chance of generation of electrical Arc between dissolved wires. To conquer this electrodes located at battery distances. For this reason the size of the DC fuse gets amplified.

AC fuses:

The AC fuse is lighter in size and oscillated 50 to 60 times in each and every second from least to highest. As a result, there is no scope for Arc generation between the dissolved wires. For this reason, they can be crammed into a small size. Further, AC fuses are classified into two parts namely HV fuses and LV fuses. Here LV and HV indicates the low voltage and high voltage LV fuses. The low voltage fuses are divided into five types such as rewirable, cartridge, dropout, striker and switch fuses.

Rewirable fuses:

Rewirable fuses are LV fuses, which are almost used in small applications like wiring in in the house, small scale industries, and other tiny current applications. These types of fuses include two essential parts such as a fuse base which has two terminals like in and out. In general, this element is fabricated with porcelain. Another part of this fuse is a fuse carrier, which grip the fuse element. This element is fabricated with aluminium, tinned copper and lead. The main advantage of a fuse carrier is, we can simply plug and remove from the base of the fuse without the risk of shock. As the fuse is damaged due to heavy current, then we can simply eliminate the fuse carrier as well as put back the fuse wire.

Cartridge type fuses:

The cartridge type of fuses has entirely closed containers and the metal contact as well. The applications of this fuses mainly include low voltage (LV), high voltage (HV) and small fuses. Again this types of fuses are classified into two types, they are D type and link type fuses.

D type Cartridge Fuse

This type of fuse is composed with the cartridge, base of the fuse, adapt or ring, and cap. The base of the fuse includes a fuse cap, which is packed with the fuse ingredient by cartridge using an adapter ring. It is composed of the cartridge, fuse base, cap and adaptor ring. The fuse base has the fuse cap, which is fitted with the fuse element with a cartridge through the adaptor ring. The connection of the circuit is finished when the tilt of the cartridge builts contact through the conductor.

High Rupturing capacity or Link Type Fuse:

The link type fuse is also known as high rupturing capacity (HRC) or BS type fuse. In this sort of fuse, the current flow with fuse element is specified under standard condition in this BS type fuse, the flow of current by fuse element is given under normal condition. The arc which is generated by the fuse blown is controlled is fabricated with porcelain, ceramic and silver. The container of the fuse element is packed with silica sand. This type of use is again characterized into two parts includes a blade type and bolted type.

Blade and bolted type fuses

The knife type fuse for plugin type of fuses are designed with plastic. This type of use can be simply changeable in the electric current exclusive of any load in bolted type fuse, plates of this fuse are conducting are set to the base of the fuse.

Striker type fuse

Describe the type of fuse is employed for tripping and closing the electrical circuit. This fuses are having plenty of force as well as displacement.

Switch type fuse

Basically the switch type fuse is enclosed with a metal switch and also a fuse. These fuses are mainly used in low and intermediate voltage levels.

HV (High voltage) Fuses

Generally, HV fuses are used to protect the transformers like instrument transformers, small Power transformer and also used in power systems. These fuses are normally charged for voltages over 1500 volt to 138000 volte.

The fuse part in HV fuses are fabricated with either copper, silver or in some cases tin is used, in order to offer consistent and steady performance. These fuses are classified into three types which include the following.

Cartridge type HRC fuse

The fuse component of the HRC is cut in The helix form which evades the effect of the corona at the upper voltages. It includes to fuse elements namely low resistance and high resistance, and that are located parallel by each other. The low resistance wires take the usual current which is is blown out as well as decreases the short circuit current throughout the fault state.

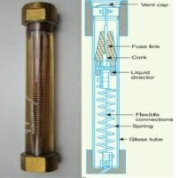

Liquid type HRC fuse

This type of fuse is packed with carbon tetrachloride also preserved at both the tops of the caps. Once the error occurs when the following current surpasses away from the allowable limit and the element of the fuse is blown out. The flute of the fuse performs as an Arc extinguishing standard for the HRC fuse types. They may be used to protect the transformer as well as the support protection to the breaker circuit.

Expulsion type HV fuse

These types of fuses are extensively used to protect the feeders as well as transformer due to they're low priced. It is designed for 11kV, also their cracking capability is up to 250 MVA. This type of use includes and unfilled open finished cylinder designed with synthetic resin bonded paper. The elements of the fuse are positioned in the cylinder, and the tops of the tubes are linked to appropriate equipment at every finish. The ark generating is blown off in the inside covering of the cylinder, and gases thus shaved destroys the arc.

A)Applications of Fuse

The different types of fuses and their uses have discussed are essential components in all the electrical circuits. Some of the main applications of uses in the electrical and electronics field include the following.

Power Transformers, electrical appliances, like ACs (Air Conditioners), TV, washing machines, music systems and many more, electrical cabling in home, mobile phones, motor starters, laptops, power chargers, cameras, scanners, printers, add photo copiers, automobiles, electronic devices and gaming's.

B)Advantages of an Electrical Fuse

1) It is the cheapest form of protection and it doesn't need any maintenance.

2) Its operation is completely automatic and requires less time as compared to circuit breakers.

3) The smaller sizes of fuse element impose a current limiting effect under short circuit conditions.

4) Its inverse time current characteristic enables its use for overload protection.

D)Disadvantages of an Electrical Fuse

1) Considerable time is required in replacing a fuse after the operation.

2) The current time characteristic of fuse cannot always be correlated with that of the protective device.

Miniature Circuit Breaker:

Miniature Circuit breakers (MCB) are electromechanical devices which are used to protect electrical equipment from an over current. MCB is a a mechanical switching device which is capable of making, caring and breaking currents under normal circuit conditions and also making, caring for a specified time and automatically breaking currents under specified abnormal circuit conditions such as those of short circuit. In short MCB is a device for over load and short circuit protection.

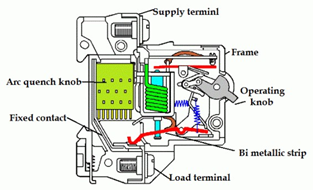

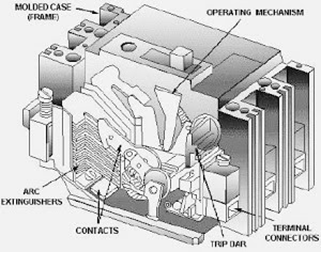

A) Construction :- The construction of miniature circuit breakers is very simple, robust and maintenance free. MCB is replaced by a new one when it is failing because MCB is not repaired or maintained. There are three types of miniature circuit breakers in construction,

1) Frame:- Frame is a rigid, strong, insulated housing in which the other components are mounted. It is a moulded case.

2) Trip unit : For the proper working of the miniature circuit breaker trip unit is responsible. Two main types of trip mechanism are provided in Miniature circuit breaker (MCB). a bimetallic strip provides protection against overload current and an electromagnet provides protection against short circuit current. Trip unit is the main part of the MCB.

3) Operating Mechanism :- The operating mechanism of MCB provides with the manual operation for closing and opening operation of the miniature circuit breaker. It has three positions “ON”, “OFF”, “TRIPPED”. By observing the position of the switching latch one can determine the condition of MCB whether it is closed, tripped or manually switched off. If the MCB is tripped due to overcurrent or overheating. The external switching latch in the “TRIPPED” position. When manually switch off the miniature circuit breaker, the switching latch will be in “OFF” position. The switch is positioned at “ON”, in a closed condition of the miniature circuit breaker.

B)Working:- The principle of operation is simple. Functions of miniature circuit breaker is interrupting the continuity of electrical flow through the circuit once a fault is detected. In simple terms of MCB is a switch, which automatically turns off when the overcurrent flowing through it. Generally, MCB is designed to to protect against overcurrent and over temperature false. There are two contacts one is fixed and the other movable. When the current exceeds the predefined limit a solenoid forces the movable contact to open (ie. Disconnect from the fixed contact) and the MCB getting off thereby stopping the current to flow in the circuit point the MCB is manually turned on to restart the flow of current. This mechanism is used to protect from the faults arising due to over current. To protect against fault arising due to overheating for increase in temperature bimetallic strip is used. MCB are generally designed to trip within 2.5 million seconds when an overcurrent fault arises. In case of temperature rise or overheating it may take 2 seconds to 2 minutes for the MCB to trip. If the circuit is overloaded for a long time, the bimetallic strip becomes overheated and deformed. This the formation of bimetallic strip causes, displacement of latch point moving contact of the MCB is show arrange by means of spring pressure, with this large., That is little displacement of large causes, release of spring and makes the moving contact to move for opening the MCB. The current coil for trip coil is placed such a manner that during short circuit fault the MMF of that causes its plunger to hit the same latch. And make the large to be displaced. Hence the MCB will open in the same manner. And it protects the circuit from the overcurrent overloading.

A) Advantages:-

1) With a miniature circuit breaker, it is very simple to resume to the supply. You just need to push the knob of MCB back to on position. But in case of fuse, the entire fuse wire needs to be replaced.

2) A miniature circuit breaker is more sensitive to current then fuse. It detects any abnormality in the current flow and automatically switches off the electrical current.

3) A miniature circuit breaker is reusable and hence has less maintenance and replacement cost point where as a fuse leads to the replaced whenever it goes faulty.

4) In case of a miniature circuit breaker, the faulty zone of an electrical circuit can be easily identified.

B) Types of MCB

There are three standard characteristics are available for domestic as well as commercial MCB are given by B,C and D. Each type has its own function

Type B

MCB are mainly used where switching surges are small or non exist and are generally suitable for domestic applications and light commercial applications. There are no devices with long high starting current in domestic applications and has the best suited MCB is type B. These are designed to trip at fault currents in the range of 3 to 5 times the rated current. Suppose if the rated current is 10 ampere then the MCB trips at 30-50 A.

Type C

MCB are designed for high inductive circuits where surge currents are expected. These are generally used for commercial and industrial applications where a number of fluorescent lamps been turned ON or starting of small motors may give high search currents.

These are more sensitive than type B MCB and causes reduced nuisance trips. Type C MCB are designed to operate for trip at the fault currents of 5 to 10 times that of rated current. For 10 A type C MCB, the operating current range is 50 – 100 A.

Type D

MCBs are designed for heavy industrial applications where normal surge currents are very high. These are ideal for electrical welders and site Transformers where frequent high surge currents are expected.

The most common applications of type D MCBs include motors, UPS systems comma x-ray machines, Transformers and battery charging systems. These are designed to trip at 10 – 20 times The rated current. For 10 A type D MCBs, the operating current range is 100 – 200 A.

The setting or characteristics of an MCP are fixed in the factory itself by the manufacturer and they are not adjustable at the user end or at the site. Tripping currents for operation at 0.1 second or less different MCBs are given below.

Type B | 3-5 times rated current |

Type C | 5-10 times rated current |

Type D | 10-20 times rated current |

Earth Leakage Circuit Breaker (ELCB)

An ECLB is one kind of safety device used for installing an electric device with high Earth impedance to avoid shock. These devices is identify small stray voltages of the the electrical device on the metal enclosures and intrude the circuit if a dangerous voltage is identified. The main purpose of Earth leakage circuit breaker is to stop damage to humans and animals due to electric shock. Earth leakage circuit breaker is a device used to directly detect currents leakage to earth from an installation and cut the power and mainly used in TT earthing systems.

There are two types of ELCBs :

1) Voltage Earth leakage Circuit Breaker (voltage ELCB)

2) Current Earth Leakage Circuit System (Current ELCB)

Voltage ELCB have first introduced about 60 years ago and current ELCB was first introduced about 40 years ago. For many years, the voltage operated ELCB and the differential current operated ELCB were both are referred to as ELCB because it was a simpler name to remember. But the use of a common name for two different devices gave rise to.

Considerable confusion in the electrical industry. If the wrong type was used on an installation, the level of protection given could be substantially less than that intended. To ignore this confusion, IEC decided to apply the term residual current devices (RCD) two differential current operated ELCBs. Residual current refers to any current over and above the load current.

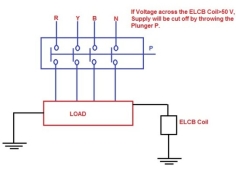

A)Working Principle of Voltage ELCB:-

ELCB is a voltage operated device. It has a coil and if the voltage across the coil exceeds as a predetermined value such as 50 V, the current through the coil will be sufficient enough to trip the circuit. Voltage ELCB is connected in between the metallic part of equipment and the Earth. If we take an example of insulation failure then the voltage across the coil of voltage ELCB will drive enough Karan to cut the power supply till the manually reset. The way to identify an ELCB is by looking for green or green and yellow Earth wire entering the device. They relay on voltage returning to the trip via the earth wire during a fault and effort only limited protection to the installation and no personal protection at all. You should use plugin 30 mA RCD's for any appliances and extension leads that may be used outside as a minimum.

Advantages of voltage operated ELCB

- ELCB are less sensitive to fault conditions and have few nuisance trips.

- While current and voltage on the ground line generally fault current from live wire, this is not continuously the case, therefore there are conditions in which an ELCB can annoyance trip.

- When installation of the electrical instrument has two contacts to earth, a near high current lighting attack will root a voltage gradient in the earth, offering the ELCB sense coil with sufficient voltage to source it to a trip.

- If either of the soil wires became detached from the ELCB , it will no longer install will frequently no longer be corrected earthed.

- These ELCB are the necessity for a second connection and the opportunity that any extra connection to ground on the theatre system can in activate the detector.

Disadvantages of voltage operated ELCB

- They do not sense errors that don't permit current through the CPC to the ground rod.

- They do not permit an only building systems to be simply divided into many sections with independent error protection because earthing systems are typically used mutual earth rod.

- They may be skipped outside voltages from something associated with the earthing system like as metal, a TN-C-S or a TN-S Earth mutual neutral and earth.

- As electrical leaky utilizations like washing machines, some water heaters and cookers might source the ELCB to trip.

- ELCB present an extra resistance and an extra point of failure in the earthing system.

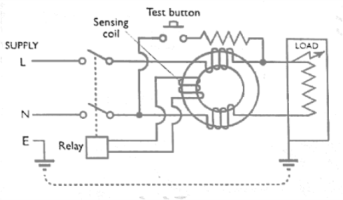

B) Working Principle of Current (ELCB) :

The working of current ELCB is quite interesting but easy. Current operated ELCB is also known as Residual Current devices (RCD). Residual current device (RCD) has a toroidal iron core over which phase and neutral windings are wound. A search coil is also mood on the same iron core which in turn is connected to the trip coil. Figure below shows the constructional detail of RCD or current ELCB.

Under normal operating condition, the current through the phase building and neutral building are same but both the windings are wound in such a manner to oppose the mmfs of each other, therefore net mmf in the toroidal iron core will be zero. Let us consider a condition where Earth leakage current exists in the lord side. In this case the current through the phase and neutral will no longer be equal rather phase current will be more than the neutral current. Does MMF produced by face building will be more than the MMF produced by neutral building because of which a net MMF will exist in the toroidal iron core.

Net MMF in core = MMF by phase winding - MMF by neutral winding

This net MMF in the core will link with the search coil and aa MMF is changing in nature (current is AC), an EMF will be induced across the terminals of search coil. This will intern drive a current through the trip coil which will pull (because of current flow through the trip coil ok, it will behave as an electromagnet and hence will pull the lever to open contact) the supply contacts to isolate the power supply. Notice that current ELCB works on residual current that is the reason it is also called residual current device. A RCD/ Current ELCB is also provided with test button to check the healthiness of the safety device. If you carefully observe the figure, you will notice that, when we press the test button, load and face building are bypassed due to which only MMF because of neutral winding will exist in the core (as there is no opposing MMF as was the case with both the windings in service) which will cause RCD to trip to isolate supply.

Moulded Case Circuit Breaker:

Melded Case Circuit Breaker are electromechanical devices which protect a circuit from overcurrent and short circuit. They provide overcurrent and short circuit protection for circuits ranging from 63 Amps up to 3000 Amps. Their primary functions are to provide a means to manually open a circuit and automatically open a circuit under overload or short circuit conditions. The overcurrent, in an electrical circuit result from short circuit overload for faulty design.

Unlike fuse, and MCCB can be easily reset after of faulty and offers improved operational safety and convenience without incurring operating cost.

Moulded case circuit breakers generally have a thermal element for overcurrent and magnetic element for short current release which has to operate faster. MCCBs are manufactured such that end user will not have access to internal workings of the overcurrent protection device. Generally constructed of two pieces of heavy duty electrically insulated plastic, these two halves are riveted together to form the whole point inside the plastic shell in a series of thermal elements and a spring loaded trigger point when the thermal element gets too warm from an over current situation, the spring strips, which in turn will shut off the electrical circuit.

A) Sizing the MCCBs : MCCBs in an electrical circuit should be sized according to the circuit's expected operating current and possible fault currents. The three main criteria while selecting MCCBs are:

- The rated working voltage (Ue) the MCCB should be similar to the system voltage.

- The trip value of the MCCB should be adjusted according to the current drawn by the load.

- The breaking capacity of the MCCB must be higher than the theoretical possible fault currents.

A) Types of MCCB:

Types of MCCB | Operating current | Operating time | Application | Suitability | Surge current | Installation location |

Type B | Trips between 3 and 5 times rated current (In) | 0.04 – 13 seconds | Domestic applications (lighting and resistive elements) | Resistive load application | Low | Sub feeder of distribution board |

Type C | Trips between 5 and 10 times rated current (In) | 0.04 – 5 seconds | Commercial or industrial applications | Inductive load applications | Moderate | At incoming/outgoing of distribution board |

Type D | Trips between 10 to 20 times rated current (In) | 0.04 – 3 seconds | Commercial or industrial applications | Inductive capacitive load applications (pumps, motor, large winding motors e.t.c.) | High | At incoming of distribution board/panels |

Type K | Trips between 8 to 12 times rated current (In) | 0.04 – 5 seconds | Industrial applications | Inductive and motor loads with high in rush currents | High | At incoming of distribution board/panels |

Type Z | Trips between 2 to 3 times rated current (In) | 0.04 – 5 seconds | Highly sensitive to short circuit and are used for protection of highly sensitive devices such as semiconductor or devices | Medical instruments | Very low | At sub feeder of of distribution board for IT equipment |

There are six types of wires :

Vulcanised Indian rubber wire.

Tough Rubber sheathed wire

Poly vinyl chloride wire

Lead alloy sheathed wire

Weather Proof wires

Flexible wire

- VIR

A VIR wire mainly consists of tinned conductor having rubber coating.

Tinning of conductor prevents the sticking of rubber to the conductor

Thickness of rubber mainly depends on the operating voltage to which the wire is designed.

A cotton bradding is done over the rubber insulations to protect the conductor against moisture.

The wire is finished with wax for cleanliness.

TRS (Tough Rubber Sheathed) wires.

- This type of wire is a modification of V.I.R. Wire. It consists of the ordinary rubber coated conductors with an additional sheath of tough rubber.

- This layer provides better protection against moisture and wear and tear. Also, it provides an extra insulation.

- These wires are generally available in single conductor, two conductors or three conductors.

P.V.C

This is the most commonly used for wiring purpose.

The conductor is insulated by poly vinyl chloride

It has the following properties:

Moisture proof

Tough

Durable

Chemically inert

It softens at high temperatures therefore it is not suitable for connection to heating appliances.

Lead alloy sheathed wires:

The ordinary wires can be used only at dry places but for damp places these wires are covered with continuous lead sheaths. The layer of lead covering is very thin like 0.12cm thick. These wires provides mechanical protection to the wires.

Weather- proof wires.

These types of wires are used outdoor that is providing a service connection from overhead line to building etc.

In this type of wire the conductor is not tinned and the conductor is covered with three braids of fibrous yarn and saturated with water- proof compound.

Flexible wires

These wires consists of number of strands instead of a single conductor. (Strand is a very thin conductor).

The conductor is insulated with P.V.C. Material.

These wires are very useful for household portable appliances where flexibility of wire is more important.

Typical specifications 55/.01mm(55 strands of 0.1mm diameter), maximum current 6A,used for household purposes.

TYPES OF CABLES.

The types of cables basically decided based on the voltage level for which it is manufactured and material used for the insulation such as paper, cotton, rubber etc. the classification of cables according to the voltage levels is,

Low Tension Cables (L.T. Cables). Medium and High- tension Cables (H.T. Cables).

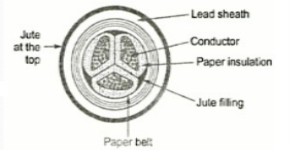

BELTED CABLES.

These cables are used for the voltage level up to 11 kV. The construction of belted cable is is shown in fig.

The cores are not in circular shape.

The cores are insulated from each other by use of impregnated paper.

The gaps are filled with fibrous material like jute.

The belt is covered with lead sheath.

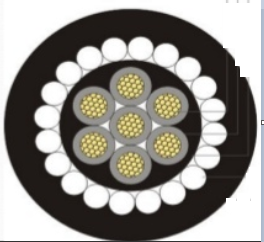

SCREENED TYPE CABLES.

These cables are used for the voltage levels of 22 kV.

The two types of screened cables are: H-Type cables. S.L. Type cables.

H-Type cables.

Designed by M. Hochstetler and hence named H-type cable.

No paper belt in this type of cable.

Each conductor is insulated with a paper, covered with a metallic screen.

S.L. Cables.

S.L. Leads for Separate Lead Screened Cables.

Each lead is insulated with an impregnated paper than covered by separate sheath lead.

SUPER TENSION (S.T.) CABLES.

The S.T. Cables are intended for 132 kV to 25 kV voltage levels.

In such cables, the following methods are specially used to eliminate the possibility of void formation:

Instead of solid type insulation, low viscosity oils under pressure is used for impregnation.

Using inert gas at high pressure in b/w the lead sheath & dielectric.

OIL FILLED CABLES

In case of oil filled cables, the channels or ducts are provided within or adjacent to the cores, through which oil under pressure is circulated.

It consists of concentric standard conductor but built around a hallow cylindrical steel spiral core, which acts as a channel for oil.

GAS PRESSURE CABLES

An inert gas like N at high pressure is introduced lead sheath and dielectric.

Gas like SF6 is also used in cables.

Pressure is about 12-15 atmosphere.

Working power factors is also high.

The system of connecting the metal casing of an electrical appliance to a copper plate buried deep inside the earth is called as earthling. Many appliances such as an electric heater, a toaster, an oven, a refrigerator etc. have a metallic body (casing). If with use the insulation of a wire breaks or melts, the live wire may touch the metal casing. If we happen to touch the casing carrying a current, we may receive a severe shock which may cause death. To avoid this, metal casings of all electrical appliances are earthed. One end of a thick copper wire is connected to the metal casing of the appliance and the other end is connected to a copper plate buried deep inside the earth. The current through the metal casing then flows to the earth and the person touching the casing is saved.

Cell: A device which is used as a source of EMF and which works on the principle of conversion of chemical energy into electrical energy is called cell.

Battery: the combination of various cells to obtain desired voltage level is called as a battery.

Electrolyte: which undergoes decomposition due to flow of electrons.

- Basic electrical energy generation in cell.

- In any cell two different conducting materials are immersed in an electrolyte. The chemical reaction results in separating charges. The charges accumulate on the conductor such charged conductors are called as electrodes.

+Ve charge electrodes-> anode

-ve charged electrodes-> cathode

- Discharge accumulated on electrodes create potential difference between two conductors.

- The conductors and are marked as positive and negative and connected to load. Thus chemical energy is converted into electrical energy. Hence cell is an electrochemical device.

Types of cell

- Primary cell

- Secondary cell

Primary | Secondary |

Electrical energy indirectly obtained from chemical energy. | Electrical energy is already present in the cell in form of chemical energy and then converted to electrical energy. |

Chemical reactions are irreversible (cannot be recharged) | Chemical reactions are reversible. |

Cell is replaced when it goes down. | Cell is recharged back. |

Polarisation is present. | Polarization is absent. |

Low efficiency. | High efficiency. |

Capacity is low. | Capacity is high |

Less cost | High initial cost. |

No maintenance is required. | Frequent charging and other maintenance is required. |

- Basic components of battery

- Positive electrode i.e. anode

- Negative electrode i.e. cathode

- Electrolyte

- Separator

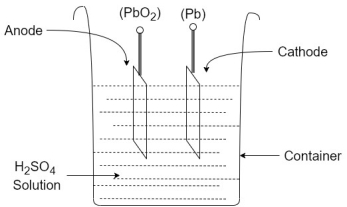

Lead acid battery

Construction

- Positive plate or anode:- it is lead peroxide plate of chocolate dark brown colour.

- Negative plate or cathode:- it is made up of pure lead which is grey colour.

- Electrolyte:- for necessary chemical reaction solution of sulphuric acid is used as electrolyte.

- Separators:- the positive and negative plates are arranged in groups and are placed alternately. The separators are used to prevent them from coming in contact with each other resulting in short circuit of cell.

- Plate connector:- the number of negative and positive plates are assembled alternately. To connect the positive plates together separate connectors are used which are called plate connectors. The upward connection of the plate connectors are nothing but the terminals of the cell.

- Vent plug:- these are made up of rubber and screwed to the cover of cell. It functions to allow the escape of gases and prevent escape of electrolyte.

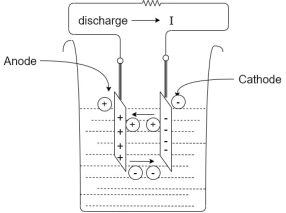

Charging and discharging of lead acid battery

- When the current is passed for the first time through electrolyte the

In the electrolyte is electrolysed as:

In the electrolyte is electrolysed as:

- Hydrogen ion is positively charged get attracted towards one electrodes which acts as cathode the hydrogen does not react with lead electrode hence retains its original state and colour.

- The oxygen ion as negatively charged get attracted towards other lead plate which acts as anode oxygen combines with lead and form lead peroxide this results in dark brown in colour.

- Hence there exist a potential difference between anode and cathode which is used to drive external circuit.

Discharging: -

When external supply is disconnected and a resistance is connected across the anode and cathode then current flows through the resistance drawing and electrical energy from the battery this is discharging.

Recharging- The cell provides the discharge current for limited time and it is necessary to recharge it after regular time interval. Again and EMF is injected through cell terminal with help of external supply.

Rating of lead acid battery

- The capacity is about hundred to 300 Ampere hours.

- The voltage is 2.2 volt for fully charged condition.

- The cost is low.

- The internal resistance is very low.

- The current rating are high.

- The ampere hour efficiency is about 90 to 95% with 10 hour rate.

Maintenance and precautions to be taken for lead acid battery

- The battery must be recharge immediately when it discharges.

- The level of electrolyte must be kept above top of plates.

- The rate of charge and discharge should not exceed as specified by manufacturer.

- Maintain specific gravity of electrolyte between 1.28 to 1.18.

- The loss of water due to evaporation and gassing must be made up using only distilled water.

- The connecting plugs should be kept clean and properly tightened.

- It should not be discharged till its voltage for below 1.8 volt.

- It should not be kept long in discharged condition.

- The temperature of battery should not exceed 45°c otherwise plates get deteriorate rapidly.

- The battery terminal should not be shorted to check whether battery is charged or not.

Applications

- In emergency lighting systems.

- In automobiles for starting.

- UPS systems

- Railway signalling

- Electrical substations and power stations

- For component feeder drop in case of heavy loads.

- For energizing trip coils in release and switchgears.

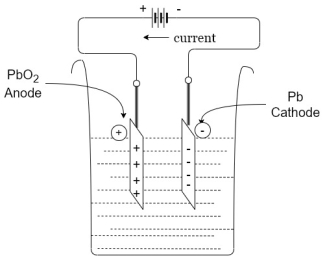

Lithium ion battery

The lithium ion battery works on the principle of movement of lithium ions from electrodes.

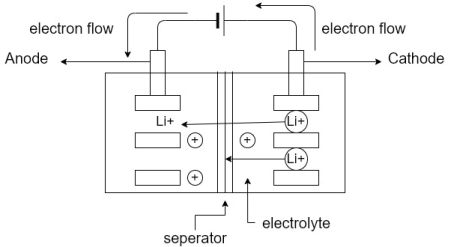

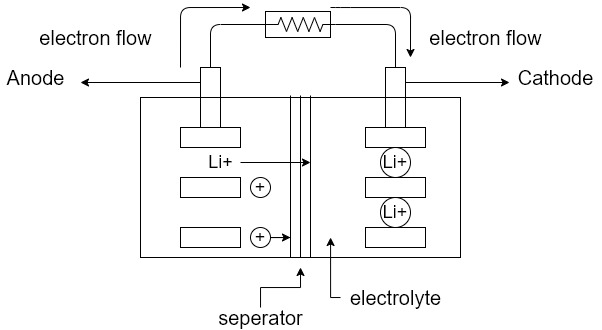

Construction

- The lithium ion battery is made up of an anode cathode, separator, electrolyte and to current collectors (+ve and -ve)

Anode-> lithium ion uses carbon electrode as its anode with a current collector of thin copper foil.

Cathode -> it uses lithium cobalt oxide commonly used for cathode with the current collector made up of thin aluminium foil.

Separator-> a separator is a fine porous polymer film.

Electrolyte-> it is the solution based on a lithium salt in an organic solvent.

Both electrodes are made up of materials which can “intercalote” or “absorb” the lithium ions.

Working

- Lithium ions are inserted in cathode.

- For charging the battery is connected to an external power supply.

- Due to this oxidation occurs at the cathode and it loses electrons which are negatively charged.

- To maintain the charge balance in the cathode equal number of lithium ions are already dissolved in electrolyte solution.

- The lithium ion travel through electrolyte and reach to anode.

- The separator use does not allow the electrons to flow through an electrolyte. The electrons travel through the external wire and reach to anode from cathode.

- At cathode the electrons get tied with lithium ions.

- At time of discharging the opposite reactions occur

- Anode releases electrons and ions.

- Ions get dissolved in electrolyte and electrons travel from cathode to anode through external circuit.

- Due to flow of electrons from the external circuit the current is established and device connected to battery is operated.

- When the cathode is full of lithium ions discharging stops and battery needs to be recharged again.

Advantages

- Cell voltage is high when is about 3.6 volte. Less number of cells are required if high voltage is required.

- The battery is light in weight and compact in size.

- It holds charge for longer period. It only losses 5% of its charge month

- It is not required to discharge it completely before charging.

- It has built-in protection to prevent overheating.

- It is rechargeable battery.

Disadvantages

- Its performance is affected due to high temperature.

- Not possible to recharge if it is completely discharged.

- It is costly

- It can burst into flames if separator get damaged.

- It requires protection circuit to maintain voltage and current within safe limits.

Applications

- Used in cameras and calculators.

- Used in mobile phones radios and laptops

- Used in aerospace applications.

- Used in electric vehicles and mine detectors.

- Used in toys and rechargeable flashlights.

Battery efficiency

- It is defined as ratio of output during discharging to the input required during charging.

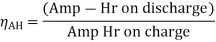

Ampere hour efficiency or quantity

- It is defined as ratio of output in ampere Hours during discharging to input in ampere Hours during charging.

It is denoted by

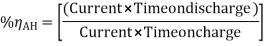

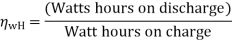

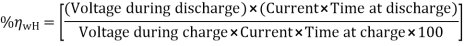

2.Watt hour efficiency

It is defined as the ratio of output in watt hour during discharging to the input in watt hours during charging denoted by

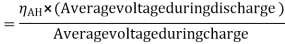

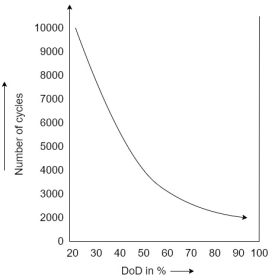

Concept of depth of discharging

- The depth of discharge is Q. Key factor for any factory it is denoted by DOD.

- It indicated the degree to which the battery can be discharged to certain minimum voltage from its full state of charge.

- The the depth of discharge give the indication that up to which level of discharge the battery capacity can be used safely.

- DOD is defined as the capacity in ampere hours that is discharged from a fully charged battery, divided by battery nominal capacity.

- DOD is normally represented in percentage.

- For example if a 200 Ah battery is charged at 90 A for 30 minutes then its depth of discharged is

=22.5%

- The department of discharge is important because the lifespan of many battery such as lead acid battery and lithium ion battery depends heavily upon the number of charge and discharge cycles.

- If the DOD is high then lifespan of battery get shortened .for example battery may have 5000 cycles at 20% but only 1500 cycles at 80% of the body as shown in below graph

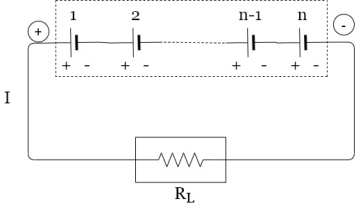

Grouping of batteries

A single battery is not sufficient to provide the necessary voltage in many cases. Thus number of batteries are connected in following manner to obtain desired voltage and result.

- Series grouping of batteries

- Parallel grouping of batteries

- Series parallel grouping of batteries

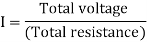

Series grouping

E= EMF of each batteries

r= Internal resistance of each battery

V=Total voltage =n×E volts

=Total resistance

=Total resistance

= Total batteries

=

In series circuit current remain same so in this method does not improve current capacity. The current capacity is same as that of each battery connected in series. But voltage can be increased by increasing number of batteries n.

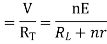

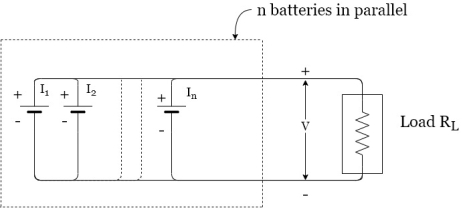

Parallel grouping

- In this method positive terminal of batteries are connected together and negative terminals are connected together as shown above.

- The Terminal of each battery must be same as E

V=battery voltage=E=EMF

r=internal resistance of each battery

=Current through nth branch.

=Current through nth branch.

I=Total current

- In parallel grouping the voltage remains the same but by increasing number of batteries the current capacity can be increased.

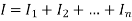

Series parallel grouping

- Each group is a series combination of batteries as shown in above figure and various groups are connected in parallel.

- This is used to satisfy both voltage and current requirement of load.

Safety precautions in battery maintenance

- Person doing the maintenance must be authorized person.

- Must have protecting equipment such as goggles, chemical resistance gloves, argon and shoes.

- Before entering battery room ensure that the ventilation system is operable and in service.

- Verify that the UPS is off and power code is disconnected from source.

- Ensure that sufficient water facilities are available nearby.

- Never connect cell in series of parallel. They do not have identical output voltage

- Verify circuit polarities before making the connections.

- Use protective devices while charging or discharging.

Use temperature census while charging or discharging

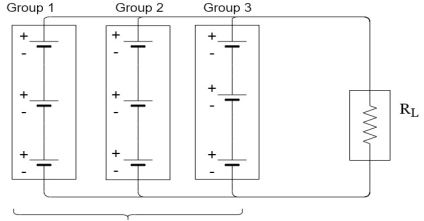

Energy consumption is the use of power or energy of a system by making use of supply. The consumption is done in Giga Joule per year, kilograms of oil equivalent per year (kg/a) and in Watts.

The energy consumption formula is articulated as,

Where,

E is energy in kilowatt-hours(kWh),

P is power in Watts,

Problem 1: Compute the energy consumption in a system that consumes 190 Watts of power and works for 3 hrs a day.

Answer:

Given: Power P = 190 W, total number of hours = 3 hrs

E =(190*3*60*60)/1000

E =2052 kWh

Therefore, the energy consumption is 2052 kWh

Problem 2: A toy car consumes energy of 500 Watts of power if it works for 2 hrs a day using it. Calculate the energy consumption a day.

Answer:

Given: Power P = 500 W, total number of hours= 2 hrs

E = (500*2*60*60)/1000

E =3600 kWh

Battery Backup

The battery backup is the duration time needs while blackout . This duration can be specified depending on the needs and requirement where battery can provide embedded power storage device used to keep critical equipment working during short power outages.

To calculate battery back up time correctly we need to know the exact output load by watt plus duration for handling equipment’s at full load.

Full load is calculated using 0.8 power factor of the input KVA while the autonomy load is calculated using 0.7 or 0.66 power factor of the input KVA.