Unit - 2

Irrigation Channels and Design

Unlined canals:

- These are the canals which are made up of natural soil and no lining of impervious material is provided.

- The velocity of flow is always kept low, to provide protection to the bed and banks.

- As these canals have high seepages and water losses are high. If the length of such canals is high the water losses go on increasing.

Lined canals:

- These canals have been provided with a lining of impervious material on its banks and bed. This helps to prevent the seepage of water.

- As the velocity of flows can be kept greater the cross-section area can be reduced.

Key Takeaways:

Unlined canals: These are the canals which are made up of natural soil and no lining of impervious material is provided.

Lined canals: These canals have been provided with a lining of impervious material on its banks and bed. This helps to prevent the seepage of water.

Theory of Kennedy

- Kennedy had the pioneer research, work, for developing non-sitting and non-sourcing channel. His field observations were carried on the Upper Bari Doab Canal System in Punjab. (In Pakistan) He had selected a number of sites on various channels, where in, for the last thirty years, there was no problem of any situation and so there was no head of clearance of the channels and had almost no maintenance cost so, these sites, clearly indicated that these channels were stable.

- On the basis of his observations, Kennedy came to the conclusion that,

The silt carried by the flow of water in a channel, is kept suspended by the vertical components of the eddies. These eddies are generated over the fall width of a channel and they go on rising up to the surface. The eddies are developed because of the friction of the flowing water, against the bed and they rise against the depth of the water in a channel. Some of the eddies are developed from the sides (banks) of the channel, but as they are almost horizontal to the surface, they have no silt supporting power so, the silt supporting power of a channel is proportional to the width of the bed of the channel and not to its wetted perimeter.

- He introduced another perimeter i.e., Critical Velocity (V0). Critical velocity can be defined as "The mean velocity that keeps the channel free from silting or souring".

- The relation between Vo and the depth of the flow was calculated by plotting the observation of the mean velocity and the depth of the flow.

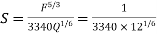

- (It was converted from F.P.S to metric units). The following equation has been derived from the above observations.

… (1)

… (1)

Where in, V0 = Critical velocity (in m/s)

D = Depth of the flow (in m)

- Kennedy made a number of observations on channels of B/D ratio. (Ranging between 3.5 and 12). The data which was plotted, did not indicate any effect of variation of the bed width, so, he came to the conclusion that, the bed width of a channel has no effect on the critical velocity.

- All the observations made by Kennedy, were based on the upper Bari Doab Canal System having sandy silt of almost same quality when he noted that the Vo gets affected by the grade or quality of silt; he introduced another factor 'm'. (Which is known as critical velocity ratio i.e., C.V.R) this new equation reads as,

Where in, m = =C.V.R

=C.V.R

- On the basis of the size of the silt the value of mis determined e.g., the silt grades which are finer than the silt grades in the upper Bari Doab Canal System have been given the value of 'm' between 0.8 and 0.9 and in case of the silt grades coarser than those in the upper Bari Doab Canal System the value of m was fixed between 1.1 and 1

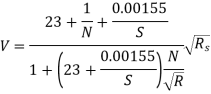

- To determine the mean velocity of the flow in the channel Kennedy has used the following equation developed by kutter; which reads as follows,

Where in, V = Mean velocity of flow (in m/s)

R = Hydraulic mean radius (in m)

S = Slope of the bed

N = Rugosity coefficient

- In case of the channels which are un-lined. The value of N i.e., rugosity coefficient, mainly depends upon the nature of the material in the bed and on the sides of the channels. And also, on the conditions of the channels. For the channels in North India, Buckley has suggested the following values of N, for the unlined channels (show in the Table)

Table: Value of N for the unlined channel in North India

Sr.no | Conditions of the channel | Value of N |

1 | Very good | 0.025 |

2 | Good | 0.0250 |

3 | Indifferent | 0.0275 |

4 | Poor | 0.0300 |

- For various discharge, the values of 'N' have been recommended by the Central Board of Irrigation and power (given in Table).

Table: Values of N based on the quantity of discharge

Sr.no | Discharge (Cumec) | Value of N for unlined channels in ordinary soil |

1 | 14 to 140 | 0.025 |

2 | 140 to 280 | 0.0225 |

3 | >280 | 0.02 |

- We should note that the limitations of Kutter's equations are incorporated in Kennedy's method of design of channels.

- In this designed method for the channel, Kennedy has not given any equation for the bed slope of the channel so, the bed slope is decided on the basis of the available slope of the ground. It can be determined from the longitudinal or 'L' section of the alignment.

- So, by knowing Q, S, N and many channel can be designed by making use of three equations i.e., continuity Equation, Kennedy's V.D relationship Equation and Kutter's Equation by varying the bed slope, for the same value of Q, N and m; different types of channel sections can be obtained. [Let us observe the following example to get the point clear].

Q = 5 cumec

m=1

N=0.025

Side slopes = 1 horizontal to 2 verticals

Sr.no | Slope | B | D | B/D |

1 | 1 in 5000 | 8.59m | 1.00m | 8.59 |

2 | 1 in 4000 | 4.54m | 1.40m | 3.24 |

3 | 1 in 2000 | 1.44m | 2.18m | 0.66 |

- All the three channels in the above example satisfy the Equations and so, these channels, according to Kennedy's theory, must be non-silting and non-scouring but in reality, it has been observed that same of them have given the best results while same have not so, the silt transportation issue has not been solved by Kennedy so, it is necessary to have the means to 'ix the bed width to depth ratio (B/D ratio). In various states of India these B/D ratios were fired on the basis of the field observations.

Design of Canal by Kennedy's Theory:

- Following three equations are used for the design of channel,

A: Q = AXV

B:

C: V = 0.55 m D0.64

- For the design of channel following information is necessary.

A: Discharge Q

B: Rugosity coefficient N

C: C.V.R.m

D: B/D ratio or Bed slope S [from longitudinal section]

- If we have information about bed slope S, the following procedure is adopted.

- The given are,

Q, N, m and S.

Following steps are followed.

- Step 1: The trial value of D (in meters) is assumed.

- Step 2: The velocity of V is calculated by using the (C) equation.

- Step 3: By using equation (A), the cross-section area is calculated.

e.g., A=Q/V

- Step 4: Assume, the side slopes of the channel as 1/2(horizontal) to 1 (vertical); the bed width is calculated by using the following equation,

A=BD+

- Step 5: From the following equation the, value to perimeter and the hydraulic mean radius R is computed

P=B+ √5D

R =

- Step 6: By using the equation (B) the actual mean velocity of the flow is calculated, if the value of V is almost same as found in the 2nd step. We can assume that the depth is correct.

- If the value of 'V' is different (the trial value), repeat, the calculations till the values indicated by the step 2nd and step 6th tally.

- If we have the information about B/D ratio the following procedure is adopted.

- The givens are,

Q, N, m and B/D.

Following steps are followed.

- Step 1: Calculate A in term of D as indicated below,

Let B/D=x (it is the given value)

So, B=Dx

As A = BD+

∴ A =

Or A=D2(x+0.5)

- Step 2: Substitute the value of (A) from the step 1st and the value of V from Equation (C) (i.e., V = 0.55 m D0.64)

Thus,

Q = AxV

Or Q=D²(x+0.5) x 0.55 m D0.64

Let us find the value of D

D=

In the above equation as the values of Q, m and x are known, D can be determined.

- Step 3:

As we know the value of D, let us calculate the values of B and R.

B = xD

R

- Step 4: By using the Equation (C) the velocity of V can be calculated.

- Step 5: Knowing V, R and N we can calculate the bed slope S, by using the Equation (B) (by trial and error).

Silt Transporting Capacity of a Channel:

- According to Kennedy the total quantity of silt transported depends upon the bed width B of the channel and upto some extents on the power of the critical velocity i.e., V0. Let is assume that the total quantity transported is Q.

So, Qt  BVo

BVo

Or Qt = a BV0 n … (1)

Where in, n = An unknown index of V0

a = Constant

Let, P is the percentage of silt in the water and Q is the discharge of the channel.

So, Q = PQ .... (2)

In case of wide channel,

Q = BDV0 (approximately) …. (3)

Introducing Equation (3) in Equation (2).

We get,

Q = PBD V0 … (4)

Equating the values Qt, in the Equation (1) and (4).

We get,

a B V0n = PBD VO

Or V0= … (5)

… (5)

(Equation V, is of a same form as given by Kennedy),

Vo = CDy=CD0.64 …. (6)

Equating the indices of D in the Equations (5) and (6),

We get,

1/n-1 = 0.64

So, n = 2.5 = 2.56

So, the quantity of silt transported can be calculated by the equation.

Qt = a B V0 5/2

Limitations of Kennedy's Theory:

His theory has the following drawbacks:

- A: He has used Kutter's equation to determine the mean velocity of a stream and so all the drawbacks, Kutter's equation have are naturally incorporated in his theory.

- B: He has not considered B/D ratio.

- C: He has not developed any equation for the bed slope in fast little variation in the bed slope leads to variations in the designs of the channels.

- D: He has not considered the concentration and grade of the silt. In this theory, the complex phenomenon of silt transportation has been expressed by a single factor m. It is called as critical velocity ratio.

- E: He has not developed any method to determine the value of m and so, the value of 'm' is determined arbitrarily.

- F: His theory is aimed to design only an average regime channel.

- G: His method is based on trial and error and so it is quite cumbersome.

- His theory is known as Lacey's regime theory. He had wide observations and his theory is based on his field observations only. He had carried out the detailed study of the problem of designing stable cannels in the alluvial soils. (He had his study in theory is alluvial soil is common character of the soils in Uttar Pradesh).

- He strongly believed that the width depth and bed. Slops of a channel constructed in easily credible alluvial soils and carrying a fixed discharge and the silt load, are uniquely determined by the nature. The changes in the original channel (modification) due to siltation and scouring leads to the development of regime channel.

- Regime channel can be defined as it is a stable channel whose width depth and bed slopes have undergone, modification by the process of silting and souring and finally reach the stage of equilibrium.

- To call any channel a regime channel, certain conditions are to be established. Which are follows.

A: The channel must be flowing over the region having incoherent alluvial and the same material (alluvial soil) must be transported by the channel.

B: The concentration (silt charges) and the silt grade must remain constant.

C: The discharge should be constant.

- Incoherent alluvium means a loose granular material which can be scoured and also can be deposited easily. i.e., The transportation or deposition are the easy processes. Such incoherent alluvium is rarely reproduced in the field.

- Conditions expressed above are known as true regime conditions. If they are fully available the channel will be in true regime channel. (In reality these conditions are never fully obtained).

- In case of regime on the artificial channels, two stages of regime get developed.

1: Initial stage

- It is the first stage of regime has come into use. This stage is attained only by the variation of bed slope and depth. Let us see the process of reaching the initial stage.

- When a channel is excavated by waking smaller width and flatter bed slope. When the flow takes in the channel, due to deposition of silt on the bed, the bed slope is increased.

- This helps to increase the velocity of flow. This allows the given discharge to flow through the narrow channel (due to reduction in the width of the channel). As the bed slope increases the depth of the channel also varies. It reaches the stable stage which is called as 'Initial Regime' But, one must note that this is a temporary stage of stability because the width of the channel has not been adjusted to suit. The requirements of a regime channel.

2: Final regime

- It is the final stage of the regime attained by a channel when together with the bed slope and the depth the width of the channel also has been adjusted.

- This stage is called as Final Regime or True Regime and the channel who has attained this stage is called as regime channel.

Design of Canal by Lacey's Theory:

- Design procedure by Lacey's theory is simple and straight in which canal section and bed slope are unique for a given discharge and the silt factor.

Design procedure:

- For a given discharge and silt factor following design procedure is used. If the silt factor is not given or known, then it can be computed from the average size of the particle from the equation given as:

F = 1.76 √m

F = Silt factor

m = Average size of particle in mm, equal to D50 size.

- Find out the velocity from the known value of discharge and silt factor from the following equation:

2. Determine the area of flow for given discharge and calculated velocity (V).

A = Q/V

3. Determine the perimeter of wetted area for given discharge from the following equation:

P = 4.75 √Q

Where, P = perimeter

Q = discharge

4. Determine the depth D and width B of the canal from the geometrical relations of area, width, depth and perimeter by assuming the side slope as 0.5: 1.

A = BD +0.5 D² …. (1)

P = B+D√5 …. (2)

5. Find out the bed slope (s) form the following equation:

6. Check for design:

Determine hydraulic radius R form the calculated values of B and D by using the following expression.

R =  …. (3)

…. (3)

And then compare the value obtained from Equation (iii) with 5V² the value obtained in equation as R=5V2/2F

∴R = 5V² /2F … (4)

If both values of R obtained from Equations (3) and (4) are approximately equal, then design is satisfactory.

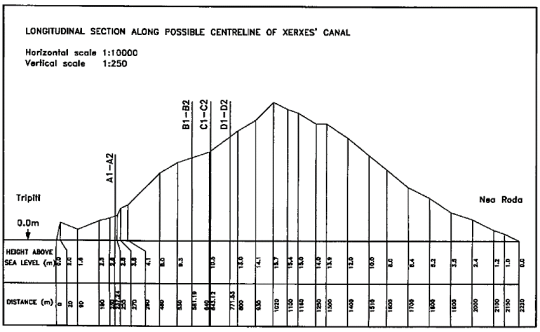

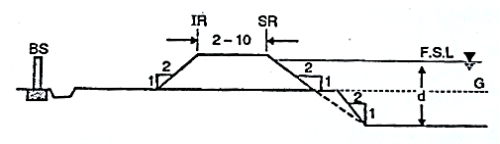

- The longitudinal slope of a canal consequently is likewise acknowledged or is followed as regards to the to be had united states of america slope.

- However, the slope of canal mattress could usually be regular alongside sure distances, while the neighborhood floor slope won't be the same.

- The alignment of a canal gadget relies upon at the topography of the land and different factors.

- The subsequent step is to determine at the elevation of the mattress stages of the canal sure durations alongside its route, which could permit the sphere engineers to begin canal creation at the precise locations.

- Also, the whole deliver level (FSL) of the canal needs to be constant alongside its length, which could permit the dedication of the financial institution stages.

Fig 1: Longitudinal section

- The layout discharge of an irrigation channel is constant and relies upon the irrigated regions of vegetation in distinct seasons and the water necessities of vegetation. The layout of the canal is especially ruled through the amount of silt withinside the water and the form of boundary floor of the channel.

- Depending upon those factors, the irrigation channels may be widely categorized into following types:

- Non-alluvial channels: These are excavated in non-alluvial soils inclusive of loam, clay, moorum, boulder, etc. There isn't any silt trouble in those channels and they're notably strong.

- Rigid boundary channels: In the Rigid boundary channels, the floor of the channel is lined. In such channels, notably excessive speed may be authorized which does now no longer permit the silt to get deposited; hence, the trouble of silt does now no longer exist.

- Alluvial channels: These are excavated in alluvial soils, inclusive of silt. In such channels, the amount of silt can also additionally range from phase to phase alongside the reach. The silt content material can also additionally boom because of scouring of mattress and facets of the channel and it is able to lower because of silting at a few sections. If speed is excessive, scouring happens and if speed is low, silting can also additionally occur. Such channels have to be designed for a nonscouring and a non-silting speed referred to as the important speed.

Design of Non-alluvial channels

- Non-alluvial channels are taken into consideration strong as there may be no silt trouble in such channels. These channels are generally designed on the premise of the most permissible speed which the channel boundary floor can face up to without scouring.

- The aspect slopes of the channel excavated in clay are commonly saved 1:1 in slicing and 1.5:1 in filling. For the channels in grit, tender rock and tough rock, the secure aspect slopes are generally taken as 0.5:1, 0.25:1 and 0.125:1 respectively. In tough rock, the edges can also additionally also be saved vertical.

Fig 2: In cutting

Fig 3: In filling

Fig 4: In partial cutting and filling

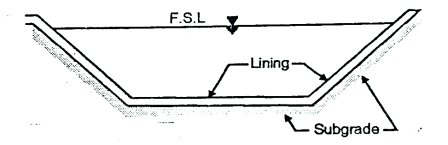

- It is the impervious layer which protects the bed and sides of canal.

- Lining is generally a construction of a thin 2.5 to 15 cm thick layer of lining material, generally RCC or CC bricks, stones etc.

Fig 5: Canal lining

- Lining an irrigation canal or channel needs extra amount to be spent on the construction but in the long run, this lining which helps to control the seepage through the banks and bed and this extra water made available through the process of lining can justify the extra expenses made on the lining of the channel.

Purpose or need of Canal Lining:

- In canal system while water flows towards irrigable area it may losses due to seepage that means crops will not get required quantity of water, which affect the yield of crop.

- Therefore, it is necessary to provide impervious laver on the bed and side of canal to minimize losses.

Key Takeaways:

It is the impervious layer which protects the bed and sides of canal. Lining is generally a construction of a thin 2.5 to 15 cm thick layer of lining material, generally RCC or CC bricks, stones etc.

The following are the advantages of canal lining:

- Reduction in losses due to seepage

- Lining prevents seepage, so finally more area can be irrigated by same quantity of water and valuable water is saved.

2. Prevention of water logging

- Seepage is main cause of water logging if canal is lined the seepage is reduced and thus helps in protection from water logging.

3. Low maintenance cost

- The maintenance of lined canal is less as compared to unlined canal.

4. Prevention of weed growth

- Lining prevents the growth of weeds.

5. Steeper bed slope can be provided

- Hard surface lining can sustain higher velocities, that means steeper bed slopes can be provided.

6. Less breaches

- In lined canal possibility of breaching is less as section due to lining is more stable and strong.

7. Less silting

- Because of higher velocity silting is less.

8. Low evaporation losses

- Because of higher velocities water can reach quickly to area and thus evaporation losses are minimum.

9. Less salt problem

- As canal water does not comes in contact with harmful salt present in natural soil, salt problem reduced to some extent.

10. As we save the wastage of water through seepage the extra water is made available for irrigating some more land. This helps to reduce the cost of irrigation per unit of land.

11. The lining helps to reduce the loss of water through the bed of the channel, by percolation. If this not prevented the ground. Water level (water table) is brought up and it causes the water logging conditions.

12. Through lining the surface of the channel is made smooth. Which helps to increase the velocity of flow; this helps to provide greater discharge through a smaller area of cross section of a channel.

13. This higher velocity also helps to provide a flatter hydraulic gradient (or the bed slope). This also helps to generate more power through these channels due to increase in the velocity.

14. As the velocity of the flow is high the rate of evaporation is reduced. So, the losses through evaporation as they are reduced, more amount of water is made available for irrigation.

15. As the velocity of flow is high the chances of siltation are reduced.

16. As, due to lining work the width of the channel is reduced so it helps to save the extra cost of the construction.

17. Due to lining of the channel, the growth of weeds is reduced.

18. By lining the channel, the water is not allowed to came in contact with the soil having salts. (Which may be harmful for he crops)

19. Lining reduces the cost of maintenance of the channel, as it makes the flow of the water to move very smoothly.

20. It provides a very stable channel section and it goes very easy to operate.

Disadvantages or Demerits of Lining:

- High initial cost: The initial cost of lined canal is high.

- Leakage from joint: There might be chances of leakage through joint.

- Difficult to repair: If it is damaged it is difficult to repair.

- Difficult to shift outlet: As lining is strong it is difficult to shift outlet in later stage.

- In lined channels berms are not provided.

- The lining increases the initial cost of investment required for the construction of an irrigation channel.

- It goes very difficult to repair the damaged lining work.

- Shifting of the outlet, if required is not lining is a permanent construction.

- These lined channels are without berm. So, the safely provided by berm, for the traffic on the service road, is absent.

Canal linings are of the following type:

- Cement/lime concrete lining

- Cement mortar lining

- Stone masonry lining

- Brick lining

- Shotcrete lining

- Asphaltic lining

- Precast concrete block lining

- Sodium carbonate lining

Cement or lime concrete lining

- Definition: The lining which is done by concrete is called as concrete lining.

- It is very useful as it permits high reduction in seepage losses. It is suitable for both small and big canals. It is strong and durable and can be used to any thickness.

- High velocity is possible due to reduced cross section and strong pavement which prevents silting tendency in canal. Its maintenance cost is less.

- The disadvantage of such lining that is its initial cost is more and cracks may develop due to temperature and shrinkage.

Cement mortar lining

- In this type of lining seepage losses are reduced by 90 to 95%. It is commonly used due to its durability, impermeability and its hydraulic efficiency.

- Material used in this lining are Portland cement, sand gate, water. Sometimes for special purposes admixtures are added to it for required result.

Stone masonry lining

- Such type of lining is suitable where stones are available in large quantities.

- To make surface proper sometimes it is plastered.

Brick lining

- Definition: When bricks are used for lining then it is called as brick lining.

- It is economical and gives fair protection from seepage but it is not as impermeable as concrete lining and it has low resistance to erosion.

Shotcrete lining

- In shotcrete lining survey of cement mortar is forced under pressure through nozzle on the surface of canal.

- It is a mixture of cement and sand. It is also used for resurfacing old lined surface. Thickness of this lining varies from 3.5 cm to 5 cm.

Asphaltic lining

- In this type of lining asphalt cement is used with sand and gravel. It provides smooth flexible surface the only drawback of this lining is it absorb heat and encourages weeds growth causing rapid deterioration.

Precast concrete block lining

- In such type of lining concrete blocks are casted in factories are used to prepare bed, it has high durability hydraulic efficiency the thickness of such lining may vary from 5 to 6.5 cm.

Sodium carbonate lining

- It consists of local sandy soil along with clay and sodium carbonate it is not durable and hence only used for field channel.

Key Takeaways:

Canal linings are of the following type:

- Cement/lime concrete lining

- Cement mortar lining

- Stone masonry lining

- Brick lining

- Shotcrete lining

- Asphaltic lining

- Precast concrete block lining

- Sodium carbonate lining

The requirement of good canal lining material should have following qualities:

- Water tightness

- Low cost

- Strength

- Durability

- Easy in construction

- Repairability

- Resistance to growth of weeds

- Hydraulic efficiency

Water tightness:

- To reduce seepage losses the lining material should be water

Low cost:

- The lining material should have low initial cost.

Strength:

- The material should be quite strong to withstand various pressures behind lining.

Durability:

- It should be durable and should provide sufficient resistance against forces such as weathering, chemical attack and wearing.

Easy in construction:

- The material selected should be such that there should not be any difficulty in giving the desired shape.

Repairability:

- The lining material should be such that it can be easily repaired.

Resistance to growth of weeds:

- It should be able to resist the growth of weeds and attack of burrowing animals.

Hydraulic efficiency:

- The surface of lining material should be smooth for higher hydraulic efficiency.

Key Takeaways:

The requirement of good canal lining material should have following qualities:

- Water tightness

- Low cost

- Strength

- Durability

- Easy in construction

- Repairability

- Resistance to growth of weeds

- Hydraulic efficiency

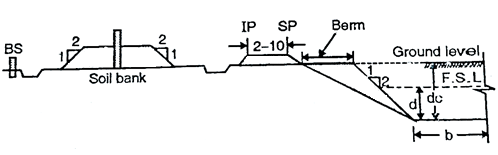

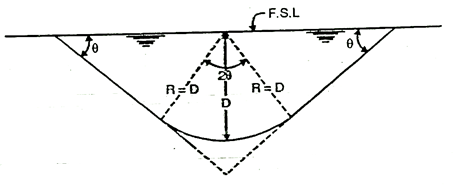

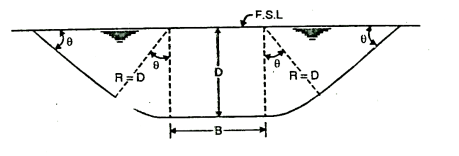

- Two types of sections are adopted, in case of the channels lined with hard surface material. A triangular section with circular bed is adopted for a small channel and a trapezoidal section with rounded corners, is adopted for large channels (Refer Figs. (a) and (b) del. Showing the cross section of the lined channels).

Fig 6: Triangular section with circular bottom

Fig 7: Trapezoidal section with roundel curves

- Free board: For the channels having different discharges carrying capacity and the values recommended are given in the Table.

Table: Discharge - free board relationship

Sr.no | Types of channels | Discharge (in cumec) | Freeboard (in m) |

1 | Main and branch channels | >10 | 0.75 |

2 | Branch channels and major distributaries | 5-10 | 0.60 |

3 | Major distributaries | 1-5 | 0.50 |

4 | Minor distributaries | <1 | 0.30 |

5 | Water courses | <0.06 | 0.10-0.15 |

- The free board is measured from the full supply level to the top of the lining.

- Berms: It is always beneficial to provide berms, in the deep cut reaches. The width of the berms, should be equal to the full supply depth of the channel. (This helps to have better maintains, and salt clearance) Refer Fig. (e). In such sections the inner sides above the berm should be provided with turfing or with pitching.

- Dowla: It should be provided on the channel side of the service road, on both the banks of the lined channel. (Refer Fig. (a, b, c)).

- Drainage: Adequate drainage must be provided to prevent the rainwater to enter in the channel. (Refer Fig.)

Limitations of the velocity of flow in the lined channels:

- Depending upon the type of lining used for the channel the velocity acceptance level varies. The following Table indicates the tolerance level of the channels for the flow velocity.

Table: Limitations of the velocity flows

Sr.no | Types of lining | Acceptable velocity(m/s) |

1 | Cement concrete lining | 2.7m/s |

2 | Brick or burnt tile lining | 1.8m/s |

3 | Boulder lining | 1.5m/s |

Fig: 8

The values of rugosity coefficient for lined channels:

- The values of coefficient N always change as the surface characteristics of the channel lining change. The following Table indicates the variations in the value of N.

Table: Variations in the value of N

Sr. No | Surface characteristics | Value of N |

1 | Concrete with surface noted below |

|

a | Formed, no finish/pec tiles or slabs | 0.018 to 0.020 |

b | Trowel float finish | 0.015 to 0.018 |

c | Gunited finish | 0.018 to 0.022 |

2 | Concrete bed trowel finish and the side as noted below |

|

a | Hammer dressed stone masonary | 0.019 to 0.021 |

b | Course rubble masonary | 0.018 to 0.020 |

c | Random rubble masonary | 0.020 to0.025 |

d | Masonary plastered | 0.015 to 0.017 |

e | Dry bolder lining | 0.020 to 0.030 |

3 | Brick tile lining | 0.018 to 0.020 |

Procedure for Design of Lined Canal Section:

For design of lined channel section, following data is required.

- Discharge Q.

- Rugosity coefficient N.

- Bed slope S.

- Side slopes.

- Limiting velocity V.

For the design purpose two equations are used.

Equation No.1:

Q = AXV ...Continuity equation.

Equation No. 2:

V=  …. Manning’s equation.

…. Manning’s equation.

Fig 9: In cutting

Fig 10: In filling

Fig 11: In partial cutting and filling

- The extra cost paid for lining can be justified if extra cost is less or equal to the extra benefits that have been gained due to lining of the channel i.e., saving the wastage of water, by preventing seepages is an additional benefit we have gains through proper lining of the channel.

- By using the following equation, we can calculate the maximum rate of expenditure on lining.

- Let C= Cost of lining in Rs; per sq.m; including the additional cost of dressing the banks

- For lining and also accounting for saving resulting from small cross sections quantity of earth work and the structure required for lined sections.

- This type of calculation can be made on new canal and not on the old unlined canal to be covered into a lines canal.

S and S =Seepage losses in unlined and lined canals, in cubic m; per sq.m. Of wetted surface, per day (i.e., 24 hrs.)

P and P = Wetted perimeter in m. Of unlined and lined sections.

T= Total perimeter of lining (in m.)

d= Total no. Of running days of a channel, in a year.

W= Value of water saved (in Rs.) per cu. m.

L = Length of the channel (in m.)

y =Life of the channel (in years)

M = Total annual saving (in Rs.) in operation and maintenance, due to lining.

B = Annual estimated value (in Rs.), of other benefits, for the length of the channel under consideration (like, prevention of water logging. Reduction in the cost of drainage for the adjoining land, reduced risk of breaching etc.)

X = Present rate of interest.

- The addition cost spent on the construction of a lined channel=TLC (In Rs).

- This cost (TLC) must be recovered from the saving during the useful life of the lining (y) in years. If the prevalent rate of interest is X the Net Present Worth (NPW) of the total annual benefits 'a' over the life of the lining (y years) is determined by the following formula.

NPW =

- To make the work of lining economical the additional initial cost of lined canal (TLC) must be equal or less than Net Present Worth (NPW) of the annual benefits i.e.

TCL ≤ NPW

- In this method we must note that it is very difficult to have the actual benefits groups under item B and M. (mainly in case of new project work). So, these values are based on the experience of similar existing project.

- It is assumed for the calculations, that the life expectancy, of concrete, brick tiles, boulder lining etc. is 60 years.

Process of Water Logging:

- In case of agriculture land when due to over watering, the normal circulation of air within the soil pores is totally cut off, it is called as "water logged condition".

- This affects the fertility of soil productivity of the land and it leads to reduction in the yields per ha and total production of the crop is also reduced.

- The depth, at which the water table make the water logging conditions, depends upon, the height of the capillary fringe and the type of crop.

- The capillary fringe means the height to which the water will rise above the normal water table due to the capillary action. (It is more in fine textured soil and is less in the coarser soils). Generally, the height of the capillary fringes varies between 0.9 and 1.5m.

- The problem of water logging of the agricultural fields is very acute in Northern plains of India mainly in Uttar Pradesh and Bihar.

- This is mainly, due to fertile plain areas of Ganga basin and a huge, good network of surface canal irrigation. Recently, the reports of water logging have been received from the Chambal project in Rajasthan and Madhya Pradesh.

- As per the national reports, the total land getting affected by water logging in various state of India, is about 3 million hectares out of which I million and is shared by are single state i.e., Punjab, the state that leads the green revolution.

- So, it is high time to note down the short and long term effects of water logging in the command area and steps must be taken to control this huge loss of the natural resources like soil and also of surface water.

Key Takeaways:

In case of agriculture land when due to over watering, the normal circulation of air within the soil pores is totally cut off, it is called as "water logged condition".

- It converts the good fertile land into infertile land.

- It reduced the production capacity of the land through the reduction in the yields of the crops and the total production from the field reports of small field near Patiala in Punjab within period of about 10 years, the yields of cotton have gone down from 746Kg(f) to that of 401 Kg(f) and wheat from 1344Kg(f) per ha. To 896kg(f) per ha.

Following are the important factors responsible for the reduction in the yields of crops:

Absence of aeration of soils is die root zone of plant:

- The plants get the necessary nutrients from the soils, through the process of nitrification of soils; which is carried by some microorganisms which break up the compounds into simple forms which the plants can absorb.

- For their survival, these microbes need oxygen (they can act in the anaerobic conditions) when land get water logged the oxygen is lost from the soil, the microbes cannot function under these conditions the proportion of nutrients required by the plants, is not generated So the yields are reduced,

Difficulties in the process of cultivation:

- When the ground level reaches the surface of the agricultural field no process of farming is possible.

Growth of water-weeds:

- As the water is easily available, the growth of water-weeds becomes very fast.

Increase in the level of salts:

- When the water table come near the surface, all the dissolved salts, which were taken down by the process of percolation are brought up, by the capillary action.

- It is called as salivation of soils which converts the good fertile soils into bad, non-fertile soils. e.g., in Bihar and Utter Pradesh, due to over irrigation, all the good, fertile soils also the canals have become saline, and useless for any cultivation.

Restricted root growth:

- As the water table has been lifted up, the roots are not required to go deep, for getting water it cuts down its growth and affects the total yields.

Lower soil temperature:

- The germination seed is hampered because; the soil temperature, under the conditions of saturation is brought down, and the yields are reduced.

Plant diseases:

- Due to less aeration, low temperature of the soil, less nutrients, the plants become weak and are easily attacked by various pests. This also, reduces the yields of the crops.

Following are the main causes of water logging. (Most of us are man-made only).

- Seepage from the nearly channel.

- Over irrigation of the fields.

- Inadequate surface drainage system.

- Obstruction of man-made constructions in the natural drainage i.e., by construction of a darn over a river, creates artificial reservoirs. Which create the problem of back water spread to create water logging.

- Obstruction of sub-soil drainage. i.e., when the construction of cause ways, bridges is carried, which need very deep foundations. They create problem to sub-soil drainage.

- Nature of soil: In some soil the water holding capacity is high e.g., clayey soils. They create the problem of water logging.

- Inaccurate method of cultivation: If the holy of way to the field is not properly cared on the pools of water end developed, me the problems of water logging

Following steps, if taken in time, the waterlogging can be prevented:

- If the channels are properly lined, in the bed and sides the seepage can be controlled to control further effect of water logging.

- By keeping the full supply level of the channel, blow top level the channel, over flowing of the canal water can be controlled.

- By providing intercepting drains along the channels, the extra amount of water can be handled of properly.

- By making the people aware about the proper use of water, over watering which causes water logging can be prevented. This can be done by making the canal water costly or by changing the cropping pattern.

- By providing a proper drainage system (by developing drains), the water logging conditions can be avoided.

- By providing a system to pump out the water in the field, the water logging can be controlled.

- By keeping the field open for one season (without cropping it) to allow the water to get evaporated to reduce the percentage of excess water it is called as Efflorescence.

- As already mentioned, excess irrigation is dangerous to the soil and also wastage of water. So, it is necessary to get the excess water out from the surface soil: we have to develop a system called as drains.

- To remove the excess water from the surface soil or from the sub surface soil, it is necessary to use either natural channels or the artificial channels.

- It is necessary to get the following field information before such drainage channels or drains are provided, such as,

- Type of soil

- The depth of soil.

- The topography of the region

- The present natural drainage available in the area

- The average annual rainfall of the region.

- When the excess water is drained out, the soil became free and ensures the air circulation in the root zone of the crops to increase the total yields per hour and to reduce the unwanted growth of weeds.

- The main objective of the drains is to remove the excess water from the soil, with less cost and least maintenance.

Types of Drains:

The drains can be classified on the basis of their location as,

- Surface Drains

- Sub-surface Drains

Surface Drains:

- They can be subdivided into two as, Shallow Surface Drains and Deep Surface Drains.

Shallow Surface Brains

- They are used to take away the extra water. Provided through irrigation and it also helps to have a quick dispose of the storm water.

- By this method, the rate of percolation is reduced. They are not useful to relieve the land which is already water logged.

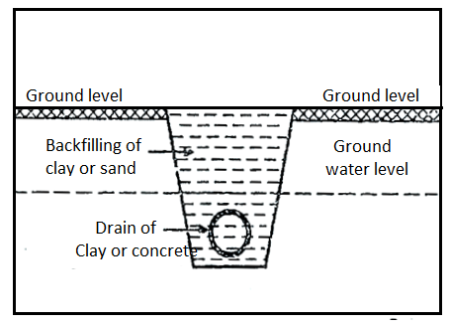

Fig 12: The shallow surface drainage

Deep open surface drains

- They used to take out the extra water from the sub-soils and so they can be used as a method of prevention of water-logging.

- They are used for the reclamation of the wet lands.

Fig 13: The deep open surface drainage

Drawbacks of Open Drains

- For the construction of open drains the fertile land is wasted.

- They create obstructions to the farming activities.

- To cross such wide drains cutting the transport linkages, the bridges are required to be provided.

- Some of the important plant nutrients are lost, due to open drains in the fields.

Sub-Surface or Tile Drains:

- These drains are useful for both i.e., for prevention water logging and for relieving the land, under water-logging conditions.

- These are tile drains, of porous earthen ware. They are laid, below the ground level, putting each other with open joints and are covered by earth. So, they do not make use of the fertile land or they do not disturb the farming activities.

- Generally, they are spaced with a distance of 15 to 45 m. The usual diameter of the tile drain is 100 mm. These drains are located about 0.3 m lower than the desired water table. They are laid, with a gradient, steeper than I in 500.

- The closed drains are designed to carry the seepage water and their capacity is determined by the general rate of infiltration (we already have discussed the methods used to calculate the rate of infiltration, in chapter I of this book).

- Spacing of closed drains: As already seen, the usual spacing of these drains is between 15 and 45m, the closer spacing is being used for the soils have low permeability and for the soils which are very highly permeable, they are spaced away from each other’s, keeping the range between 15 m and 45 m.

Advantages of Sub-Surface drains Over Open Drains:

The sub-surface or Tile drains have following advantages over the open drains:

- There is no wastage of land to be used for cultivation.

- The tile-drains do not abstract the cultivation operation.

- The plant nutrients provided by the bacteria is not washed off.

- They do not require any maintenance cost.

- The free circulation of air in the sub-soil allows more growth of bacteria to provide more nutrients for the plants, to increase the total yields.

Refer Fig.(a) and (b) which shows the tile drain with filter and tile drain without filter.

Fig 14: Tile drains without filter

Fig 15: Tile drains with filter

Limitations of Tile Drains:

The Tile Drains have the following limitations:

- The initial cost of installation is higher than the open drains.

- The drain-capacity is lesser of these Tile-drains is lesser than the open drains. (As they are closed).

- It is difficult to located the failure of the Tile-drain system.

- The replacement or Repair work of the Tile-drain is difficult, time consuming and costly.

Key Takeaways:

Types of Drains:

The drains can be classified on the basis of their location as,

- Surface Drains

- Sub-surface Drains

Numericals:

Q. Design an irrigation channel in alluvial soil according to Lacey's silt factor theory.

Full supply discharge = 12 m³/s; Lacey's slit factor = 1

Channel side slopes = 1/2: 1.

Soln.:

Given:

Q=12 m³/s; f= Lacey's silt factor = 1;

S = channel slope = ½: 1 = 1/2(H):1(V)

To find velocity (V)

To find area of flow (A)

A= =

=

To find the perimeter of wetted area (P)

P = perimeter =4.75

To find B and D

Using the relations of width (B) and depth (D):

Find D and B:

B= Width and D= Depth of channel

A = BD +0.5 D² and P=B+D

∴BD+0.5D2=18.18

B+D√5 = 16.45

From Equation (2), we get,

B = 16.45-D

Substituting the value of B in Equation (1), we get

(16.45-D√5) D+0.5 D² = 18.18

16.45 D-√5 D² +0.5D² = 18.18

16.45 D+D³ (-√5 +0.5) = 18.18

16.45 D-1.736 D² = 18.18

∴1.736 D2-16.45 D+ 18.18= 0

Solving Equation (3) for D, we get

D= 8.19 m or D= 1.277= 1.28 m

D=8.19 m is not valid, ∴D =1.28 m

∴B= 16.45-D√5=16.45-1.28x√5=13.58 m

D=Depth of channel = 1.28 m and B = 13.58 m

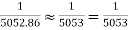

To find bed slope (S)

=

=

Check

A = BD+0.5D²

= 13.58×1.28+0.5× (1.28) ^2

= 18.20 m²  18.18 m² …. OK (satisfactory)

18.18 m² …. OK (satisfactory)

P= B+D√5= 13.58+1.28√5 = 16.44 m 16.45 m …. OK (satisfactory)

16.45 m …. OK (satisfactory)

R= A/P= 18.18 /16.45 = 1.105 m …(a)

R =2.5V2/f=2.5× (0.66)2/1=1.089 …(b)

…(b)

Values of R from (a) and (b) are approximately equal, hence design is satisfactory.

Q. Design a trapezoidal irrigation channel to carry discharge of 40 m/s using Kennedy's theory. Assume ratio of base width (B) to depth (D) as 2.5 critical velocity ratio= 1, Kutter's rugosity coefficient 'n' = 0.023 and side slopes 1H: 2V.

Soln.:

Given:

Q = Discharge = 40 m³/s;

n = Kutter's rugosity coefficient = 0.023

m = critical velocity ratio = 1;

Slopes = 1H: 2V

B/D= 2.5, ∴ B=2.5 D

To find velocity (V) and R in channel

…. ∵m=1

…. ∵m=1

= …. (1)

…. (1)

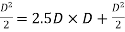

A = Area of the channel section having a side slope 1:2.

A=BD+

=2.5

∴A = 3D²

We know, Q = AV0 ...continuity equation

40 = 3D² x 0.55 D0.64=1.65D2.64

∴ =

= ^1/2.64=

^1/2.64=

=3.3 m

∴B = 2.5D=2.5x3.3 =8.25 8.3 m

8.3 m

∴B = 8.3 m

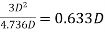

R = Hydraulic mean radius=A/P=

∵Perimeter (P)=B+√5 D

=

=

∴R=0.633D=0.633×3.3=2.088

From Equation (1), we have

V=0.55D0.64=0.55×3.30.64

∴V = 1.18 m/s

References:

- Fundamental of Hydraulic Engineering System by Houghalen, Pearson Publication.

- Irrigation and water Power engineering by B.C. Punmia, Laxmi Publications.

- Engineering Hydrology by K. Subramanya, TMH.

- Irrigation Water Power and Water Resource Engg. By K.R. Arora.

- Water resource engineering by Ralph A. Wurbs & Wesley P. James, Pearson Publication.