Unit - 1

Introduction

A steel structures is an assemblage of a group of members/elements expected to carry their applied forces and transform them safely to the ground the applied forces may be axial forces, bending or torsion or a combination of those and it depends on orientation of the member. Industrial buildings, some commercial buildings like warehouses, some public buildings like stadiums, transport terminals, bridges of railway lines, various towers are constructed with steel. Now day pre-engineered steel buildings are popular in all countries.

In a pre-engineered building, various components are manufactured in a factory and are erected at a site of construction by which building can be completed very quickly. These buildings are a combination of built-up sections, hot rolled sections and cold formed elements.

This concept provides a complete building envelop system which is air-tight, energy efficient and optimum in weight and cost. These can be used for various purposes such as factories, ware houses, supermarkets and offices.

The design steel structure, civil (structural) engineer plays important role. The design should suit the purpose, safety, economy and durability. Thus, safety is one of the paramount responsibilities of the designer.

However, it is difficult to access safety and economy due to uncertainty about the various factors like (i) uncertainty about loading (ii) uncertainty about material strength and (iii) uncertainty about structural dimensions and behavior. Hence standardization of all designs based on experience is required.

Most governments attempt to ensure structural safety through regulations and laws. Designers then attempts to achieve maximum economy within the range of designs that the regulations allow.

Frequently the professions are allowed to regulate themselves; a 'Code of Practices'. IS 800-2007 Code for General Construction in Steel designed and introduced method of limit state design which overcome on working stress method (IS 800-1984).

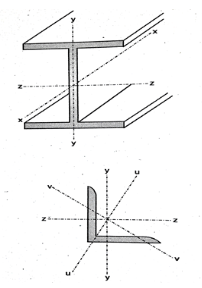

Two fundamental changes have been made in the version of IS 800-2007 first, the switching over from allowable stress (working stress) design approach to limit state design approach and second, the convention of member axes; the axis along the member length is designated axes as x-x axis the major axis of the section as z-z axis, and the minor axis of the section as y-y axis. (Applicable for beam or I section) For angle section. y-y axis perpendicular to the smaller leg z-z axis parallel to smaller leg in angle section u-u major axis (when it does not coincide with z-z axis). v-v minor axis (when it does to coincide with the y-y axis)

Key takeaways:

- This concept provides a complete building envelop system which is air-tight, energy efficient and optimum in weight and cost.

- These can be used for various purposes such as factories, ware houses, supermarkets and offices.

- The design steel structure, civil (structural) engineer plays important role.

- The design should suit the purpose, safety, economy and durability. Thus, safety is one of the paramount responsibilities of the designer.

1. Advantages:

1) High strength:

Steel members have high strength per unit weight. Therefore, a steel member of a small section can resist heavy loads. This property is applicable for the construction of long-span bridges, tall buildings and for buildings on soils where low bearing capacity of soil.

2) Ductility:

Steel being ductile material does not fail suddenly, but gives visible evidence of impending failure by large deflections.

3) Toughness:

Structural steels are enough tough, so that steel members subjected to large deformations during fabrication and erection will not fracture. Also, the steel may be bent, hammered, sheared or even the bolt holes may be punched without any damage.

4) Prefabrication:

As steel is light in weight, it can be manufactured at the factory and transported at site. This results in speedy construction saving in time and expense, ensuring better quality of finished structures.

5) Durability:

The properties of steel mostly do not change with time. This makes the steel most durable material for a structure.

6) Long life span:

If steel is properly maintained then steel structures have long life span.

7) Demount ability:

The steel structures can be disassembled and reused where ever required.

Recycling Steel is an ultimate recyclable material.

8) Retrofitting and strengthening:

Repairs retrofit and strengthening of steel member is much simple.

9) Addition and alteration:

Addition of any steel member and also alteration can be made easily to steel structures

2. Disadvantages:

1) Cost:

The cost of steel structures for any type of structures is more than the R.C.C structures.

2) Corrosion:

Steel structures are susceptible to corrosion when fully exposed to air and water. Therefore, it requires periodic painting, cleaning etc.

3) Fire proof treatment:

Structural steel members are non-combustible but they lose their strength rapidly during fire. Therefore, steel structures require fire proof treatments which increase cost.

4) Fatigue:

Fatigue of steel involves reduction in the strength when steel is subjected to large number of stress reversals and even to a large number of variations of tensile stresses.

5) Aesthetic view:

Steel does not give pleasing appearance unless it is painted.

Key takeaways:

- Steel members have high strength per unit weight. Therefore, a steel member of a small section can resist heavy loads.

- Steel being ductile material does not fail suddenly, but gives visible evidence of impending failure by large deflections

- Structural steel members are non-combustible but they lose their strength rapidly during fire

1. Tower:

Towers may be self-supporting or cable-stayed. Towers are made of steel angles or tubes, bolted at site. Towers are of different types such as telephone tower, windmill tower, observation towers, lighting towers, power transmission towers etc. The function of tower is to provide support.

2. Roof truss:

A truss is a framed structure consisting of different members like tie, principal rafter, strut and slings; forming triangles i.e., a perfect frame. The steel roof trusses are used when

(1) Span is very large and the beam construction is not economical

(2) The building is in area of heavy rainfall.

Various types of trusses are

(i) Howe truss

(ii) Simple fink truss

(iii)Compound French truss

(vi) Simple tan truss

(v) Pratt truss

(vi) Compound fink truss

(vii) North-light truss etc.

3. Water tank:

They may be circular, rectangular or spherical. They may rest on the ground or be elevated. The function of water tank is to contain material.

4. Bridges:

The truss and plate-girder bridges are commonly used for small to moderate spans, cable-stayed and suspension bridges for long spans. Sometimes arch bridge and cantilever bridge are also used. Foot Bridge is very common in a railway station. The function of bridge is to provide runway.

5. Gantry girder:

The travelling overhead cranes are commonly used in workshops and factories. The function and gantry girder are to lift and move the heavy materials and machinery from one place to other.

6. Column:

These are the members that resist compressive components of loads in a truss, and bridge piers. In building structure loads and moments are transmitted to column through beams. Generally, a compound column is used consisting of channels placed face to face or back-to-back. The two components must be tied together with the help of lacing or battening. The function of column is to give support.

Key takeaways:

- Towers may be self-supporting or cable-stayed. Towers are made of steel angles or tubes, bolted at site.

- These are the members that resist compressive components of loads in a truss, and bridge piers.

- They may be circular, rectangular or spherical. They may rest on the ground or be elevated. The function of water tank is to contain material.

The main aim of structural designer is to select the appropriate cross section for individual members of the structure.

This selection is done using widely available standard rolled steel sections which are of any standard. Rolled steel sections manufactured are listed below with designation:

1. Rolled Steel I-section

2. Steel channel Sections

3. Rolled Steel Angle Sections

4. Rolled Steel Tee-sections

5. Steel Plates

6. Rolled Steel Strips

7. Rolled Steel Flats

8. Rolled Steel Bars

1. Rolled steel I section

Following series of rolled steel I sections are manufactured in India:

(a) Indian Standard Junior Beams - ISJB

(b) Indian Standard Light Beams - ISLB

(c) Indian Standard Medium Beams - ISMB

(d) Indian Standard Wide-flange Beams - ISWB

(e) Indian Standard Heavy Beams - ISHB

The above sections are designated by the series to which they belong followed by depth (in mm) and weight (in kg/m) per meter run e.g., ISMB 300@ 44.2 kg/m.

2. Rolled Steel Channel Sections

These sections are classified into the following series:

(a) Indian Standard Junior Channel - ISJC

(b) Indian Standard Light Channel - ISLC

(c) Indian Standard Medium Weight Channel - ISMC

(d) Indian Standard Special Channel - ISSC

Rolled steel channel sections are designated by the series to which they belong, followed by depth (in mm) and weight (in kg/m).

3. Rolled Steel Angle Sections:

These sections are classified into the following series:

(a) Indian Standard Equal Angle - ISA

(b) Indian Standard Unequal Angle - ISA

These sections are designated by series of names ISA followed by length thickness of leg.

4. Rolled steel Tee section:

These sections are classified into following series:

(a) Indian Standard Normal Tee Bars = ISNT

(b) Indian Standard Heavy Flanged Tee Bars = ISHT

(c) Indian Standard Special Legged Tee Bars = ISLT

(d) Indian Standard Light Legged Tee Bars = ISLT

(e) Indian Standard Junior Tee Bars = ISJT

These sections are designated by the series to which they belong, followed by depth (in mm) and weight per meter length (in kg/m) c.g. ISNT 60 @ 5.3 kg/m.

5. Rolled Steel Plates

These plates are classified into the following series.

Indian Standard Plate (ISPL) These plates are designated by ISPL, followed by dimension in mm i.e., length, width and thickness, e.g., ISPL 2000 x 1100 x 8. These are available for various thicknesses (mm) and widths (mm). Thicknesses of plates are more than 5 mm. (t>5 mm).

6. Rolled Steel Strips:

These strips are designated as Indian Standard Strip ISST, followed by width (mm) and thickness (mm) e.g., ISST 160 x 1.4.

Thickness of strips are less than 5 mm (t<5 mm).

7. Rolled Steel Flats:

They are designated by width, followed by Indian standard Flats ISF, and thickness e.g., 50 ISF 5. Flats have thickness more than 5 mm but width is limited (b< 250 mm).

8. Rolled Steel Bars

Rolled steel bars are classified in to following series:

(a) Indian Standard Round Bar (ISRO)

(b) Indian Standard square Bar (ISSQ)

These are designated by ISRO, followed by diameter in case of round bar and ISSQ followed by width e.g., ISRO-12, ISBQ-16.

Key takeaways:

- The main aim of structural designer is to select the appropriate cross section for individual members of the structure.

- This selection is done using widely available standard rolled steel sections which are of any standard.

- Thickness of strips are less than 5 mm (t<5 mm).

- Indian Standard Plate (ISPL) These plates are designated by ISPL, followed by dimension in mm i.e., length, width and thickness

Various loads are expected to act on a structure may be classified as given below:

(a) Dead Loads (DL)

(b) Imposed Loads (IL)

(c) Wind Loads (WL)

(d) Earthquake Loads (EL)

(e) Erection Loads (ER)

(f) Accidental Loads (AL)

(g) Secondary effects.

Judicious combination of the loads is necessary to ensure the required safety and economy in the design keeping in view the probability of their,

(a) Acting together combination of various loads.

The various load combination are given as below:

1. DL

2. DL+ WL

3. DL+TL

4. DL+IL+EL

5. DLNL+TL

6. DL+IL+EL+TL

7. DL+IL+EL+TL.

Where TL-Temperature Loads

All type of loads and load combinations required for design are briefly explained at the time of design of respective steel members

To decide the size, shapes and connection details of the members, the following design philosophies listed below are used in the order of their evolution and they are briefly explained.

1. Working Stress Method (WSM)

2. Ultimate Load Design (ULD)

3. Limit State Method (LSM)

1. Working Stress Method (Allowable Stress Design)

It is one of the oldest methods of design suitable for all structures. Through IS-800-2007 insists for the limit state design, permits use of this method wherever LSM cannot be conveniently adopted.

With the development of linear elastic theory in the 19th century, the stress-strain behavior of material is considered as linear till the yield stress. To take care of uncertainties in the design, permissible or Allowable stress is kept action of yield stress by the ratio known as factor of safety. So that the members designed are to keep the stresses within the permissible value.

Allowable or permissible stress = Yield stress/Factor of safety

Working stress due Permissible or to working loads

(a) For beams FOS = 1.67 Allowable stress

(b) For long column FOS = 1.92

(c) For short column FOS = 1.67

(d) For connections FOS = 2.5-3

A set of load combinations is given below, which are unlikely to act on the structure. (Stress due to DL + WL+LL) < 1.33 (Stress due to DL+LL) Allowable stress (Stress due to DL + WL) S Allowable stress

Advantages:

1) This method is simple.

2) This is reasonably reliable.

3) As the working stresses are low, the serviceability requirements are satisfied automatically.

Limitations:

1) Assumption of linear elastic behavior and the stresses under working loads can kept within the permissible stresses are not found to be realistic.

2) Many factors like the effect of stress concentrations, creep, shrinkage, residual stresses and other secondary effect are not considered.

3) This method does not consider material non linearity and non-linearity of structural members.

4) This method does not provide a realistic measure of the actual factor of safety for the design.

5) It gives uneconomical sections.

2. Ultimate Load Method (Load Factor Method) (ULM)

Ultimate limitation of the working stress method to determine actual load carrying capacity, made researchers to develop ultimate load method, which is also known as plastic design method.

In this method, a section is said to have formed a plastic hinge when all fibres yield. But the structure continues to resists load until sufficient number of plastic hinges are formed to transfer the structure in to a collapse mechanism. At this state the load is known as ultimate load. Safety measures are introduced by using load factor, which is defined as the ratio of design load to working load. This lo factors as per IS 800-1984 are given in table.

Thus, E (Working load + Load factor (LF)) Ultimate load

Sr. No. | Working load | Maximum load factor |

1 | DL | 1.7 |

2 | DL+IL | 1.7 |

3 | DL+WL or EL | 1.7 |

4 | DL+IL+WL or EL | 1.3 |

Advantages:

- Due to plastic hinge concept, redistribution internal forces are accounted.

- It allows varied selection of load factors.

Limitations:

- Limitation on deflection and also it does not guarantee other serviceability limits like instability and fatigue.

- This method is more comprehensive method to take care of strength.

- It does not guarantee of serviceability performance.

3. Limit State Method of Design (LSM)

IS 800-2007, a code of practice, applicable to the structural use of hot-rolled steel is largely based on limit state method of design. However, it still retains the working stress method where LSM cannot be adopted. The limit state method of design developed to take account of all uncertainty’s limitations of WSM and ULM] that can make the structure unfit for use by considering actual behavior of material and structure.

In the Limit State Method (LSM), basically statistical methods have been used for determination of loads and material properties with a probability of structure reaching the limit state of strength and serviceability. However, it is not yet possible to adopt a complete probability basis for design and therefore the method adopted partial factors of safety which are introduced to take account of all the uncertainties.

Advantages of Limit state method over working stress method:

- In this method, possibility of material non linearity, structural non-linearity, calculation error is considered.

- Factor of safety are called partial safety factors determined by statistical analysis.

- This method provides a realistic measure of the actual factor of safety.

- This method designs any structural element for strength as well as serviceability criteria.

- This method considered reserve strength of material beyond elastic limit of stress-strain curve.

Key takeaways:

- Allowable or permissible stress = Yield stress/Factor of safety

- In this method, possibility of material non linearity, structural non-linearity, calculation error is considered.

- This method designs any structural element for strength as well as serviceability criteria.

- This method considered reserve strength of material beyond elastic limit of stress-strain curve.

The Working Stress Method assumes that all cloth used within side the layout behaves in a linear elastic way and calculations are primarily based totally on carrier situations. The predicted running hundred sat the shape are triggered as stresses at the shape for the duration of the layout and those are restricted (to be under the permissible stresses) to make certain ok protection. The thing of protection is the ratio of the power of the cloth to the permissible pressure. However, as running hundreds can't be stored in the permissible stresses this technique isn't always continually viable.

The assumption within side the Ultimate Load Method is that the cloth isn't always linear-elastic which means that extraordinary hundreds can have extraordinary protection elements. Calculations are primarily based totally on closing load situations and the pressure situations on the web page of failure or approaching crumble is analyzed. This effect in extra slender (consequently extra economic!) sections

However, this technique can bring about cracks and deflections which can be excessive because of the serviceability home snow no longer being met.

In the Limit State Method (aka as Limit State Design), the layout of the shape is taken into consideration for each the serviceability and closing load kingdom. This is consequently the higher layout philosophy to employ. The extraordinary restrict states is the Ultimate Limit State (ULS) and the Serviceability Limit State (SLS), for which distinction are made within side the code SANS10160: five.1.3... These states every have their own minimal degree of reliability - that's colloquially called the Safety Index.

The extraordinary restrict states of Limit State Design:

Ultimate Limit State offers with states simply earlier than the shape collapses. This pertains to the protection of human beings and the protection of the shape (power, fatigue, bucking, sliding and overturning). It has a protection index of β= 3.

Serviceability Limit State offers with functioning of the shape, acceptability of protection and look of the shape (deflections, crack width, malfunction and lack of durability). This has a protection index β= 1. Five.

Calculations regarding the impact of a carried-out load and the power or resistance of the shape have to fall in the Safety Index. This is executed throughway Partial Safety Factors. Partial protection elements have emerged inside restricting Dom layout as a method of adjusting parameters to account for versions in order that the best values are used for layout purposes. Partial protection elements are derived from thinking about a frequency distribution statistical evaluation of movements on a shape. Nominal hundreds, observed on symmetric bell curves, have an opportunity of being handed through five%. The overlap of nominal loading of imply load and imply power curves describes the failure condition. This suggests the need of getting a cloth/resistance partial protection thing.

For every layout technique and restricting Dom, an extraordinary set of layout parameters are used. In the Ultimate Load Method for strengthened concrete layout, partial protection elements of 1. Five for concrete and 1.15 for metal are used. While within side the Working Stress Method, the protection thing is regularly known as being the ratio of the power of the cloth to the permissible pressure. However, within side the Ultimate Limit State: protection elements of 1.2 instances the use less hundreds, 1.6 instances the stay hundreds and 1.3 instances the wind hundreds are implemented.

This philosophy is a development over the conventional layout philosophies. It considers the protection on the closing load and serviceability on the running load, form of extension of the WSM and ULM.

“Limit kingdom is the kingdom of approaching failure, past which a shape ceases to carry out its meant characteristic satisfactorily, in phrases of both protection and serviceability.”

Key takeaways:

- In this method, possibility of material non linearity, structural non-linearity, calculation error is considered.

- Factor of safety are called partial safety factors determined by statistical analysis.

- This method provides a realistic measure of the actual factor of safety.

1. Ultimate Limit State of strength:

It considers power, overturning, fatigue, sliding etc.

2. Serviceability Limit State:

It considers crack width, deflection, vibration etc.

It makes use of more than one protection elements for the desired protection and serviceability on the closing load and running load respectively through thinking about all restrict states. These are called “partial protection elements”.

Partial protection thing for materials:

The power of concrete in real shape is taken as (0. Sixty-seven *function power), i.e.,0. Sixty-sevenfck. The partial protection thing (for closing restrict kingdom) for concrete is 1. Five and that for metal is 1.15. The fee is better for concrete as its miles predicted to have extra variability as compared to metal. The partial protection thing (for serviceability restrict kingdom) for concrete and that for metal is taken as 1.0. This is taken as solidarity as we're interested by estimating the real deflections are crack width for the duration of carrier hundreds.

Partial protection thing for hundreds:

Various load combinations are laid out in IS 456 are

For Ultimate limit states or strength of limit state

- UL = 1.5(DL+LL)

- UL = 1.5(DL+QL) OR 0.9DL+1.5QL

- UL = 1.2(DL+LL+QL)

The load factor of 1.2 is considered for the combination of three because the probability of the three loads reaching its peak together is less.

For serviceability limit states

- SL = 1.0 (DL+LL)

- SL = 1.0 (DL+QL)

- SL = 1.0DL+ 0.8LL+ 0.8 QL

The load factor is taken as 0.8 in the third case as the probability of wind load or earthquake load acting with the peak of live load is less. For all cases the safety factor is taken as 1.0 as we are considering the serviceability of structure here.

Where DL is dead load, LL is live load and QL is earthquake/wind load.

Key takeaways:

- Ultimate Limit State of strength: It considers power, overturning, fatigue, sliding etc.

- Serviceability Limit State: It considers crack width, deflection, vibration etc.

- The load factor is taken as 0.8 in the third case as the probability of wind load or earthquake load acting with the peak of live load is less

1. Riveted connections:

The riveted connections are these days obsolete. The know-how of this kind of connections for the power assessment and rehabilitation for an older shape is essential. While the relationship technique for riveted connections are equal as that of the bolted connections.

Rivet:

A rivet is made of spherical ductile metallic bar that is known as etc. ‘shank’ and with a head at the only quit. It is made of moderate metallic or excessive tensile metallic.

Riveting:

Riveting is the unique technique of connecting collectively portions of metallic. This technique is carried out through putting the ductile metallic pins known as etc. rivet into the holes of portions to be joined and shaped a head on the quit of the rivet to prevent every metallic piece from coming out.

The shank of the rivet is made of the period to the quantity via the unique elements that is to be linked and with enough greater period for a second head to be made at the opposite quit.

The rivets are commonly categorized as follows:

- Hot pushed rivets: The rivets which might be pushed within side the warm conditions

- Shop rivets: The rivets which might be located in workshop

- Field rivets: The rivets which might be located within side the site/field.

- Cold pushed rivets: Since excessive strain is needed to shape the top at room temperature this kind of rivet is limited.

Clamp movement:

When warm pushed rivets are well cooled down then the diameter and shank period get reduced. Because of this, the compression of the plates happens and those outcomes in friction among the plates, this technique is known as categorized clamp movement.

Disadvantages of riveted connections are as follows:

- It is related to very excessive stage of noise pollution

- There is a want to warmth the rivet until purple warm color.

- Skilled labors are vital to investigate the relationship.

- The fee to get rid of the poorly hooked up rivet could be very excessive.

- The excessive-fee set up within side the connection.

2. Bolted Connection:

Most generally used connections consist of the bolted connections. This connection has the benefit of pliability in assembling elements of the shape as well as dissembling it and that is vital if there may be inspection or a few routine maintenances. This kind of connections is relevant for participants subjected to anxiety or shear or each anxiety and shear.

A bolt is a metallic pin with a head shaped at one quit and the shank threaded on the different quit in order that nut may be received. Generally, the bolts are used to attach the portions of metals through putting them via the holes within side the metals; on the threaded quit, nuts ought to be tightened.

The blessings of bolted connections are as follows:

- The technique of erection of shape may be made faster.

- Skilled labors aren't vital.

- Connections do now no longer contain the noise.

- Requirement of labors is less.

- Immediate use of shape is feasible in case of bolted connection.

- The opportunity association of structural participants is feasible if required.

- Lesser running place is needed.

The risks of bolted connections are as follows:

- The cloth fee could be very excessive.

- Due to the place discount at the basis of the thread and because of concentration of pressure, the tensile power of this kind of connection is reduced.

- Bolts get free if it's far subjected to vibrations or shocks.

Classification of bolted connections:

The classifications of bolted connections are made on the premise of resultant pressure transferred, kind of pressure and pressure mechanism.

On the premise of resultant pressure transferred:

- Concentric connections: When the burden of structural member passes via the CG of the segment then this kind of connections are made.

- Eccentric connections: Whenever the ensuring pressure is performing far from the CG of the connections.

- Moment resisting connections: Whenever the connections are subjected to moments.

On the premise of kind of pressure:

- The connections are categorized as shear connections whilst the switch of load passed off via shear. Example: lap joint, butt joint

- Tension connection: Whenever the switch of load passed off via anxiety at the bolts.

- Combined anxiety shear connections: on every occasion the bracket connection is used to join the willing member to the column of the shape.

On the premise of pressure mechanism:

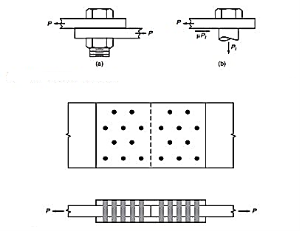

- Bearing kind connections: To switch the pressure bolts under go towards the hole

- Friction kind connections: Due to tensioning of the bolts the pressure is transferred via friction among the plates.

The layout philosophy:

The traditional technique to research the relationship is primarily based totally at the following conditions:

- The deformation of the relationship is omitted because the linked factors of the systems is taken into consideration as inflexible connections

- The connectors used to at technique factors of the segment behave like linear – elastic manner till it fails.

- The ductility belongings of connectors of the systems are unlimited.

In sensible situations, the linked sections like angles, gusset plates, etc. are bendy deformation happens on the low depth of load also.

The bearing pressure performing at the bolt is proven at (c) and the shear pressure at (d) and (e). The most shear performing at the bolt, P, happen son the touch surface of the plates. The shear pressure at the bolt on the vital shear aircraft is

Fv= P/Ab

Where

Ab is nominal cross-sectional place of the bolt = pie*d2/4

The slip-vital bolt proven in Fig. 10.3a, relies upon Fl the friction brought about among the linked elements through the clamping movement of the pretension bolts to switch the burden from one linked part to another. No slip happens at carrier hundreds and, as proven at (b), the pressure among the linked plates is transferred through friction.

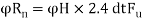

A lap joint isn't always a desired connection due to the bending stresses produced within side the participants through the eccentricity of the hundreds. A greater appropriate connection is the butt splice and that is proven in Fig. The bolts in a splice joint are in double shear

With two critical shear planes. Hence, each bolt has twice the shear capacity of a bolt in a lap joint. Figure shows a hanger connected by bolts to the bottom flange of a girder. Here the bolts are in tension. An example of a situation where bolts are subjected to combined shear and tension is shown in Fig. In this connection, all bolts are equally loaded in shear. However, because of the eccentricity of the applied load, the top row of bolts also resists tensile stress.

Example 1.

Bolts in Shear and Bearing with Deformation a Design Consideration The connection shown in Fig. Consists of four, grade A490, ¾-in-diameter bolts. The bolts are snug-tight and threads are excluded from the shear planes. Deformation around the bolt holes is a design consideration and the bolt spacing is as indicated. The angles and gusset plate are fabricated from A36 steel. Assuming that the angles and gusset plate are satisfactory, determine the shear force that may be applied to the bolts in the connection. The bolt edge distance perpendicular to the direction of the tensile force is obtained from Fig.

L=1.75 in

The bolt edge distance in the direction of the tensile force is obtained from Fig. 10.7

Lc=2 in

Lc= clear distance, in the direction of force, between the edge of the hole and the edge of the 3/4-in gusset plate

= Lc- (d+1/16)/2

= 1.59 in

The bolt pitch is obtained from Fig. 10.7 as s = 3 in

4d

>3d +1/16 ... Full bearing capacity possible on all bolts \

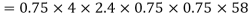

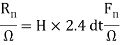

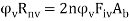

Hence, tear out does not govern and a nominal bearing stress of 2.4Fu is applicable. The available bearing capacity of the four bolts on the 3/4-in plate material is

LRFD | ASD

|

The design bearing strength is    | The allowable bearing strength is    |

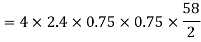

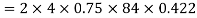

The double shear capacity of the for, grade  in diameter bolts with threads excluded from the shear planes is

in diameter bolts with threads excluded from the shear planes is

LRFD | ASD

|

The design shear strength is

| The allowable shear strength is    |

Key takeaways:

- The riveted connections are these days obsolete. The know-how of this kind of connections for the power assessment and rehabilitation for an older shape is essential.

- Concentric connections: When the burden of structural member passes via the CG of the segment then this kind of connections are made.

- Eccentric connections: Whenever the ensuring pressure is performing far from the CG of the connections.

- Moment resisting connections: Whenever the connections are subjected to moments.

- Welds connecting numerous joints are homogenous, isotropic and elastic elements

- Components linked with the aid of using weld are inflexible and their deformations are neglected

- Best stresses because of outside forces are considered.

There are two types of welded connection

5. Butt weld

6. Fillet weld

1. Butt weld

Butt weld is also known as groove weld. The various shape of the groove made are

- Square butt weld

- Single V butt weld

- Double V butt weld

- Single U butt weld

- Double U butt weld

The size of butt weld is the effective throat thickness. In case of double butt weld when complete penetration is achieves, the thickness of weld is taken as thickness of thinner plate.

For single butt weld when complete penetration is not achieved the thickness of weld is taken as 5/8 times thickness of thinner plate.

Effective length of butt weld is equal to length of full-size weld

Minimum length of weld= 4x size of weld

2. Fillet weld

Fillet weld is approximately triangular cross sectional joining two surfaces which are perpendicular to each other standard fillet weld when the cross section of fillet weld is isosceles triangle.

Minimum size of fillet weld is 3 mm

In drawing only effective length is shown. Actual weld length is equal to effective length + twice the size of weld.

Design strength of fillet weld is

Key takeaways:

- The size of butt weld is the effective throat thickness. In case of double butt weld when complete penetration is achieves, the thickness of weld is taken as thickness of thinner plate.

- For single butt weld when complete penetration is not achieved the thickness of weld is taken as 5/8 times thickness of thinner plate.

- Effective length of butt weld is equal to length of full-size weld

- Minimum length of weld= 4x size of weld

A. Design of fillet weld:

1. Effective Throat

a. Calculation: The powerful throat will be the shortest distance from the joint root to the weld face of the diagrammatic weld (see Annex I). Note: See Annex II for formulation governing the calculation of powerful throats for fillet welds in skewed T-joints. A tabulation of measured legs (W) and ideal root openings (R) related to powerful throats (E) has been furnished for dihedral angles among 60° and 135°.

b. Shear Stress

Stress at the powerful throat of fillet welds is taken into consideration as shear pressure irrespective of the path of the application.

c. Reinforcing Fillet Welds

The powerful throat of a mixture partial joint penetration groove weld and a fillet weld will be the shortest distance from the joint root to the weld face of the diagrammatic weld minus 1/eight in. (three mm) for any groove element requiring such deduction (see Figure three and Annex I).

2. Length

a. Effective Length (Straight):

The powerful period of a directly fillet weld will be the general period of the huge fillet, together with boxing. No discount in powerful period will be assumed in layout calculations to permit for the begin or forestall crater of the weld.

b. Minimum Length:

The minimal powerful duration of a fillet weld will be at the least 4 instances the nominal length, or the powerful length of the weld will be taken into consideration now no longer to exceed 25% of its powerful duration.

c. Effective Area:

The powerful vicinity will be the powerful weld duration improved with the aid of using the powerful throat. Stress in a fillet weld will be taken into consideration as implemented to this powerful vicinity, for any course of implemented load.

d. Minimum Leg Size:

Minimum size leg required fillet weld

E. Maximum Fillet Weld Size:

The most fillet weld length precise alongside edges of fabric will be the following: (1) the thickness of the bottom steel, for steel much less than 1/four in. (6 mm) thick (see Figure 2.1, Detail A) (2) 1/sixteen in. (2 mm) much less than the thickness of base steel, for steel 1/four in. (6 mm) or extra in thickness (see Figure 2.1, Detail B), until the weld is specific on the drawing to be constructed out to attain complete throat thickness. In the as-welded condition, the gap among the fringe of the bottom steel and the toe of the weld might also additionally be much less than 1/sixteen in. (2 mm), furnished the weld length is virtually verifiable.

B. Design if intermittent fillet weld

The minimal duration of an intermittent fillet weld shall be 1-half of in. (forty mm). Minimum length: The minimal powerful duration of a fillet weld will be at the least 4 instances the nominal length, or the powerful length of the weld will be taken into consideration now no longer to exceed 25% of its powerful duration

C. Design of plug and slot weld

1) Effective Area:

The powerful place will be the nominal place of the hollow or slot within side the aircraft of the faying surface

2) Minimum Spacing (Plug Welds):

The minimal middle-to-middle spacing of plug welds will be 4 instances the diameter of the hollow.

3) Minimum Spacing (Slot Welds):

The minimal spacing of strains of slot welds in a route transverse to their duration will be 4 instances the width of the slot.

Minimal middle-to-middle spacing in a longitudinal route on any line will be instances the duration of the slot.

4) Slot Ends:

The ends of the slot will be semicircular or shall have the corners rounded to a radius now no longer less than the thickness of the component containing it, besides those ends which expand to the brink of the component.

5) Prequalified Dimensions:

For plug and slot weld dimensions which are prequalified, see three.

Prohibition in Q&T Steel. Plug and slot welds aren't authorized in quenched and tempered steels

6) Limitation:

Plug or slot weld length layout will be primarily based totally on shear within side the aircraft of the faying surfaces.

Key takeaways:

- The powerful throat will be the shortest distance from the joint root to the weld face of the diagrammatic weld

- Plug or slot weld length layout will be primarily based totally on shear within side the aircraft of the faying surfaces.

- The minimal spacing of strains of slot welds in a route transverse to their duration will be 4 instances the width of the slot.

Failure of a welded joint may be of types:

(a) The ones "failed' in the course of inspection after fabrication,

(b) The ones failed in the course of carrier.

The defects which can also additionally fail a weld joint in the course of carrier if left in an aspect undetected are the following: creaks, loss of penetration, loss of fusion, porosity etc.

Among those defects, the linear ones which include the shortage of penetration, loss of aspect wall fusions etc. and particularly the cracks are extra harmful.

Linear defects at the floor or within side the subsurface vicinity is once more extra critical due to the fact the 2 modes of screw ups e.g., fatigue and strain corrosion cracking which might be the maximum ordinary mechanisms of screw ups in business additives W2 originate from the floor or subsurface regions.

Key takeaways:

1. The ones "failed' in the course of inspection after fabrication,

2. The ones failed in the course of carrier.

3. Among those defects, the linear ones which include the shortage of penetration, loss of aspect wall fusions etc. and particularly the cracks are extra harmful.

A. Welded joints Vs Bolted joint

Sr. No | Welded joint | Bolted joint |

1. | Good aesthetical look | Bad aesthetical look |

2 | Skilled labour required | Skilled labour is not required |

3 | Difficult in inspect welded joint | Inspection of connection is very easy |

4 | Not necessary to drill the hole | Necessary to drill the hole |

5 | Welding requirement are more expensive it required initial investment | Less rigid connection |

6 | More rigid connection | Not required initial investment |

7 | Connection required constant power supply | Connection can be done at site |

B. Welded joint Vs Riveted joint

Sr. No | Welded joint | Riveted joint |

1 | Skilled labour required | It is related to very excessive stage of noise pollution

|

2 | Difficult in inspect welded joint | There is a want to warmth the rivet until purple warm color.

|

3 | Not necessary to drill the hole | Skilled labors are vital to investigate the relationship.

|

4 | Welding requirement are more expensive it required initial investment | The fee to get rid of the poorly hooked up rivet could be very excessive.

|

5 | More rigid connection | The excessive-fee set up within side the connection.

|

References:

- Design of Steel Structures- Limit State Method by N. Subramanian, Oxford University Press

- Limit State Design of Steel structures by S.K. Duggal, Mc-Graw Hill

- Design of steel structures by S.S. Bhavikatti, I.K. International Publishing house.

- Design of Steel Structures by K. S. Sairam, Pearson

- Steel Design by William T. Segui, Cengage Learning

- Fundamentals of Structural Steel Design by M.L. Gambhir, Mc Graw Hill

- Steel Structures-Design and Practice by N. Subramanian, Oxford University Press