Unit - 4

Highway construction

Highway production is normally preceded via way of means of precise surveys and subgrade preparation. The techniques and generation for building highways has advanced over the years and grow to be an increasing number of sophisticated. This development in generation has raised the extent of talent units required to manipulate motorway production projects. This talent varies from venture to venture, relying on elements consisting of the venture's complexity and nature, the contrasts among new production and reconstruction, and variations among city location and rural location projects.

There are some of factors of motorway production which may be damaged up into technical and industrial factors of the system.

1. A sturdy base for the higher street shape:

The backside layer basically accommodates an unbound aggregate of coarse and great overwhelmed stone, in addition to overwhelmed sand, to reap the preferred load-bearing potential and take in site visitors hundreds in order that the underlying subgrade isn't always deformed

The base route serves as a basis for the paving. Depending at the stresses to be expected, the street accommodates numerous layers of various thickness to be able to resist the maximum numerous climate situations and continue to be serviceable for plenty decades.

2. A gravel layer protects in opposition to frost:

Roads are uncovered to specifically excessive stresses whilst the water contained withinside the pavement shape starts offevolved to freeze. Water expands whilst freezing, that can result in frost harm a good way to in the end have an effect additionally on the street surface. This is avoided with the aid of using a so-referred to as frost blanket which generally includes a aggregate of gravel and sand, supplemented with the aid of using overwhelmed mineral aggregate. When compacted, those layers of frost-resistant substances behavior water farfar from the higher pavement layers, decreasing tensions very correctly on the identical time.

3. Bituminous certain base layers

Mixes containing bitumen are known as warm-paved or cold-paved asphalt base courses, relying on whether or not the combinationture is warm or cold. The base direction is stated to be hydraulically certain whilst cement or lime is used as binder.

4. Hydraulically certain base layers

When the mineral mixture combination is certain with cement or lime, the ensuing base layer is referred to as a hydraulically certain base layer. Mineral mixture combos used for this sort of base layer encompass uncrushed gravel or coarse mixture, chippings, and overwhelmed or herbal sand. Ever extra frequently, those mixes additionally comprise a percent of recycled creation materials.

Earthworks are engineering works created thru the processing of elements of the earth's floor related to portions of soil or unformed rock.

Typical earthworks consist of avenue construction, railway beds, causeways, dams, levees, canals, and berms. Other not unusualplace earthworks are land grading to reconfigure the topography of a site, or to stabilize slopes.

The functions of earthwork are the introduction of engineering works from the soil (consisting of dams, railroads, highways, canals, channels, and trenches), the laying of foundations for homes and systems which might be erected from different materials, the leveling of regions beneathneath improvement for building.

Water Bound Macadam (WBM)

Water bound macadam road is a road in which the wearing course consists of clean crushed aggregates which are mechanically interlocked by rolling. These aggregates bound together with filler material and water laid on a well-compacted base course.

Water bound macadam road is the most commonly used road construction procedure for over more than 190 years and in the first phase in most of the road projects, water-bound macadam road is constructed, and the surfacing is done with the premix carpet bituminous macadam or cement concrete.

Materials for water bound macadam road

- Coarse Aggregate

- Screenings (Filler Material)

- Binding Material

1. Coarse aggregate:

Coarse aggregates consist of a mixture of hard and durable crushed aggregates and broken stones, and aggregate should be properly graded for each layer of the WBM road construction.

It should be hard and durable.

The coarse aggregate should be free from elongated particles and flaky particles.

2. Screenings: (filler material)

Screenings are the material that is used up to fill up the excess voids present in the compacted layer of course aggregate and these materials are the aggregates of a smaller size than the coarse aggregates.

3. Binding material

Binding material should be properly approved by engineer and it should have a plasticity index value less than 6 for the construction of water bound macadam road.

4. Construction procedure of water bound macadam road

There are the following steps in the construction procedure of WBM road as given below;

5. Preparation of foundation for WBM road

For the required grade and camber of WBM road, the subgrade or base course is properly prepared and the potholes and the depressions on the surface of the road is properly filled up & compacted.

6. Provision for lateral confinement

The shoulders having a thickness as that of compacted WBM layer should be constructed before laying of aggregates and with the proper quality of earth, they should be constructed.

The purpose of constructing shoulders is that the road surface to be constructed retains in between them and for the further laying of course aggregates, it becomes easy.

7. Spreading of coarse aggregates

After the construction of the shoulders, the coarse aggregates are uniformly spread on the prepared base and the total number of layers and thickness of water bound macadam road depends upon the details of pavement design.

Single-layer of compacted thickness 75 mm may be sufficient for ordinary roads and 2 layers of 150 mm each compacted thickness may be provided for special roads.

8. Rolling operation

For compacting the coarse aggregates, the rolling operation is carried out and it is done with the help of vibratory rollers or with the help of 3-wheeled power rollers weighing 6 to 10 tones.

For driving the rollers, skilled operators should be used because the fault rolling operations cause the formation of corrugations, the unequal finish of road surface, etc.

9. Application of screenings

The screenings are applied to properly fill the voids remained after the rolling operation is properly finished and in 3 or more layers as per the site conditions screening may be applied.

For each layer of screenings, compaction is carried out with the help of dry rollers, and to remove the uncompacted screening material, brooming of each layer should be properly done after compaction.

10. The sprinkling of water and grouting

The road surface is properly sprinkled with plenty of water after the application of screening and brooming is done to sweep the wet screening properly into the voids after the water is sprinkled.

11. Application of binding material

As screenings, the same procedure is used in this step and rolling operation is carried out after each layer of water is sprinkled.

To washout, the binding material that gets stuck to the wheels of the rollers, the wheels of the roller should be constantly watered at the time of rolling operation.

12. Setting and drying of surface

The road is allowed to cure or set over-night after the final rolling operation and the next day again sufficient amount of screenings or binding materials can be used and compaction is done if the depressions or voids are visible.

13. Preparation of shoulders

The shoulders are constructed alongside by filling earth to specified cross slope at the time of the curing of the road and compacted properly.

14. Open for traffic

The road is then made open for traffic after proper drying and without any depressions. By placing obstacles longitudinally in the form of drums, barricades, etc the traffic should be well distributed over the full width of the road.

Maintenance of WBM road

- By the period of time when the potholes and ruts occur on the road, they should be filled with adequate materials and properly compacted.

- By means of dragging, the corrugations that occurred on the roads should be removed and by fresh materials, broken materials of the roads should be properly restored.

- In 2-5 years or based according to the traffic volume, the surface of the road should be renewed.

- The loose aggregates start coming on the top of the surface of the road so they should be removed and leveled surface should be added by fresh binding material.

Advantages of water bound macadam road

There are the following advantages of water bound macadam road such as;

- The construction cost is comparatively low in WBM road.

- No skilled laborers are required in the construction of WBM road.

- From locally available materials they are constructed.

- It can resist a load of traffic of about 900 tons per lane per day if these roads are maintained properly and from time to time.

Disadvantages of water bound macadam road

There are also some disadvantages of water bound macadam road such as;

- There is a high cost for maintenance on this road.

- There is a very less overall life span of these roads.

- The WBM roads can cause inconvenience and danger to traffic if they are not properly maintained.

- It leads to softening and yielding of subsoil because WBM roads are permeable to rainwater.

Key Takeaways:

1. Hardness: - Hardness is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion.

2. Durability: - Durability is the ability of a physical product to remain functional, without requiring excessive maintenance or repair, when faced with the challenges of normal.

Granular Sub Base (GSB):

Granular Sub Base (GSB) is natural or designed construction material, used for road construction as a sub-base layer. Granular Sub Base is a layer in road foundation just above the compacted sub-grade layer. GSB or granular sub-base prevents capillary water from rising; its particle size is so designed that the capillary action stops and can’t go beyond GSB layer. Secondly, it works like a drainage layer where water can pass without damaging other road layers.

1) Equipment and Machinery

The following sets of equipment are necessary for the for GSB construction work.

- Grader /Loader/Excavator

- Vibratory Rollers (80 -100 KN static weight)

- Water Tanker (10,000 Litres)

- Tippers / Dumpers -10T /20T (as per site requirement)

2) Material

The material shall be crushed stone aggregate free from organic and other deleterious constituents or natural river bed material having proper gradation. It shall conform to grading-I of Table 400-1 of MORTH specification, with the percentage passing 0.075mm size restricted to 5%. The material shall have four days soaked CBR of a minimum of 30%.

3) Physical properties of Granular Sub Base Material

The portion of the total aggregate passing through 4.75mm sieve shall have a sand equivalent value of not less than fifty when tested in accordance with the requirement of IS 2720 (Part-37).

IS Sieve Designation (mm) | Percent by weight passing the IS sieve Grading-I |

75 | 100 |

53 | 80 – 100 |

26.5 | 55 – 90 |

9.5 | 35 – 65 |

4.75 | 25-55 |

2.36 | 20 – 40 |

0.425 | 10- 25 |

0.075 | 3 – 10 |

A mix of different sizes of Crushed aggregates from approved sources shall be so proportioned to achieve the grading specified.

The Proportioning shall be done by ascertaining the proper gradation of the individual ingredients and the blend determined by trial and error method to achieve the gradation specified. MDD & OMC shall be established for the material so blended. It will be ensured before the actual execution that material used in GSB has a CBR value of 30% or more when compacted and finished.

In case of variation of gradation in the course of work, the proportion shall be suitably modified, and the entire required test shall be carried out in accordance with relevant specification.

The material shall be blended at source/crusher to achieve the specified gradation. This shall be jointly checked at the site for conformance to gradation and other tests as defined in section 900 of MORTH.

4) Spreading:

Mark the lines of GSB with lime powder or pegs on the completed subgrade.

Requisite sub-surface drain and drain outlet at the level of sub-grade/sub-base shall be completed before the commencement of GSB construction.

Now prior to the laying of sub-base, the subgrade already finished shall be made by removing all vegetation and other Sub-extraneous matter, lightly sprinkled with water if necessary and rolled with two passes of 80 -100 KN smooth wheeled roller.

The material shall be loaded with the help of loader on the dumpers for transporting to the GSB location.

The required material shall be dumped between the limiting lines marked with the help of lime powder.

The material of the GSB layer confirming Table 400.1 shall be spread in layers of uniform thickness of 200 mm compacted thickness for new flexible pavement,150 mm compacted thickness for Service Roads and rigid pavement at Toll Plazas. Grader shall be used for this activity.

The moisture content of the material should have of OMC +1.0% or –2.0%, if not, either mixing or drying process must be adopted. Water can be added to raise the moisture content up to the required limits. After spraying water with the help of the browser, the material shall be properly mixed to obtain a homogeneous mix. The mixing can continue with the help of grader. The grader shall then carry out final well-defined grading.

5) Compaction

Compaction of GSB shall start immediately after achieving the required moisture content. The compaction shall be done with a vibratory compactor. The compaction pattern, including no of passes required, shall be finalized after the full-scale experiment at the site to achieve 98% of MDD determined as per IS: 2720 (Part -8). The general pattern shall be as follows:

a) Initial rolling -2 static passes with Vibratory roller

b) Subsequent rolling – 4 vibratory pass

Note: One roller pass shall include both forward and reverse movement of the roller). The speed of the roller shall not top 5.0 Km /Hour.

The compaction shall commence from the lower edge and shall move to upper edge width by width. Quality control tests shall be carried out prior to the commencement of the next layer.

The rain cuts shall be repaired before placing the drainage layer.

The compaction behind structure shall be accomplished with the use of vibratory roller or plate compactors to achieve 98% if MDD.

The surface of GSB shall have a suitable cross fall to enable efficient surface drainage.

The finished level GSB shall be within the tolerance limits specified in Table 900.1, i.e. +10.0mm to – 20.0mm.

Key takeaway:

1. GSB (Granular Sub Base): - (63 - 40 mm aggregate or 70mm down aggregates).

2. The rain cuts shall be repaired before placing the drainage layer.

3. The compaction behind structure shall be accomplished with the use of vibratory roller or plate compactors to achieve 98% if MDD.

4. The surface of GSB shall have a suitable cross fall to enable efficient surface drainage.

Wet mix macadam (WMM):

Wet Mix Macadam consist of laying spreading and compacting of clean, crushed, well-graded granular materials on a prepared and approved Granular sub-Base. The material is well mixed with water and rolled to a dense mass.

The thickness of single compacted Wet Mixed Macadam (WMM) Base shall not be less than 75 mm.

While constructing a road, there needs to lay down the base course material right before hot mix asphalt is laid, and that process done through the Wet Mix Macadam. The materials used for the sub-base, base or existing pavement are prepared in a plant as per the specifications provided. Once it is prepared, it is brought to the site for overlaying and rolling under the guidelines of engineers.

The WMM process is a newly developed concept. Earlier it was done through the WBM (water bound macadam) process. Though WBM process is cheaper than the WMM, the later gives plenty of benefits. In short, the outputs of WMM pay you of the debt. So, let’s find out the benefits we get from the WMM process.

- The roads constructed through WMM process are durable

- The WMM roads get dry sooner as compared to that of WBM

- The WMM process allows constructing road faster than other processes

- Roads can be ready in no time and can be applied or topped with Bituminous layers soon after the laying process done

- WMM process saves plenty of water

Apart from that, the WMM machines are easily operated and give a bunch of benefits.

Similarly, there are so many additional benefits which can compensate you well if you use this wet mix plant to construct the road.

Here’s the list of components which set the Wet Mix Macadam plant apart from others.

- Feeders

- Vibrating Screen

- Conveyor

- Pug Mill mixer

- Conveyor

- Silo or Hopper

- Water tank

- Control Panel

1) Aggregate Feeders:

It’s a four-bin aggregate with a manually adjustable gate in each to store four types of aggregates. It helps to discharge the materials and smoothens wet mix process.

2) Vibrating Screen:

It works to filter the oversized aggregates and deliver it to the charging conveyor belt.

3) Conveyor:

Conveyor or charging conveyor delivers the material to pug mill mixer after that they are filtered through a vibrating screen. Once the panel receives the material, the water and cement flow get synchronized and ease the mixing process.

The pug mill mixer consists liner plates, arms, and tips and spreads materials when comes in contact with water and at last, the load out conveyor transfers the mixer to the storage which later transmitted to other truck for further process.

All components used during the process to simplify the mixing process and help wet mix macadam plants achieve the highest goal.

The wet mix plant is very much in trend for its friendly features including ease of operation, providing high-quality services and giving a satisfactory result to the builder.

Key Takeaways:

- WMM (Wet Mix Macadam): - (40 mm down aggregates, mix design required)

- The thickness of single compacted Wet Mixed Macadam (WMM) Base shall not be less than 75 mm.

- Conveyor or charging conveyor delivers the material to pug mill mixer after that they are filtered through a vibrating screen

1) Bituminous Base Course. Base route layer in a bituminous pavement includes mineral aggregates inclusive of gravel, stones and sands bonded collectively with bituminous materials.

2) Bituminous Binder Course. Binder route layer is an intermediate layer among base route and floor layer.

3) Bituminous Concrete Layer.

1. Bituminous Base Course:

Base path layer in a bituminous pavement includes mineral aggregates which includes gravel, stones and sands bonded collectively with bituminous materials. This layer is used as the muse on which floor path or binder is placed.

2. Bituminous Binder Course:

Binder direction layer is an intermediate layer among base direction and floor layer. It is the primary layer in case of two-layer bituminous resurfacing. Bituminous binder direction is manufactured from bituminous-combination combination, additionally referred to as as levelling direction.

3. Bituminous Concrete Layer

Bituminous concrete layer is a combination of aggregates constantly graded from most length to minimal sizes (commonly much less than 25mm to 0.075mm aggregates). Sufficient bitumen is delivered to the combinationture in order that the compacted concrete blend efficaciously impervious and has suitable dissipative and elastic properties.

1. Jointed Plain Concrete Pavement (JPCP).

2. Jointed Reinforced Concrete Pavement (JRCP).

3. Continuous Reinforced Concrete Pavement (CRCP).

4. Pre-Stressed Concrete Pavement (PCP).

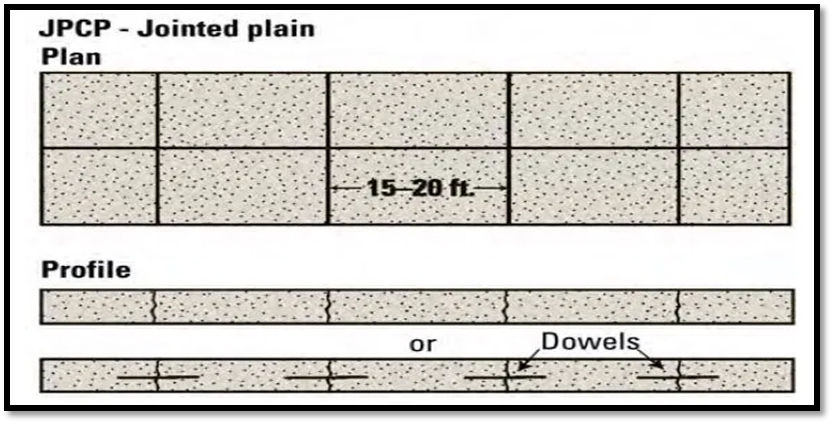

- Jointed Plain Concrete Pavement:

Because of their cost-effectiveness and reliability, the vast majority of concrete pavements constructed today are JPCP designs.

They do not contain reinforcement.

They have transverse joints generally spaced less than 5 to 6.5 m apart.

They may contain dowel bars across the transverse joints to transfer traffic loads across slabs and may contain tie bars across longitudinal joints to promote aggregate interlock between slabs.

Fig.: Jointed Plain Concrete Pavement

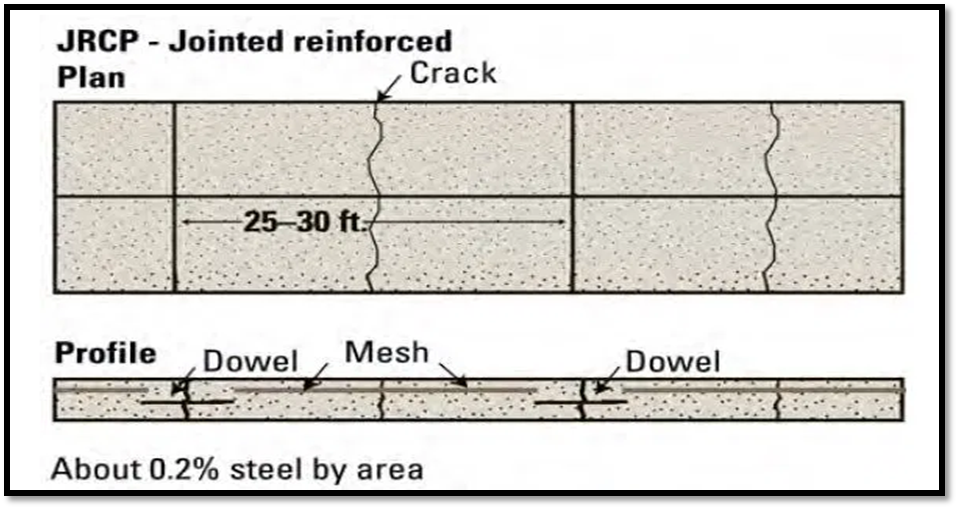

2. Jointed Reinforced Concrete Pavement:

Although reinforcements do not improve the structural capacity significantly, they can drastically increase the joint spacing to 10 to 30m.

Dowel bars are required for load transfer.

Reinforcement’s help to keep the slab together even after cracks.

The reinforcement, distributed throughout the slab, composes about 0.15 to 0.25 percent of the cross-sectional area and is designed to hold tightly together any transverse cracks that develop in the slab.

It is difficult to ensure that joints are cut where the reinforcement has been discontinued.

This pavement type is not as common as it once was on State highways, but it is used to some extent by municipalities.

Fig.: Jointed Reinforced Concrete Pavement

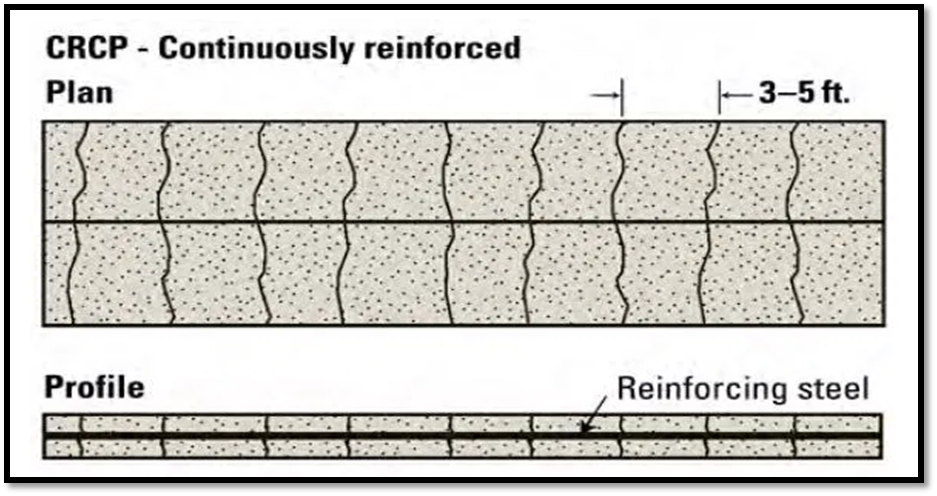

3. Continuous Reinforced Concrete Pavement:

CRCP designs have no transverse joints, but contain a significant amount of longitudinal reinforcement, typically 0.6 to 0.8 percent of the cross-sectional area.

Transverse reinforcement is often used.

The high content of reinforcement both influences the development of transverse cracks within an acceptable spacing (about 0.9 to 2.5 m apart) and serves to hold cracks tightly together.

Fig.: Continuous Reinforced Concrete Pavement

Asphaltic concrete is a aggregate of asphalt, coarse aggregates, first-rate aggregates & filler material. After mixing, we're heating them as much as very last product called “HOT MIX”. There are fundamental kinds of flowers used to fabricate warm blend asphalt: Batch kind plant Drum(continuous) kind plant.

The asphalt plant is specially composed of bloodless mixture deliver system, drum dryer, coal burner, coal feeder, dirt collector, warm mixture elevator, vibrating screen, filler deliver system, weighing and combining system, asphalt storage, bitumen deliver system.

The motive of an HMA plant is to combo mixture and asphalt collectively at an multiplied temperature to produce a homogeneous asphalt paving combination. There are 3 fundamental forms of HMA plant life in use: batch, parallel-float drum-mix, and counter-float drum-mix. All 3 sorts serve the identical ultimate motive, and the asphalt combination have to be basically comparable no matter the kind of plant used to manufacture it.

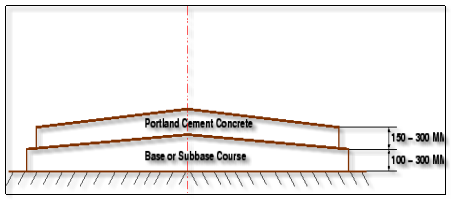

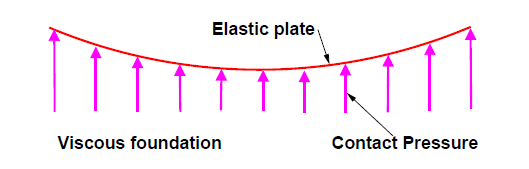

A rigid pavement, in contrast to a flexible one, derives its capacity to resist loads by virtue of its flexural strength.

Flexural strength allows the pavement to bridge over minor irregularities or weak spots in the subgrade or other courses such as the base or sub-base upon which it rests. Thus, the inherent strength of the pavement slab itself plays a major role in resisting the wheel loads; this, however, cannot under-rate the need for a strong subgrade.

It simply means that, provided a certain minimum support is derived from the subgrade, the performance of the rigid pavement is governed by the strength of the pavement slab rather than by that of the subgrade. Rigid pavements consist of cement concrete (OPC), which may be plain, reinforced or pre-stressed concrete.

The primary difference between a rigid pavement and a flexible one is in the structural behavior; the critical condition of stress is the maximum flexural stress in the pavement slab not only due to the wheel load, but also due to warping caused by changes in temperature in the summer and winter seasons, and during the day and night. The warping of the slab is caused by the temperature gradient between the top and bottom, and the consequent flexure.

Further, temperature changes tend to cause stresses due to friction at the interface between the slab and the layer below, which opposes the movement of the slab.

A rigid pavement can serve the dual purpose of a base and a wearing course. However, it is not normally laid directly over the subgrade when the latter consists of fine-grained soil.

Providing a base or a sub-base below the pavement can enhance the life of the pavement significantly, and may prove economical in the long run.

|

Fig.: Typical Cross section of Rigid pavement |

Fig.: Stress Distribution

References:

- Khanna S. K., Justo C.E.G, & Veeraragavan, A. “Highway Engineering”, Nem Chandand Bros., Roorkee- 247 667.

2. Khanna S. K., Justo C.E.G, & Veeraragavan A., “Highway Materials and Pavement Testing”, Nemchand and Bros., Roorkee- 247 667.

3. LR Kadiyali, Transportation Engineering, Khanna Publication.

4. L.R. Kadiyali, Transportation Engineering, Khanna Publishing House

5. Saxena, Subhash C, A Textbook of Highway and Traffic Engineering, CBS Publishers &Distributers, New Delhi

6. Kumar, R Srinivasa, “A Text book of Highway Engineering”, Universities Press, Hyderabad.

7. Kumar, R Srinivasa, “Pavement Design”, Universities Press, Hyderabad.

8. Chakraborty Partha & Das Animesh, “Principles of Transportation Engineering”, Prentice Hall (India), New Delhi,

9. IRC: 37- Latest revision, “Tentative Guidelines for the design of Flexible Pavements” Indian Roads Congress, New Delhi

10. IRC:58-2015 Guidelines for the Design of Plain Jointed Rigid Pavements for Highways(Fourth Revision) (with CD)

11. IRC:65-2017 Guidelines for Planning and Design of Roundabouts (First Revision)

12. IRC:73-1980 Geometric Design Standards for Rural (Non-Urban) Highways

13. IRC:106-1990 Guidelines for Capacity of Urban Roads in Plain Areas

14. IRC: 93-1985 Guidelines on Design and Installation of Road Traffic Signals.

15. IRC:92-2017 Guidelines for Design of Interchanges in Urban Areas (First Revision)

16. IRC: SP: 68-2005, “Guidelines for Construction of Roller Compacted Concrete Pavements”, Indian Roads Congress, New Delhi.

17. IRC: 15-2002, “Standard Specifications and Code of Practice for construction of Concrete Roads” Indian Roads Congress, New Delhi.

18. MORTH, “Specifications for Road and Bridge Works”, Ministry of Shipping, Road Transport & Highways, Published by Indian Roads Congress, New Delhi.