Unit - 5

Compensators

For getting the required performance we need to adjust the design parameters and this is called compensation. To achieve the required output parameters a device called compensator is used. The compensators are mainly used to increase the steady state accuracy of system. These compensators minimise the overshoot. As these compensators are introduced in the system the transfer function changes and hence the performance specifications also change.

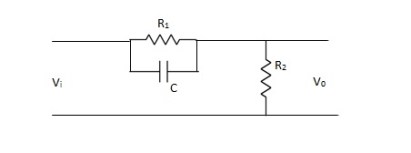

Phase – Lead Compensation:

The phase of output voltage leads the phase of input voltage for the applied sinusoidal input. The circuit diagram is shown below. The transfer function is given as,

Fig. Phase Lead Compensation

Vo/Vi = α(1 + ST)/(1 + S α T)

Where, α = R2/R1 + R2 and α< 1

T = R1C

w = 1/T lower corner frequency due to zero.

w = 1/ αT upper corner frequency due to pole.

Mid frequency is given as,

wm = 1/T√ α

The maximum phase lead angle is φm

Φm = tan-1(1- α)/2√α = Sin-11- α/1 + α

Advantages of Phase Lead Compensation

Let us discuss some of the advantages of the phase lead compensation-

- Due to the presence of phase lead network the speed of the system increases because it shifts gain crossover frequency to a higher value.

- Due to the presence of phase lead compensation maximum overshoot of the system decreases.

Disadvantages of Phase Lead Compensation

Some of the disadvantages of the phase lead compensation –

- Steady state error is not improved

Key takeaway

Effect of Phase Lead Compensation

- The velocity constant Kv increases.

- The slope of the magnitude plot reduces at the gain crossover frequency so that relative stability improves and error decrease due to error is directly proportional to the slope.

- Phase margin increases.

- Response becomes faster.

Phase Lag Compensation:

The phase of the output voltage lags the phase of the input voltage for applied sinusoidal input. The circuit diagram is shown below,

Fig. Phase Lag Compensation

Vo/Vi = 1 + ST/1 + SβT

Where, β = R1 + R2/R2, β> 1

T = R2C

w = 1/T upper corner frequency due to zero

w= 1/βT lower corner frequency due to pole

The mid frequency wm,

wm = 1/T√β

The maximum phase lead angle Φm

Φm = tan-11- β/2 √β

= sin-11 – β/1 + β

Advantages of Phase Lag Compensation

Let us discuss some of the advantages of phase lag compensation –

- Phase lag network allows low frequencies and high frequencies are attenuated.

- Due to the presence of phase lag compensation the steady state accuracy increases.

Disadvantages of Phase Lag Compensation

Some of the disadvantages of the phase lag compensation –

- Due to the presence of phase lag compensation the speed of the system decreases

Key takeaway

Effect of Phase Lag Compensation

- Gain crossover frequency increases.

- Bandwidth decreases.

- Phase margin will be increase.

- Response will be slower before due to decreasing bandwidth, the rise time and the settling time become larger.

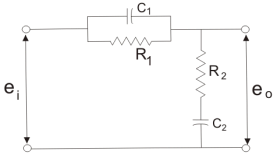

Phase Lag-Lead Network:

To overcome the disadvantages of lead and lag compensation, they are used together. As lead compensation does not provide phase margin but has fast response and lag compensation stabilize the system but does not provide enough bandwidth.

Fig. Lag-Lead Compensation

eo/ei = (1 + α ST1)/(1 + ST2)

Where, αT1 = R1C1

T2= R2C2

We can say in the lag-lead compensation pole is more dominating than the zero and because of this lag-lead network may introduces positive phase angle to the system when connected in series.

Key takeaway

Phase Lead Network | Phase Lag Network |

1>. It is used to improve the transient response | 1>It is used to improve the Steady state response.

|

2>. It acts as a high pass filter. | 2>It acts as a low pass filter. |

3>. The system becomes fast as Bandwidth increases as rise Time decreases. | 3>The Bandwidth decreases through rise time the speed is slow.

|

4>. As the circuit acts as differentiator, signal to noise ratio is poor.

| 4>Signal to noise ratio is higher as it acts as integrator. |

5>. Maximum peak overshoot is reduced. | 5>It reduces steady state error thus improve the steady state accuracy |

In simple terms, a sensor is a device that detects changes and events in a physical stimulus and provides a corresponding output signal that can be measured and/or recorded. Here, the output signal can be any measurable signal and is generally an electrical quantity.

Sensors are devices that perform input function in a system as they ‘sense’ the changes in a quantity. The best example of a sensor is mercury thermometer. Here the quantity that is being measured is heat or temperature. The measured temperature is converted to a readable value on the calibrated glass tube, based on the expansion and contraction of liquid mercury.

Actuators are devices that work opposite to sensors. A sensor converts a physical event into an electrical signal, whereas an actuator converts electrical signal into a physical event. When sensors are used at input of a system, actuators are used to perform output function in a system as they control an external device.

Transducer

Transducers are the devices that convert energy in one form into another form. Generally, the energy is in the form of a signal. Transducer is a term collectively used for both sensors and actuators.

The basic requirements of a sensor are:

- Range: It indicates the limits of the input in which it can vary. In case of temperature measurement, a thermocouple can have a range of 25 – 250 0C.

- Accuracy: It is the degree of exactness between actual measurement and true value. Accuracy is expressed as percentage of full range output.

- Sensitivity: Sensitivity is a relationship between input physical signal and output electrical signal. It is the ratio of change in output of the sensor to unit change in input value that causes change in output.

- Stability: It is the ability of the sensor to produce the same output for constant input over a period of time.

- Repeatability: It is the ability of the sensor to produce same output for different applications with same input value.

- Response Time: It is the speed of change in output on a stepwise change in input.

- Linearity: It is specified in terms of percentage of nonlinearity. Nonlinearity is an indication of deviation of curve of actual measurement from the curve of ideal measurement.

- Ruggedness: It is a measure of the durability when the sensor is used under extreme operating conditions.

- Hysteresis: The hysteresis is defined as the maximum difference in output at any measurable value within the sensor’s specified range when approaching the point first with increasing and then with decreasing the input parameter. Hysteresis is a characteristic that a transducer has in being unable to repeat its functionality faithfully when used in the opposite direction of operation.

Classification of Sensors

The scheme of classifying sensors can range from very simple to very complex. The stimulus that is being sensed is an important factor in this classification.

Some of the stimuli are

- Acoustic: Wave, spectrum and wave velocity.

- Electric: Current, charge, potential, electric field, permittivity and conductivity.

- Magnetic: Magnetic field, magnetic flux and permeability.

- Thermal: Temperature, specific heat and thermal conductivity.

- Mechanical: Position, acceleration, force, pressure, stress, strain, mass, density, momentum, torque, shape, orientation, roughness, stiffness, compliance, crystallinity and structural.

- Optical: Wave, wave velocity, refractive index, reflectivity, absorption and emissivity.

The sensors’ conversion phenomenon is also an important factor in classification of sensors. Some of the conversion phenomena are magneto electric, thermoelectric and photoelectric.

Based on the applications of sensors, their classification can be made as follows.

I. Displacement, Position and Proximity Sensors

- Resistive Element or Potentiometer

- Capacitive Elements

- Strain Gauged Element

- Inductive Proximity Sensors

- Eddy Current Proximity Sensors

- Differential Transformers

- Optical Encoders

- Hall Effect Sensors

- Pneumatic Sensors

- Proximity Switches

- Rotary Encoders

II. Temperature Sensors

- Thermistors

- Thermocouple

- Bimetallic Strips

- Resistance Temperature Detectors

- Thermostat

III. Light Sensors

- Photo Diode

- Phototransistor

- Light Dependent Resistor

IV. Velocity and Motion

- Pyroelectric Sensors

- Tachogenerator

- Incremental encoder

V. Fluid Pressure

- Diaphragm Pressure Gauge

- Tactile Sensor

- Piezoelectric Sensors

- Capsules, Bellows, Pressure Tubes

VI. Liquid Flow and Level

- Turbine Meter

- Orifice Plate and Venturi Tube

VII. IR Sensor

- Infrared Transmitter and Receiver Pair

VIII. Force

- Strain Gauge

- Load Cell

IX. Touch Sensors

- Resistive Touch Sensor

- Capacitive Touch Sensors

X. UV Sensors

- Ultraviolet Light Detector

- Photo Stability Sensors

- UV Photo Tubes

- Germicidal UV Detectors

All the sensors can be classified into two types based on the power or signal requirement. They are Active sensors and passive sensors.

A Simple System using Transducers

A public addressing system is an example of a system using sensors and actuators.

It consists of a microphone, an amplifier and a loudspeaker. The sensor or the device with input function is a microphone. It senses the sound signals and transforms them into electrical signals. The amplifier receives these electrical signals and amplifies their strength.

The actuator or the device with output function is loudspeaker. It receives the amplified electrical signals from the amplifier and converts them back into sound signals but with more reach.

References:

1. Control Systems Engineering, I.J. Nagrath, M. Gopal

2. Modern Control system (II Edition) – Katsuhiko Ogata

3. Control systems by Smarajit Ghosh (second Edition, Pearson Education)