Unit - 2

Engine auxiliary systems

Auxiliary gadget is described as peripheral gadget that can be a crucial a part of the extrusion procedure to enhance or optimize the extrusion procedure performance and simplicity of operation. Within the plastics enterprise a vital element is the equipment auxiliary zone additionally referred to as secondary zone.

To offer the tens of thousands and thousands of plastic merchandise used international many distinctive fabricating strains are used. These strains have number one and auxiliary gadget. Primary gadget refers back to the gadget that fabricates a product consisting of an injection moulding gadget, extruder, blow milder, thermoformed, etc. Auxiliary gadget (AE) helps the number one gadget. This kind gadget is needed on the way to produce merchandise that healthy into the general production cycle. There are many differing types helping non-computerized to computerized upstream and downstream manufacturing in-line or off-line structures maximizing the general processing performance of productiveness and decreasing running cost. Normally a steam boiler plant consists of extra equipment to permit the operation.

Such gadget is generally offered from 1/3 events and consists of:

- Burners

- Fans, ducts, dampers

- Air heaters

- Hoppers, silos, crushers

- Soot blowers, conveyors

To be able to format and carry out a steam boiler one desires to understand the functioning of diverse quantities of tool. Therefore you can find that pumps, blowers, fans, and several flue fuel line cleaning devices, e.g., are cited extra thoroughly in distinct relevant literature. Some of auxiliary systems are right now related to those standards. They are all crucial lights, horn and heating.

Key Takeaways:

- These strains have number one and auxiliary gadget.

- Normally a steam boiler plant consists of extra equipment to permit the operation.

- To be able to format and carry out a steam boiler one desires to understand the functioning of diverse quantities of tool.

- The goal of Electronic Fuel Injection System is to alter and optimize the gasoline/air ratio that enters a vehicle’s engine. Fuel injection has currently grow to be the primary gasoline transport gadget utilized in car petrol engines.

- This submit will speak what's Electronic Fuel Injection System (EFI), its architecture, types, the way it works, applications, benefits and disadvantages. A gadget which targets at optimizing gasoline/air ratio coming into a car’s engine is referred as Electronic Fuel Injection System. EFI System has nearly absolutely changed utilization of carburettors.

- Carburetors are desirable for performance, however because of their indistinct nature, they can’t make wonderful horsepower, get stable fuel line mileage, and by skip an emission test, all with the identical tune, additionally they had many mechanical elements that might grow to be gummy over period.

- This way they have been extra protection-intensive, with a carburettor rebuild regularly being a part of a habitual protection schedule. OEM’s appeared to EFI to clear up their complicated emission problems.

- The preliminary EFI turned into primarily simply processor managed carburettors connected to an oxygen sensor and throttle function sensor, all stressed out to an Electronic Control Unit. The Electronic Fuel Injection System includes digital additives and sensors. It must be saved easy and nicely calibrated to enhance the engine’s electricity and performance and to reduce down fuel line consumption.

Types of Fuel Injection

To understand the concept better, we first have to understand types of Fuel Injection. The Fuel Injection types used in newer cars are:

- Single-Point or Throttle Body Injection

- Port or Multi-Point Fuel Injection

- Sequential Fuel Injection

- Direct Injection

- Single-Point or Throttle Body Injection

The first and easy sort of Fuel Injection changed into the Single-Point injection. Here the carburettor is changed via way of means of one or gas injector nozzles with inside the throttle body, that's the throat of the engine’s air consumption manifold. Single-Point Injection changed into a stepping stone to the extra complicated multi-factor machine for a few manufacturers. They are low-cost and less difficult to service.

- Port or Multi-Point Fuel Injection

In Multi-factor Fuel injection a separate injector nozzle is dedicated to every cylinder, proper outdoor its consumption port, because of which the machine is likewise known as Port Injection System. When the gas vapour is shot near the consumption port it makes certain that gas is drawn absolutely into the cylinder. The fundamental advantage is that MPFI meters gas greater exactly than the TBI designs do. It is higher at accomplishing the preferred gas/air ratio and enhancing all associated aspects.

The TBI and carburettors are designed in this type of manner that the consumption manifold conducts the engine’s warmth that's the degree to vaporize liquid gas. It isn't always vital on engines which might be geared up with MPFI wherein the consumption Manifold may be made from lighter-weight material, even plastic. MPFI machine effects in expanded gas economy. Standard steel consumption Manifolds need to be placed on pinnacle of the engine to behaviour warmth, however in case of MPFI it could be placed greater creatively, granting the engineers layout flexibility.

- Sequential Fuel Injection

Sequential Fuel Injection, additionally called the Sequential Port Fuel Injection (SPFI) or Timed Injection, is a sort of Multi-Port Injection. Although the MPFI has a couple of injectors, all of them spray their gasoline on the identical time or in groups. This can also additionally end result in “putting around” of the gasoline in a port for so long as a hundred and fifty milliseconds on the time of engine idling. It might not appear to be much, however it’s enough of a challenge that the engineers addressed it i.e. sequential gasoline injection triggers each injector nozzle separately. They are essentially timed just like the spark plugs and spray the gasoline right now earlier than or as their consumption valve opens. Although looks like a minor step, the performance and emission enhancements are available fantastically small doses.

- Direct Injection

Direct Injection injects gasoline instantly into the combustion chambers, beyond the valves. The Direct Injection presents engineers a further variable to persuade exactly how combustion arise with inside the cylinders. The field of engine layout scrutinizes how the gasoline/air combination swirls round with inside the cylinders and the way the explosion travels from the ignition point. Direct Injection is one which may be utilized in low-emission lean-burn engines.

Key Takeaways:

- EFI System has nearly absolutely changed utilization of carburettors.

- OEM’s appeared to EFI to clear up their complicated emission problems.

- To understand the concept better, we first have to understand types of Fuel Injection.

- The fundamental advantage is that MPFI meters gas greater exactly than the TBI designs do.

- Although the MPFI has a couple of injectors, all of them spray their gasoline on the identical time or in groups.

In unit injector (UI) and unit pump (UP) structures, every engine cylinder is served with the aid of using a separate injection pumping detail or injection pump in near proximity to the cylinder. Unit pump (UP) structures allow brief excessive strain gasoline strains with the aid of using finding the pump near the injector. Combining the pumping detail and the injector into one meeting as in unit injector (UI) structures, lets in those strains to be removed altogether. The elimination—or duration reduction—of excessive strain gasoline strains with inside the UI/UP injection structures consequences in benefits:

- The opportunity of wave superposition—which bothered the P-L-N structures with the aid of using inflicting after-injections and contributing to injection delays—is substantially reduced.

- Higher injection strain: the UI gadget has historically had the best injection strain functionality amongst all kinds of injection gadget. In the early 2000s, UI structures had strain competencies of two hundred MPa, in comparison to one hundred sixty MPa in not unusual place rail structures. Since then, UI/UP gadget height injection pressures have risen to as excessive 250 MPa for a few 2007 version 12 months applications.

- With regards to gas pressure, it ought to be mentioned that not unusual place rail gas injection gadget pressures have risen as properly and in a few structures have reached or handed the pressures to be had from UI/UP structures.

- While there may be no technical cause retaining UI/UP pressures from growing even further, engine producers are more and more the use of not unusual place rail structures in programs historically ruled via way of means of UI/UP structures. For this cause, UI/UP structures will possibly see little evolution past their contemporary height pressures of approximately 250 MPa.

- With the creation of electronics to diesel engines, digital unit injector (EUI) and digital unit pump (EUP) structures had been developed. These hire an electromagnetically operated spill valve for gas manage.

- Due to the presence of gas lines, the unit pump gadget may be labelled as a version of the P-L-N injection gadget. However, the layout of unit pump and unit injector structures is frequently similar, making it handy to talk about those structures together. In fact, a few producers provide their injection structures in each UI and UP versions.

- The industrial utility of unit injectors commenced with inside the Thirties on Winton (a GM subsidiary) and GM diesel engines. Winton persevered to deliver engines to the Electro-Motive Corporation (EMC), whilst GM transferred diesel engine manufacturing to its Detroit Diesel Division.

- The Detroit Diesel Corporation’s two-stroke engine line is one of the higher acknowledged programs of unit injector technology. From the Thirties to the mid-1980s, Detroit Diesel used a mechanical unit injector layout.

- In 1985, Detroit Diesel’s Series ninety two two-stroke engine have become the primary heavy-obligation diesel engine to undertake electronically managed unit injection [Bara 1990]. Since this creation of digital manage, unit injectors persevered to conform to better degrees of sophistication.

- The evolution for light-obligation and heavy-obligation programs observed distinct paths.

Key Takeaways:

- Unit pump (UP) structures allow brief excessive strain gasoline strains with the aid of using finding the pump near the injector.

- In fact, a few producers provide their injection structures in each UI and UP versions.

- Since this creation of digital manage, unit injectors persevered to conform to better degrees of sophistication.

Two principal kinds of pump in use are the rotary and axial plunger distributor pumps.

The rotary vendors GF with unmarried or more than one rotary through-feed transmit media from desk bound reasserts to rotating device parts. The compact and strong layout with double bearing makes the rotary vendors a dependable method of protective your media deliver in opposition to mechanical loads.

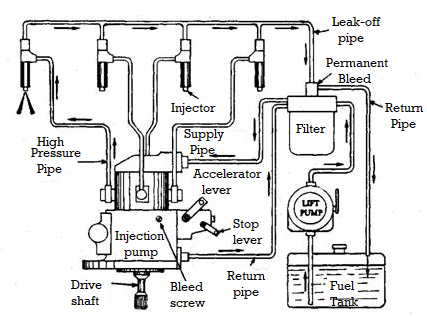

Distributor-type Injection Pump

In distributor-type fuel-injection pumps system (Fig. 10.25) two or more plungers serve all the cylinders of the engine, and the fuel is injected to each cylinder in turn by a distributor. Two main types of pump in use are the rotary and axial plunger distributor pumps. Rotary types distributor pump are those in which the plungers reciprocate in the head of the distributor rotor while revolving around its axis, similar to the Lucas and Stan dyne units. Whereas in the axial plunger type distributor pump, the pumping plunger is coaxial with the drive shaft and, rotating with it, serves also as the distributor, similar to the Bosch VE series.

- In distributor-kind gas-injection pumps system or greater plungers serve all of the cylinders of the engine, and the gas is injected to every cylinder in flip with the aid of using a distributor.

- Two important varieties of pump in use are the rotary and axial plunger distributor pumps. Rotary kinds distributor pump are the ones wherein the plungers reciprocate with inside the head of the distributor rotor even as revolving round its axis, much like the Lucas and Standyne units. Distributor pumps are typically lighter and greater compact, are much less costly, than their in-line counter parts.

- Also, their governors and injection enhance gadgets are easier and smaller. This form of pump generally includes a switch pump used for preserving it complete of gas and additionally for powering a number of the manage systems. Consequently, switch pump transport pressures of as much as 785 kPa and above are necessary. For reaching this pressure, vane kind pumps are typically used.

Common Rail Direct Injection System:

- Common rail direct gasoline injection is a right away gasoline injection machine constructed round a excessive-strain (over 2,000 bar or 2 hundred MPa or 29,000 psi) gasoline rail feeding solenoid valves, in preference to a low-strain gasoline pump feeding unit injectors (or pump nozzles).

- High-strain injection supplies electricity and gasoline intake advantages over in advance decrease strain gasoline injection, through injecting gasoline as a bigger range of smaller droplets, giving a miles better ratio of floor vicinity to volume. This offers progressed vaporization from the floor of the gasoline droplets, and so greater green combining of atmospheric oxygen with vaporized gasoline handing over greater whole combustion. Common rail injection is broadly utilized in diesel engines. It is likewise the idea of gas direct injection structures used on petrol engines.

- The gasoline in an electronically managed engine is saved at variable strain in a cylinder or ‘rail’ related to the engine’s gasoline injectors through man or woman pipes, making it a ‘not unusual place rail’ to all of the injectors. The strain is managed through a gasoline pump however it's far the gasoline injectors, running in parallel with the gasoline pump, that manage the timing of the gasoline injection and the quantity of gasoline injected. In assessment in advance mechanical structures depend on the gasoline pump for strain, timing and quantity.

- A in addition gain of the CRDi machine is that it injects the gasoline at once into the combustion chamber. The oblique injection (IDI) machine in older engines injected gasoline right into a pre-combustion chamber which then fed the primary combustion chamber.

- Common rail structures offer a stage of flexibleness which may be exploited for sophistication main emission manage, electricity and gasoline intake. This permits Original Equipment Manufacturers (OEMs) to layout for maximum overall performance and superb end-consumer cost throughout a variety of machines and applications.

- An growing range of cutting-edge diesel engines rent not unusual place rail direct injection (CRDi) gasoline structures for the power they offer whilst assembly the maximum stringent emission manage standards.

- Lower gasoline pump top torque necessities. As excessive pace direct injection (HSDI) engines developed, greater of the strength to combine the air with gasoline got here from the gasoline spray momentum in preference to the swirl mechanisms hired in older, IDI combustion structures.

- Only excessive strain gasoline injection structures had been capable of offer the combination strength and properly spray training wanted for low PM and HC emissions.

- To generate the strength required to inject the gasoline in about 1 millisecond, the traditional distributor pump could should offer almost 1 kW of hydraulic electricity in four (in a 4-cylinder engine) 1 ms bursts in line with pump revolution, hence setting full-size pressure at the power shaft One of the motives.

- In the back of the fashion closer to not unusual place rail structures became to reduce the most pump torque requirement. While the electricity and common torque necessities of the not unusual place rail pump had been similar, excessive strain gasoline transport is to an accumulator and hence the height float rate (and top torque required to power the pump) does now no longer should coincide with the injection occasion as is the case with the distributor pump.

- Pump discharge float may be unfold out over an extended part of the engine cycle to maintain pump torque call for greater even.

Key Takeaways:

- Two main types of pump in use are the rotary and axial plunger distributor pumps.

- Two important varieties of pump in use are the rotary and axial plunger distributor pumps.

- Common rail injection is broadly utilized in diesel engines.

- . In assessment in advance mechanical structures depend on the gasoline pump for strain, timing and quantity.

- In the back of the fashion closer to not unusual place rail structures became to reduce the most pump torque requirement.

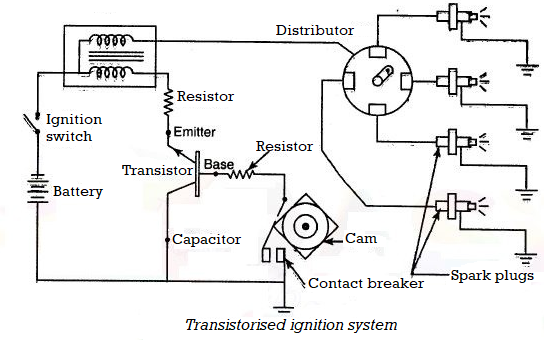

Transistor based Ignition System

A transistor interrupts a in particular immoderate cutting-edge carrying circuit, i.e, it controls immoderate cutting-edge with inside the collector circuit with a whole lot much less cutting-edge with inside the bottom circuit. Therefore, a transistor is used to assist the artwork of a hint breaker.

Construction:

It consists of battery, ignition switch, transistor, collector, emitter, ballast resistor, contact breaker, ignition coil. Distributor and spark plugs. The emitter of the transistor is connected to the ignition coil via a ballast resistor. A collector is connected to the battery.

Working:

The cam with inside the distributor is rotated thru the engine. It opens and closes the contact breaker points.

When the touch breaker factors are closed:

- A small modern flows with inside the base circuit of the transistor.

- A huge modern flows with inside the emitter or collector circuit of the transistor and the number one winding of the Ignition coil because of the ordinary transistor action.

- A magnetic discipline is installation with inside the number one winding of the coil.

When the touch breaker factors are Open:

1. The number one modern and the magnetic discipline with inside the coil crumble abruptly because of on the spot reverting of the transistor to the non-conductive state.

2. It produces a excessive voltage with inside the secondary circuit.

3. This excessive voltage is directed to the respective spark plugs via the rotor of the distributor.

4. This excessive voltage produces a spark whilst it's far attempted to leap the spark plug gap. It ignites air-gasoline aggregate with inside the cylinder.

Advantages:

1. It will increase the existence of contact breaker factors.

2. It offers excessive ignition voltages.

3. It offers longer period of sparks.

Disadvantages:

1. More mechanical factors are wanted just like a traditional system.

2. It has an inclination to aspect tracking.

Capacitive Discharge Ignition System:

At present, many stuff had been modified due to technology. The researchers invented the CDI (Capacitive Discharge Ignition) gadget for SI (Spark Ignition) Engine the usage of digital ignition & touch factor ignition. This gadget consists of a pulse manage circuit, spark plug, pulse technology circuit, predominant price & discharge capacitor coil, etc. There are distinct styles of ignition structures wherein distinct conventional ignition structures are advanced to apply in distinct applications.

These ignition structures are advanced the usage of businesses like CDI (Capacitor Discharge Ignition) structures in addition to IDI (Inductive Discharge Ignition) structures. The quick shape of the Capacitor discharge ignition is CDI which is likewise referred to as thyristor ignition. It is one type of car digital ignition gadget, utilized in motorcycles, outboard motors, chainsaws, lawnmowers, turbine-powered aircraft, small engines, etc.

A Capacitor Discharge Ignition or CDI is a digital ignition tool that shops an electrical price after which discharges it thru an ignition coil with the intention to produce a effective spark from the spark plugs in a petroleum engine. Here the ignition is furnished through the capacitor price. The capacitor really prices and discharges inside a fragment of time making it viable to create sparks CDIs are typically discovered on motorbikes and scooters.

Capacitor Discharge Ignition Module

The common CDI module consists of distinct circuits like charging & triggering, a mini transformer & the principle capacitor. The gadget voltage may be extended from 250V to 600V thru a electricity deliver on this module. After that, the float of electrical modern-day could be there towards the charging circuit in order that capacitor may be charged. The rectifier in the charging circuit can keep away from the release of the capacitor earlier than the ignition moment.

Once the triggering circuit receives the triggering sign, then this circuit will prevent the running of the charging circuit & permits the capacitor for discharging its o/p rapid towards the ignition coil of low inductance. In Capacitor discharge ignition, the coil works like a pulse transformer as opposed to an electricity garage medium as it does inside an inductive gadget. The o/p of the voltage towards the spark plugs is extraordinarily reliant at the CDI design.

Working Principle of a CDI System

A capacitor discharge ignition works with the aid of using passing an electrical present day over a capacitor. This form of ignition builds up a rate quickly. A CDI ignition begins offevolved with the aid of using producing a rate and storing it up earlier than sending it out to the spark plug so that it will ignite the engine.

This strength passes via a capacitor and is transferred to an ignition coil that facilitates increase the strength with the aid of using appearing as a transformer and permitting the electricity to byskip via it in preference to catching any of it. The CDI ignition systems, therefore, permit the engine to hold strolling so long as there's a rate with inside the strength source.

Construction of Capacitor Discharge Ignition

A Capacitor Discharge Ignition includes numerous elements and is included with the ignition device of a vehicle. The primary elements of a CDI encompass the stator, charging coil, corridor sensor, flywheel, and timing mark.

Flywheel and Stator

The flywheel is a massive horseshoe everlasting magnet rolled right into a circle that turns-ON the crankshaft. The Stator is the plate conserving all the electric coils of wire that is used to strength ON the ignition coil, bike’s lights, and battery charging circuits.

Charging Coil

The charging coil is one coil with inside the stator that is used to provide 6 volts to rate the capacitor C1. Based at the flywheel’s motion the unmarried pulsed strength is produced and is furnished to the sparking plug with the aid of using the charging coil to make certain the most spark.

Hall Sensor

The Hall Sensor measures the Hall effect, the on the spot factor wherein the flywheel’s magnet adjustments from a north to a south pole. When the pole alternate occurs, the tool sends a unmarried, tiny pulse to the CDI field which triggers it to unload the electricity from the charging capacitor into the excessive voltage transformer.

Timing Mark

The timing mark is an arbitrary alignment factor shared through the engine case and stator plate. It suggests the factor at which the pinnacle of the piston’s tour is equal to the cause factor at the flywheel and stator. By rotating the stator plate left and right, you correctly extrade the cause factor of the CDI, therefore advancing or retarding your timing, respectively.

The CDI field has a group of semiconductor rectifiers that related to G1 at the field lets in simplest the fine pulse to go into the capacitor. While the wave getting into the CDI, the rectifier lets in simplest the fine wave.

Trigger Circuit

The cause circuit is a transfer, possibly the usage of a Transistor, Thyristor, or SCR. This brought about through a pulse from the Hall Sensor at the stator. They simplest permit modern-day from one facet of the circuit till they're brought about. Once Capacitor C1 is absolutely charged, the circuit may be brought about again.

This is why there's timing worried with the motor. If the capacitor and stator coil have been perfect, they might fee straight away and we will cause them as speedy as we wish. However, they require a fragment of a 2nd to complete fee. If the circuit triggers too speedy, then the spark from the spark plug could be notably weak.

Certainly, with the better accelerating motors, we may also have the triggering quicker than the capacitor complete fee, with a purpose to have an effect on performance. Whenever the capacitor is discharged, then the transfer turns itself off, and the capacitor expenses again.

Different Types of CDI

CDI modules are categorised into kinds that are mentioned beneath.

AC-CDI Module

The electric supply of this module receives simplest from the AC generated thru the alternator. This is the primary CDI gadget utilized in small engines. So, now no longer all of the ignition structures that have small engines aren't CDI. Some of the engines use magneto ignition specifically older Briggs in addition to Stratton. The entire ignition gadget, points & coils are beneath the magnetized flywheel. Another kind of ignition gadget this is maximum often utilized in small bikes with inside the 12 months 1960 – 70 called Energy Transfer. A sturdy DC modern-day pulse may be generated through a coil beneath the flywheel due to the fact the flywheel magnet is going over it.

DC-CDI Module

This type of module works with the battery & as a result a further DC/AC inverter circuit is used inside the capacitor discharge ignition module to growth the voltage from 2V DC – 400/six hundred V DC to make the CDI module extremely larger. But, motors that make use of DC-CDI kind structures can have greater correct ignition timing, in addition to the engine, may be activated greater actually as soon as it receives cold.

Advantages of CDI

• The essential benefit of CDI is that the capacitor may be absolutely charged in a completely quick time (commonly 1ms).

• The capacitor discharge ignition machine has a quick brief response, a quick voltage rise (among three to ten kV/ µs) as compared to inductive structures (three hundred to 500 V/ µs), and a shorter spark period (approximately 50-eighty µs).

• The rapid voltage growing makes CDI structures unaffected to shunt resistance.

Disadvantages of CDI

The hazards of CDI consist of the following.

• The capacitor discharge ignition machine generates massive electromagnetic noise and that is the principle cause why CDIs are not often utilized by vehicle manufacturers.

• The quick spark period isn't always exact for lighting fixtures fairly lean combinations as used at low electricity levels. To remedy this trouble many CDI ignitions launch a couple of sparks at low engine speeds.

Key Takeaways:

- It consists of battery, ignition switch, transistor, collector, emitter, ballast resistor, contact breaker, ignition coil.

- A small modern flows with inside the base circuit of the transistor.

- It ignites air-gasoline aggregate with inside the cylinder.

- It offers excessive ignition voltages.

- It is one type of car digital ignition gadget, utilized in motorcycles, outboard motors, chainsaws, lawnmowers, turbine-powered aircraft, small engines, etc

- Here the ignition is furnished through the capacitor price.

- A turbocharger is a device that enables an engine produce greater strength and torque via pressured induction. Essentially, a faster sucks in air, chills it, after which force-feeds the engine greater air than what it'd get via its fashionable consumption. The stop end result is lots greater “Wheel!”

- A turbocharger includes a compressor wheel and exhaust fuel line turbine wheel coupled collectively with the aid of using a strong shaft and this is used to enhance the consumption air strain of an inner combustion engine.

- The exhaust fuel line turbine extracts strength from the exhaust fuel line and makes use of it to pressure the compressor and conquer friction. In maximum automotive-kind applications, each the compressor and turbine wheel are of the radial float kind.

- Some applications, including medium- and low- velocity diesel engines, can use an axial float turbine wheel as opposed to a radial float turbine. The float of gases via a normal turbocharger with radial float compressor and turbine wheels is proven in Figure 1

![[schematic]](https://glossaread-contain.s3.ap-south-1.amazonaws.com/epub/1651134694_377931.jpeg)

Figure. Turbocharger construction and flow of gases

Centre-Housing

The shaft wheel assembly (SWA) refers back to the shaft with the compressor and turbine wheels attached, i.e., the rotating assembly. The middle housing rotating assembly (CHRA) refers to SWA mounted with inside the middle-housing however without the compressor and turbine housings. The middle housing is normally forged from grey forged iron however aluminum also can be utilized in a few applications.

Turbochargers for excessive exhaust fuel line temperature applications, this kind of spark ignition engines, also can include cooling passages with inside the middle housing.

Bearings

The turbocharger bearing device seems easy in layout however it performs a key function in some of crucial functions. Some of the extra critical ones include: the manage of radial and axial movement of the shaft and wheels and the minimization of friction losses with inside the bearing device. Bearing structures have acquired big interest due to their effect on turbocharger friction and its effect on engine gasoline efficiency.

With the exception of a few massive turbochargers for low-pace engines, the bearings that assist the shaft are commonly placed among the wheels in an overhung position. This bendy rotor layout guarantees that the turbocharger will function above its first, and probably second, crucial speeds and may consequently be problem to rotor dynamic situations including whirl and synchronous vibration.

Seals

Seals are placed at each ends of the bearing housing. These seals constitute a hard layout hassle because of the want to maintain frictional losses low, the quite massive actions of the shaft because of bearing clearance and damaging stress gradients beneath neath a few situations.

Turbocharger seals are one of a kind from the tender lip seals commonly observed in rotating device working at a lot decrease speeds and temperatures. The piston ring kind seal is one kind this is regularly used.

It includes a metallic ring, comparable in look to a piston ring. The seal stays desk bound while the shaft rotates. Labyrinth-kind seals are every other kind on occasion used.

Generally turbocharger shaft seals will now no longer save you oil leakage if the stress differential reverses such that the stress with inside the middle housing is better than with inside the consumption or exhaust structures.

Key takeaways:

- The stop end result is lots greater “Wheel!”

- In maximum automotive-kind applications, each the compressor and turbine wheel are of the radial float kind

- The middle housing is normally forged from grey forged iron however aluminum also can be utilized in a few applications.

- The turbocharger bearing device seems easy in layout however it performs a key function in some of crucial functions.

- Seals are placed at each ends of the bearing housing

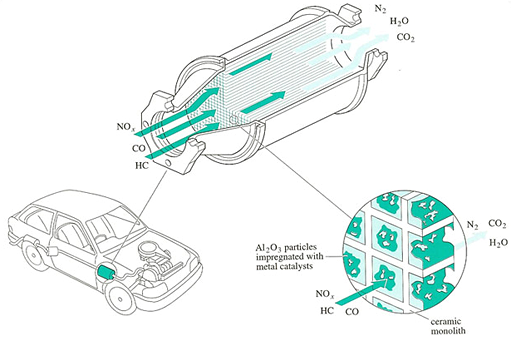

Ensuring proper nice air is critical for the safety of public health. Governments global have followed a number of more and more disturbing measures to lower air pollutants with a selected cognizance at the emissions from motor cars.

A crucial a part of this approach has been the improvement of the three-manner catalytic converter to get rid of exhaust pollution along with carbon monoxide, unburnt hydrocarbons and nitrogen oxides.

This route takes an in-intensity examine the development of this converter for petrol-pushed cars and investigates the catalytic chemistry taking region on the molecular level. It is believed which you have already got a systematic background.

Exhaust pollution

- The maximum crucial chemical response in a petroleum engine – that is, the only that offers the electricity to pressure the vehicle – is the combustion of gas in air. In an ‘ideal’ system, combustion could be entire in order that the handiest exhaust merchandise could be carbon dioxide and steam.

- In practice, the entire oxidation of the gas relies upon on some of factors: first, there need to be enough oxygen present; second, there need to be good enough blending of the petrol and air; and finally, there need to be enough time for the aggregate to react at excessive temperature earlier than the gases are In inner combustion engines, the time to be had for combustion is confined via way of means of the engine’s cycle to only some milliseconds.

- There is incomplete combustion of the gas and this results in emissions of the partial oxidation product, carbon monoxide (CO), and a huge variety of unstable natural compounds (VOC), which include hydrocarbons (HC), aromatics and oxygenated species. These emissions are especially excessive at some stage in each idling and deceleration, while inadequate air is taken in for entire combustion to occur.

The three-way catalytic converter

Composition

The present day three-manner catalyst, proven schematically in Figure 1, is commonly a multicomponent material, containing the treasured metals rhodium, platinum and (to a lesser extent) palladium, ceria (CeO2), γ-alumina (Al2O3), and different metallic oxides. It commonly includes a ceramic monolith of cordierite (2Mg.2Al2O3. 5SiO2) with robust porous partitions enclosing an array of parallel channels. A traditional monolith has sixty four channel openings according to cm2 Metallic monoliths also are used, specifically for small converters, however those are extra expensive.

Figure. Schematic diagram of the 3-manner catalytic converter.

The catalytic converter, in a metallic canister, is located with inside the exhaust device of the vehicle. To acquire a big floor region for catalysis, the inner surfaces of the monolith are protected with a skinny coating (30–50 μm) of a noticeably porous material, called the washcoat.

The overall floor region is now equal to that of approximately or 3 soccer pitches. The washcoat typically includes alumina (70–85%) with a big floor region, with oxides, which include BaO, delivered as structural promoters (stabilisers to hold floor region) and others, for instance CeO2, as chemical promoters. This device will become the assist for the treasured metallic components (Pt, Pd and Rh).

These metals represent handiest a small fraction (1–2%) of the whole mass of the washcoat, however they're found in a noticeably dispersed form. They are typically implemented via way of means of deposition from solution, despite the fact that they will alternatively be brought at some point of formation of the washcoat itself.

Exact catalyst formulations are, as one would possibly expect, carefully guarded secrets. Some compositions use all 3 metals; others use Rh collectively with handiest one of the different, usually Pt, as with inside the gift era of Pt-Rh converters used with inside the UK, wherein Pt constitutes 80–90% of the whole treasured metallic mass.

Catalyst performance

- It is obvious that the catalytic converter reduces the emissions of all 3 instructions of pollution pretty dramatically over a huge variety of speeds. Before we talk the records in any detail, some phrases approximately how they have been acquired are in order.

- Federal and European Test Procedures are used to check emissions from a complete ‘finished’ converter and engine together, to make certain that a brand new vehicle model, for instance, will meet the contemporary emissions legislation.

- In the studies and improvement of automobile catalysts, interest checking out fulfils the feature of screening and evaluating novel and changed catalysts, and analyzing their overall performance below extraordinary conditions.

- The system of screening ought to offer a dependable manner of figuring out substances so that it will carry out as active, selective and sturdy catalysts below automobile conditions.

The method generally taken is to degree conversion of the pollution as a feature of temperature, the use of a simulated exhaust-fueloline combination flowing via a mattress of powdered catalyst: the flow-fee must be excessive sufficient to imitate the ‘via-put’ or area pace of a catalytic converter (generally a touch time for the gases with the catalyst of seventy two milliseconds is The check is then repeated the use of a extraordinary simulated exhaust-fuel line to symbolize a extraordinary engine mode. Ageing research are executed via way of means of exposing the catalyst to extraordinary, and frequently severe conditions, for various lengths of time.

Key Takeaways:

- It is believed which you have already got a systematic background.

- The overall floor region is now equal to that of approximately or 3 soccer pitches.

- These metals represent handiest a small fraction (1–2%) of the whole mass of the wash coat, however they're found in a noticeably dispersed form.

- The first emission norms for Indian motor automobiles had been the idle emission limits that got here into impact in 1989. These rules had been changed via way of means of mass emission limits for petrol engines in 1991 and diesel engines in 1992. By 1995, the usage of catalytic converters became made obligatory for all motors that had been bought in metros.

- As automobile owners, you ought to have heard approximately phrases like ‘BS3’ and ‘BS4’ emission requirements for a automobile’s engine. These norms are instituted via way of means of the Government of India to outline the output of permissible air pollution from an inner combustion engine that strength the motor automobiles. These emission norms and the timelines for his or her advent are determined via way of means of the Central Pollution Control Board, which comes below the Ministry of Environment & Forests and weather change.

- The Bharat Stage Emission Standards are primarily based totally on European norms, which can be normally categorized as ‘Euro 2’, ‘Euro 3’, et al.

- India 2000, which became primarily based totally at the Euro 1 requirements, became changed with Bharat Stage II (BSII) norms in 2001.

- These had been observed via way of means of BS3, whilst the latter became then changed with BS4 requirements. India is now ready to leapfrog to BS6 emission requirements, with a purpose to roll out on 1 April 2020.

- The sale of BSIV-compliant automobiles could be banned with the advent of the following stage of emission requirements. The implementation agenda of car emission requirements in India is summarized with inside the following table-

Key Takeaways:

- The first emission norms for Indian motor automobiles had been the idle emission limits that got here into impact in 1989.

- These norms are instituted via way of means of the Government of India to outline the output of permissible air pollution from an inner combustion engine that strength the motor automobiles.

- India is now ready to leapfrog to BS6 emission requirements, with a purpose to roll out on 1 April 2020.

References:

- Automotive Engineering- Hietner.

- Automobile Engineering - Narang.

- Automobile Engineering – Dr. Kirpal Singh

- Automotive Mechanics- Crouse.