Unit - 2

Engine performance-test

Determination of ignition timing at differing tempo and load conditions.

The take a look at is accomplished within side the direction of a large form of ignition enhance positions in. Order to determine engine ordinary overall performance tiers with differing load conditions.

Engine ordinary overall performance is frequently characterized thru manner of method of the engine strolling behavior within side the tempo–load domain, for example, the behavior of emissions, fuel consumption, noise, mechanical and thermal loading.

Engine ordinary overall performance maps speak with the regular price contour plots of a given ordinary overall performance parameter within side the tempo–torque domain. A first-rate facts of engine ordinary overall performance maps is important to a gadget format engineer.

Performance Test According to Indian Standard:

After the preliminary run the performance test shall be conducted in accordance with the methods specified in IS 1601-1960:

The complete usual overall performance test for a variable tempo engine will contain of the following determinations at suitable speeds over the engine tempo kind of the engine unique through manner of manner of the manufacturer.

(1) At each suitable tempo-

(i) Maximum brake power

(ii) Maximum torque

(iii) Frictional power.

(2) Specific fuel consumption at 100, 80, 60, 40, and 20 percent of the maximum load at the corresponding tempo.

(3) Fuel consumption price in grams in step with hour at advocated no load minimum tempo. In every test, a sufficient kind of runs could be made at some stage in the rate variety.

A run could be made at the lowest steady tempo at which the engine operates. Performance information could be received beneathneath stabilized running conditions.

Durations of the experimental run depends upon two principles:

(a) No facts will be taken till load, velocity and temperature had been stabilized.

(b) Recorded facts will be common sustained values maintained over a duration of atleast one minute, without a good sized alternate arise in the course of that time.

Power Testing:

For all electricity assessments with outcomes to be plotted as opposed to pace, a unmarried collection of stabilized runs at ascending pace is enough. This collection of runs have to development constantly from the bottom to the maximum. If the engine calls for to be idled among run to keep away from excessively excessive temperature, enough time have to be allowed for the engine once more to attain to its stabilized situation earlier than taking readings. The brake load recorded have to be consistent and consistent during the run.

Speed Testing:

Engine pace ought to be held as regular as some distance as viable by way of carried out dynamometer load at huge open throttle, or by means of throttle adjustment at element load.

Frictional Power:

The friction energy shall comply with straight away after the energy take a look at and if now no longer feasible then relaxation will be carried out below situations the ones for the energy take a look at.

Fuel Consumption:

Fuel consumption may be measured simultaneously with brake power; The fuel consumption measurement shall now not be started until the engine is stabilized. A measuring c language of now not tons much less than 60 seconds may be used at the same time as measuring tempo and fuel consumption.

All specific fuel consumption figures may be based definitely upon determined brake power. Besides the tests cited above severa special desired and precise motive tests are performed on I.C. Engines in step with IS: 1602-1960, IS: 1603-1960, IS:10000-1980 and IS:7347-1974. For an engine geared up with fixed-geometry hardware without flexible controls (e.g., fixed-geometry turbine, mechanical camshaft, mechanical water pump), most reliable system typical overall performance is a massive compromise amongst high-tempo and low-tempo operations, or amongst high-load and low-load operations.

The trade-off effect is in particular remarkable at the same time as the style of the engine tempo (or load) is wide. Mapping the running trends of engine purchaser applications (e.g., car using cycles, marine engine load cycles) to the engine tempo–load map and mapping the engine tempo–load trends to the issue feature map (e.g., a compressor map) are vital format techniques for a system engineer in accomplishing system integration.

Owing to the paramount importance of engine tempo–load trends, standard examples of engine typical overall performance maps are illustrated and cited in this section.

Test Bed Calibration

Engine prevalent usual overall performance measured on indoor take a look at beds will range from that during an “limitless environment.”

Test mattress calibration permits information from an indoor take a look at mattress to be adjusted to mirror limitless environment conditions. In addition, engines of a given mark can be examined on a couple of take a look at mattress, every with a first rate configuration and in the end first rate calibration factors.

Fig: Test bed setup

For shaft power engines in which air is ducted from ambient as steady with now no longer unusual place installations, and the dimensions made at duct entry, the take a look at mattress configuration does now not typically want to be calibrated for. All that stays is the same old requirement for all instrumentation to be functioning satisfactorily.

2.1.1 Purpose:

After studying this unit, you need to have the cap potential to

- Understand the overall ordinary popular normal overall performance parameters in assessment of IC engine normal ordinary popular normal overall performance,

- Differentiate among the overall ordinary popular normal overall performance of SI engine and CI engines

1. The trying out of the engine affords development with inside the overall performance of the engine with the aid of using growing the performance and gasoline economic system of the engine. The non-stop trying out of engine can preserve gasoline green operation of the engine and assist in prognosis of the screw ups of components or components.

2. Testing the running conduct of inner combustion engines is the not unusual place reason of engine take a look at stands. Various parameters like gasoline intake or exhaust fuel line conduct have been normally measured as a characteristic of torque and rotary pace and mapped in an engine overall performance map.

3. Testing the running conduct of inner combustion engines is the not unusual place reason of engine take a look at stands.

4. A characteristic of torque and rotary pace and mapped in an engine overall performance map.

5. One of the principle focuses with inside the studies paintings of the IVG, optical measurements in combustion systems, is systematically implemented for in-cylinder investigations of the combustion process.

6. Due to the software of an asynchronous system as a brake its miles feasible to use specific take a look at procedures. This permits us to run inner combustion engines beneath neath practical situations and take a look at new combustion strategies beneath neath component and complete load situations and diverse rotation speeds.

7. The engine take a look at stand is utilized in studies tasks that make a contribution to the similarly improvement with inside the era of inner combustion engines. The aid of the studies packages is both associated with governmental or commercial funding.

2.1.2 Measurement of Power:

Measurement of Speed

One of the number one measurements is that of tempo. A sizable sort of tempo measuring devices are available within side the market. They range from a mechanical tachometer to digital and prompted electric powered tachometers. The first-rate method of measuring tempo is to rely the extensive style of revolutions in a given time.

This gives an accurate measurement of tempo. Many engines are prepared with such revolution counters. A mechanical tachometer or an electrical tachometer additionally may be used for measuring the rate. The electric powered tachometer has a three-section permanent-magnet alternator to which a voltmeter is attached. The output of the alternator is a linear function of the rate and is without delay indicated on the voltmeter dial.

Both electric powered and mechanical varieties of tachometers are laid low with the temperature variations and are not very accurate. For accurate and non-forestall measurement of tempo a magnetic pick-up located near a toothed wheel coupled to the engine shaft can be used. The magnetic pick-up will produce a pulse for every revolution and a pulse counter will because it ought to be diploma the rate.

Fuel Consumption Measurement

Fuel consumption is measured in two ways:

(a) The gasoline intake of an engine is measured via figuring out the quantity go with the flow in a given time interval and multiplying it via the perfect gravity of the gasoline which want to be measured every so often to get a correct value.

(b) Another technique is to degree the time required for intake of a given mass of gasoline. Accurate length of gasoline intake might be very important in engine trying out work. IC Engine Testing As already stated primary types of gasoline length strategies are:

• Volumetric kind

• Gravimetric kind.

Gravimetric Fuel Flow Measurement

The performance of an engine is associated with the kilograms of gasoline which might be fed on and now no longer the wide variety of litres. The approach of measuring quantity go with the drift after which correcting it for particular gravity versions is pretty inconvenient and inherently confined in accuracy. Instead if the burden of the gasoline fed on is immediately measured a high-quality development in accuracy and price may be obtained. There are 3 styles of gravimetric kind structures which might be commercially to be had encompass Actual weighing of gasoline fed on, Four Orifice Flowmeter, etc.

Measurement of Air Consumption

For finding out the general everyday commonplace common ordinary overall performance of the engine accurate length of every is essential. In IC engines, the incredible length of air consumption is quite hard because of the reality the float is pulsating, due to the cyclic nature of the engine and because of the reality the air a compressible fluid.

Therefore, the smooth technique of the use of an orifice withinside the induction pipe is not incredible for the purpose that studying may be pulsating and unreliable. Pulsation produced errors are extra or hundreds plenty lots a whole lot much less inversely proportional to the pressure in a few unspecified time withinside the destiny of the orifice for a given set of float conditions.

The numerous strategies and meters used for air float length include

(a) Air hassle technique, and

(b) Viscous-float air meter.

Measurement of Exhaust Smoke

The critical necessities of the Bosch smoke meter is one wherein a difficult and fast amount of exhaust fueloline is passed via a difficult and fast smooth out paper and the density of the smoke stains at the paper are evaluated optically. In a cutting-edge extrade of this form of smoke meter gadgets are used for the scale of the depth of smoke stain on smooth out paper. In Von Brand smoke meter that might provide a non-prevent reading a smooth out tape is constantly moved at a uniform fee to which the exhaust from the engine is fed. The unmarried received from the recording head is calibrated to offer smoke density.

Measurement of friction horse power

• The difference amongst indicated strength and the brake strength output of an engine is the friction strength.

• Almost invariably, the difference amongst a superb engine and a horrible engine is due to difference amongst their frictional losses.

• The frictional losses are ultimately dissipated to the cooling system (and exhaust) as they appear withinside the form of frictional warmth and this affects the cooling cap potential required. Moreover, lower friction manner availability of more brake strength; as a end result brake precise fuel consumption is lower.

• The bsfc rises with a growth in tempo and at some tempo it renders the sue of engine prohibitive. Thus, the quantity of friction involves a choice the maximum output of the engine which can be received economically. In the format and attempting out of an engine; measurement of friction strength is crucial for getting an notion into the techniques thru manner of method of which the output of an engine can be increased.

Basic format and ordinary overall performance parameters in internal combustion engines embody compression ratio, swept volume, clearance volume, power output, indicated power, thermal efficiency, indicated advocate effective pressure, brake advocate effective pressure, precise fuel consumption, and more.

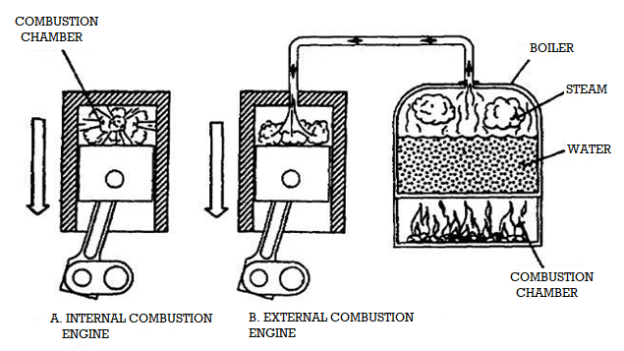

Heat Engines

Heat engines are power conversion machines—they convert chemical power in a gas into paintings with the aid of using combusting the gas in air to supply warmness. This warmness is used to elevate the temperature and strain of a operating fluid this is then used to carry out beneficial paintings. Heat engines may be categorized as:

- Internal combustion engines, or

- External combustion engines.

They also can be categorized as both reciprocating or rotary. In reciprocating engines, the operating fluid is used to transport a piston in a linear fashion. The linear movement is then usually transformed to rotary movement via a crank-slider (connecting rod/crankshaft) mechanism. In a rotary engine, the operating fluid spins a rotor this is related to the output shaft.

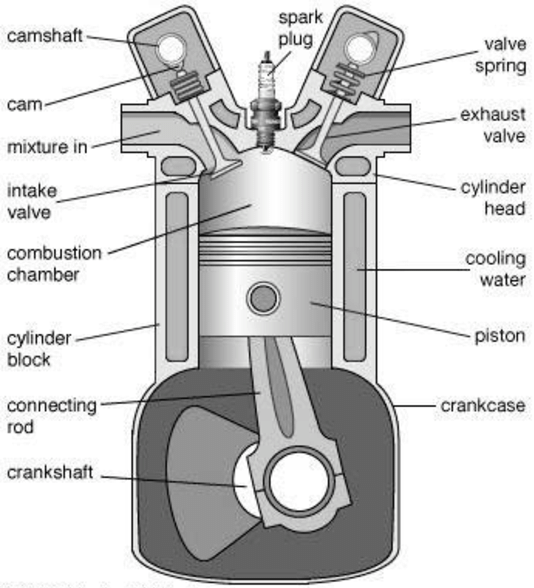

Internal Combustion Engines

In internal combustion (IC) engines, the taking walks fluid consists of air, a fueloline-air aggregate or the products of combustion of the fueloline-air aggregate itself. Reciprocating piston engines are in all likelihood the most no longer unusual place form of internal combustion engine known. They energy cars, trucks, trains and most marine vessels. They are also carried out in loads of small software program software applications. They can be fueled with liquid fuels which incorporates gasoline and diesel fueloline or gaseous fuels which incorporates natural fueloline and LPG. Two no longer unusual place sub training of reciprocating piston engines are the two-stroke and the four-stroke engine. Examples of rotary internal combustion engines encompass the Wankel rotary engine and the fueloline turbine.

Fig: Internal Combustion Engines

External Combustion Engines

In outside combustion engines, the running fluid is totally separated from the fuel-air mixture. Heat from the combustion merchandise is transferred to the running fluid via the partitions of a warmth exchanger. The steam engine is a widely known instance of an outside combustion engine.

An instance of a reciprocating outside combustion engine is the Stirling engine wherein warmth is brought to the running fluid at excessive temperature and rejected at low temperature. Heat brought to the running fluid may be generated from almost any warmth supply, along with burning fossil fuels, wood, or some other natural material. The Rankin cycle upon which many steam engine designs are primarily based totally is any other instance of an outside combustion engine.

Fig: External Combustion Engines

Heat brought from an outside supply elevates the temperature of a liquid, along with water, till it's far transformed into vapor this is used to transport a piston or spin a turbine. Steam engines powered automobiles within side the USA among 1900 and 1916; however, all of them however disappeared via way of means of 1924. Steam powered vans had been famous in England till the mid-1930s. While steam powered locomotives in many nations had been progressively changed via way of means of diesel locomotives over tons of the twentieth century, some remained in main-line provider properly into the twenty first century.

Performance Parameters:

Engine overall performance is a sign of the diploma of achievement of the engine plays its assigned task, i.e. the conversion of the chemical power contained withinside the gasoline into the beneficial mechanical work.

The overall performance of an engine is evaluated on the idea of the following:

(a) Specific Fuel Consumption.

(b) Brake Mean Effective Pressure.

(c) Specific Power Output.

(d) Specific Weight.

(e) Exhaust Smoke and Other Emissions.

The specific software of the engine comes to a decision the relative significance of those overall performance parameters.

For Example: For a plane engine unique weight is greater vital while for a business engine unique gasoline intake is greater vital.

For the assessment of an engine overall performance few greater parameters are selected and the impact of diverse running conditions, layout standards and adjustments on those parameters are studied.

The simple overall performance parameters are the following:

(a) Power and Mechanical Efficiency.

(b) Mean Effective Pressure and Torque.

(c) Specific Output.

(d) Volumetric Efficiency.

(e) Fuel-air Ratio.

1. Power and Mechanical Efficiency

The fundamental cause of taking walks an engine is to advantage mechanical energy.

• Power is defined due to the fact the charge of doing art work and is equal to the product of stress and linear tempo or the product of torque and angular tempo.

• Thus, the scale of energy consists of the scale of stress (or torque) similarly to speed. The stress or torque is measured with the help of a dynamometer and the speed thru a tachometer.

The energy superior thru an engine and measured at the output shaft is called the brake energy (bp) and is given by,

bp= 2πNT/60

2. Mean Effective Pressure and Torque

Mean powerful stress is described as a hypothetical/common stress which is believed to be appearing at the piston for the duration of the energy stroke. Therefore,

Where, Pm = Mean effective pressure, N/m2

Ip = Indicated power, Watt,

L = Length of the stroke, m,

A = Area of the piston, m2,

N = Rotational speed of the engine, rpm ( It is N/2 for four stroke engine), and

k = Number of cylinders.

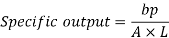

3. Specific Output

Specific output of an engine is defined as the brake power (output) per unit of piston displacement and is given by,

• The particular output includes elements – the bmep (force) to be had to paintings and the rate with which it's miles walking.

• Therefore, for the equal piston displacement and bmep an engine walking at better pace will deliver greater output.

• It is plain that the output of an engine may be stepped forward with the aid of the usage of growing every pace or bmep.

Increasing pace includes growth within side the mechanical strain of several engine components on the equal time as growing bmep calls for higher warm temperature launch and greater load on engine cylinder.

4. Volumetric Efficiency

Volumetric performance of an engine is a sign of the degree of the diploma to which the engine fills its swept extent. It is described because the ratio of the mass of air inducted into the engine cylinder for the duration of the suction stroke to the mass of the air similar to the swept extent of the engine at atmospheric stress and temperature.

Alternatively, it could be described because the ratio of the real extent inhaled for the duration of suction stroke measured at consumption situations to the swept extent of the piston.

Volumetric performance, ηv = Mass of fee virtually sucked in/Mass of fee similar to the cylinder consumption and situations.

The quantity of air taken within the cylinder is depending on the volumetric performance of an engine and for this reason places a restrict on the quantity of gasoline which may be efficaciously burned and the strength output. For supercharged engine the volumetric performance has no which means because it comes out to be extra than unity.

5. Fuel-Air Ratio (F/A)

IC Engine Testing Fuel-air ratio (F/A) is the ratio of the mass of gasoline to the mass of air within side the gasoline-air aggregate. Air-gasoline ratio (A/F) is reciprocal of gasoline-air ratio.

Fuel-air ratio of the aggregate impacts the combustion phenomenon in that it determines the flame propagation velocity, the warmth launch within side the combustion chamber, the most temperature and the completeness of combustion.

Relative gasoline-air ratio is described because the ratio of the real gasoline-air ratio to that of the stoichiometric gasoline-air ratio required to burn the gasoline supplied. Stoichiometric gasoline-air ratio is the ratio of gasoline to air is one wherein case gasoline is absolutely burned because of minimal amount of air supplied.

Relative fuel-air ratio, FR = Actual Fuel – Fuel Ratio/Stoichiometric fuel Air ratio

References:

1. Obert E. F, “Internal Combustion Engines and Air Pollution”, Harper and Row Publication Inc. NY, 1973.

2. Heisler H, “Advanced Engine Technology”, Edward Arnold, 1995.

3. Heywood J. B, “Internal Combustion Engine Fundamentals”, McGraw Hill Book Co. NY, 1989

4. Heldt P. M, “High Speed Combustion Engines”, Oxford & IBH publishing Co. India, 1985.

5. Stockel M W, Stockel T S and Johanson C, “Auto Fundamentals”, The Goodheart, Wilcox Co. Inc., Illinois, 1996.